The Aluminum Condenser Header Pipe is a key component in heat exchange systems, positioned at the inlet and outlet of condensers. It ensures even distribution and efficient collection of refrigerant, maintaining stable flow and pressure across parallel channels like microchannel or flat tubes, which enhances heat transfer efficiency and system stability.

As a professional aluminum manufacturer, Chalco offers a one-stop solution covering strip rolling, alloy cladding, HFW welding, cutting, and custom profiling. Our high-performance header pipes are widely used in automotive air conditioning, new energy heat pumps, HVAC, and industrial refrigeration.

- Core alloys: 3003, 3305, 6063

- Cladding alloys: 4045, 4343, 4043, 7072 (zinc-clad available)

- Structure: Single-layer clad, double-layer clad, double-layer + zinc composite

- Shapes: Round, D-shaped, square, and other customized cross-sections

Chalco can deliver fast-response customization based on your drawings, performance requirements, and project applications. Contact us for samples and a competitive quote.

Instant QuoteProduct Categories of Aluminum Condenser Header Pipe

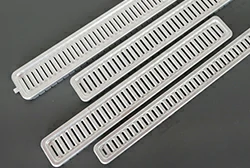

Round Header Pipe

The round structure is the most common form of aluminum condenser header pipe. It offers uniform pressure resistance, low processing cost, and supports various sizes and interface types. It is suitable for most residential air conditioners, automotive condensers, and industrial refrigeration equipment.

D-Shaped Header Pipe (Semi-Round)

The D-shaped header pipe features a cross-section with one flat side and one curved side, delivering excellent fitting performance and compact assembly. It is ideal for parallel flow condensers and space-constrained heat pump systems, and is especially common in new energy vehicle thermal management modules.

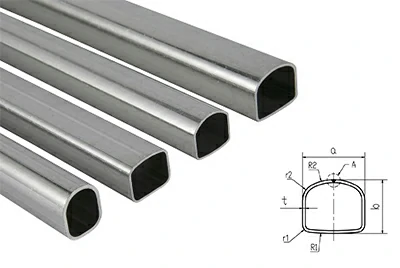

Square Header Pipe

The square cross-section structure is designed for HVAC systems with specific requirements for appearance, modular assembly, or neat pipe layout. Its flat surfaces facilitate multi-point fixing and piping integration, making it widely used in custom radiator housings and compact heat exchangers.

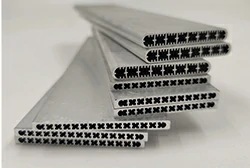

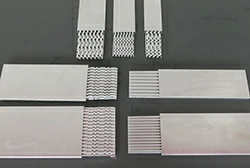

Pre-Punched Header Pipe (Stamped)

This type features pre-punched holes, with hole positions and spacing customizable. It enables quick assembly with microchannel tubes, making it a preferred piping solution for fully automated heat exchanger production lines.

Product Specifications & Technical Parameters

Chalco's aluminum condenser header pipes offer standard and custom configurations, covering diverse needs in size, wall thickness, tolerance, standards, and forming. They support multi-stage processing, complex interfaces, and bulk supply for automated assembly and system integration.

Size Range

Outer Diameter: 4 - 61 mm (common sizes: 9 - 45 mm)

Wall Thickness: 0.5 - 3.0 mm (up to 4.5 mm available)

Standard Length: 500 - 6000 mm

Extended Length: Up to 100 m (coil form)

International Standards: ASTM B491, ASTM B313, ASTM B547, ASTM B117, etc.

Processing Methods & Structural Techniques

- High-Frequency Welding (HF Welding): Used for standard pipe forming; features compact welds and is suitable for brazing assembly

- Cold Drawing: Ideal for D-shaped, reduced-diameter, and complex profiles; offers high precision and excellent strength

- Fixed-Length Processing: Supports precise cutting, end-face chamfering, flaring, and necking

- Pre-Punched Forming: For pre-punched header pipes; hole positions preset to enhance assembly efficiency

- Optional Enhancements: Flaring sections, diameter transitions, pre-welding positioning, and other fine structural customizations

Quality Control

- Weld Width: ≤2 mm; Weld Height: ≤0.08 mm

- Straightness: ≤0.5 mm per 500 mm; Cutting Angle: 90° ±2°

- Surface Quality: Free of dents, scratches, oil stains, or aluminum chips; meets automated brazing and sealing requirements

- Salt Spray Resistance: ≥1000 hours (compliant with ASTM B117)

For special standards, custom profiles, or precise tolerances, send us your drawings or samples. Chalco provides sample testing, structural optimization, and scalable delivery tailored to your project.

Instant QuoteAdvantages of Aluminum in Header Pipe Applications

In condenser systems, header pipes must withstand high-temperature and high-pressure refrigerant environments, as well as external factors such as humidity, salt spray, and vibration. Aluminum stands out as the ideal material due to its excellent performance characteristics. Compared with traditional copper and stainless steel, aluminum offers superior engineering adaptability and cost-efficiency in structural piping applications.

- Lightweight design: Aluminum's density is only one-third that of copper, significantly reducing system weight. Ideal for new energy vehicles, commercial air conditioners, and portable HVAC equipment.

- High thermal conductivity: With thermal conductivity up to 237 W/(m·K), aluminum helps rapidly dissipate heat from the exchanger module, boosting system efficiency.

- Excellent corrosion resistance: Its natural oxide layer provides protection. When combined with multilayer clad structures (such as 7072 cladding + zinc coating), it performs well under salt spray, humid heat, and industrial gas exposure.

- Compatible with brazing systems: Aluminum’s excellent brazability makes it ideal for high-frequency welded pipes. It supports automated welding lines, enhancing welding efficiency and consistency.

- Great workability: Suitable for cutting, bending, flaring, and cold drawing, enabling complex cross-section designs such as D-shape, reducing sections, and flat tubes to meet various thermal system needs.

- Strong sustainability: 100% recyclable, environmentally friendly, with a carbon footprint much lower than copper and stainless steel over its life cycle.

Industry Solutions for Aluminum Condenser Header Pipe

Aluminum condenser header pipes are used in fluid heat exchange systems across industries like automotive thermal management, home appliances, industrial refrigeration, HVAC, and new energy equipment. With lightweight, high thermal conductivity, corrosion resistance, and adaptability, Chalco's aluminum header pipes meet the performance and structural needs of various conditions.

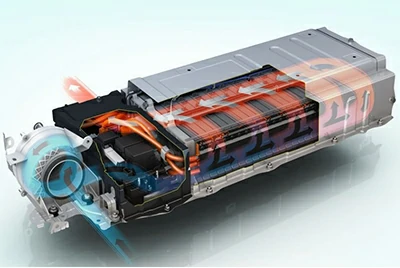

Vehicle Air Conditioning & New Energy Heat Pumps

In these systems, condenser header pipes manage fluid distribution and collection while meeting lightweight, corrosion resistance, high strength, and brazing reliability requirements. New energy vehicles, with limited thermal management space, demand high precision in the cross-sectional structure, interface, and brazing efficiency.

Chalco Recommended Solutions:

- Product Types: D-shaped header pipe, reduced diameter interface pipe

- Alloy Structure: 3003 core layer + 7072 cladding + double-layer structure (zinc-coated optional)

- Supporting Systems: Parallel flow condenser, heat pump condenser module

- Typical Applications: Automotive condensers, electronic expansion valve connection sections, battery cooling subsystems, etc.

Residential & Commercial HVAC

Condenser header pipes in these systems must endure high humidity, salt spray, and outdoor exposure, requiring strong corrosion resistance, welding adaptability, and dimensional consistency. High manufacturing precision is also necessary for bulk brazing and automated assembly, with cleanliness control and pipe consistency.

Chalco Recommended Solutions:

- Product Types: Standard round header pipe, punched header pipe, flat structure pipe

- Alloy Structure: 3003 or 3105 core layer + 4045 / 7072 cladding (zinc composite optional)

- Supporting Systems: Microchannel condenser, air-cooled outdoor units, automatic brazed condenser modules

- Typical Applications: Split-type air conditioner condensers, commercial central air conditioning heat exchange units, heat pump air conditioner outdoor units, etc.

Industrial Cooling Systems

In cold storage, refrigeration, food processing, and chemical heat exchangers, header pipes must withstand thermal cycling, high pressures, and corrosive gases. The focus is on weld seal integrity, structural strength, dimensional consistency, and corrosion resistance for reliable operation.

Chalco Recommended Solutions:

- Product Types: Round header pipe, square pipe, fixed-length flared structure pipe

- Alloy Structure: 3105 or 3003 core layer + 4343 / 7072 cladding (zinc-coated optional)

- Supporting Systems: Industrial condensers, air-cooled refrigeration heat exchangers, vertical/horizontal cooling modules

- Typical Applications: Cold storage condensers, refrigeration compressor modules, industrial circulating cooling units, food/pharmaceutical cooling units

Photovoltaic & Energy Systems

For photovoltaic inverters, battery thermal management, and 5G cooling, header pipes face challenges like compact space, high heat flux, and complex interfaces. These systems require thin-walled, lightweight design, high thermal conductivity, and custom structural capabilities for efficient heat dissipation and device integration.

Chalco Recommended Solutions:

- Product Types: D-shaped header pipe, reduced diameter multi-interface structure pipe

- Alloy Structure: 3003 core layer + 7072 or 4045 cladding + cold-drawn high-precision forming

- Supporting Systems: Energy storage cooling modules, liquid-cooled heat exchangers, inverter condenser units, 5G communication station thermal control modules

- Typical Applications: Battery pack heat exchangers, photovoltaic inverter cooling channels, new energy air/water-cooled hybrid modules

No matter whether your project is focused on automotive, air conditioning, industrial, or new energy thermal control fields, Chalco can provide structurally matched, performance-stable aluminum condenser header pipe solutions. Contact us for custom recommendations and engineering sample support.

Instant QuoteFull Industry Chain Aluminum Material Solutions for Heat Transfer Field

As a global leader in aluminum material services, Chalco is committed to providing full industry chain solutions for the heat transfer field, ranging from basic material development to precision component manufacturing.

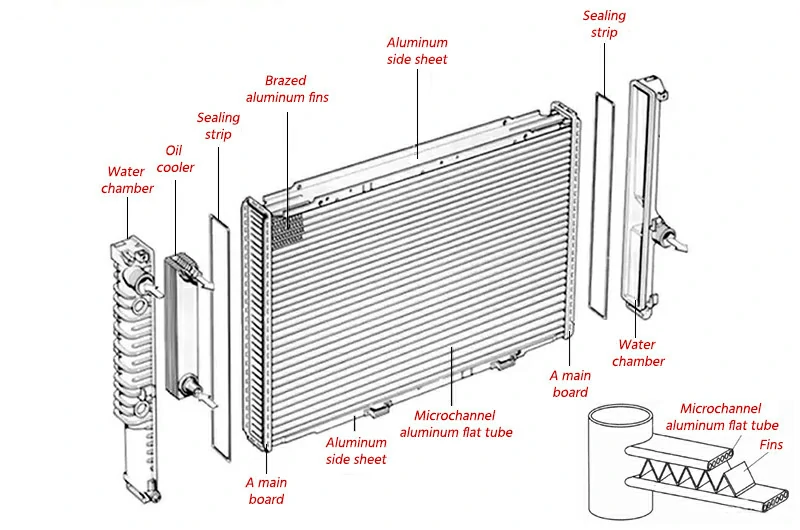

Brazing Composite Materials

Pipes and Flow Channel Components

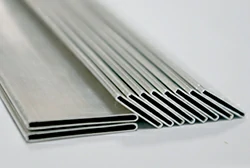

Radiator Aluminum Flat Tube

Water Tank Flat Tube

Intercooler Fin Tube

Intercooler Square Tube

Heat Exchange Stamped Components

Radiator Main Board

Radiator Side Board

Header Pipe Caps/Spacers

Intercooler Main Board

Header Pipe Fittings

Stamped Header Pipe

Let Chalco's full industry chain aluminum material capabilities help you reduce costs and improve efficiency in thermal management. Submit your requirements now and receive your tailored solution within 24 hours!

Instant QuoteWhy Choose Chalco as Your Header Pipe Supplier

When choosing a condenser header pipe supplier, customers consider material performance, product stability, delivery efficiency, technical support, and service collaboration. Chalco, a professional aluminum processing company, offers a comprehensive solution that adapts to all processes and requirements, helping clients reduce costs, improve efficiency, and enhance system performance.

Integrated Manufacturing Capabilities

Chalco operates 4 high-frequency welding production lines with an annual capacity of 4,000 tons, covering the full manufacturing process, from aluminum rolling to cutting. We use advanced international equipment, ensuring stable, high-precision manufacturing for various products.

Comprehensive Customization Support

Chalco offers multi-dimensional customization, including alloy composition, cross-sectional design, interface treatment, and hole distribution. We support welding, stamping, bending, and cutting processes and assist with material selection, structural optimization, and prototyping.

Instant QuoteStrict Quality Control

All products undergo rigorous inspections for dimensions, straightness, welding seams, and air-tightness. We provide test reports and compliance documents per ASTM and EN standards, ensuring compatibility with automated brazing, TIG welding, and expanded fitting assembly.

Global Service Experience

Chalco's header pipes are exported globally, with extensive experience in international project management and foreign trade delivery. We offer standard products and support the development of high-corrosion-resistant alloys, D-type tube structures, custom interfaces, and square tube forming. We collaborate with clients to reduce costs and improve efficiency.

Header Pipe Dimensions

Round Header Pipe Dimensions Table

| Round Collector | OD/a(mm) | Wall Thickness/t(mm) |

| P20x1.15 | 20±0.1 | 1.15 |

| P20x1.2 | 20±0.1 | 1.2 |

| P20x1.5 | 20±0.1 | 1.5 |

| P20x1.12 | 20±0.1 | 1.12 |

| P28x1.0 | 20±0.1 | 1.3 |

| P28x1.6 | 28±0.12 | 1.6 |

| P33.4×1.5 | 33.40-0.2 | 1.5 |

| P30x1.2 | 30+0.20 | 1.2 |

| P30x1.5 | 30±0.05 | 1.5 |

| P30x1.6 | 30±0.1 | 1.6 |

| P19x1.3 | 19±0.05 | 1.3 |

| P15.88×1 | 15.88±0.2 | 1 |

| P19x1.2 | 19 | 1.2 |

| P31.6×1.5 | 31.6±0.2 | 1.5 |

| P25x1.3 | 25±0.1 | 1.3 |

| P38x2 | 38±0.15 | 2 |

| P22x1.3 | 19±0.05 | 1.2 |

| P26x1.9 | 26±0.08 | 1.9 |

| P25x1.8 | 25±0.08 | 1.8 |

| P23x1.7 | 23±0.08 | 1.7 |

| P20.4×1.7 | 20.4±0.1 | 1.7 |

D-Type Header Pipe Dimensions Table

| D-type collector | Dimensions(mm) | ||

| Width(a) | Height(b) | Material Wall Thickness(t) | |

| PD20.4×18 | 20.4±0.1 | 18±0.1 | 1.2 |

| PD20x18 | 20±0.1 | 18±0.1 | 1 |

| PD20.4×18.5 | 20.4±0.05 | 18.5±0.05 | 1 |

| PD25.5×19 | 25.5±0.1 | 19±0.05 | 1.2 |

| PD15.1×12.7 | 15.1±0.05 | 12.7±0.05 | 1.2 |

| PD16×16 | 16 | 16 | 1.2 |

| PD18×19 | 18 | 19 | 1 |

| PD18×22 | 18 | 22 | 1.5 |

| PD20×17 | 20 | 17 | 1 |

| PD21.4×19.4 | 21.4 | 19.4 | 1 |

| PD21×18 | 21 | 18 | 1 |

| PD21×19.5 | 21 | 19.5 | 1 |

| PD23.35×22.4 | 23.35 | 22.4 | 1.6 |

| PD25.5×19 | 25.5 | 19 | 1.2 |

| PD26×22.4 | 26 | 22.4 | 1.2 |

| PD32×18 | 32 | 18 | 1.2 |

| 32 | 18 | 1.8 | |

| PD32×23 | 32 | 23 | 1.2 |

| PD38×27 | 38 | 27 | 2 |

| PD44×19 | 44 | 19 | 1 |

FAQ

How do aluminum condenser header pipes compare to copper pipes in terms of performance? Are they suitable for replacement?

Aluminum offers significant advantages in weight and cost, with its density being only 30% of copper, reducing overall costs by 40%-60%. Combined with 7072 coating or a copper-aluminum composite structure (e.g., 0.2mm copper layer + aluminum substrate), it can balance strength and corrosion resistance, making it widely suitable for high-pressure environments (e.g., automotive air conditioning at 4.5MPa).

What are the common causes of welding seam leakage in header pipes, and how can it be effectively controlled?

Welding seam leaks are typically caused by porosity, micro-cracks, and inclusions. Possible factors include:

- Uneven cutting surfaces of aluminum strips, unprocessed burrs

- Poorly designed forming guide rollers, leading to concentrated forming stress

- Unstable control of high-frequency welding parameters (frequency, current, extrusion pressure)

Solutions include optimizing the aluminum strip slitting process, upgrading guide mold structures, refining welding current/pressure settings, and enhancing online monitoring and quality traceability in automated welding lines.

Can aluminum condenser header pipes be used in corrosive environments for long-term use?

Yes, aluminum's natural oxide film provides basic protection and performs well in ordinary humid and hot environments. For coastal, high-salinity, or chemical environments, its corrosion resistance can be further improved through 7072 coating, dual composite structures with zinc layers, or anodizing treatments, extending its service life.

How can welding quality be ensured? Is traditional brazing reliable?

Chalco uses high-frequency welding + TLP diffusion bonding composite technology, providing welding seam strength of 80-100 MPa (compared to 50-60 MPa for traditional brazing). Combining infrared thermal imaging for online detection with AI defect prediction algorithms significantly enhances the consistency and sealing of welding seams.

Do you support hole positioning, interface customization, or custom structures for header pipes?

Yes, Chalco supports punching, stamping, flaring, necking, and reducing interfaces, with the ability to customize prototypes according to customer drawings. This is especially suited for multi-port header pipe designs in automated assembly and modular condenser systems.

Are your header pipes compatible with automatic brazing lines? Can you provide batch consistency control for welded structures?

Yes. Chalco's aluminum header pipes are designed for high-frequency welding + brazing processes, compatible with mainstream automatic brazing production lines. The products are controlled for straightness, port consistency, surface cleanliness, and welding seam air-tightness, ensuring compatibility with the entire production line's cycle, and guaranteeing high yield rates and structural consistency.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote