We offer a ready-die program for aluminum square bars designed for volume production and fast delivery. Side lengths cover 6.35–250 mm (inch / metric), with a focus on 6000 series alloys such as 6061 / 6082 / 6063 / 6005A. Paired with a 12,500 T extrusion press, we can stably produce large cross-sections and long lengths, and pre-process them so they are machine-ready (cut-to-length, chamfered, two- or four-side milling) to reduce preparation steps and waiting time.

- Use In-Stock Dies, No Tooling Cost: If your size matches an in-stock die, we can start production directly, significantly reducing sampling lead time and upfront cost.

- Machining-Ready Delivery: Optional cut-to-length, chamfering, and two- or four-side face milling so bars can go straight into your fixtures for roughing.

- Near-Size Fast Alternatives: For sizes within ±0.5–1.0 mm of an in-stock side length, edges can typically be trimmed by face milling—no new die required (small sizes can be evaluated for cold drawing).

- Complete Standards and Documentation: Supplied to EN / ASTM standards, with EN 10204 3.1 inspection certificates; dimensional and straightness reports can be provided on request.

Download Aluminum Square Bar Mold List (PDF)

Aluminum Square Bar Die Table

The die table is designed to quickly locate available aluminum square bar die sizes and corner types. If your target size is close to a listed dimension, we can evaluate a near-size solution (project-based). When you need unified chamfering, two-side or four-side face milling as pre-processing, please specify target side-length tolerance, corner requirements, and length in the remarks so everything can be confirmed in one step.

-

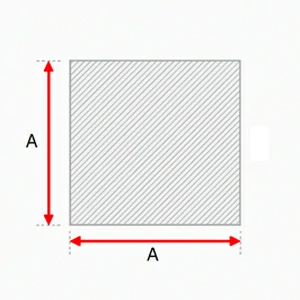

A = side length.

Corner type: sharp corners are default; radiused corners are marked as R0.5 / R1.0 …

Optional machining: cut-to-length, chamfering (e.g. C0.5–C2), two-side or four-side face milling.

Units: you can select mm or " (inch) in the table header.

Then use the schematic together with the die table below to select your size.

| A(in) | A(mm) | Densidad (Kg/m) | Extrusion tones | Alloy | Ronnd edge |

| 0.25 | 6.35 | 0.109 | 500T | 6061-T6511 | |

| 0.25 | 6.35 | 0.109 | 500T | 6061-T6511 | R0.38 |

| 7.95 | 0.17 | 500T | 6061-T6 | R0.38 | |

| 8 | 0.173 | 500T | 6060-T66 | ||

| 8.15 | 0.18 | 500T | 6082-T4 | ||

| 0.375 | 9.525 | 0.245 | 500T | 6082-T6 | |

| 10 | 0.27 | 500T | 6060-T6 | ||

| 11 | 0.328 | 500T | 6082-T6 | ||

| 12 | 0.389 | 660T | 6060-T66 | ||

| 0.5 | 12.7 | 0.435 | 660T | 6061-T6511 | |

| 14 | 0.529 | 660T | 6060-T66 | ||

| 15 | 0.608 | 880T | 6060-T66 | ||

| 15.88 | 0.68 | 880T | 6061-T6511 | ||

| 16 | 0.688 | 880T | 2007-T4511 | R1.2 | |

| 18 | 0.875 | 880T | 6060-T6 | ||

| 0.75 | 19.05 | 0.978 | 880T | 6061-T6511 | |

| 20 | 1.08 | 880T | 6060-T66 | ||

| 20 | 1.082 | 1250T | 6082-T651 | ||

| 22.2 | 1.334 | 1250T | 6061-T6511 | ||

| 25 | 1.688 | 1250T | 6060-T66 | ||

| 25 | 1.769 | 1250T | 6666-T6 | ||

| 1 | 25.4 | 1.742 | 2000T | 2024-T3511 | |

| 25.5 | 1.865 | 2000T | 6666-T6 | ||

| 30 | 2.43 | 1250T | 6060-T66 | ||

| 30 | 2.439 | 2000T | 6082 T6 | ||

| 30 | 2.444 | 2000T | 6082 T5 | ||

| 30 | 2.551 | 2000T | 6666-T6 | ||

| 1.25 | 31.75 | 2.722 | 2000T | 6061-T6 | |

| 32 | 2.883 | 2000T | 6666-T6 | ||

| 35 | 3.33 | 3150T | 6082-T6 | ||

| 35 | 3.479 | 2000T | 6666-T6 | ||

| 1.5 | 38.1 | 3.919 | 3150T | 6061-T6 | |

| 40 | 4.32 | 1250T | 6060-T5 | ||

| 40 | 4.47 | 2750T | 2007-T4 | R2 | |

| 40 | 4.336 | 3150T | 6082 T6 | ||

| 40 | 4.521 | 2750T | 6666-T6 | ||

| 43 | 4.992 | 2750T | 6082-T6511 | ||

| 1.75 | 44.45 | 5.335 | 2000T | 6061-T6511 | |

| 45 | 5.468 | 3150T | 6082-T6 | ||

| 45 | 5.66 | 3600T | 2007-T4 | R2 | |

| 45 | 5.483 | 3600T | 6082-T651 | ||

| 45 | 5.728 | 3150T | 6666-T6 | ||

| 50 | 6.75 | 3600T | 6061-T6 | ||

| 50 | 6.75 | 3600T | 6082-T6 | ||

| 50 | 6.99 | 3600T | 2007-T4 | R2 | |

| 50 | 6.775 | 3600T | 6082-T6 | ||

| 50 | 7.068 | 3150T | 6666-T6 | ||

| 2 | 50.8 | 6.968 | 3150T | 6061-T6511 | |

| 2 | 50.8 | 6.967 | 3600T | 6061-T6511 | R0.5 |

| 2 | 50.8 | 6.994 | 3600T | 6061-T6511 | |

| 55 | 8.168 | 3600T | 6082-T6 | ||

| 55 | 8.46 | 3600T | 2007-T4 | R2 | |

| 55 | 8.194 | 3600T | 6082-T6 | ||

| 55 | 8.56 | 3600T | 6666-T6 | ||

| 2.25 | 57.15 | 8.819 | 3600T | 6061-T6511 | |

| 60 | 9.72 | 3600T | 6060-T6 | ||

| 60 | 9.72 | 3600T | 6082-T6 | ||

| 60 | 10.07 | 3600T | 2007-T4 | R2 | |

| 60 | 10.07 | 2000T反挤 | 7075-T6511 | R2.0 | |

| 60 | 9.79 | 3600T | 6082-T6 | ||

| 60 | 9.751 | 3600T | 6082-T6 | ||

| 60 | 10.184 | 3600T | 6666-T6 | ||

| 2.5 | 63.5 | 10.887 | 3600T | 6061-T6 | |

| 65 | 11.408 | 3600T | 6082-T6 | ||

| 65 | 11.82 | 3600T | 2007-T4 | R2 | |

| 65 | 11.445 | 3600T | 6082-T651 | ||

| 65 | 12.074 | 3600T | 6666-T6 | ||

| 2.75 | 69.85 | 13.173 | 3600T | 6061-T6511 | |

| 2.75 | 69.85 | 13.173 | 7500T 440*260 | 6061-T6511 | R0.2 |

| 70 | 13.23 | 3600T | 6060-T5 | ||

| 70 | 13.71 | 3600T | 2007-T4 | R2 | |

| 70 | 13.279 | 7500T 440*260 | 6082-T6 | ||

| 70 | 13.894 | 3600T | 6666-T6 | ||

| 71 | 13.608 | 7500T 440*260 | 6082-T6 | R1.0 | |

| 75 | 15.188 | 7500T | 6082-T6511 | ||

| 75 | 15.74 | 7500T 440*260 | 2007-T4 | R2 | |

| 75 | 15.239 | 7500T | 6082-T651 | ||

| 75 | 15.938 | 3600T | 6666-T6 | ||

| 3 | 76.2 | 15.677 | 3600T | 6061-T6511 | |

| 3 | 76.2 | 15.677 | 7500T 440*260 | 6061-T6511 | R0.5 |

| 80 | 17.28 | 3600T | 6060T66/6082T6 | ||

| 80 | 17.911 | 7500T 440*260 | 2007-T4 | R2 | |

| 80 | 17.344 | 7500T 440*260 | 6082-T6 | ||

| 80 | 18.145 | 3600T | 6666-T6 | ||

| 82 | 18.154 | 5500T反挤 | 6082-T6511 | R0.5 | |

| 85 | 19.508 | 3600T | 6082-T6 | ||

| 85 | 20.22 | 7500T 440*260 | 2007-T4 | R2 | |

| 88 | 20.909 | 7500T 378*210 | 6061-T651 | ||

| 3.5 | 88.9 | 21.33 | 3600T | 6061-T6511 | |

| 90 | 21.87 | 3600T | 6060T66/6082T6 | ||

| 90 | 22.671 | 7500T 440*260 | 2007-T4 | R2 | |

| 90 | 22.985 | 7500T | 6666-T6 | ||

| 95.25 | 24.496 | 7500T | 6061-T6511 | ||

| 100 | 27 | 7500T | 6082-T6511 | ||

| 100 | 27.99 | 7500T 440*260 | 2007-T4 | R2 | |

| 100 | 27.1 | 7500T | 6082-T6 | ||

| 4 | 101.6 | 27.871 | 7500T | 6061-T6511 | |

| 4 | 101.6 | 27.871 | 12500T 440*260 | 6061-T6511 | R0.2 |

| 102 | 28.088 | 7500T 440*150 | 6082-T6511 | R1.0 | |

| 105 | 29.758 | 9000T | 6082-T6511 | R2.0 | |

| 105 | 29.765 | 7500T 440*260 | 6082-T651 | R1.0 | |

| 110 | 32.67 | 7500T | 6082-T6511 | ||

| 110 | 33.87 | 5500T反挤 | 2007-T4 | R1 | |

| 4.5 | 114.3 | 35.272 | 12500T 600*420 | 6061-T6511 | R1 |

| 4.5 | 114.3 | 35.274 | 7500T 440*260 | 6082-T6 | |

| 115 | 35.705 | 7500T | 2007-T4 | R1.0 | |

| 120 | 38.88 | 7500T | 6082-T6 | ||

| 120 | 39.021 | 12500T 440*150 | 6082-T6 | R1.5 | |

| 120 | 40.31 | 5500T反挤 | 7075-T6511 | R2.0 | |

| 125 | 42.185 | 9000T | 6082-T6 | R1.0 | |

| 5 | 127 | 43.548 | 7500T | 6061-T6511 | |

| 130 | 45.63 | 7500T | 6082-T6 | ||

| 140 | 52.918 | 12500T 600*420 | 2007 T4 | R1 | |

| 140 | 52.919 | 12500T | 6082-T651 | R0.5 | |

| 140 | 53.142 | 12500T 440*150 | 6082-T6 | R1.5 | |

| 150 | 60.75 | 7500T | 2007 T4511 | ||

| 150 | 60.741 | 9000T Φ780X425 | 2007-T4511 | R2.0 | |

| 150 | 60.988 | 12500T 440*150 | 6082-T6 | R1.5 | |

| 6 | 152.4 | 62.71 | 12500T | 7075-T6511 | |

| 155 | 64.865 | 12500T 600*420 | 6082-T6 | R1.0 | |

| 160 | 69.118 | 12500T 600*420 | 2007-T4 | R1.0 | |

| 165 | 73.498 | 12500T 600*420 | 6082-T6511 | R2 | |

| 6.5 | 165.1 | 73.594 | 12500T | 6082-T6 | R1 |

| 170 | 78.028 | 12500T 600*420 | 6082-T6 | R1.0 | |

| 170 | 78.39 | 12500T 440*150 | 6082-T6 | R1.8 | |

| 180 | 87.478 | 12500T 780*420 | 2011-T6 | R1.0 | |

| 180 | 87.479 | 12500T 600*420 | 6082-T651 | R0.5 | |

| 190 | 97.468 | 12500T 600*420 | 6082-T651 | R1 | |

| 194 | 101.589 | 12500T 440*260 | 6082-T6 | 3.5 | |

| 200 | 107.979 | 12500T | 6082-T6511 | R3.0 | |

| 200 | 107.998 | 12500T 600*420 | 6082-T6511 | R1 | |

| 220 | 130.679 | 12500T 780*420 | 6082-T6511 | ||

| 250 | 168.749 | 12500T 600*420 | 6082-T6 | R0.5 |

Didn't Find an Exact Side Length Match?

Preferred Alloy: We keep regular stock of 6061 aluminum square bar covering 6.35–250 mm with multiple tempers available; see the inner page on 6061 Aluminum Square Bar for details.

Near-Size Feasibility: For sizes with about ±0.5–1.0 mm difference from the in-stock A dimension, we can evaluate a fast near-size solution without opening a new die.

New Die Option: Non-standard sizes can be trialed with a new die; typical lead time is about 3–5 days for samples, 7–14 days for batch production (depending on size and processing route).

Quick Evaluation: Provide A, length, alloy, corner type (sharp or specific R value) and target tolerances, and we will return a solution and budget.

Standards & Documentation: Produced to EN / ASTM, supplied with EN 10204 3.1 material certificates; dimensional and straightness reports are available on request.

Aluminum Square Bar Stock & Mainstream Sizes

We maintain year-round production of square aluminum bar—primarily 6000 series with a focus on 6061—covering side lengths A = 6.35–250 mm (inch / metric). Popular sizes are kept in stock, while dimensions matching in-stock dies can be scheduled for fast production. Optional cut-to-length, unified chamfering, and, for strict tolerances in small and mid sizes, cold-drawing can be evaluated. Large cross-sections are stably supplied via our 12,500 T extrusion press.

PDF Download: [6061 Square Aluminum Bar Stock List]

If you require high-strength 7075 square aluminum bar, we can match existing dies for fast scheduling.

Supply Status

- In Stock – Popular sizes can be shipped immediately or cut to required length

- Fast Production – Matches in-stock dies, short-cycle scheduling

- Custom Production – Low-frequency or non-standard sizes, rapid tooling after confirmation

Popular Inch Sizes

- 1/4" square aluminum bar

- 3/8" square aluminum bar

- 1/2" square aluminum bar

- 5/8" square aluminum bar

- 3/4" square aluminum bar

- 1" square aluminum bar

- 1.5" square aluminum bar

- 2" square aluminum bar

Popular Metric Sizes

- 10mm square aluminum bar

- 12mm square aluminum bar

- 15mm square aluminum bar

- 20mm square aluminum bar

- 25mm square aluminum bar

- 30mm square aluminum bar

- 40mm square aluminum bar

- 50mm square aluminum bar

Processing · Precision · Value-Added Machining

The value of aluminum square bar lies in dimensional accuracy and consistency. Around side-length tolerance, flatness, squareness, diagonal deviation, and long-length straightness/twist, we use extrusion as the base process, apply cold-drawing when tighter tolerances or straighter bars are required, and can add chamfering / face-milling so material arrives ready to fixture and rough-machine.

Delivery Conditions

Extruded Supply (Cut & Chamfer): Cut-to-length, unified chamfering and deburring—ideal for standard machining preparation and pre-assembly staging.

Cold-Drawn Square Bar (Tight Tolerance): For projects requiring tighter side-length tolerances, better straightness, and more consistent surfaces. Common for small-to-mid sizes and batch parts; tolerance windows and checkpoints confirmed per project.

Reference-Face Preparation (Optional): Precision end-cutting or localized / single-side face-milling to establish clamping datum or key mating surfaces. Not intended as a universal two- / four-side face-milling replacement.

Geometry Control & Standards

Dimensions and tolerances follow EN 755 / ASTM B221, with controlled straightness and twist (typical ranges confirmed by size and length). Upon request, we can provide measurement records for side-length tolerance, flatness, squareness, and diagonal difference, along with EN 10204 3.1 material certificates. Sharp corners are default; R-corners or unified chamfering follow drawings.

Dimensions and tolerances follow EN 755 / ASTM B221, with controlled straightness and twist. Side-length tolerance, flatness, squareness, diagonal deviation measurement records available per project, and EN 10204 3.1 is supplied with shipment. Sharp corners standard; R-corners or unified chamfering per drawing.

Path to Achievement & Cost Balance

For batch projects, we prioritize hitting the tolerance window at the extrusion stage, and apply cold-drawing where further tightening is required. Face-milling is used mainly for sampling, small batches, or when specific datum faces are needed. Both cold-drawing and face-milling are added processes and therefore affect cost and takt time. We provide optimal combinations and boundary guidance based on volume, size, and target tolerances.

Featured Case Studies (Aluminum Square Bars)

Case 01|German CNC Shop · 6061 Cold-Drawn Square Bar (Small-Batch Fixtures)

Application: Fixtures, clamping blocks

Specification: 6061-T6, A = 25 mm × 1200 mm

Solution: Matched A = 25 mm in-stock die and applied cold-drawing to tighten side-length tolerance. Delivered cut-to-length with unified C1 chamfer, including EN 10204 3.1 certificate and dimensional records.

Outcome: Material arrived ready to clamp and rough-machine, eliminating pre-milling and deburring steps. Overall machining takt improved by ≈12%, and delivery was 5 days earlier compared with a new-die route.

Case 02|U.S. Chassis Components Supplier · 6061 Long-Length Batch (Ton-Scale Bars)

Application: Frame support bar stock

Specification: 6061-T6, A = 40 mm × 3 m (≈ 5 tons)

Solution: Matched in-stock die and set extrusion bias to achieve target side-length tolerance directly at extrusion. Delivered cut-to-length with unified C0.5 chamfer, eliminating individual bar face-milling.

Outcome: Material entered machining immediately, avoiding per-bar processing time and queueing. Total material cost reduced by ≈6%, and scheduling was shortened by ≈1 week.

Case 03|Italian Automation Equipment Manufacturer · 6082 Datum Blocks (Local Reference Faces)

Application: Assembly datum blocks

Specification: 6082-T6, A = 50 mm × 600 mm (≈ 800 kg)

Solution: Extruded using A = 50 mm in-stock die. Applied localized two-side precision cut / face-milling to form clamping datum surfaces, with unified C1 chamfer. Remaining faces kept as extrusion surfaces to control cost.

Outcome: Clamping achieved in one setup, with more stable assembly positioning. Workstation changeover time reduced, and the first 100 sets passed 100% inbound dimensional inspection.

More Die Libraries

We maintain a large and continuously updated die library covering round bars, square bars, profiles, micro-channel tubes, and more. Below are navigation entries to commonly used die tables — you may browse and request quotations directly.

Packaging & Logistics

Packaging Method: Square bar ends are protected with end caps, bundles are wrapped with anti-corrosion film or kraft paper, and secured with wooden pallets or wooden crates to prevent bending and impact—suitable for sea freight and air freight.

Labeling & Traceability: Each bundle or crate is labeled or marked with alloy, size, length, quantity, and heat/batch number. QR codes or customer-specific coding can be added upon request.

Documentation Included: Supplied with Commercial Invoice, Packing List, Bill of Lading or Air Waybill, and EN 10204 3.1 material certificate. Certificate of Origin or dimensional/mechanical reports can be added if required.

Trade Terms & Transport Support: Supports EXW / FOB / CIF / DDP, and can assist with customs clearance, delivery, and cargo insurance, with packing photos or video records provided for traceability.

FAQ

Should I Choose Extruded Supply, Cold-Drawn Square Bar, or Local Face-Milling?

For small batch or sampling, choose extruded supply with cut-to-length, chamfering, or limited datum face-milling for fast fixturing and rough machining. For tight side-length tolerance and better straightness in small-to-mid sizes, choose cold-drawn square bar. For ton-scale orders, dimensions are targeted at the extrusion stage, with only minimal machining for functional surfaces.

How Do I Specify Corner Type? Can You Produce Sharp Corners, R-Corners, or Unified Chamfers?

Sharp corners are the default. If the die has R-corners, the exact R value is listed. We can apply unified chamfers (e.g., C0.5–C2) or specified R values based on drawings, reviewed together with side-length tolerance to assess machining volume and cost.

How Are Side-Length Tolerance, Flatness, and Squareness Guaranteed? Can You Provide Inspection and Certificates?

Dimensions and tolerances follow EN 755 / ASTM B221, with controlled straightness and twist as standard. Cold-drawing or datum-face processing can further tighten key geometry. Measurement records for side-length tolerance, flatness, squareness, and diagonal deviation can be supplied with EN 10204 3.1 certificates.

What Applications Are 6061 Aluminum Square Bars Best For? What If We Need Anodizing?

6061 is ideal for fixtures, equipment supports, and block machining—balancing strength and machinability. For anodized appearance, surface finishing is typically done after machining, and we recommend confirming consistency requirements for edges and milled faces in advance.

For Batch Orders, Can Dimensions Be Achieved Without Face-Milling Every Bar?

Yes. For ton-scale quantities, extrusion settings can be biased to place the dimension directly in the tolerance window, minimizing per-bar machining. Only critical clamping or mating surfaces receive localized fine machining.

What Information Is Needed for a Quote?

We recommend providing side length and length, alloy and temper, target tolerance and corner requirements, whether cold-drawn or datum-face processing is needed, estimated quantity, and destination. Pricing reflects process route, batch level, and transport mode.

What About Lead Time and Delivery Options? What Does Packaging and Documentation Include?

Lead time depends on process and volume: extruded supply is fastest, with cold-drawing or machining adding steps. Rush scheduling and partial shipments are available. Supports EXW/FOB/CIF/DDP. Packaging includes end protection, anti-rust bundle wrap, and pallet/crate stabilization, with Commercial Invoice, Packing List, Bill of Lading or Air Waybill, and EN 10204 3.1 certificate; dimensional or straightness reports can be added if required.