2024 aluminum alloy is one of the most widely used high-strength aluminum alloys in the aerospace field, possessing excellent strength-to-weight ratio, outstanding fatigue resistance, and good machinability. In the forged state, 2024 aluminum alloy exhibits excellent structural stability, making it an ideal material for various high-performance components.

Chalco offers custom 2024 aluminum alloy forgings, widely used in aerospace, military equipment, and precision engineering to meet the structural requirements of high strength and lightweight materials.

Overview of Basic Parameters for Chalco 2024 Aluminum Forgings

- Available statuses: 2024-T3, T4, T6, T351, T851, T42

- Processing methods: free forging, die forging, seamless ring rolling, rough machining, finish machining

- Size range: Forged plate thickness ≤ 600mm, forged ring diameter ≤ 10mm

- Typical applications: aerospace structural components, military parts, engine mounts, landing gear connectors

- Standards to be implemented: ASTM B247, AMS 4120, AMS 4339, AMS-QQ-A-225/6, EN 586-2, GB/T 6892

Core Performance Characteristics of 2024 Aluminum Forgings

High strength performance: Extremely high strength can be obtained after heat treatment (T4, T6, T351, T851), suitable for load-bearing structural components.

Excellent fatigue resistance: It is very suitable for environments that are subjected to alternating loads, such as aircraft wing spars and landing gear components.

Excellent machinability: Enables high-precision machining of complex structures and adapts to various design requirements.

Medium corrosion resistance: Protective measures (such as anodizing, aluminum cladding, etc.) are recommended in corrosive environments.

Good heat treatment responsiveness: suitable for adjusting mechanical properties through solution treatment and artificial aging.

Chalco 2024 Aluminum Forging Product Types

Chalco has a mature forging process system that supports the production of various types of 2024 aluminum alloy forgings, suitable for customer projects with different load levels, structural complexity and subsequent processing requirements.

-

2024 forged block

2024 forging blocks have high strength and good machinability, making them suitable for deep-cavity rough/finished parts. They are also easily strengthened by heat treatment .

Popular sizes: Thickness 100–600mm, width/length up to 2000mm

-

2024 aluminum forged ring

Alloy 2024 exhibits excellent dynamic balance and fatigue life, making it suitable for high-speed rotation applications. Chalco supports both seamless rolling and die forging processes.

Popular sizes: outer diameter 200–1800 mm, maximum size up to 10m.

-

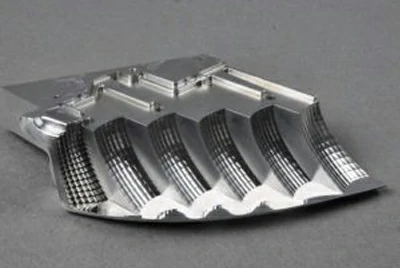

2024 forged die blank/mold base

With high strength, good machinability, and a uniform internal structure, it is ideal for deep-cavity machining and high-load mold parts. Chalco supports integrated pre-forging, rough machining, and heat treatment.

-

2024 aluminum forged base plate

The 2024 forged plate offers high strength, dimensional stability, and excellent fatigue resistance, especially in T351/T851. Chalco supports custom rough machining to shorten assembly preparation cycles.

-

2024 aluminum forged shaft

2024 forged shafts in T351 and T851 conditions possess excellent tensile and shear strength, making them suitable for structures subjected to cyclic loads.

Popular sizes: diameter 60–400mm, length up to 2000mm .

-

2024 aluminum forged rod/bar

Compared to rolled round bars, forged bars have a denser internal structure, resulting in better fatigue resistance and machinability.

Popular sizes: Diameter 50–300mm, length customized upon request.

-

2024 aluminum forged disc

2024 disc forgings, after heat treatment, possess good rigidity and strength, making them suitable for assembly after machining.

Popular size range: Diameter 100–800mm, Thickness 30–200mm

-

2024 al irregular /custom forgings

Chalco supports integrated multi-die forging and finishing to ensure strength while reducing processing costs.

Delivery options: Raw materials, rough-finished products, semi-finished products, or finished products can be delivered.

Available Heat Treatment Conditions and Corresponding Properties of Chalco 2024 Aluminum Forgings

2024 aluminum alloy is a typical heat-treatable aluminum alloy, whose strength comes from solution treatment and artificial aging. To meet the strength, stability, and formability requirements of different applications, Chalco offers 2024 aluminum alloy forgings in various heat-treated states. All states are strictly controlled through standardized processes and come with a complete set of test reports.

| List of heat treatment parameters for Chalco 2024 forgings | |||||

| Performance indicators | T3 | T4 | T6 | T351 | T851 |

| Tensile strength (MPa) | 430–470 | 450–480 | 470–500 | 440–470 | 470–500 |

| Yield strength (MPa) | 270–300 | 300–330 | 320–350 | 280–310 | 320–350 |

| Elongation (%) | 12–16 | 14–18 | 10–14 | 13–16 | 10–15 |

| Brinell hardness (HB) | 115–125 | 120–130 | 125–135 | 115–125 | 120–135 |

| Fatigue strength (R=–1, MPa) | 145–160 | 155–170 | 160–180 | 150–165 | 160–180 |

| Dimensional stability | ★★☆☆☆ | ★☆☆☆☆ | ★★☆☆☆ | ★★★★☆ | ★★★★★ |

-

T3 condition (solution treatment + cold working + natural aging)

This state exhibits a certain degree of cold working stress, moderate strength, and good elasticity, making it suitable for lightweight structural components or transitional connection parts. Customizable directional control and structural straightening services are available.

-

T4 / T42 condition (solution + natural aging / aging determined by customer)

The T4 temper offers excellent processability and is suitable for intermediate conditions before complex molding. The T42 temper requires aging treatment by the customer before use. Chalco provides anti-deformation packaging and reheat treatment options.

-

T6 condition (solution treatment + artificial aging)

It possesses extremely high strength, making it ideal for 2024 forgings used in load-bearing structures. However, it has relatively high residual stress. Chalco can control dimensional deviations through intermediate aging and precise roughing and finishing.

-

T351 condition (T3 + stress relief)

The T351 temper combines good strength with low residual stress, making it suitable for machining large or irregularly shaped forgings with high deformation control requirements. We offer multi-die forging with stress relief processes to ensure quality.

-

T851 condition (T6 + stress relief)

With the highest mechanical properties and excellent dimensional stability of alloy 2024, it is the preferred state for forgings in the aerospace field. Chalco provides delivery with flaw detection and integrated heat treatment.

Heat Treatment and Quality Control Capabilities

To ensure that every forging maintains stable performance, uniforms microstructure, and good machinability under different conditions, Chalco is equipped with a complete heat treatment production line and quality control system, enabling full-process independent control from solution treatment, aging treatment, stress relief, to condition switching and customer customization.

- Independent solution treatment furnace, isothermal treatment line, aging chamber

- Supports delivery of the entire T3, T4, T6, T351, and T851 series.

- It can achieve ±3% error control for state consistency.

- We can provide full-process testing services including flaw detection, metallography, and mechanical properties as needed.

- Differentiated processes are matched for different forging shapes (blocks, rings, shafts).

- We undertake project-based processing of clients' special situations (intermediate state, re-expiration).

Application Fields of Chalco 2024 Aluminum Forgings

2024 aluminum alloy is widely used in aerospace, military, and high-performance engineering fields due to its excellent strength-to-weight ratio and fatigue properties. Chalco can customize forging solutions with various structural forms and heat treatment conditions to meet the needs of different industries.

2024 Aluminum Forging for Aerospace Applications

2024 forgings are a common material choice for aerospace structural components and are suitable for high-strength parts subjected to cyclic loads.

- We recommend forgings in the 2024-T851 / T351 condition to optimize fatigue life.

- Supports customized development of die forgings, forging rings, and irregularly shaped connectors.

- We provide integrated delivery including UT flaw detection, mechanical property testing, and CNC precision machining.

2024 Aluminum Forging for Military Equipment Applications

2024 forgings are widely used in military structural components that combine lightweight design with high rigidity, particularly in ground and airborne equipment.

- Provides high-strength 2024-T6/T4 temper materials and rough machining support.

- It can assist in the design of multi-axis load-bearing connectors and shell structure forgings.

- It can meet the requirements of high-security delivery and batch stability for military products.

2024 Aluminum Forging for Automotive and High-Performance Sports Industry Solutions

For automotive and high-performance sports products, extreme lightweighting and load-bearing strength are required, and 2024 forgings are one of the materials widely used by high-end racing teams.

- Supply T351 condition forgings, optimize machining deformation control

- We provide subframe forgings, connecting seats, and steering structure products.

- Complete milling surface treatment + heat treatment + anodizing surface treatment services

2024 Aluminum Forging for Industrial Structural Equipment

2024 forgings are typically used in industrial components requiring high strength, and are particularly suitable for high-load rotating parts or positioning support structures.

- We provide blanks for large-size forging blocks, forging shafts, forging discs and other structural parts.

- Supports flexible status selection such as T6/T4/T42, facilitating subsequent processing.

- Mass production and standardized heat treatment can be carried out according to the customer's BOM list.

Regardless of the industry, Chalco can develop a comprehensive solution tailored to the specific usage environment and performance requirements of forgings, encompassing alloy selection, forging processes, heat treatment conditions, and delivery methods. This helps customers achieve optimal performance and cost-effective forging solutions.

Chalco's 2024 Aluminum Forging Capabilities and Manufacturing Assurance

Leveraging its advanced equipment system and comprehensive supporting capabilities, Chalco can provide customers with a full-process 2024 aluminum alloy forging manufacturing service, from forging and heat treatment to precision machining and testing, ensuring stable product quality and efficient delivery.

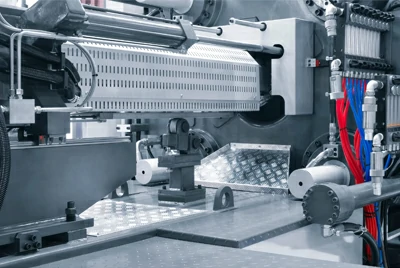

Diverse forging methods: Supports various forging processes such as free forging, die forging, and seamless ring rolling to meet the needs of different structural parts.

Large forging capability: Maximum forging diameter up to 2000mm, thickness up to 600mm, suitable for large-scale components in aerospace, military and other industries.

The machining process is fully equipped: it includes CNC turning, milling, drilling, and boring machining centers, enabling it to complete rough and finish machining before delivery.

Full coverage of heat treatment: It has multiple standard heat treatment processes such as T4, T6, T351, and T851, with precise and traceable condition control.

Full quality inspection process: ultrasonic testing, hardness testing, dimensional inspection, metallographic analysis, and chemical composition reporting, meeting international certification requirements such as AMS, ASTM, and ISO.

Chalco consistently focuses on rigorous process control, meticulous attention to detail, and the pursuit of repeatability to provide high-quality 2024 forging solutions to customers worldwide.

Reasons for Choosing Chalco as the Supplier for 2024 Aluminum Forging

By choosing Chalco, you not only get reliable 2024 forgings, but also a complete delivery and service system:

Integrated manufacturing process: Forging, heat treatment, and machining are all completed in-house by Chalco, resulting in higher efficiency and more consistent quality.

Rapid delivery capability: Short lead time for standard forgings, expedited processing for customized parts , meeting project schedule requirements.

A full-process traceability system: records can be kept from raw material batches to every step of the process, ensuring product safety and compliance.

Comprehensive technical support: providing material selection advice, structural optimization guidance, and custom drawing services.

Global customer coverage: Supports international shipping and has experience serving high-end clients such as aviation and military industries.

Whether you're looking for standardized parts or driving customized engineering projects, Chalco is a trusted 2024 forging partner.

Frequently Asked Questions (FAQ)

What is the strength of a forging in the 2024-T6 condition?

Forgings in the 2024-T6 condition have a tensile strength of approximately 470–500 MPa and a yield strength of over 320 MPa, making them suitable for high-strength structural applications.

What size range of 2024 forgings can you provide?

We can supply forging blocks, forging rings, forging shafts, etc. with a thickness of 20–600mm and a maximum diameter of 2000mm, and a maximum length of 2 meters. Custom sizes are also supported.

Do you provide rough or fine machining services?

Yes. We can provide roughing, semi-finishing, or finished-grade CNC finishing according to customer drawings, with surface accuracy and dimensional tolerances controlled within ±0.05mm.

Is it possible to specify the heat-treated condition for delivery?

Yes. We support multiple states such as T4, T6, T351, and T851, and can provide T42 or intermediate processing state delivery according to project needs.

What is the minimum order quantity for forgings in 2024?

The MOQ for standard products is 50–100kg, depending on the structure and specifications of the forgings. Large projects support bulk customization and long-term supply agreements.

Can you provide a price reference? What factors influence the price?

Prices will vary depending on size, condition, processing requirements, quantity, and alloy market fluctuations. Please provide drawings or specifications; we can provide a quote within 24 hours.

Do your 2024 forgings meet international standards?

Our products comply with standards such as ASTM B247, AMS 4120, EN, and GB, and we can provide third-party testing and quality reports upon customer request.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote