Aluminum air pipe is a lightweight and corrosion-resistant piping solution used in industrial compressed air systems. It provides clean air delivery, stable pressure performance, and efficient installation, making it suitable for factory workshops, automation lines, and pneumatic applications.

Chalco aluminum air piping products are supplied in multiple sizes and configurations to support different airflow and layout requirements. With controlled manufacturing quality and material consistency, aluminum air pipe is widely used where efficiency, reliability, and long-term operation are required.

Aluminum Air Pipe Product Specifications

Pipe Types: Blue, black, silver, green, and gray anodized or powder-coated aluminum pipes for easy pressure level or zone identification

Pipe Sizes: Outer diameter from 20 mm (3/4") to 220 mm (8")

Materials: 6063-T6 (marine grade), 6060, 6082 aluminum alloys

Connection Types: Elbows, tees, ball valves, reducers, flanges, and quick-connect adapters

Coating Options: PTFE, powder coating, or electrostatic spraying for enhanced corrosion resistance and aesthetics

Compliance Standards: ASTM B241, ISO 8573, EN 755, ASME B31.3, CE, REACH, TUV, QUALICOAT, and ISO 9001

Certification: Selected grades certified by Lloyd's Register, meeting global standards for safety and pressure performance

Aluminum Air Pipe Product Types and Finishes

Chalco aluminum air pipe products are designed for reliable operation across common industrial pressure and temperature ranges. The product range covers major size standards and provides stable mechanical performance for compressed air distribution.

Instant Quote

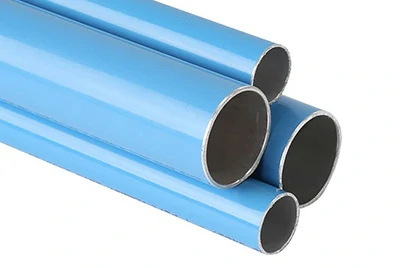

Blue Aluminum Compressed Air Pipe

Designed for standard industrial air systems and tool lines, with a durable powder-coated or anodized blue finish.

Black Aluminum Compressed Air Pipe

Ideal for oil-lubricated or moisture-prone environments, finished with a corrosion-resistant black powder coating.

Silver Aluminum Compressed Air Pipe

Used in clean areas and visible installations, featuring a bright anodized silver finish for easy maintenance.

Gray Aluminum Compressed Air Pipe

Suitable for HVAC systems and commercial overhead piping, coated in a neutral gray powder finish.

Green Aluminum Compressed Air Pipe

Applied in nitrogen or inert gas systems, finished with a green electrostatic coating for easy identification.

The following tables summarize typical size ranges pressure ratings and operating conditions of Chalco aluminum air pipe products.

| Pipe Size & Pressure Ratings | |||

| Nominal Size | Outer Diameter (mm) | Max Working Pressure | Typical Application |

| 3/4" | 20 mm | 16 bar / 232 psi | Tool lines, lab air drops |

| 2" | 50 mm | 16 bar / 232 psi | Main workshop lines |

| 4" | 100 mm | 16 bar / 232 psi | Central air systems |

| 6"–8" | 160–220 mm | 13 bar / 188 psi | High-volume distribution |

- Burst pressure: Up to 1160 psi (5:1 safety factor)

- Temperature range: -20°C to +80°C (fluid)

- Vacuum rating: -0.98 bar / -28.94 in Hg

| Operating Conditions by Pressure Level | |

| Max Pressure | Max Temperature |

| 101 psi | 185°F (85°C) |

| 145 psi | 158°F (70°C) |

| 188 psi | 140°F (60°C) |

| 232 psi | 115°F (46°C) |

Compatible Fittings and Connectors for Aluminum Air Pipe

Chalco offers a full range of high-precision aluminum fittings and connectors for compressed air piping systems. Our fittings are engineered for secure sealing, fast installation, and long-term pressure stability, covering all pipe diameters from 16 mm to 160 mm.

Instant Quote- Compression fitting diameters: 16, 20, 25, 32, 40, 50, 63, 80, 100 and 160 mm

- Compact connector diameters: 50, 63, 80, 100 and 160 mm

-

PF SERIES FITTINGS – 20 (¾ ” ) – 25 (1 ” ) – 40 (1 ½ ” ) – 50 (2 ” ) mm

PF SERIES FITTINGS – 20 (¾ ” ) – 25 (1 ” ) – 40 (1 ½ ” ) – 50 (2 ” ) mm

Aluminum high pressure die casting EN AC-46100 (Similar to A03830) EN 1706 (ASTM B85)

Wrought aluminum alloy EN AW-6026 (Similar to alloy 6082) EN 755-2 (ASTM B221)

-

PM SERIES FITTINGS - 63 (2 ½”) – 80 (3”) mm

PM SERIES FITTINGS - 63 (2 ½”) – 80 (3”) mm

Aluminum high pressure die casting EN AC-43400 (similar to A360) ASTM B85 / EN 1706

Wrought aluminum alloy 6082 ASTM B221

-

BIGGER DIAMETERS FITTINGS - 63 (2 ½”) – 80 (3”) mm

BIGGER DIAMETERS FITTINGS - 63 (2 ½”) – 80 (3”) mm

Aluminum permanent mold casting EN AC-43100 (Similar to A13600) EN 1706 (ASTM B85)

Stainless Steel EN 1.4301 (Similar to alloy 304) EN 10088-2 (AISI 304)

-

QUICKDROPS FITTINGS 100 (4”) - 158 (6”) mm

QUICKDROPS FITTINGS 100 (4”) - 158 (6”) mm

Aluminum high pressure die-casting EN AC-44500 (similar to A413) EN 1706 (ASTM B85)

-

BLACK SERIES FITTINGS 63 (2 ½”) - 80 (3”) mm

BLACK SERIES FITTINGS 63 (2 ½”) - 80 (3”) mm

Aluminum high pressure die casting EN AC-46100 (Similar to A03830) EN 1706 (ASTM B85)

Aluminum permanent mold casting EN AC-43100 (Similar to A13600) EN 1706 (ASTM B85)

Wrought aluminum alloy EN AW-6026 (Similar to alloy 6082) EN 755-2 (ASTM B221)

Elbow

Ball valve

Tee

Reducer

Adapter

Flange

Chalco – the only name you need for reliable air piping

1.All-Metal Construction for Long-Term Safety:

Stronger and more temperature-resistant than plastic piping, our aluminum system ensures long-term reliability under demanding conditions.

2.High-Sealing Precision Between Pipe & Fittings:

Tightly engineered connections minimize leakage and maintain consistent pressure throughout the system.

3.100% Recyclable & Environmentally Friendly:

Made from recyclable aluminum alloys, supporting green building goals and sustainable operations.

4.90% Lighter Than Steel – Easier to Handle:

Lightweight structure simplifies transport, lifting, and installation, significantly reducing labor costs.

5.Tool-Free Modular Installation:

Quick-connect fittings enable fast setup, modification, or system expansion without special tools.

6.Corrosion & Wear Resistance for Harsh Environments:

Anodized or coated surfaces resist rust, chemical exposure, and long-term surface damage.

7.Smooth Bore for Clean, Efficient Airflow:

Low-friction inner surface reduces turbulence, improves air quality, and lowers energy loss.

8.Enhanced Energy Efficiency = Lower Operating Costs:

Optimized design reduces pressure drops and leakage, improving compressor efficiency and lowering power consumption.

Instant QuoteChalco aluminum tubes – built for air, gas & cooling applications

From industrial automation to precision labs, Chalco aluminum piping systems are engineered to meet the air delivery demands of modern industries. Explore how we support your application:

Aluminum tubes for gas transportation

Used in compressed air, inert gas, and vacuum systems. Chalco aluminum tubes ensure stable flow, corrosion resistance, and minimal pressure loss.

Contact us now

Aluminum tubes for air separation

Designed for oxygen and nitrogen delivery in low-temp, high-pressure conditions. Strong, corrosion-resistant, and clean inside.

Contact us now

Oxygen concentrator aluminum tube

Double barrel aluminum tube

Aluminum cold bent pipe

Aluminum tubes for HVAC systems

Ideal for heating and cooling loops with excellent thermal conductivity and low weight. Fast installation for rooftop or concealed use.

Contact us now

Aluminum tubes for air cooling

Applied in chillers, radiators, and electronics cooling. High thermal efficiency, compact structure, and corrosion resistance.

Contact us now

Aluminum fin tube

Aluminum coil tube

Aluminum microchannel tube

Aluminum pipes for exhaust systems

Lightweight and easy to install for industrial ventilation and air exhaust. Supports high airflow with durable structure.

Contact us now

Aluminum tuyere profile

Aluminum corrugated tube

Aluminum foil hose

Aluminum tubes for industrial pneumatic tools

Ensures efficient airflow to tools in production lines and workshops. Low pressure loss and easy layout modification.

Contact us now

Aluminum tubes for medical and laboratory gas systems

Clean, corrosion-resistant, and easy to disinfect — perfect for oxygen and specialty gas transmission in sterile environments.

Contact us now

Aluminum capillary

Aluminum gas cylinder tube

Aluminum precision tube

Choosing the right piping material – Why Aluminum Leads

Selecting the right piping material is key to system performance and cost control. Compared to steel, copper, or plastic, aluminum offers the best balance of strength, corrosion resistance, and installation efficiency — especially in compressed air and inert gas systems.

Material Comparison Table

| Material | Weight | Corrosion Resistance | Installability | Thermal Efficiency | Cost |

| Aluminum | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Stainless Steel | ★★☆☆☆ | ★★★★★ | ★★☆☆☆ | ★★★☆☆ | ★★☆☆☆ |

| Copper | ★★★☆☆ | ★★★★☆ | ★★★☆☆ | ★★★★★ | ★★★☆☆ |

| Carbon Steel | ★★☆☆☆ | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ | ★★★★☆ |

| Plastic (PVC/PE) | ★★★★★ | ★★★☆☆ | ★★★★★ | ★★☆☆☆ | ★★★★★ |

Material selection suggestions for different application scenarios

| Application | Recommended Materials |

| Compressed air systems | Aluminum, Stainless Steel |

| High-temp/high-pressure | Stainless Steel |

| HVAC & cooling systems | Aluminum, Copper |

| Medical/laboratory gas | Aluminum, Stainless Steel |

| Inert gas delivery | Aluminum |

| Food & cleanroom systems | Stainless Steel |

| Low-cost short-distance | Plastic, Copper |

Not sure which material suits your gas system best? Talk to Chalco's technical team for a fast and reliable recommendation.

Instant QuoteFAQs on aluminum compressed air piping systems

What are the benefits of using aluminum pipes for compressed air systems?

Aluminum pipes are lightweight, corrosion-resistant, and easy to install. They reduce pressure loss, improve air quality, and support modular quick-connect assembly — making them ideal for industrial compressed air distribution.

What sizes are available for Chalco aluminum air piping?

Chalco offers pipes from 3/4” (20 mm) up to 8” (220 mm) in outer diameter, with matching fittings and accessories. Larger diameters are ideal for central distribution, while smaller sizes suit branch lines and tool drops.

What is the maximum pressure rating for Chalco aluminum air pipes?

Our standard aluminum compressed air pipes are rated up to 232 psi (16 bar) for 1/2" to 4" sizes, and up to 188 psi (13 bar) for 6" to 8" sizes. Burst pressure exceeds 1100 psi with a 5:1 safety factor.

Are Chalco pipes compatible with other systems or fittings?

Yes, our modular fittings support standard connection types and can integrate with many existing systems. Please consult our technical team for compatibility checks or retrofitting support.

Can aluminum air pipes be used for vacuum, nitrogen, or medical gases?

Absolutely. Chalco aluminum tubes are suitable for compressed air, vacuum, inert gases, and clean gas applications like oxygen and nitrogen. They meet hygiene and safety standards required in lab and medical environments.

Do Chalco aluminum pipes meet international certifications?

Yes, our products comply with ASTM B241, ISO 8573, ASME B31.3, REACH, TUV, CE, and QUALICOAT standards. We also offer Lloyd's Register certified pressure pipes for high-reliability systems.

How easy is it to install or modify the system?

Chalco aluminum piping systems are designed for fast, tool-free installation using quick-connect fittings. Layouts can be easily adjusted or expanded without welding or threading.

Ready to Upgrade Your Air Piping System?

Chalco offers complete aluminum piping solutions tailored to your compressed air, gas, and HVAC needs. Whether you need standard sizes, custom fittings, or material guidance — we're here to help.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote