Brazing flux is an indispensable auxiliary material in the brazing process. It removes the oxide film on the base metal surface, reduces the surface tension of the filler metal, and promotes the uniform spread of molten filler metal in the joint gap, ultimately forming a strong, dense, and porosity-free weld. Whether in a manual brazing with flux flame station or an automated powder spraying line in a continuous furnace, the correct flux selection is crucial to ensuring weld quality.

Depending on the metal used and the temperature range, common flux types include:

Leveraging its strong capabilities in formulation development and rapid delivery, Chalco's Brazing Flux series provides customers with comprehensive brazing solutions:

- Diverse forms: powder, paste, slurry, flux-cored wire and pre-impregnated solder ring, etc., suitable for both automated production lines and manual operation.

- Wide compatibility : Covers aluminum, copper/brass, stainless steel, titanium and cemented carbide, meeting multi-metal welding needs.

- High efficiency and stability: precise activation temperature range, low post-weld residue, no cleaning required, strong corrosion resistance, and significantly reduced rework rate.

- Fast delivery: Samples for regular models are sent within 48 hours, and small batch orders are shipped within 5 days.

Overview of Chalco Flux Product Forms and Usage

Different forms of flux determine its powder application efficiency, coating uniformity, and production line cycle time. Chalco typically offers three supply forms for flexible switching:

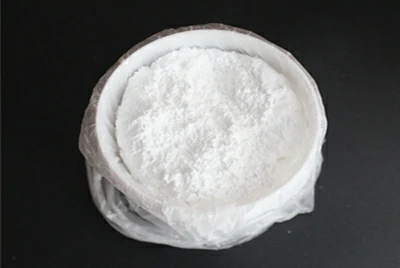

Powdered Flux (Brazing Flux Powder)

Description: Used for automatic powder spraying, dipping or spin coating; easy to control dosage and ensures uniform coverage, ideal for continuous furnace production.

Examples of applicable systems: Aluminum (FB5 KAIF, FB501S-C); Copper (FB201S-01)

Flux Paste / Slurry (Brazing Flux Paste)

Description: Can be applied by brushing, rolling or screen printing without powder dispersion; ideal for local activation and fin screen printing.

Examples of applicable systems: Aluminum (FS312S, XR-0726FLUX, CF-1S); Silver (SX-W, SX-B); Copper (FB101P)

Flux-Cored & Flux-Coating Rods (Flux Coated Brazing Rod)

Description: Flux-pre-coated or flux-cored rods enable quick manual flame brazing and on-site repairs; include filler metal as composite consumables.

Typical applications: Aluminum (field repair soldering) and copper/brass (flux-coated brazing rings)

Aluminum brazing flux

Aluminum and aluminum alloys rapidly form a dense oxide film during brazing at approximately 550 ℃ ± 25 ℃. Without highly active flux, the brazing filler metal (4045/4343/4004, etc.) cannot be adequately wetted, easily leading to incomplete soldering, slag inclusions, or porosity. Chalco's aluminum brazing flux series uses a mature formula of fluoroaluminates and halides, enabling instantaneous film removal, uniform wetting, and extremely low residue within a very narrow temperature range. It is widely used in automotive radiators, air conditioning condensers, turbocharged air coolers, and energy storage cold plates, among other applications.

- Precision activation: Narrow activation window, high single-furnace pass rate

- Non-corrosive residue: No post-weld cleaning required, salt spray resistance ≥ 1000 h

- A full range of forms: powder, slurry, paste, flux-cored wire, and pre-impregnated welding rings, catering to both automated production lines and on-site repair welding.

| Chalco Fluoroaluminate Series Brazing Fluxes—The Preferred Choice for CAB Continuous Furnaces | ||||

| Product | Chalco stock models | Activation temperature zone (°C) | Typical applications | Features/Patents |

| Potassium Fluoroaluminate Flux(Standard KAlF₄) | FB5 KAIF | 560 – 575 | Aluminum-aluminum heat exchangers and evaporators | Low residue ≤ 0.005 g/m²; 48 h in stock, samples sent upon request. |

| Cesium Fluoroaluminate Flux(Ultra-Clean Cs-Flux) | FS420S (Pink) FS312S (Cream) | 540 – 610 | High-fin screen printing, ultra-clean welding | ★ Patented product, patent number verifiable. |

| Potassium-Cesium Fluoroaluminate Flux(High-Mg Flux) | FB501S-C | 555 – 565 | Mg 0.6–0.8% Tube fittings, pressurized air coolers | Anti-Mg oxidation, cyclic salt spray > 1000 h |

| Potassium-Lithium Fluoroaluminate Flux(Marine-Grade) | FB501S-M | 566 – 577 | Seawater coolers, high corrosion-resistant heat exchangers | Li-modified, water corrosion resistance improved by ≥ 30%. |

Chalco aluminum brazing fluxes are also compatible with the NOCOLOK®-type flux system, and some models are compatible with AMS 3411.

| Halide Series — Flame/Induction Localized Brazing | ||||

| Product | Chalco stock models | Activation temperature zone (°C) | Typical applications | Features/Patents |

| Halide Flux Paste (NaCl-KCl-LiCl) | XR-0726FLUX | ointment | 550 – 630 | 4047 Al-Si Flame/Induction Soldering |

| Halide Flux Powder | FB201S-01 | powder | 550 – 630 | Induction brazing of aluminum tubes, local repair welding |

| Specialized paste-like products – for spot treatment and large-area application | ||||

| Product | Chalco stock models | Activation temperature zone (°C) | Typical applications | Features/Patents |

| Aluminum Flux Paste | CF-1S | CsAlF + organic carrier | Localized activation of large aluminum parts | Single-component, ready to use; can be coated to form a 20 µm film. |

| Al-Si Brazing Paste | BA4047-K / BA4045-K | Al-Si metal powder + Flux | Brazing of complex/irregular Al-Si joints | Particle size < 45 µm, better gap-filling properties than brazing rings. |

Recommended pairings: For flame soldering of aluminum alloys, XR-0726FLUX paste or FB201S-01 powder (550–630 ℃) can be used.

Click to view the "Aluminum Alloy Brazing Flux Selection and Process Guide" for complete technical parameters, or contact us directly for free samples and customized solutions.

Silver-based soldering flux

Chalco offers a full range of silver brazing fluxes, covering both white general-purpose (White Brazing Flux) and black high-temperature (Black Flux for Silver Brazing) types, along with Silver Solder Paste, to fully meet the needs of industrial and precision welding.

-

Silver Solder Flux

Silver Solder Flux

White Flux: General-purpose, 500–800 ℃, easy-to-clean residue; used for HVAC copper pipes and stainless steel parts.

Black Flux: High-temperature type, 850–900 ℃, for stainless steel, hard alloys, and high-nickel alloys.

Covers typical white/black flux needs with compatible temperature ranges and paste forms.

-

Silver Solder Paste

Silver Solder Paste

Silver solder paste is a premixed blend of silver alloy powder and flux. It can be supplied in syringes or bottles for bulk use.

It is easy to apply, produces dense and aesthetically pleasing solder joints, and is suitable for jewelry, electronics, small stainless steel or nickel alloy parts, and DIY repairs.

- It covers a working temperature range of 500–925 ℃, and can be used for both low-temperature jewelry repair and high-temperature stainless steel/hard alloy welding.

- Compliant with AWS A5.31 / ISO 9454 flux standards, the silver solder paste is compatible with common silver-based solder standards (such as AWS A5.8 / ISO 17672).

- The welded surface is clean and highly corrosion resistant, far superior to traditional borax brazing flux.

- Environmentally friendly formula, low halogen, low smoke, compliant with RoHS/REACH requirements.

Want to learn more about the complete parameters and packaging specifications? Please click to enter the "Silver Solder Flux & Silver Solder Paste Solutions" page to get a detailed selection guide and sample application channel.

Copper-based filler metals and fluxes

Copper and copper alloys tend to form a stable oxide film on their surface during brazing, requiring a high-efficiency flux to ensure wetting and flow. Chalco's Copper Brazing Flux series covers all needs from low-silver and silver-free brazing to high-strength copper-copper/copper-brass brazing.

Features:

- The activation temperature range is 650–1100 ℃, which meets the requirements of flame, induction and furnace brazing.

- Rapid wetting: The flux formulation can significantly improve the fluidity of the solder, making it suitable for narrow-slot and high-speed soldering processes.

- Low residue and no acid pickling required: The surface is clean after welding and can be directly proceeded to subsequent electroplating or assembly.

- Compatible with multiple forms: powder, paste, liquid and coated brazing rings, can replace traditional brass brazing flux.

- It is compatible with both bronze brazing flux and copper-to-brass brazing flux scenarios, and is suitable for Sil-Fos/BCuP systems.

Typical applications:

- Air conditioning and refrigeration copper pipes / brass fittings

- Carbide tool brazing

- Automotive fuel lines and high-voltage electrical components

- Induction brazing of copper busbars and large-section copper components

For more complete formulation comparisons and process adaptations, please visit the Copper Brazing Flux page to learn about application guidelines for liquid, ointment, and coated formulations, and request free samples or a quick quote immediately.

High-Activity Fluxes for Stainless Steel & Carbide

High-Cr stainless steel, cemented carbide (WC-Co), and nickel-based alloys have stable oxide films, requiring highly active borosilicate-fluoride fluxes to achieve rapid wetting above 750°C. This series covers the high-activity requirements of both brazing flux for steel and brazing flux for stainless steel. Chalco's ST series of black high-temperature Flux is specifically designed for vacuum, induction, and flame brazing.

| Product | Model | Form | Activation temperature zone (°C) | Typical applications | Feature |

| High-Temp Black Flux(black brazing flux) | STB-90 | ointment | 750 – 900 | 304/316L stainless steel + Ag-Cu brazing filler metal | Welding residue can be easily washed away with water, preventing intergranular corrosion. |

| Super Black Flux (carbide brazing flux) | STB-95 | ointment | 780 – 950 | WC-Co lathe tool welding pads and gear ring repair | Adding Ni/Mn salts to wet cemented carbide |

| Vacuum Active Flux | STV-80 | powder | 780 – 880 | Vacuum furnace brazing of 17-4PH and Inconel | Volatile residue ≤ 0.05 mg/cm² |

Recommended pairing: Silver-based brazing filler metals XR-Ag45Ni / XR-Ag50Sn are used with STB-90 or STB-95 to significantly improve the strength of stainless steel and carbide joints.

Fluxes for Titanium & Exotic Alloys

Titanium alloys and high-Ni special alloys are prone to forming refractory oxide films at high temperatures; Chalco TF series dual-active system Flux (fluoroborate + lithium fluoride) can rapidly remove the film within 780 – 860 ℃, while inhibiting α→β embrittlement.

| Product | Model | Form | Activation temperature zone (°C) | Typical applications | Feature |

| Titanium Active Flux | TF-80 | ointment | 780 – 840 | Ti-6Al-4V structural components | Strongly activated, wetting β-annealed layer — commonly used in aerospace-grade structural components. |

| Ti-Ni Super Flux | TF-85 | powder | 800 – 860 | Ti-Ni elastic alloys, medical devices | Low residue, does not contaminate the vacuum furnace |

| Exotic Alloy Flux | TF-90 | ointment | 800 – 880 | Hastelloy, Haynes alloy | Anti-Cr₂O₃ film, 1000+ hours of post-weld salt spray test. |

Recommended application: When using Ag-Cu-Mn or Ti-Cu-Ni solder , it is recommended to apply a thin layer of TF-80 / TF-85 by brushing; for vacuum brazing, TF-90 fine powder can be lightly sprinkled.

Frequently Asked Questions (FAQ)

1.Why is flux always used in brazing?

Before and after the solder melts, the base material will continuously generate an oxide film; the flux can instantly remove the film and reduce the surface tension in the target activation temperature zone, allowing the molten solder to fully wet and fill the gaps, otherwise it is easy to have poor soldering, slag inclusions or porosity.

2. What are the three most crucial elements when selecting a product?

- Base metal (aluminum/copper/stainless steel/titanium, etc.)

- Process temperature zone (continuous furnace, flame, induction, or vacuum)

- Solder composition (Al-Si, Ag-Cu-P, Cu-P-Sn, etc.)

Just tell us these 3 points, and Chalco engineers can match the most suitable flux and amount.

3. Is cleaning required after welding? Will the residue cause corrosion?

- Aluminum fluoroaluminates and most paste residues are in an inert glassy state, requiring no cleaning.

- Silver/copper residue can be removed by washing with water and using white paste, while black paste requires warm water and gentle brushing.

All our formulations have passed a 1000-hour salt spray test and will not cause secondary corrosion to welds or substrates. Compared to commonly used borax brazing flux, our formulations leave more residue that is easier to wash off, resulting in a cleaner surface. Formulations are available in borax-free and anti-borax brazing flux options, leaving less residue and being easier to wash off compared to traditional borax brazing flux.

4.How should flux be stored? What is its shelf life?

Keep sealed, cool, and protected from moisture: 10–30 ℃, relative humidity <50%. Unopened powder/paste has a shelf life of 12 months; once opened, it is recommended to use within 6 months and reseal immediately after use.

5.Does the product comply with environmental regulations?

All fluxes and solders are RoHS, REACH, and cadmium-free tested; SDS (Safety Data Sheets) and third-party testing reports are available upon request. Functionally equivalent to commercially available Stay-Silv® black paste, but with less residue and is cadmium-free and environmentally friendly.

6.Can you customize the particle size, viscosity, or core wire specifications?

Yes. Chalco offers custom services including 200–400 mesh powder, ultrafine <10 µm spray powder, pastes with different solid contents, and Ø 1.6–3.2 mm core wires. MOQ depends on specifications.

Still no answer to your question?

Send the base material grade, welding process, and annual production volume to the email address provided, and a Chalco engineer will provide you with one-on-one technical support and free samples.

Packaging Specifications and Delivery Services

To ensure a seamless transition for your production line from trial welding verification to stable mass production, Chalco offers flexible packaging and logistics solutions for different forms and promises fast delivery.

Standard packaging

-

Powder Type

Packaging: 10 kg vacuum aluminum foil bags × 2/box

Optional: 25 kg moisture-proof container (with inner vacuum bag)

-

Slurry / Paste

Packaging: 1 kg HDPE container (for laboratory and on-site welding repair)

Optional: 10 kg plastic drum (automatic screen printing or roller coating line)

-

Flux-Cored Wire / Welding Ring

Wire Specification: Ø 1.6–3.2 mm wire: 5 kg/roll, vacuum bag + desiccant

Welding Rings: Prepreg welding rings: 100 pieces/box, with foam insulation for impact protection

After-sales service and technical support

- Online selection: 24-hour email/WeChat response, recommending flux and furnace temperature profiles.

- On-site trial welding: For large projects, engineers can be sent to the factory to guide the adjustment of powder quantity and optimization of atmosphere.

- Quality traceability: Each batch is assigned a unique LOT number and samples are retained for ≥18 months to ensure traceability.

Start ordering or requesting samples

Send your requirements to our email address , along with the base materials, processing methods, and estimated annual usage. We will generate a formal quotation and delivery plan within one business day.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote