Aluminum and aluminum alloys instantly form a dense oxide film during brazing at 550 ℃ ± 25 ℃. Without highly active aluminum brazing flux, the molten brazing filler metal cannot adequately wet the joint, leading to incomplete soldering, slag inclusions, and porosity. Chalco utilizes mature systems such as KAlF₄ / Cs-Flux / high Mg modification to help you achieve a one-pass brazing with flux, eliminating the need for residue cleaning.

- Narrow temperature range activation: Powder or paste is instantaneously defilmed within 540–630 ℃, with a continuous furnace yield ≥ 99%.

- Low residue and no cleaning required: Al brazing flux powder residue ≤ 0.005 g/m², no whitening after 1000 h salt spray.

- Full morphology coverage: powder, aluminum brazing flux paste, flux core aluminum brazing rod, any combination

- Nocolok Compatible Replacement: Consistent with international Nocolok brazing process parameters, zero migration cost.

- 48-hour sample delivery, 5-day delivery: Ample stock of standard models, custom particle sizes from 200–400 mesh supported.

Quick Overview of Brazing Flux Forms

To meet the diverse process requirements of continuous furnace mass production, fin screen printing/local activation, and manual maintenance, Chalco offers the following three mainstream flux forms:

-

Powdered Flux, aluminum brazing flux powder

Powdered Flux, aluminum brazing flux powder

Powder spraying, dipping, and spin coating provide uniform coverage and easy control of powder application, making it the preferred choice for CAB continuous furnace mass production.

Specifications: 200–400 mesh standard, <10 µm ultrafine powder can be customized; packaging: 250 g bottle, 10 kg vacuum bag.

Representative models: FB5 KAIF, FB501S-C (Al); FB201S-01 (Cu).

-

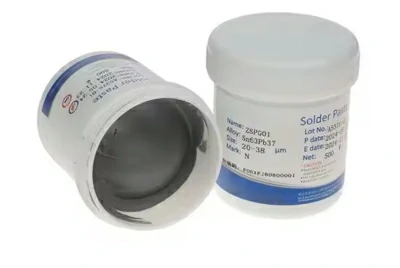

Flux Paste / Slurry, aluminum brazing flux paste

Flux Paste / Slurry, aluminum brazing flux paste

It adheres firmly and does not produce powder when brushed, rolled, or screen printed, making it suitable for finned screen printing and localized activation.

Specifications: Solid content 30–70% optional, to match different coating methods; Packaging: 1 kg can, 10 kg drum.

Representative models: FS312S, XR-0726FLUX, CF-1S (Al); SX-W, SX-B (Ag).

-

Flux-cored & Flux-coated Rod

Flux-cored & Flux-coated Rod

Flame welding and on-site repair, flux and brazing filler metal integrated, simple and efficient assembly.

Specifications: Wire diameter Ø1.6–3.2 mm. Regular stock available, customization supported; Packaging: 5 kg/roll.

Representative models: 4047 pre-impregnated core wire (Al), copper coated welding ring.

These flux systems are fully compatible with Chalco's aluminum brazing consumables, including our Aluminum Brazing Rods, Flux-core Aluminum Brazing Rods, and Aluminum Brazing Rings.

The following Chalco best-selling aluminum brazing flux series covers different systems and application scenarios, helping you quickly select an efficient and stable solution.

Halide Flux for Aluminum Brazing (FB2 series)

In local repairs, welding repairs, or induction brazing of pipe joints, the oxide film on the aluminum surface is dense and difficult to remove, and conventional fluoroaluminate systems lack sufficient activity. Chalco Halide series aluminum brazing flux uses a NaCl–KCl–LiCl compound system, with appropriate amounts of fluoride and organic carrier, which can rapidly remove the oxide film in the temperature range of 550–630 ℃, making it particularly suitable for flame and induction processes using 4047 aluminum-silicon welding wire.

Features:

- Highly active formula: Suitable for high-strength aluminum materials such as 6061, 6063, and 7xxx series. It performs best when the magnesium content is ≤ 0.3%.

- Multiple forms: Offers aluminum brazing flux powder and aluminum brazing flux paste, catering to automated powder spraying, dot coating, and brush coating processes.

- Post-weld friendly: Residue can be directly washed away with water, without the need for strong acid or mechanical cleaning.

- Typical applications: partial welding repair of automotive air conditioning pipes, heat exchanger tubes, and aluminum alloy joints.

Product Specifications

Aluminum Flux Paste

Model: CF-1S (Ointment)

Activation range: >450 ℃

Applications: Compatible with 4047 Al–Si wire. Single-component, ready to use; forms a 20 μm coating.

Packaging: 1 kg/can, 10 kg/drum

Al–Si Brazing Paste

Model: BA4047-K / BA4045-K

Activation range: 577–610 ℃

Features: Particle size <45 μm, excellent gap filling and high-reliability performance.

Fluoroaluminate Flux for Aluminum Brazing (FB5 series)

In continuous furnace mass production and CAB processes, fluoroaluminate systems are the most commonly used aluminum brazing flux powders. The Chalco FB5 series, based on KAlF₄, CsAlF, and their modified blends, covers an activation range of 540–610 ℃, stably removing oxide films from aluminum surfaces and ensuring uniform wetting of the brazing filler metal. It is widely used in automotive heat exchangers, air conditioning evaporators, energy storage cold plates, and highly corrosion-resistant marine engineering equipment.

Features:- Good compatibility: The process parameters are consistent with the international mainstream Nocolok brazing flux, and the migration cost is zero.

- Low residue: Extremely low glassy residue (≤0.005 g/m²), requiring no cleaning in most cases.

- Multiple modifications: Cs modified (ultra-clean), KCs modified (Mg resistant) and KLi modified (seawater-grade corrosion resistant) formulations are available.

- Wide range of applications: Compatible with various process windows such as CAB furnaces, induction local heating, and vacuum welding.

Product Specifications

KAlF₄ Flux (Standard Aluminum Brazing Flux Powder)

Model: FB5 KAIF (Powder)

Activation range: 562–572 ℃

Features: Low residue ≤0.005 g/m²; fast delivery; fully compatible with Nocolok processes.

CsAlF Flux (Ultra-Clean Aluminum Brazing Flux Powder/Paste)

Model: FS420S (Powder) / FS312S (Paste)

Activation range: 540–610 ℃

Features: Patented product (ZL 201410015450.8); ultra-low residue; ideal for automated processes.

KCsAlF Flux (High-Mg Aluminum Brazing Flux)

Model: FB501S-C (Powder)

Activation range: 555–565 ℃

Features: Excellent Mg oxidation resistance; withstands 1000+ h salt spray.

KLiAlF Flux (Marine-Grade Aluminum Brazing Flux)

Model: FB501S-M (Powder)

Activation range: 566–577 ℃

Features: Lithium-modified; enhances corrosion resistance in water by ≥30%.

Specialized Aluminum Brazing Paste (for spot repair and large-area coating)

In scenarios involving localized activation of large aluminum components, repair welding of complex joints, and screen printing, powdered fluxes often fail to meet process requirements. Chalco's paste-type aluminum brazing flux series combines highly active flux with fine-particle alloy powder, ensuring a dense and uniform coating, making it particularly suitable for repair welding and high-precision processes requiring aluminum brazing flux paste.

Features:- Uniform film formation: It can be used with a single component, and a dense activated layer can be formed by scraping a 20 μm layer.

- Adaptable to complex workpieces: It has good gap-filling properties for irregular Al-Si joints with large gaps.

- Low spatter residue: The coating is firm, does not fly powder, and the residue is easy to remove after welding.

- Flexible process: It can be applied by brushing, screen printing or roller coating, suitable for batch production and maintenance scenarios.

Product Specifications

Aluminum Flux Paste

Model: CF-1S (Ointment)

Composition: Cs–Al–F

Features: White, ready-to-use paste; 20 μm film thickness; non-corrosive, inert residue requiring no cleaning.

Al–Si Brazing Paste

Model: BA4047-K / BA4045-K

Appearance: Gray metallic paste (powder + flux composite)

Features: Particle size < 45 μm; excellent gap filling and reliable large-area welding.

For more details on flux selection, you can refer to our brazing flux overview and the matching silver-based solder flux paste for precision applications, or contact us for technical guidance and product support.

Chalco flux application cooperation areas and selection points

Chalco offers complete aluminum brazing flux solutions tailored to different industry applications and base alloy compositions. Whether it's continuous furnace mass production or localized welding repairs and on-site maintenance, it can quickly match efficient and stable formulations.

Automotive heat exchangers (condensers, evaporators, turbocharged air coolers)

are mostly made of 3xxx series (3003, 3102), suitable for continuous furnace CAB processes. FB5 KAIF powder flux is recommended, using either spraying or impregnation methods for uniform coverage and high yield.

New energy storage (battery cold plates, energy storage heat exchangers)

commonly uses 6xxx series (6061) materials, requiring extremely low residue. FS312S paste-like Flux is recommended, suitable for screen printing and spot coating.

Marine/shipbuilding (seawater coolers, high corrosion-resistant heat exchangers)

base materials are mostly 5xxx series (5052, 5083), which belong to high corrosion-resistant alloys. FB501S-M Marine-Grade flux, a lithium-modified system, is recommended, with salt spray resistance ≥1000 h.

Refrigeration/HVAC piping

typically uses 1xxx/3xxx series (1100, 3003) aluminum tubing, commonly used for flame welding repairs and on-site maintenance. XR-0726FLUX paste or 4047 flux-core wire are recommended for their ease of use and residue removal.

High-magnesium alloy (Mg 0.6–0.8%) clamp tubes/pressurized air coolers

require high-Mg flux (FB501S-C) to effectively combat oxide film and ensure welding reliability due to insufficient activity of ordinary flux.

| Commonly Used Aluminum Alloys and Recommended Flux Comparison Table | |||

| Alloy type | Representative brand | Typical application scenarios | Recommended Flux solution |

| 3xxx series | 3003, 3102 | Automotive heat exchangers, condensers, and evaporators | FB5 KAIF (powder), for CAB continuous furnace use |

| 6xxx department | 6061 | Battery cold plate, energy storage heat exchanger | FS312S (Paste), High-purity screen printing |

| 5xxx department | 5052, 5083 | Seawater coolers, marine cooling systems | FB501S-M (powder), Marine-Grade corrosion-resistant formulation |

| 1xxx / 3xxx series | 1100, 3003 | Partial welding repair of refrigeration pipes and air conditioning aluminum pipes | XR-0726FLUX (Paste) / 4047 Flux-Core Wire |

| High Mg alloys (0.6–0.8%) | 6xxx Modified Pipes | High-magnesium clamp tubes, pressurized air coolers | FB501S-C (powder), high Mg-specific flux |

| Al–Si composite alloy | 4045, 4343 | Coated solder plate (solder layer) | CF-1S/BA4045-K (solder paste), for repair and gap filling. |

Storage and Safety Considerations (Brazing Flux Storage & Safety)

To ensure stable performance and optimal effectiveness of aluminum brazing flux during storage and use, Chalco provides the following brazing flux storage and safety guidance:

- Keep sealed and moisture-proof: Keep the packaging intact and store in a dry environment with a temperature of 10–30 ℃ and a relative humidity of ≤50%.

- Avoid clumping: Prevent moisture from causing clumping or hardening, otherwise it will affect the flowability of the powder and the uniformity of the paste.

- Handling precautions: Wear an FFP2 protective mask when handling powders and ensure good local ventilation; avoid prolonged skin contact between the ointment and the core wire.

- Shelf life: Unopened, both powder and paste have a shelf life of 12 months; once opened, it is recommended to use within 6 months and reseal immediately after use.

- Environmental compliance: All flux products comply with RoHS and REACH requirements and can provide SDS (Safety Data Sheets) and third-party testing reports.

For SDS files, quality inspection reports, or sample delivery, please contact the Chalco engineering team immediately for full support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote