Aluminum die forgings are medium- and small-sized structural parts produced by closed-die aluminum forging, typically using high-strength 2xxx, 6xxx and 7xxx wrought aluminum alloys. They are designed to carry long-term cyclic loads and impact loads under strict weight constraints. During forging, the metal flows directionally inside the die cavity and the grain flow follows the load path, delivering higher specific strength and fatigue life at the same weight. Today, these forged aluminum parts are widely used in critical aluminum components such as automotive parts, aerospace fittings and industrial pump and valve housings.

Advantages of Aluminum Die Forgings

Compared with aluminum castings, weldments or "extrusion + machining” parts, aluminum die forgings offer clear advantages:

- Higher strength and fatigue life: the forging process consolidates shrinkage and porosity, reducing the risk of internal defects.

- Lighter and more material-efficient: near-net-shape forming allows thinner wall sections and lower machining allowance, cutting material waste.

- Better dimensional consistency: the closed die cavity ensures repeatable profiles, making mass assembly and quality control easier.

- More controllable total cost: at medium and higher volumes, tooling cost is amortized and performance is better balanced with total cost of ownership (TCO).

As a one-stop aluminum specialist, Chalco combines in-house die design, closed-die forging, heat treatment, CNC machining and surface finishing. We can work directly from your 2D/3D drawings and deliver fully inspected aluminum die-forged parts ready to be installed on vehicles or equipment.

When to Prioritize Aluminum Die Forgings?

Not every aluminum part needs to be forged. For simple geometries, lower loads or limited volumes, casting or extrusion plus machining may already meet the requirements. However, when a project has the following characteristics, aluminum die forgings are often the more suitable choice:

- Safety- / fatigue-critical components: suspension and steering parts, pressure housings, primary load-bearing brackets, where failure would affect safety or cause downtime.

- Clear lightweighting targets: significant weight reduction is needed without sacrificing strength and stiffness.

- Complex geometry with tight consistency requirements: multi-step, multi-hole, large-radius designs where high accuracy and repeatability are critical in mass production.

- Medium or higher annual volume: the product is in a stable production phase, making it worthwhile to invest in tooling, amortize cost and unify quality control.

For such parts, it is recommended to run an early Design for Manufacturability (DFM) review to compare casting, welding, extrusion + machining and closed-die forging in terms of performance and cost, and to lock in the most appropriate process route as early as possible. If you are not sure whether your part is suitable for forging, you can send your 2D/3D drawings, operating conditions and estimated annual usage to the Chalco engineering team, and we will provide manufacturability and process route recommendations.

Forging Capacity for Aluminum Die Forgings

| Project | Specifications and Capabilities |

| Alloy Series | 2xxx / 5xxx / 6xxx / 7xxx Forged Aluminum Alloys |

| Typical Alloys | 2014, 2024, 2219, 5A06, 5083, 6061, 6082, 7075, 7050, etc. |

| Supply Status | O, F, H112, T3, T4, T5, T6, T62, T652, T73, T74, etc. |

| Projected Area | General forgings ≤ 3.0m²; Complex forgings recommended ≤ 1.5m² |

| Dimensional Range (L/W/H) | Typical small to medium-sized structural parts envelope size approximately 40–500 mm, conventional longest side recommended ≤ 600 mm |

| Unit Weight | Approximately 0.2–25kg (larger single piece weight can be assessed on a project basis) |

| Wall Thickness and Cavity Structure | Conventional load-bearing wall thickness approximately 4–20 mm; minimum local wall thickness for small parts can be assessed down to ≈3 mm; supports multi-step, multi-hole, multi-rounded transition and local cavities |

| Forging Press Capacity | 125–500 MN (approximately 12,500–50,000 ton closed-die forging press); forging speed approximately 0.05–50 mm/s, speed control accuracy approximately ±5% |

| Routine Inspection Targets | Chemical composition spectral analysis; tensile property testing; hardness testing; dimensional and geometric tolerance inspection; appearance and surface quality inspection |

| Standards | ASTM B247/B247M,EN 586-2,ASTM E8/E8M,ASTM B594 |

The above describes Chalco's typical capability window for aluminum die forgings. Actual feasibility for any given part needs to be evaluated case by case based on alloy, dimensions and service conditions. You can consult our engineering team to confirm manufacturability and recommended specifications.

Aluminum Die Forgings Product Categories

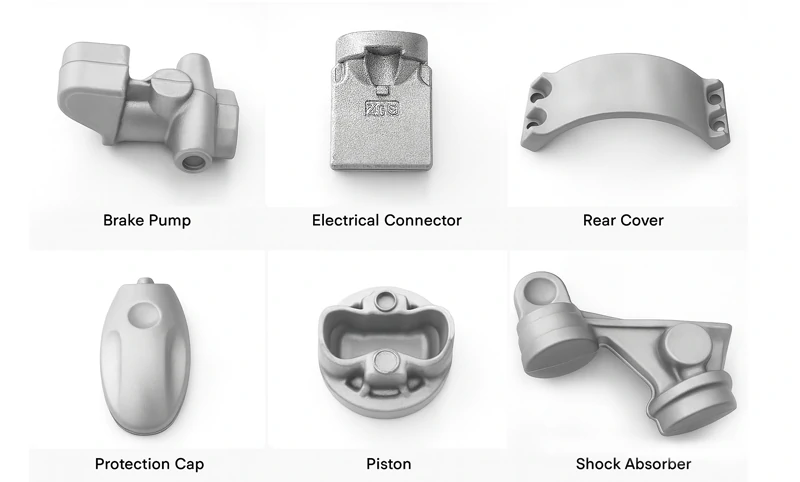

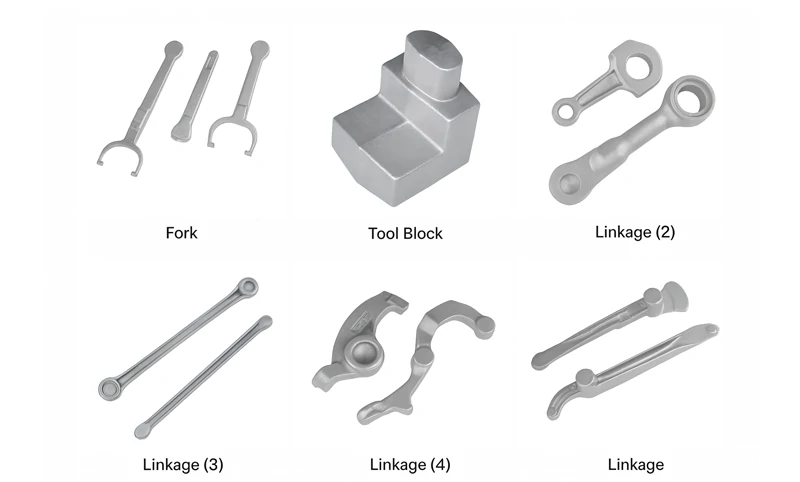

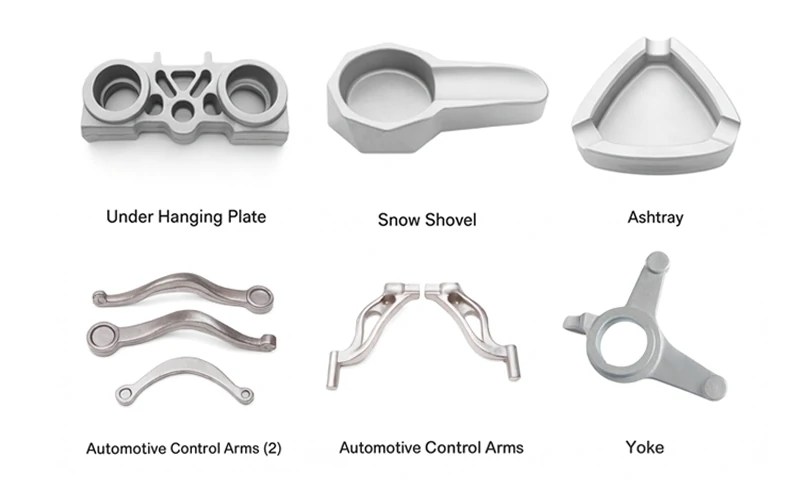

Chassis & Link Aluminum Die Forgings

Typical parts: control arms, steering knuckles, links, yokes.

Common alloys: 6082-T6, 6061-T6/T651, 5083-O/H112.

Typical applications: automotive and new energy vehicle chassis, construction machinery and trailer connection components.

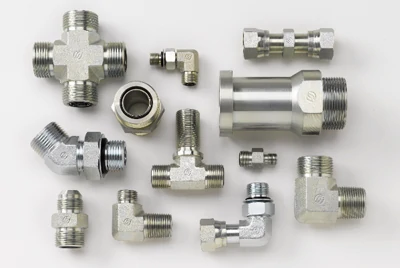

Housings & Pressure Aluminum Die Forgings

Typical parts: pump housings, valve bodies, manifold housings, end caps.

Common alloys: 6061-T6, 5A06-O, 5083-O/H112.

Typical applications: hydraulic and pneumatic systems, fluid control and power unit housings.

Discs, Rings & Shaft Aluminum Forgings

Typical parts: hubs, brake discs, rings, shaft blanks.

Common alloys: 6061-T6, 6082-T6, 7075-T6.

Typical applications: wheel and brake systems, drive shafts and rotating components.

Brackets & Structural Node Aluminum Forgings

Typical parts: mounting brackets, reinforcement blocks, connection bases, structural nodes.

Common alloys: 6061-T6, 6082-T6, 2014-T6.

Typical applications: motor and battery mounts, frame and body structural connection points.

Custom Functional Al Die Forgings

Typical parts: flanges, sensor housings, clamping blocks.

Common alloys / tempers: selected according to drawings and service conditions (2xxx / 6xxx / 7xxx series aluminum die forgings).

Typical applications: non-standard connectors and functional components, upgrades from high-load castings or weldments.

Typical Industries & Solutions

Automotive & New Energy Vehicles

In automotive and new energy vehicle projects, aluminum die forgings are mainly used in safety-related chassis and structural connection areas, where they must withstand long-term impact and fatigue loads under strict lightweighting targets.

- Typical forged parts: control arms, steering knuckles, suspension links, chassis/battery brackets.

- Operating conditions & requirements: weight reduction without sacrificing crash and fatigue safety; high dimensional consistency in mass production.

- Recommended alloys: 6082-T6, 6061-T6/T651, 5083-O/H112.

- Machining & finishing: multi-axis CNC machining and deburring; anodizing or coating as required by OEM specifications.

Industrial Hydraulics & Fluid Control

In hydraulic and fluid systems, aluminum die forgings are widely used for housings and pressure-bearing parts, where pressure safety, density and weldability must be balanced while keeping machining time under control.

- Typical forged parts: pump housings, valve bodies, hydraulic manifolds, end caps, high-pressure connector bodies.

- Operating conditions & requirements: continuous/pulsating internal pressure, leak-tightness, corrosion resistance, and in some cases weldability.

- Recommended alloys: 6061-T6/T651, 5A06-O, 5083-O/H112.

- Machining & finishing: precision machining of sealing faces and threaded holes; optional air or hydrostatic leak tests; anodizing or chemical conversion coatings to enhance corrosion resistance.

Two-Wheeler & Sports Equipment

In two-wheelers and sports equipment, aluminum die forgings not only carry structural loads but also directly influence overall appearance and lightweight performance.

- Typical forged parts: cranks, hub shells, stems/steer tubes, rocker arms, structural links for sports equipment.

- Operating conditions & requirements: extreme focus on lightweighting, combined with high fatigue life and premium surface appearance.

- Recommended alloys: 6061-T6, 6082-T6, 7075-T6/T73.

- Machining & finishing: profile machining and weight-reduction pockets; shot blasting plus anodizing, with multi-color series to match brand visual identity.

Aerospace, Rail & High-End Equipment

In high-demand equipment sectors, aluminum die forgings are used for medium and small structural parts and fittings, requiring stable strength levels, reliable NDT results and full process traceability.

- Typical forged parts: structural brackets, reinforcement blocks, hinge-type connectors, structural nodes, equipment mounting bases and other medium/small structural components.

- Operating conditions & requirements: high specific strength, vibration and fatigue reliability, batch-to-batch consistency and full traceability (with NDT).

- Recommended alloys: 2014-T6, 2024-T4/T351, 7050-T74, 7075-T73.

- Machining & finishing: precision machining of mounting faces and hole patterns; UT/PT and EN 10204 3.1 material certification as required; anodizing or chemical conversion coating to improve corrosion resistance and paint adhesion.

Aluminum Die Forging Alloy Options

-

6061 Aluminum Die Forgings

A general-purpose structural alloy with medium strength, good weldability and machinability, suitable for various brackets, mounting bases and medium-load aluminum die-forged parts.

-

6082 Aluminum Die Forgings

Higher strength and fatigue performance than 6061, commonly used for lightweight load-bearing forgings such as control arms and links.

-

5083 Aluminum Die Forgings

Excellent corrosion resistance and weldability, ideal for pressure-bearing or fluid-contact housings such as pump bodies, valve bodies and flanges.

-

2014 Aluminum Die Forgings

High strength and easy machining, often used for high-strength brackets, nodes and other medium/small load-bearing forgings, typically combined with surface protection.

-

2024 Aluminum Die Forgings

High strength with good fatigue performance, suitable for connectors and node-type forgings working under long-term cyclic loads.

-

7050 Aluminum Die Forgings

High strength and toughness with stable properties in thick sections, used for demanding structural forgings in aerospace, rail and other high-end equipment.

-

7075 Aluminum Die Forgings

Very high specific strength, suitable for weight-sensitive structural parts and motion components, usually requiring additional corrosion protection.

-

2618 Aluminum Die Forgings

A high-temperature forging alloy used for pistons, connecting rods and other forged parts in aerospace/racing engines that carry loads at elevated temperatures.

-

4032 Aluminum Die Forgings

High-silicon, low-expansion and wear-resistant, widely used for forged pistons in automotive/motorcycle engines and other moving parts requiring high dimensional stability.

If you need help with alloy selection, you can send your drawings and basic operating conditions to the Chalco engineering team, and we will recommend suitable alloys and tempers based on your target performance.

Forging Process & Quality Control for Aluminum Die Forgings

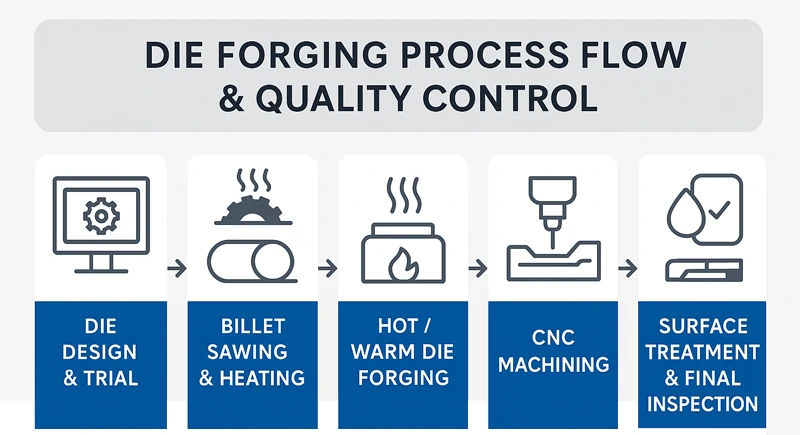

Relying on dedicated aluminum forging lines, Chalco provides one-stop aluminum die forging services for medium and small structural parts, covering die design and trial → billet sawing and heating → hot / warm closed-die forging → heat treatment → CNC machining → surface finishing and final inspection. Forged blanks and fully machined parts are controlled under the same quality system to support stable batch production.

Forming Temperature & Forging Types

By forming temperature, aluminum die forging can be roughly divided into hot forging, warm forging and cold forging, each suited to different part sizes and precision requirements:

Hot Die Forging: forming at elevated temperature with good metal plasticity and relatively low forming forces, suitable for medium and small structural parts and complex cross-sections; this is the mainstream route for structural aluminum die forgings.

Warm Forging: forming in an intermediate temperature range, balancing forming load, die fill and dimensional accuracy, often used where both strength/fatigue life and dimensional stability are important.

Cold Forging / Cold Heading: forming at or near room temperature, suitable for smaller parts produced in large volumes with tight tolerances and high surface quality requirements; this places higher demands on equipment and die precision.

Process Flow Overview

Engineering review & die design: evaluate geometry and load paths based on 2D/3D drawings, define parting lines, draft angles, flash design and machining allowances.

Billet preparation & heating: select dedicated forging stock by alloy, then cut to length, deburr/chamfer and clean surfaces. Billets and dies are heated and soaked according to the defined process curve.

Closed-die / multi-directional forging: complete one or multiple forming blows in the die cavity so that the metal fully fills the cavity and the grain flow follows the main load directions.

Heat treatment: apply tailored T6, T73, T74 and other heat treatment schedules for alloys such as 6061 / 6082 / 7050 / 7075, strictly controlling quenching and ageing.

Finish machining & surface treatment: perform turning, milling, drilling and other CNC operations on critical dimensions, followed by shot peening, anodizing or coating as required.

Key Process Controls

Forging stage: billet temperature, die temperature, number of blows and deformation per blow are executed according to process sheets; forging pressure and time are recorded for critical batches.

Heat treatment stage: furnaces are equipped with automatic recording systems; furnace temperature and soak time are fully monitored, with each heat-treatment batch traceable to mechanical test results.

Dimensions & geometrical tolerances: process and final inspection points are defined for critical dimensions, hole patterns and fit surfaces; CMM reports can be provided on request.

Inspection & Traceability

Routine tests: chemical composition, hardness, tensile strength, yield strength, elongation, dimensional checks and visual surface inspection.

On-demand tests: ultrasonic testing (UT), penetrant testing (PT), metallography, surface roughness, and pressure / leak tests (air or hydrostatic) as required.

Quality documentation: EN 10204 3.1 material certificates supplied with goods; dimensional reports, heat treatment records and NDT reports can be provided when needed, with heat number, batch number and die number clearly traceable.

If your project involves custom process specifications, third-party inspections or first article approval (FAI / PPAP), please inform the Chalco engineering team at an early stage so we can configure the forging process and inspection plan according to your target standards.

Why Choose Chalco as Your Aluminum Die Forging Partner?

Aerospace-Grade Forging Lines, One-Stop Finished Parts Delivery

Chalco has built a complete process chain from die design, aluminum die forging, heat treatment and CNC machining to surface finishing and inspection. Medium and small chassis parts, housings, rings and similar components are all produced under one quality system, reducing coordination issues and consistency risks caused by multiple subcontractors.

Multi-Alloy, Multi-Standard Capability for Automotive and Aerospace Projects

We cover 2xxx / 5xxx / 6xxx / 7xxx series as well as 2618 and 4032 and can supply aluminum die forgings in specified tempers according to ASTM / EN / AMS standards. This makes our capacity suitable for vehicle chassis, safety-critical parts and selected aerospace / high-end equipment projects.

Complete Quality System and Test Chain with Full Traceability

Based on forging lines certified for aerospace, automotive and rail-related systems, we can configure tests from chemistry, microstructure and mechanical properties through UT / PT and other NDT methods according to project needs. Shipments can be supported by EN 10204 3.1 material certificates, dimensional reports and heat treatment records, with heat numbers, batch numbers and die numbers clearly traceable.

Process Optimization and Cost Control for Complex Forgings

For complex geometries such as yokes, connecting rods and housings with internal cavities, we prioritize closed-die / multi-directional forging and near-net-shape solutions. This helps achieve proper grain flow and strength while controlling input material and machining allowance, making it ideal for upgrading high-load castings and weldments to aluminum die forgings.

If you need to compare different alloys or process routes, you are welcome to contact the Chalco engineering team to discuss your specific project.

FAQ

Is My Part Suitable for Aluminum Die Forging?

Parts that are typically suitable for aluminum die forging are safety-critical components, parts under repeated loading, or structures with demanding requirements on weight and stability. Simple shapes and low-volume parts may not justify the investment. We recommend sending your 2D/3D drawings, annual usage and operating conditions to our engineering team so we can compare closed-die forging, extrusion + machining and casting options for you.

Will the Tooling Investment Be Too High? What If Design Changes Are Needed?

Closed-die forging usually requires dedicated dies. Before cutting any tooling, we perform a DFM (Design for Manufacturability) review to confirm that geometry and volume justify the investment and provide a separate tooling quotation. If design optimization is needed later, we will assess whether the existing dies can be modified or new dies are required and clarify the related cost and lead time in advance.

If Our Annual Volume Is Not Large, Is Forging Still Worth Considering?

For parts such as suspension arms, steering knuckles and pressure housings, which are safety-critical, the strength and fatigue advantages of aluminum die forgings are often valuable even at medium volumes. For prototypes or smaller-volume projects, we can compare "forging + machining” with "solid stock machining” and propose a more suitable phased solution.

What Information Do I Need to Prepare for a Quotation or Sample Order?

We recommend providing: 2D drawings (including key dimensions and tolerances), 3D models if available, target alloy / performance, estimated annual volume, and any special test or surface treatment requirements. If you only have physical samples, you can also send them to us; we can support reverse engineering and modeling before proposing a forging route and quotation.

Our Customer Has Very Strict Test and Standard Requirements. How Far Can You Support?

On top of standard checks for chemistry, mechanical properties and dimensions, we can configure UT, PT, metallography, roughness and pressure / leak tests as required, and issue EN 10204 3.1 certificates and related reports according to ASTM / EN / AMS standards. Simply send us your target standards or customer specifications at the early stage, and we will incorporate the required tests and documentation into the process plan and quotation.

If your situation is not fully covered above, you are welcome to send us your drawings, estimated annual volume and target standards with your inquiry. We will combine them with our existing aluminum die forging capabilities to provide tailored process recommendations and quotation references.