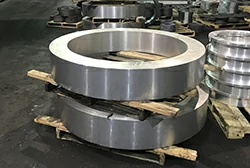

Chalco manufactures aluminum forged rings and seamless rolled rings via CNC ring rolling and open-die forging, covering OD 120–1800 mm in 6061, 6082, 7050, 7075, 2024, 5083 for aerospace, energy and marine, and rail/heavy machinery, with emphasis on concentricity, roundness, and controlled grain flow.

Quick Specs

Process: Open-die forging / Seamless rolled ring (CNC ring rolling)

Size: Typical OD 120–1800 mm · ID per drawing · Wall ≥ 10 mm

Concentricity / Roundness: ≤ 0.5–1.0 mm (size-dependent) · end-face ⟂ ≤ 0.5 mm / 300 mm

Heat Treatment: T6 / T651 / T73 (others on request)

Alloys: 6061 · 6082 · 7050 · 7075 · 2024 · 5083 (2618 / 4032 case-by-case)

Inspection & Docs: UT per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · dimensional report · EN 10204 3.1

Machining State: as-forged/rolled · rough-machined · finish-machined

Lead Time / MOQ: quoted with drawing · small batches supported

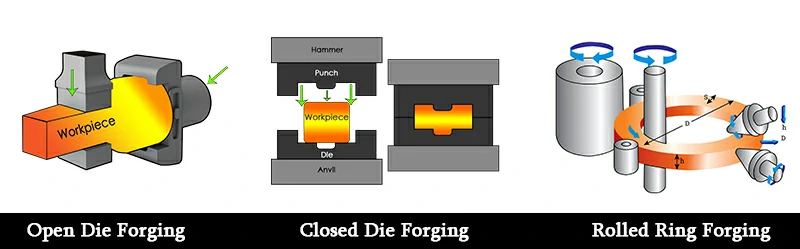

How to Choose: Aluminum Seamless Rolled Ring (CNC Ring Rolling) vs Aluminum Forged Ring (Open-Die Forging)

Pick the route by diameter–wall ratio, geometry complexity, tolerance needs, and batch size. The options below cover the most common design trade-offs for aluminum ring forgings.

- Choose Seamless Rolled Ring (CNC ring rolling): large OD / thin-wall ratios, high concentricity & roundness (≤0.5–1.0 mm size-dependent), better material yield, repeatable batches.

- Choose Forged Ring (open-die / die forging): thick-wall / heavy sections, stepped/flanged or locally reinforced geometry, prototypes or small lots with flexible forming paths.

- Hybrid Route: pre-form by open-die forging, then CNC ring rolling to refine diameter & wall with circumferential grain flow and stable dimensions.

| Feature | Aluminum Forged Ring (Open-Die / Die Forging) | Aluminum Seamless Rolled Ring (CNC radial-axial) |

|---|---|---|

| Typical Process | Upset → pierce/expand → calibrate (no ring rolling) | Pre-form ring blank → hot ring rolling (radial + axial) |

| Diameter Range (typ.) | OD 120–1800 mm (max on request) | OD 120–1800 mm (max on request) |

| Wall / Section | Thick-wall, heavy sections, stepped/flanged features | Thin-wall, large OD with controlled height |

| Grain Flow | Process-dependent; allows local reinforcement | Circumferential continuous flow → stable fatigue behavior |

| Concentricity / Roundness | Good; depends on tooling & forging path | Stable ≤0.5–1.0 mm (size-dependent) |

| Material Yield | ~50–70% (geometry-dependent) | ~75–90% (less stock removal) |

| Lead Time / Cost | Fast for prototypes; cost scales with complexity | Efficient for batches; lower unit cost at volume |

| Machining Allowance | Allows larger allowance for heavy machining | Uniform wall → reduced machining time |

| Docs & Inspection | UT on request · Dimensional report · EN 10204 3.1 | 100% UT · Dimensional report · EN 10204 3.1 |

| Best For | Thick rings, stepped/flange rings, reinforced rims, small lots | Large OD, thin-wall housings, high concentricity/roundness, batches |

Tip: Not sure which route fits your drawing? Send your specs for a 24-hour process recommendation. Our rolled ring capability also covers ultra-large diameters — see Large-Diameter Aluminum Forged Rings. For details and pricing, please consult our sales manager.

Instant QuoteAluminum Alloys for Forged & Seamless Rolled Rings

Chalco specializes in aluminum forging rings and maintains a full range of aerospace-grade alloys in stock. From lightweight 6061 to ultra-high-strength 7075, we provide standardized or fully customized solutions—including heat treatment and rough machining—to deliver rings ready for assembly.

Chalco's aluminum rings offer an excellent strength-to-weight ratio, corrosion resistance, and good machinability—ideal for high-strength couplings, rotating parts, and structural reinforcement in aerospace, transportation, and electronics.

Lightweight • Durable • Customizable

-

6061 Aluminum Ring — Forged / Seamless Rolled

General-purpose alloy with stable strength, excellent weldability and machinability

Typical temper: T6/T651 · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1

ASTM B247 | GB/T 6892 | AMS 4127 (T6)

-

7075 Aluminum Ring — Forged / Seamless Rolled

Ultra-high strength alloy widely used in high-load aerospace structures

Typical temper: T6/T73 · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1 (3.2 on request)

AMS 4045 | GB/T 6892 | HB/Z 140

-

2024 Aluminum Ring — Forged / Seamless Rolled

Excellent fatigue resistance for multi-frequency stress structures

Typical temper: T351/T4 → finish HT · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1

AMS 4144 | GB/T 6892 | HB/Z 140 (T42/T6)

-

7050 Aluminum Ring — Forged / Seamless Rolled

Strong stress-corrosion resistance for thick-wall, heavy-load components

Typical temper: T74/T76/T73 · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1 (3.2 on request)

AMS 4050 | HB/Z 140 | GJB 1438A

-

5083 Aluminum Ring — Forged / Seamless Rolled

Outstanding corrosion resistance and toughness for offshore & chemical equipment

Typical temper: O/H112 · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1

GB/T 6892 | ASTM B247 | ISO 6361

-

2618 Aluminum Ring — Forged / Seamless Rolled

Excellent high-temperature creep strength for engine and heat-load components

Typical temper: T61/T651 (case-by-case) · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1

AMS 4133 | HB/Z 140 | GJB 2446

-

2219 Aluminum Ring — Forged / Seamless Rolled

High-temperature performance—ideal for liquid-fuel tanks and hot-end parts

Typical temper: T6/T852 (per drawing) · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1 (3.2 on request)

AMS 4144 | HB/Z 140 | GJB 3225

-

7475 Aluminum Ring — Forged / Seamless Rolled

High toughness and fracture resistance for safety-critical components

Typical temper: T761/T76 (on request) · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1 (3.2 on request)

AMS 4085 | HB/Z 140

-

6082 Aluminum Ring — Forged / Seamless Rolled

Better formability than 7075—suitable for ring rolling and large-size forging

Typical temper: T6/T651 · UT: per ASTM B594 / AMS-STD-2154 (level/class per PO; 100% on request) · Docs: EN 10204 3.1

GB/T 6892 | EN 586 | ISO 6361

* All alloys are qualified for free forging, ring rolling, and die forging. Available heat-treatment states include T6, T651, T42, and O, with complete material certificates and third-party test reports.

* Need titanium or steel rings? Chalco can supply them on request—please contact our team for customized options.

Instant Quote

Tolerances & QA for Aluminum Forged Rings & Seamless Rolled Rings

For aluminum forged rings and seamless rolled rings (CNC), we control geometry and quality across the full route—heat treatment, NDT and documentation—so your parts arrive machining-ready and traceable.

| Item | Typical Control (size-dependent) | Notes |

|---|---|---|

| Concentricity | ≤ 0.5–1.0 mm | Rolled rings hold tighter on large OD / thin-wall |

| Roundness / Ovality | ≤ 0.5–1.0 mm | Controlled via CNC radial–axial reduction |

| End-face ⟂ (Perpendicularity) | ≤ 0.5 mm / 300 mm | Custom targets per drawing welcome |

| Wall / Height Uniformity | Process capability documented | Define machining allowance up front |

| Heat Treatment | T6 / T651 / T73 (others on request) | Cycle records and distortion control |

| Ultrasonic Testing (UT) | 100% per ASTM B594 or AMS-STD-2154 | Level/Class per PO; UT map & report available |

| Dimensional Inspection | Full report with key characteristics | CMM / dedicated gauges per feature |

| Documentation | EN 10204 3.1 (3.2 on request) | Heat & test traceability; third-party witnessing optional |

Note: Targets above are indicative; final tolerances are confirmed with your drawing, alloy/temper and OD–wall combination.

Instant QuoteAluminum Ring Manufacturing — Forging & Ring-Rolling Capabilities

Chalco runs three in-house routes for aluminum rings: open-die forging, closed-die forging, and CNC radial-axial seamless ring rolling. Ring rolling provides circumferential grain flow with stable concentricity and roundness; open/closed-die covers thick-section, flanged and profiled rings. All routes include billet heating, heat treatment, CNC machining and NDT; UT per project specification (ASTM B594 / AMS-STD-2154), MT/PT/RT on request.

For dimensions beyond monolithic limits, we can evaluate segment forging with circumferential joining (non-seamless) with VT/UT/RT and post-weld heat treatment after engineering review; suited to non-rotating or low–medium cycle service.

-

Open-Die Forging

8000 t presses with multi-directional forging to refine grain and remove porosity.

Strengths: thick-wall rings, stepped/flanged sections, larger OD beyond ring-rolling range; generous machining allowance.

-

Closed-Die Forging

In-house die design for repeatable geometry and clean surfaces on small–mid sizes.

Strengths: precision couplings, power-train flanges, high-cycle connectors.

-

CNC Seamless Ring Rolling

Numerical radial-axial reduction produces weld-free rings with uniform wall and fiber flow.

Strengths: large OD / thin-wall capability with stable concentricity and roundness (size-dependent); high yield and batch repeatability.

Capabilities & services:

- Section height: 30–600 mm (process-dependent)

- Single-piece weight: up to ~3 t (higher on request)

- Wall strategy: thin-wall via ring rolling; heavy section via open-die preform

- Machining allowance per drawing; rough/finish turning available

- Surface roughness after machining: Ra 0.8–3.2 µm (feature-dependent)

- Heat treatment with recorded cycles: T6/T651/T73 (others on request)

- NDT: UT per ASTM B594 / AMS-STD-2154; mechanical tests, metallography, CMM

- Documentation: EN 10204 3.1 (3.2 on request); dimensional report and UT map

- Oversize strategy: segment forging with circumferential joining (non-seamless), case-by-case

Need titanium or steel rings instead? We can adapt the same line—just ask our engineers.

Instant QuoteApplication Industries of Aluminum Forged & Rolled Rings

Aluminum ring forgings serve weight-critical and corrosion-sensitive assemblies across aerospace/defense, energy & marine, and rail & heavy machinery. We match process (open-die forging / seamless ring rolling), alloy/temper, and machining plan to your duty cycle to maximize strength, fatigue life, and dimensional stability.

Aerospace & Defense

Uses: fuselage/engine interface rings, lightweight sealing flanges, stiffener/locating rings. Alloys 7050/7075/2024 per print; UT 100% per ASTM B594 / AMS-STD-2154 with EN 10204 3.1. Thin-wall/high concentricity → ring rolling; thick-section/flanged → open-die forging.

Energy & Marine (Wind / Petro-Chemical)

Uses: main-shaft/yaw flanges, valve/pressure-vessel seal rings, corrosion-resistant pipeline interfaces. Alloys 5083/6061/6082; weldability and UT maps available on request. Large-OD thin-wall housings favor ring rolling; heavy flanged rings favor open-die.

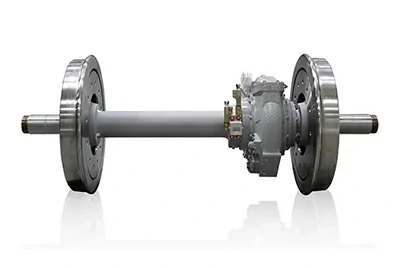

Rail & Heavy Machinery

Uses: bogie support/brake base rings, couplings and seat rings with tight concentricity. Alloys 6061/6082/7075; finish-machined to print with dimensional report. Rolled rings reduce machining time on thin walls; forged rings suit reinforced/stepped sections.

Also supported: cryogenic/chemical plants, UAV & mission-critical devices (project-specific UT/Docs).

Each project receives a tailored alloy + process + tolerance plan (RFQ guide: alloy/temper; OD×ID×wall/height; tolerance & surface; quantity; target lead time).

Customer Case Gallery

-

Up to 10 m OD for wind-turbine hubs, aerospace bulkheads, and nuclear-power structures; optimized grain flow for thick-section strength and stability.

-

Flanged Aluminum Ring

Integrated sidewall flanges for sealing and bolted joints—ideal for pressure-vessel and piping systems, reducing secondary machining.

-

Hollow Aluminum Forged Ring

Weight-reduced inner cavity lowers inertia—preferred for high-speed rotors, pump/turbine housings, and fluid-system components.

-

Profiled Aluminum Ring

Non-circular or custom contours (polygon, stepped, keyed) for special mounting envelopes or torque-transfer interfaces.

-

Ring-rolling delivers a continuous, weld-free structure with complete grain flow—suited for high-strength, high-temperature, and fatigue-sensitive service.

-

High-Strength Rolled Ring for Aerospace & Energy

For aircraft structures, gas turbines, and wind-power hubs; AMS/ASTM compliant with controlled distortion and stable mechanical properties across sections.

-

Solid Aluminum Forged Ring

Full cross-section density for maximum load transfer—used in bearing seats, couplings, and support rings in heavy machinery.

-

Gear / Toothed Aluminum Ring

External teeth, grooves, or locating features—widely used for slewing drives, turntables, and precision servo systems.

Aluminum Forged & Seamless Rolled Rings — Custom, Lead Time & Supplier Guide

As a focused aluminum ring supplier and manufacturer (open-die/closed-die forging & CNC radial-axial ring rolling in-house), we turn drawings into machining-ready rings with one accountable flow — from preform to heat treatment, machining, and inspection. Send the essentials below to get a fast, engineering-led quote.

You'll receive a process recommendation (rolled vs forged), a tolerance proposal aligned to your print, and a clear lead-time window. Prototypes and small batches are supported.

- RFQ essentials: alloy & temper; OD × ID × wall/height (± target weight); drawing & tolerances; quantity & delivery terms; QA package (UT per ASTM B594 / AMS-STD-2154, level/class per PO) & documents (EN 10204 3.1 / 3.2); machining state (as-forged/rolled / rough-machined / finish-machined).

- Supplier strengths: end-to-end in-house line; aluminum expertise across 2xxx/5xxx/6xxx/7xxx; guidance for thin-wall (ring rolling) vs heavy-section/flanged (open-die); recorded HT cycles, dimensional reports, optional third-party witnessing.

- Indicative lead time: as-forged/rolled blanks 2–4 weeks after PO; rough-machined 3–6 weeks; finish-machined to print 4–8 weeks (tolerance/QA dependent).

Frequently Asked Questions

What's the difference between a forged ring and a seamless rolled ring?

A seamless rolled ring is produced by CNC ring rolling and is part of the forging family. Rolled rings suit large OD / thin-wall with high concentricity; forged rings suit thick sections, flanges/steps, or small lots. See "How to Choose”.

What size range can you support?

See Quick Specs for typical ranges. Larger sizes can be evaluated via open-die forging based on your drawing and tolerances.

Can you deliver rough- or finish-machined rings?

Yes. We supply as-forged/rolled, rough-machined, or finish-machined per print, with dimensional reports to speed assembly.

Which QA package and documents are available?

UT per ASTM B594 / AMS-STD-2154 (level/class per PO), dimensional report, EN 10204 3.1 (3.2 on request). Details in Tolerances & QA and the RFQ essentials above.

Which drawing formats do you accept?

PDF / DWG / DXF (2D) and STEP / IGES / STP (3D).

What's the MOQ and typical lead time?

We support single-piece prototypes and small batches. For timelines, see Custom, Lead Time & Supplier Guide.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote