In precision machining and structural applications, aluminum is widely favored for its lightweight, excellent machinability, and high thermal conductivity. Among them, 6061 aluminum alloy stands out as one of the most commonly used materials thanks to its outstanding strength, dimensional stability, and corrosion resistance.

6061 aluminum is not only ideal for medium-load structural components, but also extensively used in CNC machining for parts such as bases, frames, and cores. Its versatility across various tempers makes it suitable for both strength-critical and surface-finished applications, playing a vital role in industries requiring precision and performance.

Chalco 6061 aluminum plate & block – optimized for tooling and precision machining

Chalco's 6061 aluminum plates and blocks are widely used across various CNC and precision machining fields — including mold bases, machine tool platforms, structural supports, automation fixtures, and custom mechanical components. Whether you require excellent flatness, tight dimensional tolerance, or high-strength aluminum for deep-cavity machining, Chalco offers a full range of 6061 aluminum solutions to meet your application needs.

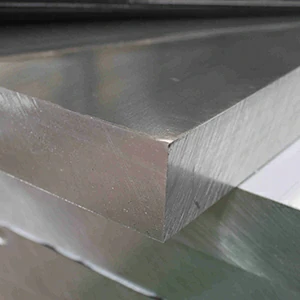

6061 aluminum plate (≥6 mm) offers excellent flatness and low internal stress through casting, heat treatment, and precision milling. Ideal for CNC base plates, equipment platforms, and automation fixtures requiring surface precision and dimensional stability.

6061 aluminum block (≥10 mm) is available in thick sizes from cast or forged billets. With high strength and generous machining allowance, it is perfect for mold bases, deep-cavity parts, and structural tooling components.

Chalco provides a comprehensive selection of 6061 aluminum plates and blocks — from standard dimensions to custom-cut sizes — tailored for mold manufacturing, CNC machining, and high-precision tooling applications.

6061 aluminum plate – flatness & machinability for CNC and mold applications

Chalco's 6061 aluminum plate (typically ≥6 mm) includes both cast and forged options, offering excellent flatness, dimensional stability, and machinability. Widely used in CNC baseplates, mold fixtures, equipment platforms, and structural assemblies, it provides reliable performance for both precision and heavy-duty applications.

Instant Quote

6061 tooling plate (cast or rolled)

Excellent flatness and low internal stress. Ideal for CNC jigs, mold bases, and fixture structures where dimensional stability is critical.

6061 ultra-wide and thick plate

Extra-wide and heavy-gauge plates (up to 2700 mm wide, 300 mm thick), perfect for machine beds, structural panels, and large equipment platforms.

6061 modular plate squares (Standard-Sized)

Standard-size square plates (e.g., 300×300, 400×400 mm) for automation systems, measurement platforms, or prototyping.

6061 Precision Machined Plate

Pre-milled or ground surface with tight thickness and flatness tolerances, ready for precision assembly and machining.

6061 ground & finished Plate

Surface-ground to tight tolerances for high-precision tooling, metrology bases, and applications requiring exceptional flatness and parallelism.

6061 plate blanks (Saw-Cut or Laser-Cut)

Custom-dimensioned plate, ideal for rapid prototyping and in-house machining.

Main performance characteristics

- Excellent flatness and dimensional stability for high-precision CNC machinin

- Low residual stress to minimize distortion during cutting or milling

- Good machinability and thermal response for consistent processing

- Clean surface finish, compatible with anodizing, coating, or film protection

Typical applications

- CNC baseplates, equipment foundations, and alignment platforms

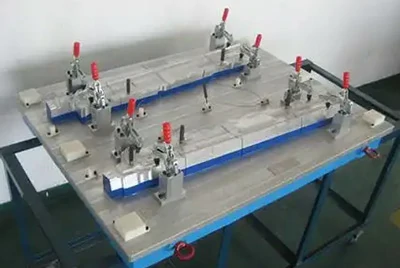

- Precision jigs, inspection tooling, and modular automation components

- Machine covers, panels, and industrial enclosures

- Mold backing plates, adapter brackets, and clamping structures

- Robotics mounts, test fixtures, and custom mechanical assemblies

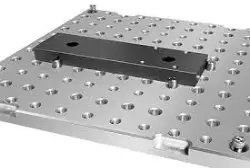

6061 aluminum block – strength & stability for CNC and mold tooling

6061 aluminum tooling block is a high-strength, solid aluminum product commonly used for mold bases, deep-cavity tooling, and structural parts in heavy-duty CNC machining. With a typical starting thickness of ≥100 mm, Chalco offers a full range of cast and forged 6061 blocks, available in standard or custom sizes, with optional rough machining and stress relief processing.

Instant Quote

6061 cast block

Cut from large size plate blank with good dimensional stability. Suitable for mold bases and deep cavity machining.

Hot-forged for high strength and density. Ideal for heavy-duty tooling and structural components.

6061 precision machined block

Rough-milled and stress-relieved for direct CNC use. Saves setup time in precision machining.

6061 large-scale mold block

Available in extra-thick sizes (≥100 mm). Perfect for large mold cores and deep-form parts.

6061 anodizing-ready block

Processed for surface treatments like anodizing or coating. Balances strength and appearance.

6061 CNC fixture block

Sized and pre-treated for jigs and supports in CNC systems. Ensures quick integration and stability.

Main performance characteristics

- High strength and thickness capacity for large or deep-structure components

- Excellent dimensional stability after stress relief and pre-machining

- Good machinability for multi-axis and deep-cavity CNC operations

- Compatible with surface treatments such as anodizing or plating

Typical applications

- Mold bases, structural frames, and precision tooling bodies

- Deep-cavity mold cores, heavy-duty dies, and high-load bearing blocks

- Machined brackets, mounting pads, and connection housings

- Custom structural inserts for automation, robotics, and machinery systems

- CNC machined parts requiring large cross-sections and high strength

Material properties & tempers of 6061 Aluminum Plate and Block

| Chemical Composition of 6061 Aluminum | |

| Element | Content (%) |

| Al | Balance |

| Si | 0.4 – 0.8 |

| Mg | 0.8 – 1.2 |

| Cu | 0.15 – 0.4 |

| Zn | ≤ 0.25 |

| Cr | 0.04 – 0.35 |

| Fe | ≤ 0.7 |

| Mn | ≤ 0.15 |

| Ti | ≤ 0.15 |

| Typical Mechanical Properties of 6061 Aluminum | ||

| Property | T6 | T651 |

| Tensile Strength (MPa) | ≥ 290 | ≥ 310 |

| Yield Strength (MPa) | ≥ 240 | ≥ 276 |

| Elongation (%) | ≥ 8 | ≥ 10 |

| Brinell Hardness (HB) | 95 | 95–100 |

| Elastic Modulus (GPa) | 68–70 | 68–70 |

| Property | T6 | T651 |

| Tensile Strength (MPa) | ≥ 290 | ≥ 310 |

| Available Tempers for 6061 Aluminum | |

| Temper | Description |

| T6 | Solution heat-treated + artificial aging; standard high strength temper. |

| T651 | T6 + stress-relief stretching; improved dimensional stability, widely used in tooling plates and blocks. |

| T652 | Solution-treated + stress-relief compression + aging; used for forgings or custom parts. |

| F/O | Soft annealed temper; available on request for secondary processing or special applications. |

6061 aluminum CNC plate and block – production & processing capabilities

Chalco offers full in-house production capabilities for both 6061 aluminum plates and blocks, from casting and forging to precision machining. Our facilities are equipped with large-format CNC mills, surface grinders, and automated saws, allowing us to provide:

- Casting: High-quality aluminum ingots cast into stable plates with low internal stress, ideal for flatness-critical applications.

- Forging: Hot-forged billets with enhanced strength and density, suitable for structural and high-load components.

- Heat Treatment: T6, T651, and custom states to balance strength and workability.

- Double-Sided Precision Milling: Ensures superior flatness and tight tolerances.

- Stress Relief & Pre-Machining: Reduces deformation risk and saves machining time.

- Laser or Saw Cutting: Custom blank sizes, contour shaping, and ready-to-machine blocks.

- Surface Treatment Ready: Options for anodizing, powder coating, or protective film application.

We support both standard stock and made-to-order projects — ensuring your parts are ready for immediate integration into CNC or mold systems.

Instant QuoteWhy choose Chalco 6061 aluminum plate & 6061 aluminum block

Certified Quality & Standards: Products meet ASTM B209, EN 485, ISO and other global standards — ensuring international compatibility.

Stable Supply & Quick Delivery: Regular stock sizes with flexible processing and fast turnaround for both domestic and international orders.

One-Stop Service: From raw material to pre-machined blank and finished plate or block — Chalco supports your full tooling supply chain with technical support and customization.

Rely on Chalco's expertise in mold materials and CNC-ready aluminum to boost your production efficiency and part reliability.

Instant Quote

Packaging & delivery of Chalco 6061 aluminum plate and block

Export packaging specifications: All products are packaged in standard export wooden boxes, equipped with moisture-proof film and shock-proof cushioning to ensure safety and integrity during transportation.

Large plate and thick material transportation solutions: For large-sized plates and heavy mold blocks, we provide customized reinforced packaging and lifting transportation solutions, suitable for sea, land or air transportation.

Global delivery capabilities: Support domestic delivery and international export, with a professional logistics team to ensure that products are delivered to the customer's designated location on time and safely.

FAQs for selecting & using 6061 aluminum for CNC and Mold applications

Is 6061 aluminum suitable for CNC machining of structural parts?

Yes. 6061 aluminum is widely used in CNC machining due to its excellent balance of strength, dimensional stability, and machinability. It is suitable for bases, housings, fixtures, and structural components across industries including automation, transportation, and general equipment.

What is the difference between 6061-T651 rolled aluminum plate and cast mold plate?

6061-T651 is a rolled plate with higher strength and can be used for structural parts, but it has higher internal stress and may deform during processing; while cast mold plates (such as 6061 tooling plate or MIC-6) have better flatness and dimensional stability and are more suitable for CNC precision machining, fixtures and mold platforms.

What is the difference between 6061 tooling plate and MIC-6?

MIC-6 is a high-precision cast aluminum plate with tighter dimensional tolerances and more consistent performance. It is suitable for assembly and measurement platforms that are extremely sensitive to tolerances. 6061 tooling plate has higher strength and a wider range of applications. It is more cost-effective in applications that take into account both strength and processability.

Can I order custom-sized aluminum plate or block with pre-machining?

Absolutely. Chalco provides custom cutting, rough milling, hole positioning, and thickness calibration services for both plates and blocks. This helps customers reduce prep time and increase machining efficiency.

Is 6061 aluminum compatible with anodizing or surface coating?

Yes. Both plates and blocks made of 6061 aluminum can be anodized or surface treated. Chalco also offers surface-ready options for critical applications involving corrosion resistance or appearance standards.

Does Chalco support aluminum blocks for deep cavity or heavy-duty applications?

Yes. Chalco offers extra-thick 6061 blocks (≥100 mm), including forged options for high-load, deep-cavity, or precision core applications. These blocks are ideal for molds, dies, and structural parts requiring high strength and stability.

What is the standard flatness tolerance for Chalco 6061 cast plate?

Standard flatness is ≤ 0.1 mm/m, depending on thickness and plate size. High-precision ground options are available upon request for metrology or alignment-critical use.

Do you support global delivery?

Yes. Chalco ships worldwide and uses export-grade wooden crates with moisture-proof protection. Our logistics support ensures safe and timely delivery to your destination.

Conclusion & inquiry

Whether you need a high-flatness aluminum plate for CNC baseplates, or a thick aluminum block for heavy-duty mold structures and deep-cavity machining, 6061 aluminum offers the strength, stability, and processability to meet demanding application requirements. Its balanced mechanical properties and broad compatibility with machining and surface treatment make it a top choice for mold bases, structural tooling, and custom CNC components.

If you're looking for the right alloy configuration, stock size, or pre-machined blank for your next project, Chalco is here to help. Contact us today for expert material selection, technical support, and fast quoting tailored to your production needs.

Welcome to submit an inquiry or contact us for samples and technical information.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote