Corrugated aluminum is a roll-formed aluminum sheet with a ribbed (wavy) profile, designed for lightweight, corrosion-resistant roofing, siding, and fencing.

Compared with galvanized or galvalume steel panels, aluminum is often preferred in high-rainfall and coastal environments where corrosion resistance matters most.

Aluminum corrugated roofing panels – supply range & specifications

We support both project orders and small-batch purchases. Share your required profile and cut length, and we'll confirm availability and the fastest lead time.

| Applications | Roofing / Siding / Fencing / Trailer Panels / Architectural Cladding |

| Profiles (Most Ordered) |

7/8" Corrugated (2.67" pitch) R-Panel / PBR Panel (36" coverage) Box Rib (4", 6", 8") Custom roll forming per drawing |

| Common Alloys |

3003 (general roofing) / 5052 (coastal & higher corrosion resistance) / 5005 (anodizing-friendly) 1050 / 1060 / 1100 available for general-purpose cladding (on request) |

| Tempers (Common) | H14 / H24 / H32 (O temper available on request) |

| Thickness (Typical Order Range) | 0.45–1.60 mm (0.018"–0.063") | Other thicknesses available by project |

| Length (Cut-to-Length) |

8 ft / 10 ft / 12 ft (most requested) Custom lengths available (commonly 3 ft up to 45–52 ft by profile & packaging) |

View more specifications (width, finish, standards, documents, options)

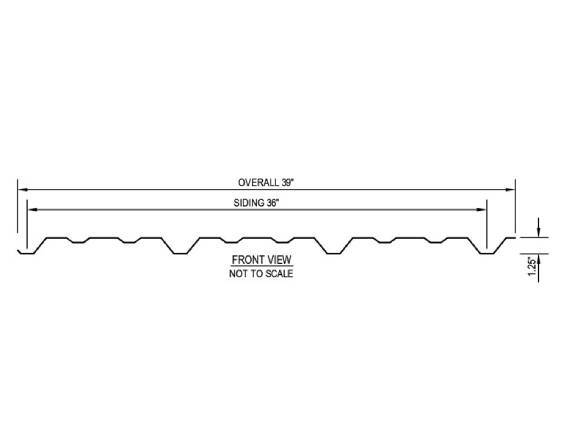

| Panel Width |

Overall width: varies by profile & market (confirm by profile drawing) Effective coverage width: use net cover for quantity take-off (roof/wall coverage differs) |

| Finish / Coating |

Mill finish (bare) PVDF / PE color coated (for outdoor roofing & cladding) Powder coated / Anodized (architectural & decorative use) |

| Perforation (Optional) | Perforated corrugated panels available for ventilation / screen / facade design |

| Standards |

Aluminum sheet/coil: ASTM B209 / GB/T 3880 (or equivalent per contract) Note: profile dimensions & coverage follow agreed profile drawing/datasheet |

| Documents | MTR / Certificate of Conformance available; third-party inspection available on request |

Need help choosing? Share your application + profile + target length, and we'll recommend the best alloy/thickness/finish and quote accordingly.

Contact Us

Most ordered corrugated & rib profiles (roofing / siding)

Explore our most commonly supplied corrugated and ribbed panel profiles for roofing, siding, fencing, and architectural cladding.

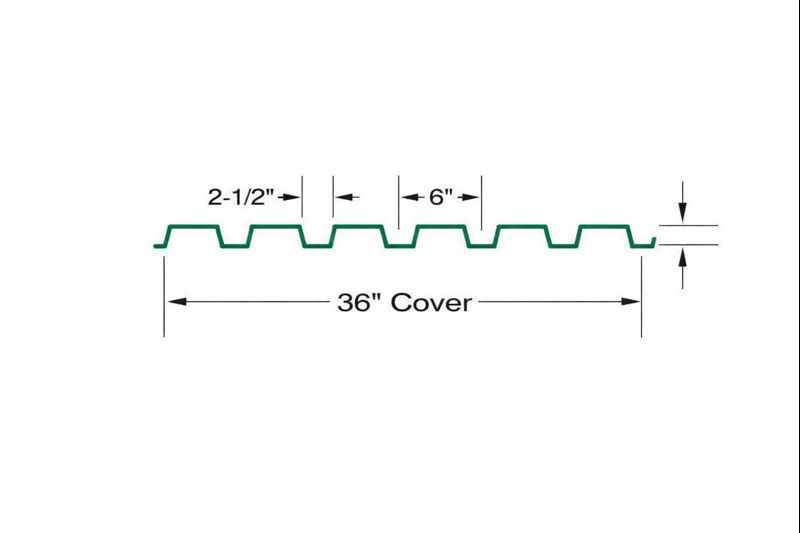

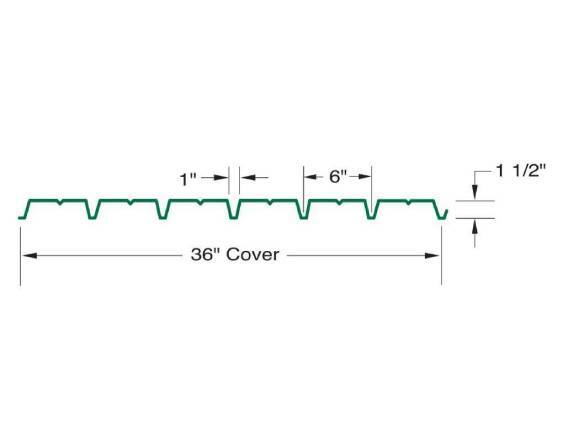

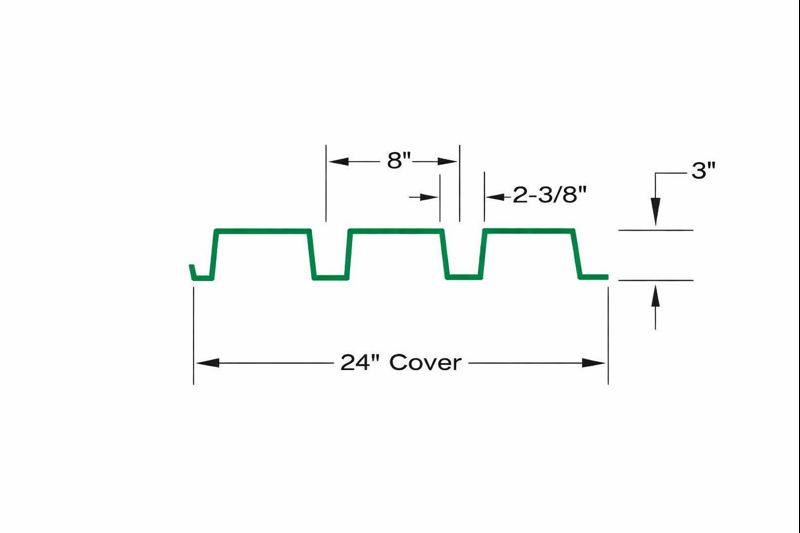

Use this section to identify the profile style (corrugated, R/PBR, box rib, 7.2, V-beam, vertical rib). For exact dimensions and cover width, refer to the size chart below or the profile drawing.

Help Me Choose a Profile

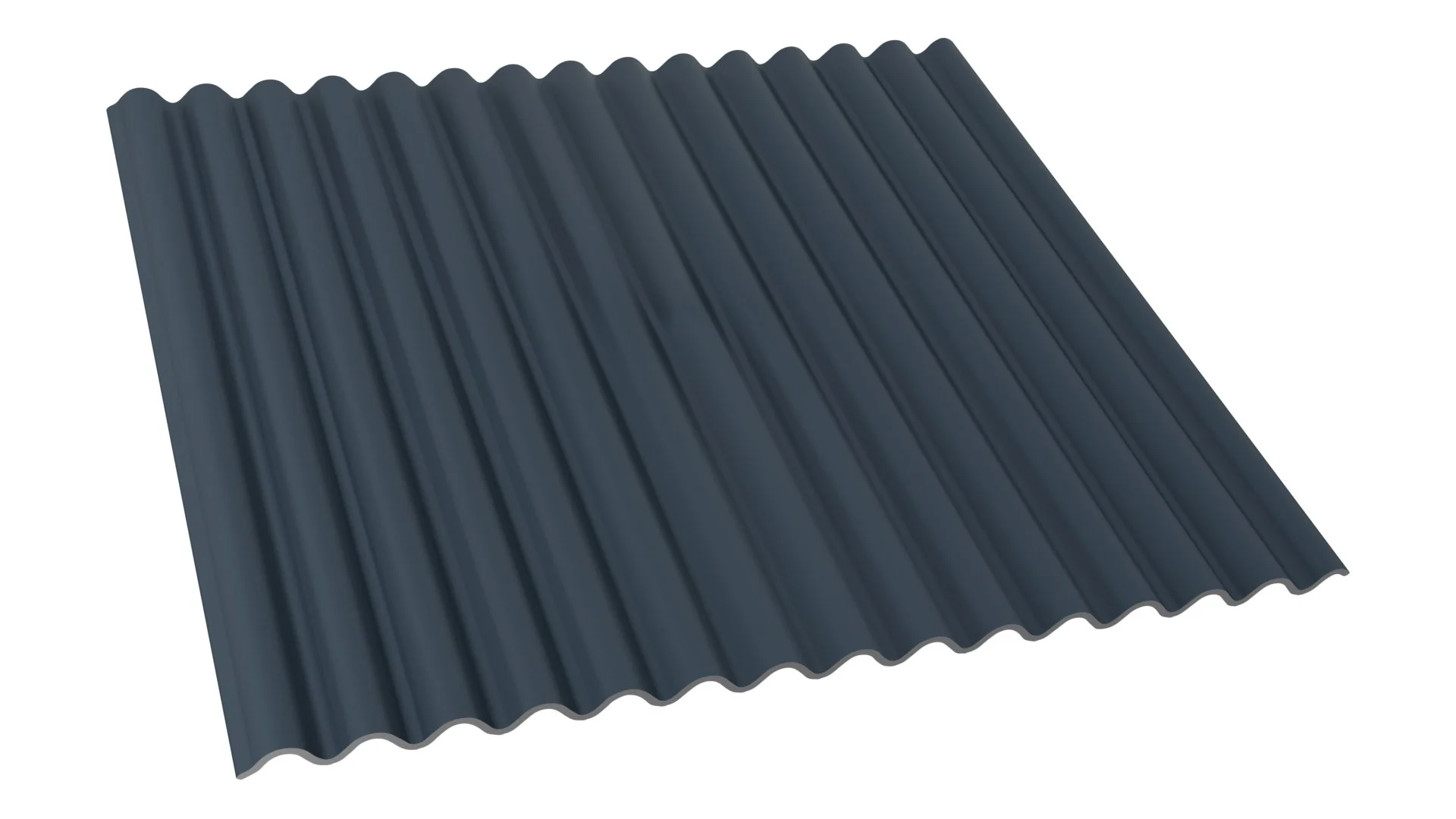

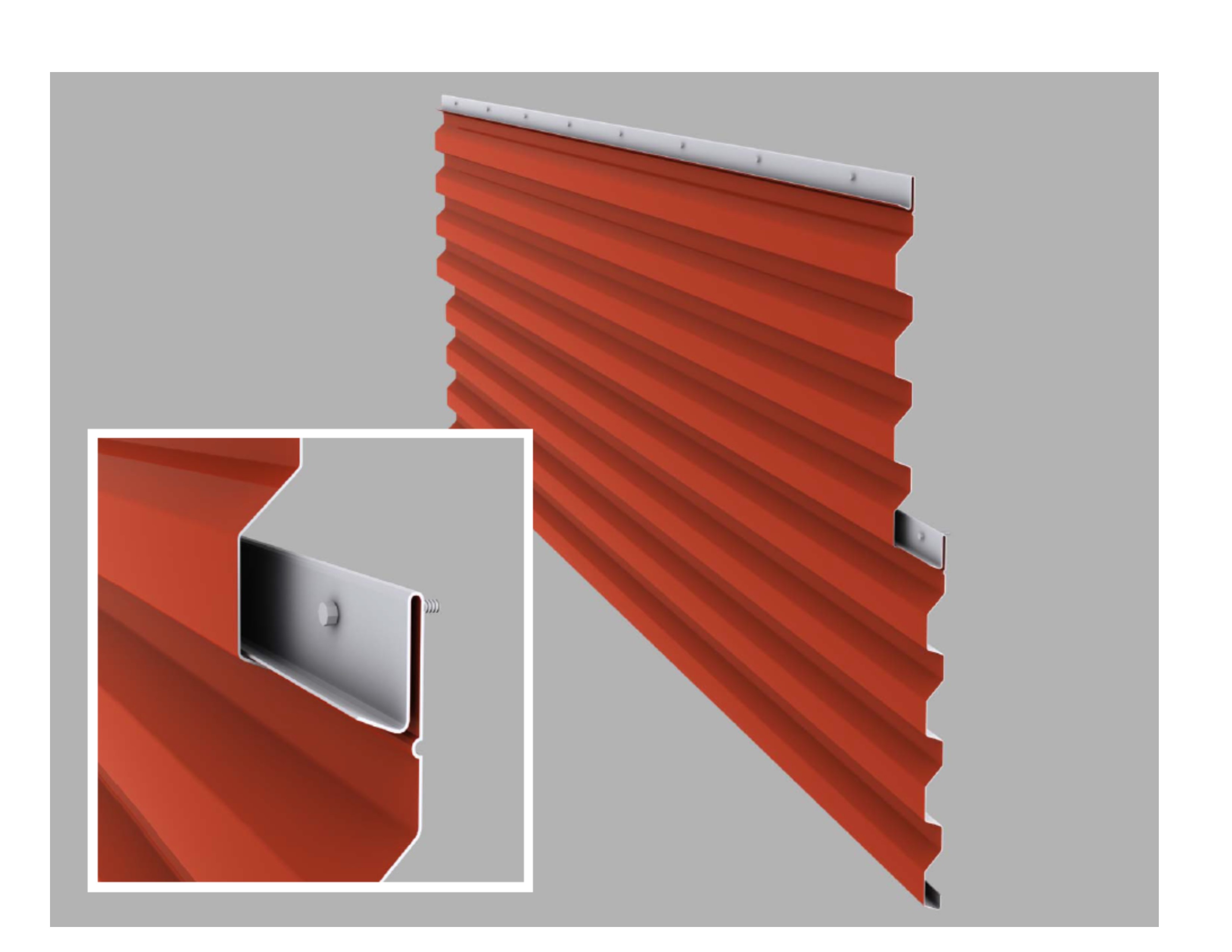

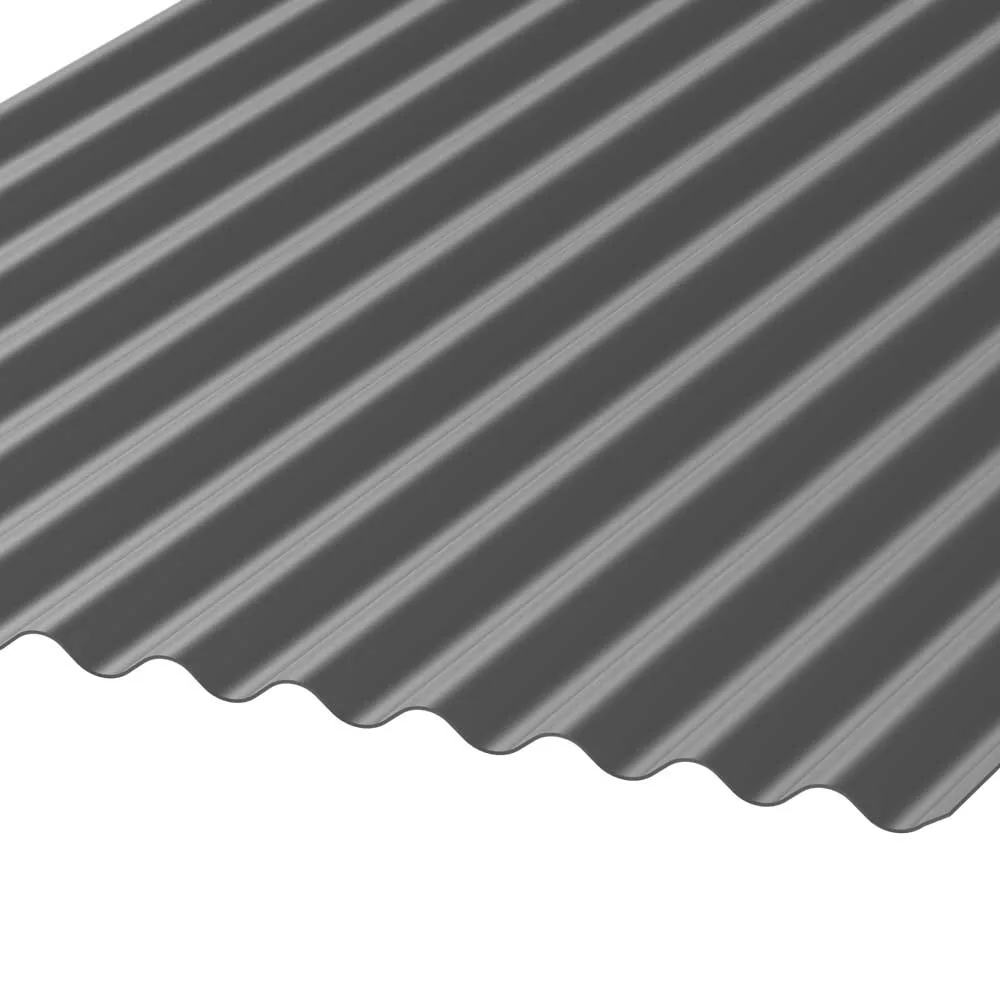

Classic 7/8″ Corrugated (2.67″ pitch)

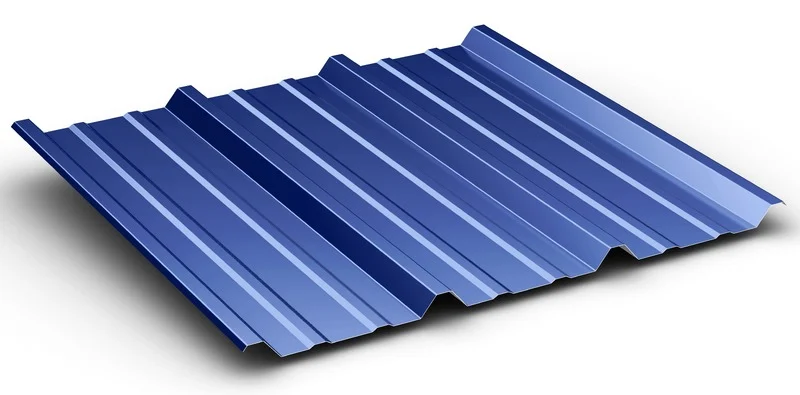

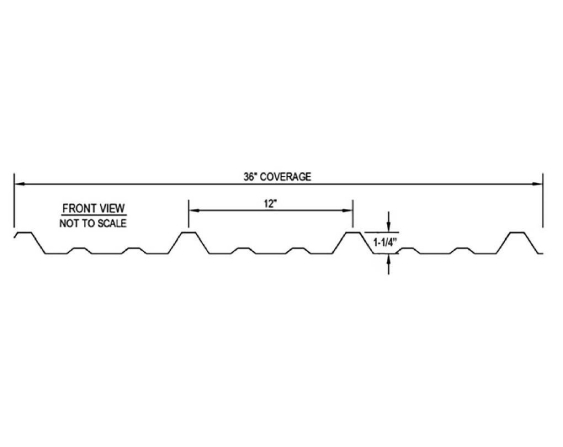

R-Panel (12″ Rib Panel)

PBR Panel (Purlin-Bearing R-Panel)

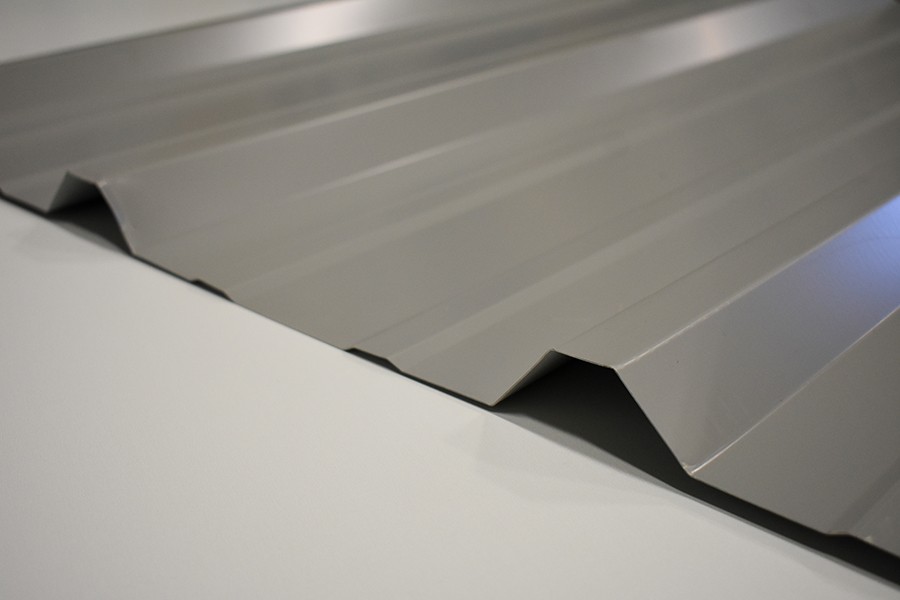

Box Rib (4″ / 6″ / 8″)

7.2 Panel (Architectural Rib Panel)

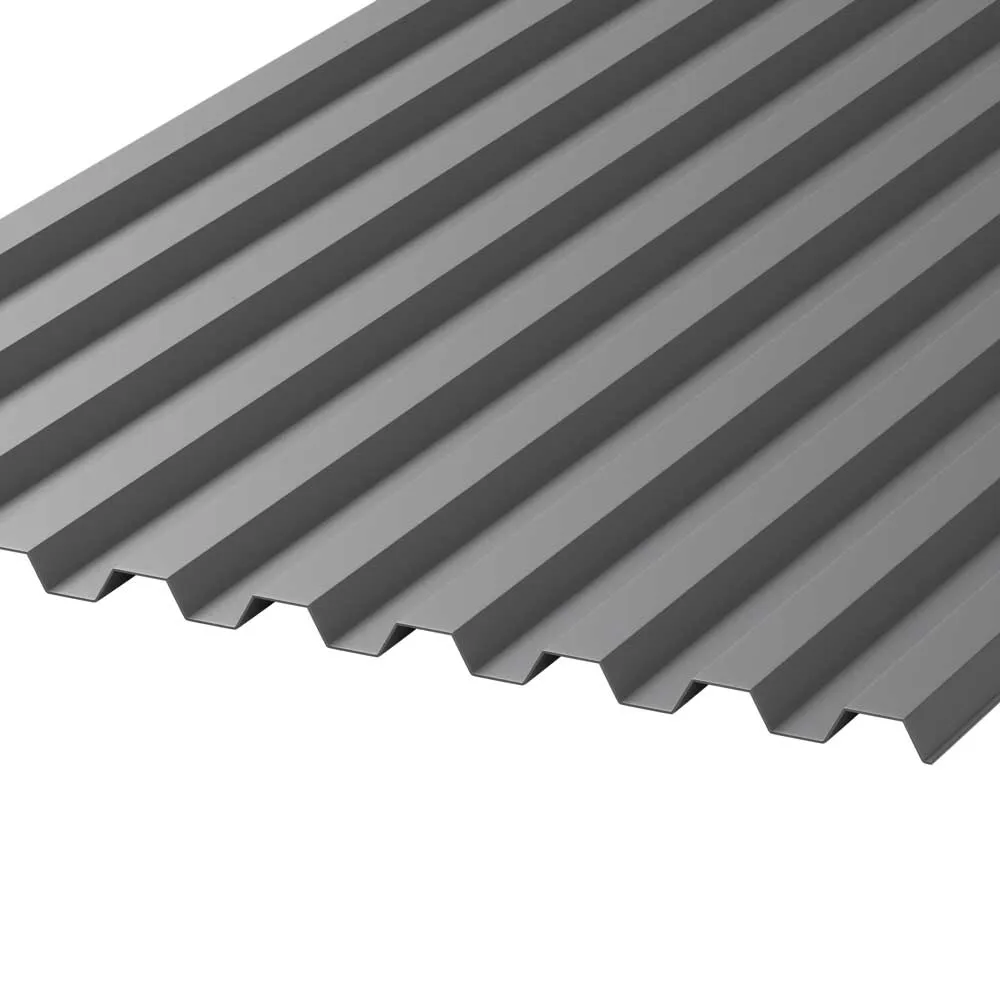

Vertical Rib Panel(Exposed-Fastener)

Perforated Corrugated

Shallow Corrugated (2.67″ × 1/2″ or 3/4″)

Aluminum corrugated metal – common profiles & popular sizes

Popular sizes and a quick spec overview (cover width, thickness, length). Final dimensions follow the corresponding profile drawing/size chart.

Get a Quick Quote-

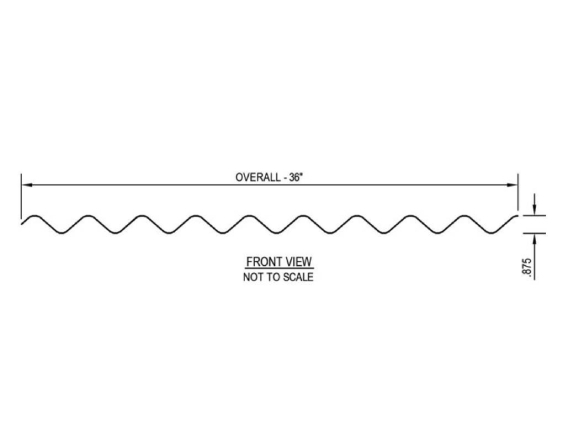

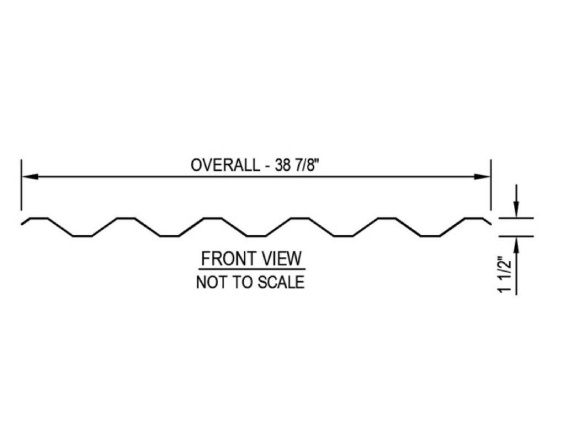

2.67" × 7/8" Corrugated PanelGet a Quote

2.67" × 7/8" Corrugated PanelGet a Quote18 / 20 / 22 / 24 / 26 ga -

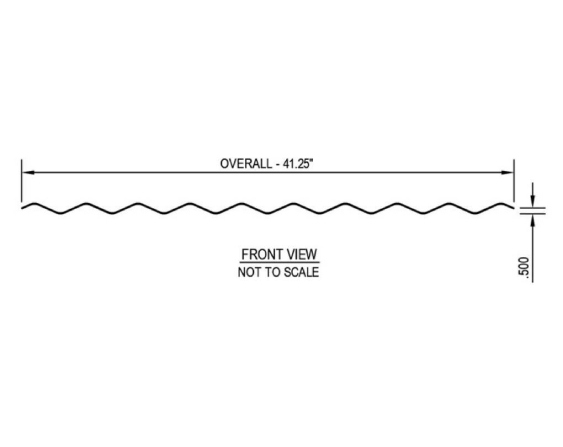

2.67" × 1/2" Corrugated PanelGet a Quote

2.67" × 1/2" Corrugated PanelGet a Quote18 / 20 / 22 / 24 / 26 ga -

12" Rib (R-Panel)Get a Quote

12" Rib (R-Panel)Get a QuoteR-Panel is an ideal choice for both roofing and wall applications -

4" Box Rib PanelGet a Quote

4" Box Rib PanelGet a QuoteThe 4" rib is an industry-standard wall panel profile, typically in 24 ga and thicker -

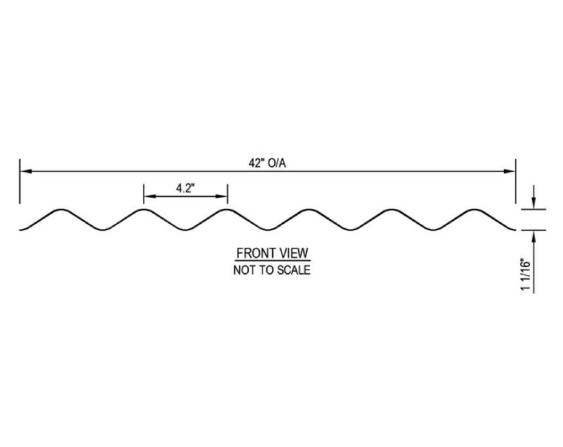

4.2" Corrugated PanelGet a Quote

4.2" Corrugated PanelGet a QuoteAvailable thickness options include 0.050", 0.040", and 0.032". Ideal for the paper and pulp industry -

7.2 PanelGet a Quote

7.2 PanelGet a QuoteThe 7.2 metal wall panel features a traditional 7.2 ribbed panel design -

V-Beam PanelGet a Quote

V-Beam PanelGet a QuoteV-Beam industrial roof and wall panels are commonly used for warehouses and buildings that require low-temperature or temperature-controlled environments -

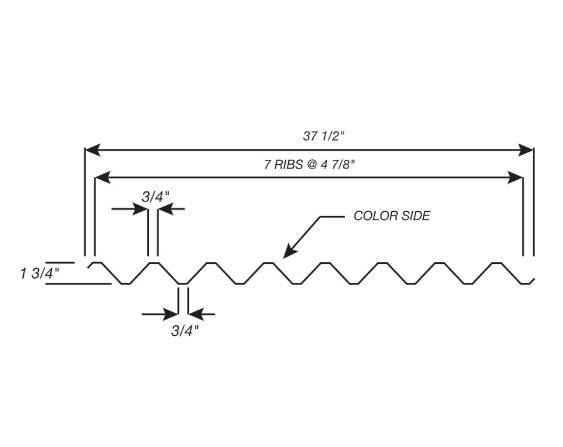

Vertical Rib Panel (Verta-Rib style, exposed-fastener)Get a Quote

Vertical Rib Panel (Verta-Rib style, exposed-fastener)Get a QuoteWith recessed-fastener-style ribs, it's a great industrial wall panel option for a smooth, flat appearance -

B-DeckGet a Quote

B-DeckGet a QuoteStandard widths: 36" and 30". Lengths can be custom cut to your requirements -

A-Deck – 36" CoverGet a Quote

A-Deck – 36" CoverGet a QuoteA-Deck is mainly used for re-decking existing decks and is also known as narrow rib deck -

N-DeckGet a Quote

N-DeckGet a QuoteThe 3" depth allows N-Deck sheets to span longer distances -

S-DeckGet a Quote

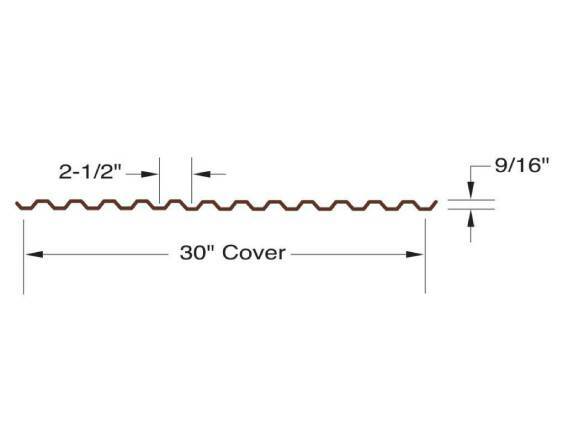

S-DeckGet a QuoteThe S-deck profile forms a continuous rib pattern with 2.67" spacing and a 9/16" rib height after forming -

Roofing & Heavy-Duty Wall PanelGet a Quote

Roofing & Heavy-Duty Wall PanelGet a QuoteThe rib profile is similar to a 2.67" × 7/8" sinusoidal corrugation. HD panels use a larger corrugation spacing for higher strength

This table is a quick spec overview of our most recommended aluminum corrugated and rib panels, helping you compare typical applications, coverage width, common thicknesses, and lengths at a glance.

Final dimensions follow the corresponding profile drawing/size chart.

| Profile / Panel Type | Typical Use | Typical Cover Width (Net) | Common Thickness | Length |

| 2.67" × 7/8" Corrugated | Roofing / Siding / Fencing / Cladding |

29 1/3" net cover (31" overall) 40" net cover (41 3/4" overall, roof) |

18 / 20 / 22 / 24 / 26 ga |

8 / 10 / 12 ft (stock) Cut-to-length (project) |

| 2.67" × 3/4" Corrugated | Roofing / Siding / Decorative cladding | Commonly same "standard / wide" families; confirm by your drawing | 18 / 20 / 22 / 24 / 26 ga |

8 / 10 / 12 ft (stock) Cut-to-length (project) |

| 2.67" × 1/2" Corrugated | Siding / Interior & light-duty exterior | Per drawing | 18 / 20 / 22 / 24 / 26 ga |

8 / 10 / 12 ft (stock) Cut-to-length (project) |

| R-Panel (12" Rib Panel) | Roofing & wall (exposed-fastener) | 36" coverage (typical) | Commonly 26–22 ga (project-based) | Cut-to-length (project) |

| PBR Panel (Purlin-Bearing R-Panel) | Roofing (purlin-bearing leg) | 36" coverage (typical) | Commonly 26–22 ga (project-based) | Cut-to-length (project) |

| 4" Box Rib Panel | Wall panel / fencing / siding |

36" coverage (common) (some markets also use 32") |

Typically 26–18 ga (varies by supplier) | Cut-to-length (project) |

| 7.2 Panel (Architectural Rib Panel) | Wall / roof (exposed-fastener rib panel) | 36" coverage (typical) | Project-based | Cut-to-length (project) |

| V-Beam Panel | Industrial roof & wall / warehouse | Per drawing | Project-based | Cut-to-length (project) |

| Vertical Rib Panel (Verta-Rib style) | Industrial wall (exposed-fastener) | 36" coverage (typical) | 18 / 20 / 22 / 24 / 26 ga (common market range) | Cut-to-length (project) |

| 4.2" Corrugated Panel | Industrial siding / specialty industries | Per drawing | 0.032" / 0.040" / 0.050" (common) | Cut-to-length (project) |

| B-Deck | Metal deck (roof/floor systems) |

36" cover (typical) (some specs: 30") |

Per project spec | Cut-to-length (project) |

| A-Deck (Narrow Rib / Re-deck) | Re-decking existing deck | 36" cover (typical) | Per project spec | Cut-to-length (project) |

| N-Deck | Longer span deck systems | Per drawing | Per project spec | Cut-to-length (project) |

| S-Deck | Form deck / ribbed template | Per drawing | Per project spec | Cut-to-length (project) |

| Roofing & Heavy-Duty Wall Panel (HD) | Higher strength / heavier-duty applications | Per drawing | Project-based | Cut-to-length (project) |

Need the exact profile match? Send your profile name (or photo/drawing) + target length + quantity + destination. We’ll confirm the closest profile and quote the fastest available lead time.

Get a QuoteAvailable finishes & color options (stock and custom)

Custom colors: Custom color matching is available. Lead time is typically 3–4 weeks after color confirmation (sample/chip approval).

Color consistency & control: we prioritize same-batch / same-coil production whenever possible to reduce shade variation. Final acceptance is based on the approved color chip/sample (not screen images). For long-term outdoor exposure, PVDF coating is recommended where specified and available.

Instant Quote

Corrugated Skinz Charwood

Corrugated Skinz Aged Bronze

Corrugated Skinz Aged Gold

Corrugated Skinz Glacier

Corrugated Patina 122 Flat

Corrugated Patina 135 Flat

Corrugated Patina 116 Fog Flat

Grey Fog Matte

Corrugated Graphix Foliage

Corrugated Gradients

Classic Antique Gold

Cobalt Sand Powder

Black Sand Powder Coat

Cream Metallic

Gold Metallic Powder

Sahara Gold Powder

Silver Metallic Powder

White Matte Powder

Common alloys & typical applications (how to choose)

Below is a practical alloy guide for aluminum corrugated metal used in roofing, siding, fencing, and architectural cladding. If you are not sure which alloy to choose, send your application + environment (coastal / industrial / normal) and we will recommend the best option.

- Best value for most roofing & siding: 3003 / 3004

- Coastal / marine / higher corrosion resistance: 5052

- Architectural anodizing / color consistency: 5005

- Light-duty cladding & general purpose: 1050 / 1060 / 1100

- Other alloys for special projects: 6061 / 6063 (confirm forming route & temper)

1050 / 1060 / 1100 aluminum corrugated sheets

Best for: light-duty wall cladding, ceilings, partitions, decorative panels, and general-purpose outdoor use.

Why choose: excellent formability and natural corrosion resistance, with a cost-friendly option for non-structural applications.

Notes: for higher wind load, dent resistance, or tougher service environments, 3003/3004 or 5052 is usually preferred.

3003 / 3004 aluminum corrugated sheet

Best for: the most common choice for roofing and siding panels in general outdoor environments.

Why choose: a balanced combination of formability, corrosion resistance, and improved dent resistance compared with pure aluminum alloys.

Typical applications: building roofs and walls, trims, enclosures, trailer/vehicle skins, containers.

5005 aluminum corrugated sheet

Best for: architectural cladding where appearance and finishing quality matter.

Why choose: good corrosion resistance and anodizing-friendly performance for cleaner, more consistent color results.

Typical applications: facade and curtain wall accents, interior decorative panels, trims, signage, architectural features.

5052 aluminum corrugated sheet

Best for: coastal / marine environments and projects requiring higher corrosion resistance.

Why choose: stronger and more corrosion-resistant than many general-purpose sheet alloys, suitable for long-term outdoor exposure.

Typical applications: coastal roofing and siding, marine-related cladding, fences, protective covers, outdoor enclosures.

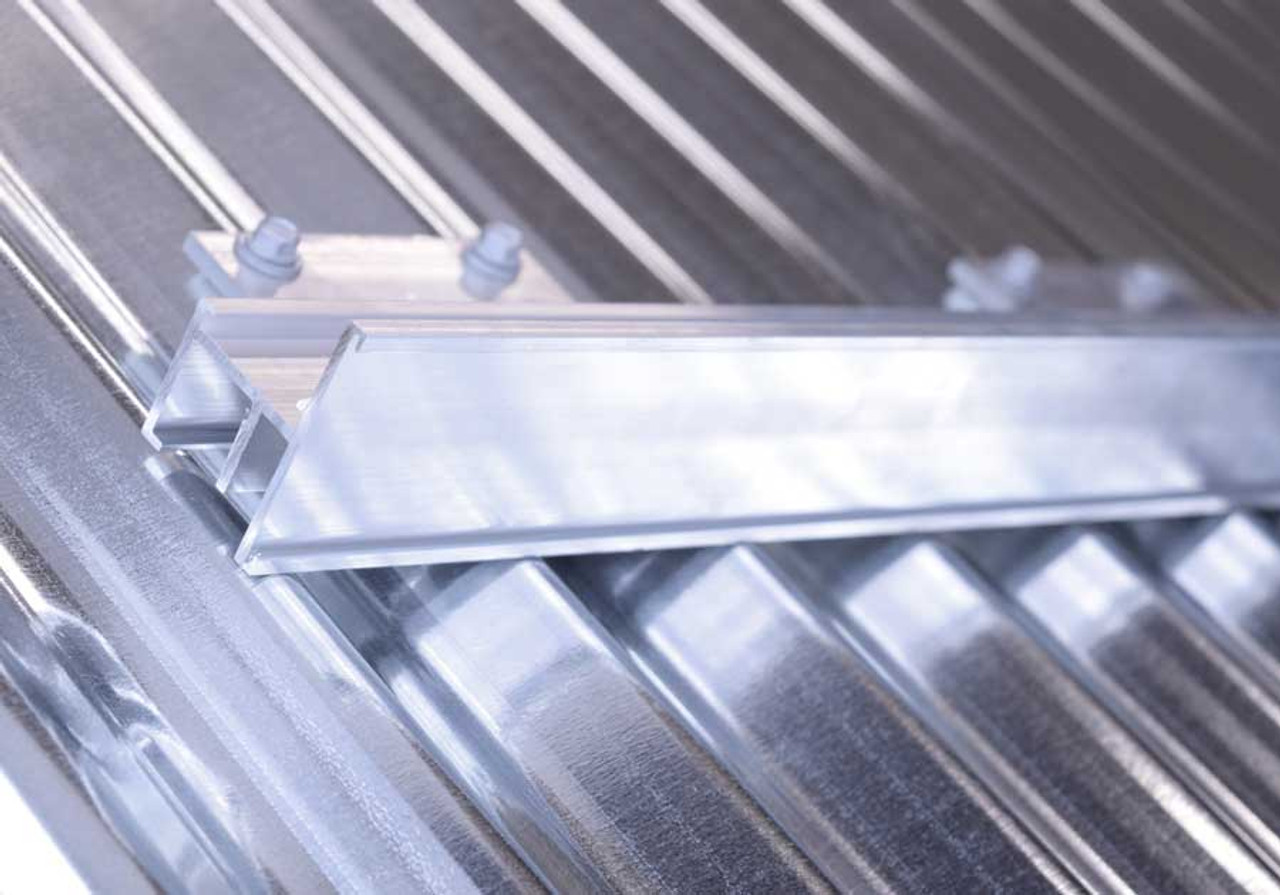

Roofing installation notes (overlap, fasteners, thermal movement & leak prevention)

Corrugated aluminum roofing is commonly an exposed-fastener system. Most leak issues come from overlap direction, fastener sealing, and movement control—so it’s worth confirming these basics before ordering.

1 Overlap (side lap & end lap)

- Side lap: install panels so the overlap faces away from the prevailing wind and driving rain.

- End lap: avoid placing end laps in low-slope areas when possible; use proper sealing and support at laps.

- Coverage width: corrugated panels have an overall width and a smaller effective coverage width due to overlaps—use coverage width to calculate quantity.

2 Fastening (screws, washers, and placement)

- Use roofing fasteners with sealing washers (e.g., EPDM) suitable for outdoor exposure.

- Do not over-tighten: over-compression can damage the washer and distort the panel, creating leak paths.

- Consistent layout: keep fastener lines straight and consistent to avoid oil-canning and uneven sealing.

3 Thermal expansion (aluminum moves)

- Aluminum expands and contracts with temperature changes. For longer panels, confirm a fastening pattern and detailing that allows controlled movement.

- Use correct holes/slots and washer seating where required by your roof design to reduce stress and "walking" fasteners.

4 Common leak risk points (what to check)

- Penetrations: skylights, vents, and pipe boots need compatible flashing and sealant.

- Ridge / eave / valley: these transitions should use proper trims and closures matched to your corrugation.

- Cut edges: keep cut edges clean and protected; if using coated panels, avoid damaging the finish at cuts.

- Corrosion compatibility: avoid incompatible fasteners/metals in direct contact; use appropriate isolation if required.

Tip for faster ordering: send your roof slope, span/purlin spacing, and the profile you plan to use. We can help confirm a practical thickness/finish choice and provide a quote-ready specification.

Corrugated aluminum price: what drives cost & how to get an accurate quote

Aluminum corrugated panels are often priced higher than typical steel corrugated sheets, but the total project value can be better in wet, coastal, or corrosion-prone environments due to longer service life and reduced maintenance.

Main price drivers: alloy (e.g., 3003 vs 5052), temper, thickness, profile type (7/8 corrugated, R/PBR, box rib), finish system (mill / anodized / powder / PVDF/PE), panel length (8–12 ft vs custom cut-to-length), order quantity, packing, and destination port.

To quote correctly, please send your profile + thickness + finish/color + length + quantity + destination. If you only have an application and photos/drawing, we can recommend the closest profile and alloy before pricing.

How pricing is calculated: we can quote by piece (per panel/sheet), by area (USD/m² or USD/ft²), or by weight (USD/ton)—whichever matches your purchasing method and project needs. For corrugated panels, quoting per piece is common when the profile, coverage width, and cut length are fixed; quoting per m²/ft² is common for cladding projects; quoting per ton is common for bulk orders.

Finish/coating: mill finish is quoted as the base material. Coating/finishing (PVDF/PE, powder coating, anodizing) is typically priced separately (or shown as a clearly listed add-on), because it depends on the finish system, color, gloss, and approval method.

Freight & packing: shipping cost is estimated from the destination, FOB/CIF/DDP , panel length & bundle size, and packing method (pallet/crate, moisture protection, edge protection). Longer cut-to-length panels may affect container loading and freight, so we confirm packing and loading plan before finalizing freight.

Request PricingAluminum vs galvanized/galvalume steel corrugated panels

Aluminum and coated-steel corrugated panels are both widely used. The right choice depends on environment, desired service life, and budget.

Initial cost is often higher than typical coated-steel corrugated sheets, but in coastal or high-humidity environments aluminum usually requires less maintenance and delivers a more predictable total cost of ownership over the service life.

- Choose aluminum for coastal or high-humidity projects, or when long-term corrosion resistance and low weight are priorities.

- Choose galvanized/galvalume steel when initial cost is the main driver and the environment is less corrosive (or heavy coatings/maintenance are acceptable).

- Dent resistance: thinner aluminum can dent more easily—select the right thickness and profile for your span and handling conditions.

- Appearance: both materials can be supplied with a wide range of finishes and colors; confirm finish system and color approval method before production.

FAQ – corrugated aluminum & corrugated metal panels

What is corrugated aluminium?

Corrugated aluminium (corrugated aluminum) is an aluminum sheet formed into a ribbed/wavy profile. The corrugation adds stiffness, helps shed water, and allows the sheet to be used as roofing, siding, fencing, and architectural cladding panels.

What are the disadvantages of aluminum roofing?

Aluminum roofing typically costs more than common corrugated steel panels and can dent more easily if the thickness/profile is not selected correctly. For best results, choose the right panel thickness and rib profile for your span, wind load, and handling conditions, and confirm the finish system for your environment (especially coastal projects).

What are the different types of corrugated metal?

"Corrugated metal" is a broad term that includes multiple ribbed profiles and materials. Common profile families include classic corrugated (wavy), R-Panel / PBR panels, box rib panels, and architectural rib panels (such as 7.2 style). Materials may be aluminum, galvanized steel, or galvalume steel, and each is selected based on corrosion exposure, budget, and desired service life.

What are the disadvantages of a corrugated metal roof?

The disadvantages depend on the material and the system. Exposed-fastener corrugated roofs require correct fastener placement and sealing to prevent leaks over time, and they can be noisier during heavy rain without proper insulation. Steel panels can be more prone to corrosion if coatings are damaged or the environment is harsh, while aluminum can dent more easily if too thin for the application.

Need help choosing? Send your application (roof/wall), environment (coastal/industrial/normal), preferred profile, and target length (8–12 ft or cut-to-length) and we will recommend the best alloy, thickness, and finish for a fast quote.

Is anodized (black) corrugated aluminum available? How do you control color consistency?

Yes. We can supply corrugated aluminum with anodized finishes, including black, for architectural and decorative applications.

For better appearance consistency, we recommend producing from the same alloy/temper and prioritizing same-batch processing for each project.

Color approval is based on an anodized sample / color chip before mass production. Please note that anodized color can vary slightly by alloy, surface preparation, and batch.

To reduce visible shade differences, we suggest ordering all panels for one facade/roof section in a single lot, and confirming the required surface quality (e.g., scratch tolerance) and protective packaging.

How to quote

To quote quickly and accurately, please copy the checklist below into your email. If you only have photos or a drawing, send them—we can match the closest profile and confirm the ordering details before pricing.

- Application: roofing / siding / fence / decorative cladding

- Profile: 7/8 corrugated, 1/2 corrugated, R/PBR panel, box rib, 7.2 panel (or your drawing)

- Alloy & temper: (e.g., 3003-H14, 5052-H32)

- Thickness: mm or inch (or gauge if you use it)

- Finish / color: mill / anodized / powder / PVDF/PE

- Length: 8–12 ft or cut-to-length (exact length list if multiple)

- Quantity: pcs or total sqm/weight

- Destination: port / ZIP code + FOB/CIF/DDP