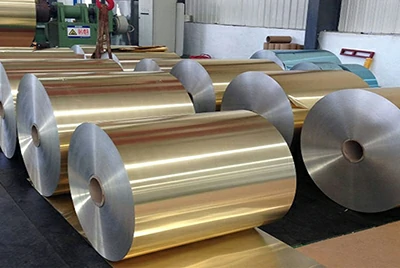

1235 aluminum alloy foil is a high-purity aluminum foil with a minimum aluminum content of 99.35%. It is one of the most widely used alloy foils in today's industrial market due to its excellent purity and stable properties.

In the annealed condition (O temper), 1235 aluminum foil offers exceptional ductility, which makes it highly suitable for further processing and forming in various industrial applications.

1235 aluminum foil introduction

Alloy: 1235 aluminum alloy

Aluminum Content: ≥ 99.35%

Standards: ASTM B479, AMS-QQ-A-1876

Temper: O (Annealed), H12, H14, H16, H18

Thickness Range: Metric: 0.014 mm – 0.2 mm; Imperial: 0.00055" – 0.008"

Width Range: Metric: 10 mm – 1700 mm; Imperial: 0.39" – 66.93"

Length: Customized as per client requirements (coils or sheets)

Surface Finish: Standard mill finish; available options include coating, lamination, embossing, etc.

Core Diameter: Standard core diameters of 76 mm (3") and 152 mm (6"); custom sizes available upon request

Packaging: Inner layer moisture-proof paper/plastic film; outer layer wooden pallets or wooden cases suitable for moisture-proof and shockproof transportation

Popular types of 1235 aluminum foil offered by Chalco

Embossed 1235 aluminum foil

Embossed 1235 aluminum foil features a textured surface that enhances strength, slip resistance, and visual appeal. It is widely used in insulation materials, kitchen foil, and other applications requiring improved surface performance.

Contact us now

Hydrophilic coated 1235 aluminum foil

With good hydrophilic properties, it ensures even water distribution. Commonly used in AC fins and heat exchangers.

Contact us nowLaminated 1235 aluminum foil

Laminated with PET, PE, or other films to enhance strength, sealability, and barrier properties. Widely used in flexible packaging.

Contact us now

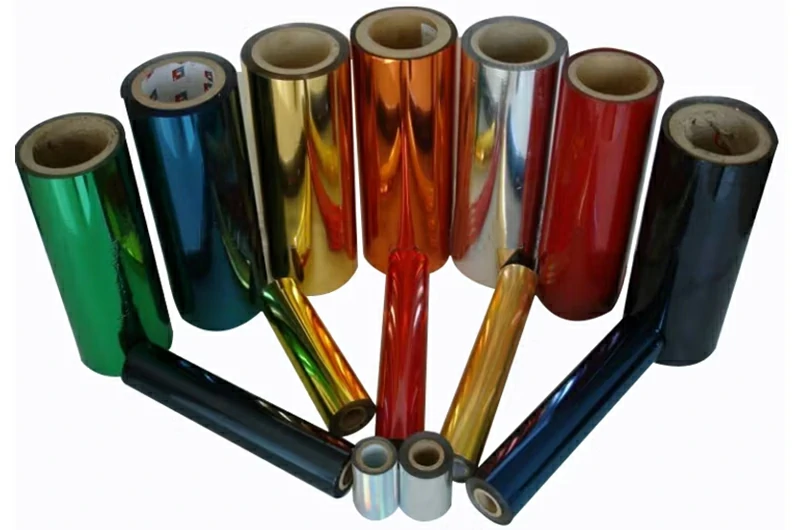

Color coated 1235 aluminum foil

Coated in various colors for enhanced appearance and brand identity. Common in food, pharmaceutical, and consumer goods packaging.

Click to learn more about color coated aluminum foil.

Contact us nowCoated 1235 aluminum foil

Applied with protective or functional coatings like lacquer or resin to enhance corrosion resistance, barrier performance, or heat sealability.

Contact us now

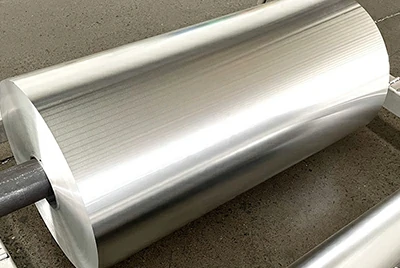

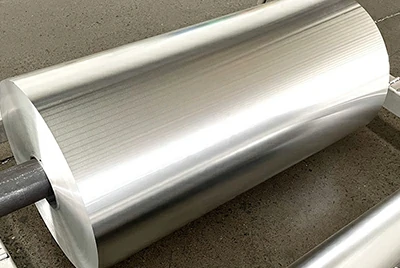

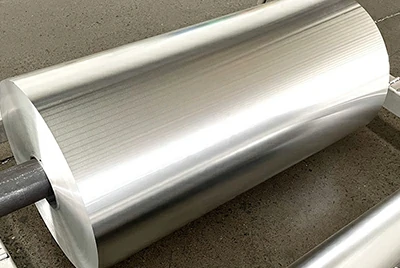

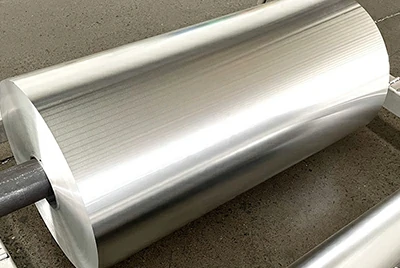

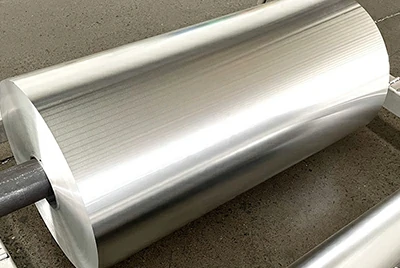

Plain surface 1235 aluminum foil

Smooth and clean surface, ideal for lamination, coating, or printing in secondary processing.

Contact us nowHeat sealing coated 1235 aluminum foil

Features direct heat sealability, ideal for sealed packaging such as pharmaceutical packs and food tray lidding.

Contact us now

Hydrophobic treated 1235 aluminum foil

Special surface treatment provides water-repellent properties, preventing condensation and moisture buildup.

Contact us nowAnodized 1235 aluminum foil

Made from high-purity 1235 alloy and processed through aluminum anodizing, this functional foil offers good conductivity and flexibility.

Contact us now

Properties of 1235 aluminum foil

High purity, aluminum content ≥99.35%

1235 belongs to the 1xxx series aluminum alloy with high purity and very low impurity levels, giving it excellent chemical stability and oxidation resistance. It is ideal for applications requiring non-reactive and contamination-free materials, such as food, pharmaceutical, and electronic packaging.

Soft and highly ductile, ideal for deep processing

In the annealed condition (such as O temper), 1235 aluminum foil offers superior ductility and formability. It is easy to die-cut, emboss, laminate, and bond, making it suitable for aluminum-plastic films, capacitor foils, tobacco inner liners, and other high-adhesion composite materials.

Good electrical conductivity for electronics and battery use

The crystalline structure of high-purity aluminum gives 1235 foil excellent conductivity. It is widely used in lithium battery current collectors, pouch packaging, cable shielding foil, and EMI shielding applications.

Lightweight and flexible, with structural stability

Compared with higher-strength alloy foils, 1235 offers better flexibility and lightweight performance. It is especially suited for roll applications in automated packaging lines, laminated film rolls, and medical banding.

Cost-effective and energy-efficient

As a pure aluminum alloy, 1235 benefits from lower raw material and processing energy costs. With mature processing technology and no need for heat treatment, it offers better price competitiveness than 2xxx, 5xxx, or 8xxx series alloys.

Alternative to 1145 foil with stable market supply

1235 shares nearly identical chemical composition and physical properties with 1145, making it a suitable substitute in most applications. As demand for 1145 declines, 1235 has become the mainstream alternative with strong market prospects.

Applications of 1235 aluminum foil

1235 battery aluminum foil

1235 battery aluminum foil Aluminum alloy with manganese as the main alloy element can not be strengthened by heat treatment and has good corrosion resistance. It can also be called rust proof aluminum, with good welding performance and good plasticity.

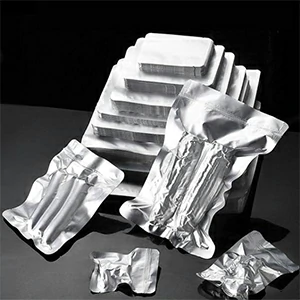

1235 packaging aluminum foil

1235 packaging aluminum foil Suitable for flexible packaging of food, pharmaceuticals, and daily care products. Offers excellent barrier, moisture resistance, and flexibility, and can be laminated or coated to form high-performance composite films.

1235 cable aluminum foil

1235 cable aluminum foil Widely used as shielding material in power and communication cables. Its excellent conductivity and EMI shielding help prevent signal interference, while good wrapability ensures easy processing.

Aluminum foil 1235 for capacitors

Aluminum foil 1235 for capacitors Used for electrolytic capacitor electrodes, requiring ultra-high purity and surface cleanliness. 1235 foil can be etched and electrochemically treated to ensure stable dielectric properties and voltage resistance.

1235 cigarette aluminum foil

1235 cigarette aluminum foil Commonly used as the aluminum layer in cigarette inner liners. With high ductility and excellent lamination properties, it bonds well with paper to improve moisture resistance, prevent aroma loss, and enhance product premium appeal.

Food-grade 1235 aluminum foil

Food-grade 1235 aluminum foil Complies with food contact safety standards (e.g. FDA, GB4806), non-toxic and odorless. Suitable for packaging chocolate, milk powder, instant noodles, coffee, and seasonings. Offers heat sealability, oil resistance, and moisture protection.

Flexible packaging aluminum foil 1235

Flexible packaging aluminum foil 1235 Used in multilayer flexible packaging films (e.g. PET/Al/PE structures), offering excellent printability, laminating compatibility, and sealability. Widely applied in lightweight packaging solutions for food, personal care, pharmaceuticals, and agriculture.

Heat sealing coated 1235 aluminum foil

Heat sealing coated 1235 aluminum foil Heat sealing coated 1235 aluminum foil is coated with a heat seal layer on high-purity 1235 aluminum, offering excellent sealability and moisture resistance. Ideal for sealing applications in food and pharmaceutical packaging.

1235 aluminum foil vs 1145 aluminum foil

| Alloy | 1235 Aluminum Foil | 1145 Aluminum Foil |

| Aluminum Content | ≥99.35% | ≥99.45% |

| Purity Level | High-purity aluminum | High-purity aluminum |

| Alloy Series | 1xxx Series (Commercially Pure Aluminum) | 1xxx Series (Commercially Pure Aluminum) |

| Typical Tempers | O, H18, H12, H14 | O, H18, H19 |

| Ductility | Excellent, suitable for deep drawing and forming | Excellent, suitable for deep drawing and forming |

| Electrical Conductivity | Very good, suitable for batteries, cables, capacitors | Very good, widely used in capacitors, cables, electronics |

| Corrosion Resistance | Good | Good |

| Workability | Easy to laminate, coat, slit, and emboss | Easy to laminate, coat, slit, and emboss |

| Typical Applications | Packaging foil, battery foil, cable foil, cigarette foil | Capacitor foil, cable wrap, food foil, decorative foil |

| Market Availability | Widely available with cost advantage | Declining supply, relatively higher cost |

Why can 1235 aluminum foil replace 1145 aluminum foil?

Chemically very similar

1235 and 1145 both belong to the 1xxx series of pure aluminum, with aluminum content exceeding 99.3% and extremely low impurity levels. Their chemical compositions are nearly identical.

Comparable processing and performance

The two alloys show minimal differences in ductility, conductivity, and corrosion resistance. They are interchangeable in most manufacturing processes and end-use applications without significantly affecting product performance.

1235 aluminum foil offers better availability and cost

1235 foil has greater production capacity and more suppliers in the current market. In contrast, 1145 is becoming less common, with reduced output and higher prices. From a cost-performance and supply stability perspective, 1235 is a more advantageous choice. .

Instant QuoteIndustry-recognized substitute

In flexible packaging, capacitors, cable shielding, and pharmaceutical foil applications, 1235 has become the standard replacement for 1145—especially in cost-sensitive scenarios or where ultra-high purity is not critical.

Chemical composition of 1235 aluminum foil

| Element | Composition (%) (%) |

| Aluminum (Al) | 99.35% |

| Chromium (Cr) | – |

| Copper (Cu) | 0.05% |

| Iron (Fe) | – |

| Magnesium (Mg) | 0.05% |

| Manganese (Mn) | 0.05% |

| Silicon (Si) | 0.65% (Si + Fe combined) |

| Titanium (Ti) | 0.06% |

| Zinc (Zn) | 0.1% |

| Other Total | – |

Mechanical properties of 1235 aluminum foil

TemperElongation (% in 2")Tensile Strength (ksi)Yield Strength (ksi)

| Temper | Elongation (% in 2") | Tensile Strength (ksi) | Yield Strength (ksi) |

| Annealed (O) | 35 | 13 | 5 |

| H12 | 12 | 16 | 15 |

| H14 | 9 | 18 | 17 |

| H16 | 6 | 21 | 20 |

| H18 | 5 | 24 | 22 |

Related recommendations for 1235 aluminum foil

1145 aerospace grade aluminum foil

8011 aluminum foil

Aluminum-ion battery aluminum foil

1100 aluminum foil for roofing

8011 aluminum foil for roofing

8011 aluminum foil for air conditioners

1235 aluminum foil FAQs

How is the price of 1235 aluminum foil calculated?

The price depends on multiple factors, including aluminum ingot market price, alloy temper, thickness, width, order quantity, and surface treatment. Bulk and repeat orders are eligible for tiered discounts and competitive pricing.

Can pricing be based on weight or square meter?

Yes. We offer flexible pricing options based on kilograms (kg), square meters (m²), or per roll, depending on your preference and project needs.

Is there a minimum order quantity (MOQ)?

Standard specifications support small-volume orders, while custom sizes or finishes may require a MOQ. Please contact us to confirm specific product requirements.

What is the standard packaging for 1235 aluminum foil?

Rolls are typically packed with plastic film + moisture-proof paper + EPE foam, then reinforced with export-grade cartons or fumigation-free wooden boxes. Heavy items are palletized to ensure safe transportation.

Can the packaging be customized?

Absolutely. We offer custom logo printing, anti-static packaging, vacuum sealing, and size-adjusted export cartons to meet branding, e-commerce, and international shipping requirements.

What export documents and certifications are provided?

We can provide Certificate of Origin (CO), Packing List, Commercial Invoice, Quality Inspection Report, MSDS, and SGS Test Reports, supporting smooth customs clearance globally.

What color options are available for color coated 1235 aluminum foil?

Chalco offers a wide range of color choices, including silver gray, champagne gold, matte black, glossy white, high-gloss blue, wood grain, and stone pattern. Custom RAL colors (e.g. RAL9005 black, RAL7035 gray) are also available upon request.

Can 1235 aluminum foil be anodized?

Yes. 1235 aluminum foil can undergo anodizing for use in nameplates, corrosion-resistant applications, or decorative finishes. However, its oxide layer is slightly softer compared to alloy-grade foils.

Can 1235 aluminum foil be heat sealed?

Yes. By applying heat seal coatings such as PE, PP, or PVC, 1235 foil can be used in heat-sealable packaging for pharmaceuticals, food, and other products.

Is 1235 aluminum foil suitable for electronic or conductive applications?

Yes. Thanks to its high purity and good conductivity, 1235 aluminum foil is widely used in electronic fields such as capacitors, battery current collectors, and cable shielding.

Why choose Chalco as your 1235 aluminum foil supplier?

Free samples

To help you better evaluate product quality and suitability, Chalco offers free samples of 1235 aluminum foil. You can request samples in specific alloy tempers, thicknesses, or surface treatments to test key parameters such as coating, color, and processing performance—minimizing procurement risk and accelerating decision-making. Contact us for samples.

Discount pricing

Exclusive discounts are available for repeat customers and bulk orders, giving you a cost advantage and stronger market competitiveness. We are committed to long-term partnerships and mutual success.

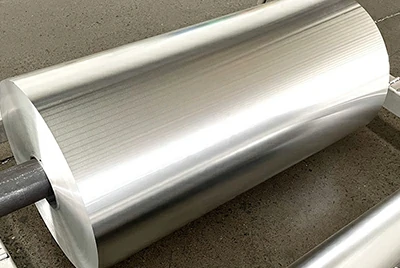

Excellent flatness control

Our production lines are equipped with Andritz leveling rolls, ensuring that the final foil has excellent flatness, a smooth surface, and improved laminating performance and appearance.

Accurate thickness & surface control

Using Honeywell online thickness gauges, we ensure precise control of foil thickness. Surface tension is optimized to ≥32 dynes (tested by dyne pen), ensuring good printability and lamination.

Foil coils are neatly wound with a layer misalignment tolerance of ≤±1.0 mm.

Stable production capacity and reliable supply

With a monthly production capacity of up to 1,200 tons, Chalco can fulfill large-volume orders and ensure on-time delivery and stable supply for your projects.