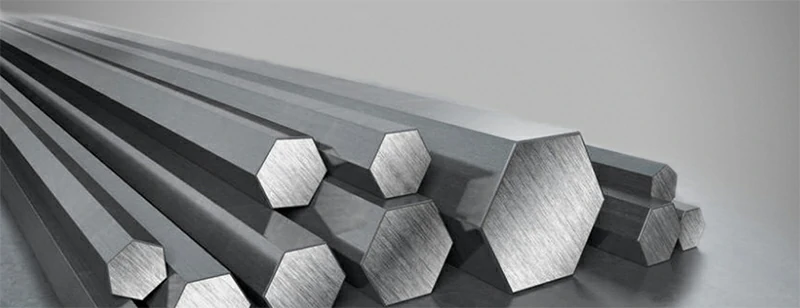

Aluminum hex bar is a solid aluminum profile with a hexagonal cross-section, widely used in high-strength, precision machining, and structural connection applications. It combines the lightweight and corrosion-resistant properties of aluminum with the torsional rigidity of a hexagonal geometry, making it ideal for fasteners, connectors, CNC machined parts, and aerospace structural components.

On this page, you will learn about:

Chalco supplies aluminum hex bars in various alloys such as 6061, 6063, 2024, 7075, 2011, and 6262, available in both extruded and cold-drawn processes. We offer custom length cutting, anodizing, thread tapping, and other deep processing services. With ample stock and fast delivery, we help you streamline the transition from design to assembly.

Instant QuoteWhy Choose Aluminum Hex Bar?

Thanks to its unique geometry and high-performance aluminum alloys, aluminum hex bar delivers excellent performance in machinery manufacturing, fastener production, and precision structural connections. Compared to round or square bars, the hexagonal shape provides notable advantages in anti-torsion, anti-slip, and positioning applications.Key Benefits Include:

- Superior anti-slip and anti-rotation performance, easy to grip with a wrench for secure connections

- Solid section provides high load-bearing capacity, suitable for high-pressure, high-torque, or precision alignment scenarios

- Excellent machinability, compatible with turning, drilling, thread tapping, CNC machining, and more

- Naturally oxidized surface, can be anodized for enhanced corrosion resistance, ideal for marine and industrial environments

- Fully RoHS/REACH compliant and 100% recyclable, supporting sustainable manufacturing systems

Aluminum Hex Bar Sizes & Customization

| Metric | Imperial | |

| Across Flats | 6mm - 150mm | 1/4" - 6" |

| Wall Thickness | 1.0mm - 12.0mm | 0.039" - 0.5" |

| Length | Cut to length, up to 6 meters | Up to 20 feet |

| Tolerance | Normal tolerance ±0.2mm, precision grade up to ±0.05mm | |

| Standard | ASTM B211, B221, EN 754-2, EN 755-3 | |

| Alloy | 6061 / 6063 / 6262 / 2011 / 2024 / 7075 | |

| Surface Treatment | Polishing, anodizing, spraying, brushing | |

| Further Processing | CNC, threading, tapping, chamfering, deburring | |

| Standard | ASTM B211,ASTM B221,AMS QQ-A-200,EN 754,EN 755 | |

For custom dimensions, sample requests, or technical guidance, feel free to contact the Chalco engineering team. We offer fast response and professional support tailored to your project.

Instant QuoteAvailable Alloys of Chalco Aluminum Hex Bar

Chalco offers a wide range of industrial-grade aluminum hex bars, covering diverse performance needs from high machinability to exceptional strength. Each alloy provides distinct advantages in strength, corrosion resistance, and machinability, making them ideal for use in aerospace structures, precision fasteners, industrial frameworks, marine equipment, and more.

6061 Aluminum Hex Bar | Extruded & Cold Drawn

6061 Aluminum Hex Bar

6061 Aluminum Hex BarA general-purpose alloy offering a balance of strength, workability, and corrosion resistance, with excellent compatibility for surface finishing. Commonly used for industrial structural components, automotive parts, aerospace brackets, and bolt heads.

ASTM-B211 AMS-QQ-A-225/8 AMS 4117

6061 Aluminum Hex Bar Best-Selling Dimensions

| Detail | Process | Detail | Process |

| 1/8" Aluminum Hex Bar 6061-T651 | Cold Finished | 1-1/16" Aluminum Hex Bar 6061-T6511 | Extrusion |

| 3/16" Aluminum Hex Bar 6061-T651 | Cold Finished | 1-1/16" Aluminum Hex Bar 6061-T651 | Cold Finished |

| 1/4" Aluminum Hex Bar 6061-T6511 | Extrusion | 1-1/8" Aluminum Hex Bar 6061-T6511 | Extrusion |

| 5/16" Aluminum Hex Bar 6061-T6511 | Extrusion | 1-1/4" Aluminum Hex Bar 6061-T6511 | Extrusion |

| 3/8" Aluminum Hex Bar 6061-T6511 | Extrusion | 1-1/4" Aluminum Hex Bar 6061-T651 | Cold Finished |

| 7/16" Aluminum Hex Bar 6061-T6511 | Extrusion | 1-3/8" Aluminum Hex Bar 6061-T6511 | Extrusion |

| 1/2" Aluminum Hex Bar 6061-T651 | Cold Finished | 1-1/2" Aluminum Hex Bar 6061-T651 | Cold Finished |

| 9/16" Aluminum Hex Bar 6061-T6511 | Extrusion | 1-5/8" Aluminum Hex Bar 6061-T6511 | Extrusion |

| 5/8" Aluminum Hex Bar 6061-T6511 | Extrusion | 1-3/4" Aluminum Hex Bar 6061-T6511 | Extrusion |

| 3/4" Aluminum Hex Bar 6061-T6511 | Extrusion | 2" Aluminum Hex Bar 6061-T651 | Cold Finished |

| 7/8" Aluminum Hex Bar 6061-T6511 | Extrusion | 2-1/4" Aluminum Hex Bar 6061-T6511 | Extrusion |

| 1" Aluminum Hex Bar 6061-T6511 | Extrusion | 2-1/2" Aluminum Hex Bar 6061-T6511 | Extrusion |

| 1" Aluminum Hex Bar 6061-T6511 | Cold Finished | 3" Aluminum Hex Bar 6061-T6511 | Extrusion |

2011 Aluminum Hex Bar | Cold Drawn

2011 Aluminum Hex Bar

2011 Aluminum Hex BarExcellent machinability, ideal for high-speed turning on automatic lathes. Produces short, brittle chips for high processing efficiency. Widely used in nuts, connectors, and precision instrument parts.

ASTM-B211 AMS-QQ-A-225/3

2011 Aluminum Hex Bar Best-Selling Dimensions

| Detail | Detail |

| 1/8" Aluminum Hex Bar 2011-T3 | 7/8" Aluminum Hex Bar 2011-T3 |

| 3/16" Aluminum Hex Bar 2011-T3 | 1" Aluminum Hex Bar 2011-T3 |

| 1/4" Aluminum Hex Bar 2011-T3 | 1-1/8" Aluminum Hex Bar 2011-T3 |

| 5/16" Aluminum Hex Bar 2011-T3 | 1-1/4" Aluminum Hex Bar 2011-T3 |

| 3/8" Aluminum Hex Bar 2011-T3 | 1-3/8" Aluminum Hex Bar 2011-T3 |

| 7/16" Aluminum Hex Bar 2011-T3 | 1-1/2" Aluminum Hex Bar 2011-T3 |

| 1/2" Aluminum Hex Bar 2011-T3 | 1-5/8" Aluminum Hex Bar 2011-T3 |

| 9/16" Aluminum Hex Bar 2011-T3 | 1-3/4" Aluminum Hex Bar 2011-T3 |

| 5/8" Aluminum Hex Bar 2011-T3 | 1-7/8" Aluminum Hex Bar 2011-T3 |

| 3/4" Aluminum Hex Bar 2011-T3 | 2" Aluminum Hex Bar 2011-T3 |

2024 Aluminum Hex Bar | Cold Drawn

2024 Aluminum Hex Bar

2024 Aluminum Hex BarA high-strength alloy with good fatigue resistance, suitable for structurally stressed applications. Lower corrosion resistance compared to other grades. Common in aerospace components and mechanical connectors.

ASTM-B211 AMS-QQ-A-225/6 AMS 4120

2024 Aluminum Hex Bar Best-Selling Dimensions

| Detail | Detail |

| 1/4" Aluminum Hex Bar-2024-T4 | 1-1/4" Aluminum Hex Bar |

| 5/16" Aluminum Hex Bar 2024-T351 | 1-3/8" Aluminum Hex Bar 2024-T351 |

| 3/8" Aluminum Hex Bar 2024-T351 | 1-1/2" Aluminum Hex Bar 2024-T351 |

| 7/16" Aluminum Hex Bar 2024-T351 | 1-5/8" Aluminum Hex Bar 2024-T351 |

| 1/2" Aluminum Hex Bar 2024-T351 | 1-3/4" Aluminum Hex Bar 2024-T351 |

| 9/16" Aluminum Hex Bar 2024-T351 | 1-7/8" Aluminum Hex Bar 2024-T351 |

| 5/8" Aluminum Hex Bar 2024-T351 | 2" Aluminum Hex Bar 2024-T351 |

| 3/4" Aluminum Hex Bar 2024-T351 | 2-1/4" Aluminum Hex Bar 2024-T351 |

| 7/8" Aluminum Hex Bar 2024-T351 | 2-1/2" Aluminum Hex Bar 2024-T351 |

| 1" Aluminum Hex Bar 2024-T351 | 2-3/4" Aluminum Hex Bar 2024-T351 |

| 1-1/8" Aluminum Hex Bar 2024-T351 | 3" Aluminum Hex Bar 2024-T351 |

7075 Aluminum Hex Bar | Extruded & Cold Drawn

7075 Aluminum Hex Bar

7075 Aluminum Hex BarExtremely strong—comparable to some steels—ideal for applications with extreme load and high-strength demands. Frequently used in aerospace, tooling, and racecar chassis.

ASTM-B211 AMS-QQ-A-225/9 AMS 4124

7075 Aluminum Hex Bar Best-Selling Dimensions

| Detail | Detail |

| 7/16" Aluminum Hex Bar 7075-T73 | 1" Aluminum Hex Bar 7075-T7351 |

| 1/2" Aluminum Hex Bar 7075-T7351 | 1-1/8" Aluminum Hex Bar 7075-T7351 |

| 9/16" Aluminum Hex Bar 7075-T7351 | 1-1/4" Aluminum Hex Bar 7075-T7351 |

| 5/8" Aluminum Hex Bar 7075-T7351 | 1-3/8" Aluminum Hex Bar 7075-T7351 |

| 11/16" Aluminum Hex Bar 7075-T7351 | 1-1/2" Aluminum Hex Bar 7075-T7351 |

| 3/4" Aluminum Hex Bar 7075-T7351 | 1-5/8" Aluminum Hex Bar 7075-T7351 |

| 13/16" Aluminum Hex Bar 7075-T7351 | 1-3/4" Aluminum Hex Bar 7075-T7351 |

| 7/8" Aluminum Hex Bar 7075-T7351 | 1-7/8" Aluminum Hex Bar 7075-T7351 |

| 15/16" Aluminum Hex Bar 7075-T7351 | 2" Aluminum Hex Bar 7075-T7351 |

6262 Aluminum Hex Bar | Extruded

6262 Aluminum Hex Bar

6262 Aluminum Hex BarOffers strength similar to 6061 with enhanced machinability and anodizing quality. Ideal for threaded components, mechanical rods, and instrument structures.

ASTM-B211 AMS-QQ-A-225/10

6262 Aluminum Hex Bar Best-Selling Dimensions

| Detail | Detail |

| 1/2" Aluminum Hex Bar 6262-T9 | 7/8" Aluminum Hex Bar 6262-T9 |

| 9/16" Aluminum Hex Bar 6262-T9 | 1" Aluminum Hex Bar 6262-T9 |

| 5/8" Aluminum Hex Bar 6262-T9 | 1-1/8" Aluminum Hex Bar 6262-T9 |

| 11/16" Aluminum Hex Bar 6262-T9 | 1-1/4" Aluminum Hex Bar 6262-T9 |

| 3/4" Aluminum Hex Bar 6262-T9 | 1-1/2" Aluminum Hex Bar 6262-T9 |

| 13/16" Aluminum Hex Bar 6262-T9 | 1-3/4" Aluminum Hex Bar 6262-T9 |

6063 Aluminum Hex Bar | Extruded

6063 Aluminum Hex Bar

6063 Aluminum Hex BarExcellent extrudability with high surface finish quality, especially suitable for anodizing. Ideal for architectural trims, railings, furniture frames, and other light-duty structural applications.

ASTM-B211

6063 Aluminum Hex Bar Best-Selling Dimensions

| Detail | Detail |

| 1/8" Aluminum Hex Bar 6063-T5 | 1" Aluminum Hex Bar 6063-T5 |

| 3/16" Aluminum Hex Bar 6063-T5 | 1-1/8" Aluminum Hex Bar 6063-T5 |

| 1/4" Aluminum Hex Bar 6063-T5 | 1-1/4" Aluminum Hex Bar 6063-T5 |

| 3/8" Aluminum Hex Bar 6063-T5 | 1-1/2" Aluminum Hex Bar 6063-T5 |

| 1/2" Aluminum Hex Bar 6063-T5 | 1-3/4" Aluminum Hex Bar 6063-T5 |

| 3/4" Aluminum Hex Bar 6063-T5 | 2" Aluminum Hex Bar 6063-T5 |

Most of the above popular specifications have existing tooling or in-stock inventory. Chalco supports custom length cutting and rapid prototyping services. For pricing or sample inquiries, feel free to submit your size and quantity requirements today.

Instant QuoteAre You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Typical Applications of Aluminum Hex Bar

Automotive & Powertrain Systems

Alloys: 6061-T651, 6262-T6511

Sizes: 1/2", 5/8", 3/4" hex bars

Features: Lightweight, easy to machine, excellent anti-rotation performance, ideal for rapid assembly systems

Typical Applications: Nuts, link rods, transmission brackets, engine bolt heads

Aerospace Structures

Alloys: 2024-T351, 7075-T6/T7351

Sizes: 1", 2" hex bars

Features: High strength and fatigue resistance, suitable for load-bearing structures and critical connectors

Typical Applications: Structural joints, fastening systems, high-load components

General Machining

Alloys: 2011-T3, 6061-T6 (high machinability)

Sizes: 3/8", 1/2", 5/8" hex bars

Features: Excellent for CNC and automatic lathe processing, short chip formation, smooth surface finish

Typical Applications: Nuts, shaft components, couplings, gear blanks

Architectural & Decorative

Alloys: 6063-T5, 6061-T6

Sizes: 10mm, 12mm, 1/4" hex bars

Features: Excellent anodizing performance, suitable for black/silver surface coatings

Typical Applications: Railing fittings, decorative rods, window and door nut components

Electrical & Electronic Structures

Alloys: 6061-T6, 6262-T9

Sizes: 3/16", 5/16" hex bars

Features: Excellent electrical and thermal conductivity, suitable for precision connectors, corrosion resistance

Typical Applications: Conductive joints, electronic housings, fasteners

Marine & Offshore Engineering

Alloys: 5086, 6061-T651

Sizes: 3/4", 1" hex bars

Key Features: Superior salt spray corrosion resistance, enhanced durability after anodizing

Typical Applications: Cabin connectors, corrosion-resistant bolts, marine-grade support brackets

For application-specific material selection or technical sizing support, feel free to contact the Chalco engineering team for custom solutions and sample services.

Instant QuoteProcessing Services for Chalco Aluminum Hex Bar

Chalco offers a full range of aluminum hex bar manufacturing and processing capabilities, covering everything from raw material shaping to surface finishing. These services are designed to meet varying demands for precision, strength, and assembly performance.

Common Processing Types

Extruded Aluminum Hex Bar

Extruded Aluminum Hex Bar Formed by high-temperature extrusion through a die, this process is suitable for most structural and machining applications. It allows mass production in various across-flat sizes (1/4" – 3") and alloy tempers (such as 6061-T6, 6262-T6511). Ideal for applications requiring general strength, good machinability, and cost-efficiency, such as bolt heads, support keys, and fixed connectors.

Cold Drawn Aluminum Hex Bar

Cold Drawn Aluminum Hex Bar Further drawn and finished after extrusion to enhance dimensional consistency, surface finish, and yield strength. This type is ideal for parts requiring high geometric precision and low surface roughness, such as precision-threaded parts, connectors, and CNC machining blanks, commonly used in automatic lathes and high-volume machining operations.

Precision Machining Capabilities

- Precision cutting (±0.2mm): Supports custom lengths and short-piece processing

- Thread tapping (e.g., 5/8"-18, 3/4"-16): Suitable for steering and linkage parts

- CNC machining: Includes milling, slotting, chamfering, face machining, and locating hole drilling

- Weld beveling: Prepares welded areas to enhance structural stability

Feel free to submit drawings and specifications to get custom machining recommendations and sample services. Chalco's professional team is ready to provide the best manufacturing solutions.

Instant Quote

Surface Finishing Options

- Anodizing: Improves corrosion resistance and surface hardness, ideal for aerospace, marine, and outdoor structures. Available in black, silver, gold, and other colors.

- Powder Coating: Offers rich color options, UV resistance, and excellent abrasion resistance, suitable for architectural exteriors and display structures.

- Brushed / Polished: Enhances visual and tactile quality, commonly used for decorative items, electronic housings, and furniture components.

- Electrophoresis: Designed for high-humidity and high-corrosion environments, such as marine equipment and heavy-duty systems.

FAQ

What are the typical applications for aluminum hex bars? Why choose a hexagonal shape?

Aluminum hex bars are widely used in mechanical parts, fasteners, tool shafts, automotive linkages, and aerospace structures. Compared to round bars, hex bars offer superior torsional resistance and anti-slip properties, making them ideal for wrench gripping and threading alignment.

What are the differences between 6061, 2024, 7075, and 6262 alloys?

6061: General-purpose alloy with high strength and good machinability; suitable for structural parts and bolt heads.

2024: Aerospace-grade, high-strength alloy with good fatigue resistance but lower corrosion resistance.

7075: Ultra-high strength alloy, ideal for aerospace, military, and extreme-load applications; slightly lower stress corrosion resistance.

6262: Balances strength with excellent machinability, perfect for automated parts and threaded components.

Are hex bars suitable for automatic lathe parts? How do they compare with round bars?

Absolutely. Due to their multi-flat surfaces providing stable clamping, aluminum hex bars are especially suited for Swiss-type lathes and sliding headstock machines, reducing centering time and improving part consistency. Compared to round bars, hex bars can eliminate certain chamfering steps and offer natural reference surfaces, saving significant machining time in mass production.

I have strict straightness requirements for hex bars. What is Chalco's control standard?

Standard straightness is controlled within ≤0.5mm/m. For precision-level applications (e.g., guides, long shafts), we can offer ≤0.2mm/m straightness, with cold drawing + rotational inspection reports. Please indicate special requirements during inquiry.

Do you support custom extrusion molds for special-shaped hex bars? What's the MOQ?

Yes. We support custom across-flat sizes, complex profiles (e.g., hex outer with round inner hole), and fit-specific parts.

Minimum order quantity is 300~500kg/specification, with a lead time of approximately 15–25 days.

We provide full-process services from 3D modeling → mold design → sample validation → mass production.

Can you provide weight calculation tools or formulas for aluminum hex bars?

Yes. Below is the general formula (in imperial units):

Weight (lbs/ft) = 0.042 × [Across Flats (in)]²

How is the price of aluminum hex bars calculated? What factors affect it?

Pricing depends on alloy type, specification, temper (e.g., T6/T651), surface treatment, and processing services. We offer pricing by length, weight, or order quantity. Submit your inquiry sheet for a fast quote.

Can you provide material certificates or third-party inspection reports?

Yes. Chalco can provide Material Test Certificates (MTC) and alloy composition analysis reports with shipment. Upon request, we also coordinate with SGS, BV, TÜV, or other third-party certifications.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote