Chalco 2017 aluminum bar is a high-strength, heat-treatable aluminum-copper alloy designed for structural and precision-machined parts. It delivers greater tensile strength than common 6xxx series alloys like 6061, while offering better machinability than higher-end grades such as 2024—making it ideal for aircraft fittings, automotive components, and industrial arms.

Chalco offers 2017 aluminum bars in tempers including T3, T4, T6, and T8, with customizable diameters, fixed-length cutting, and surface treatments like polishing or anodizing. Backed by stable inventory and strict quality control, we provide reliable supply for both domestic and international machining applications.

Brief introduction of Chalco 2017 aluminum bar rod product

Tempers offered: T3, T4, T451, T6, T8

Diameter range: 3mm to 300mm (customizable upon request)

Length: standard 6 meters; fixed-length cutting available

Available shapes: Round/Hex/Square/Flat/Custom extruded profiles; Click to check [available shapes, dimensions, and hot-selling size ]

Surface finishes: bright finish, sandblasted, anodized, deburred cut surfaces

Additional services: precision cutting; OEM marking and custom packaging; surface and structural processing upon request

Specifications: ASTM B221, ASTM B211, ASTM B316, AMS 4118, AMS-QQ-A-225/5, AMS QQ-A-200/9, UNS A92017, EN573, EN485, JIS H4040 or customer-specified standards

Chalco 2017 aluminum bar hot selling products

2017 T6 aluminum bar

High strength, hardness, and corrosion resistance, commonly used in structural components, aerospace manufacturing, and high-pressure vessels.

2017 T4 T451 aluminum bar

2017 T4 offers high strength with excellent machinability, while 2017 T451 provides outstanding strength and hardness for applications requiring corrosion resistance.

2017 T3 aluminum bar

Moderate strength and excellent workability, ideal for rivets, aircraft fittings, and lightly stressed components.

2017 cold drawn aluminum bar

Excellent surface finish and dimensional accuracy, suitable for precision machining and high-end product manufacturing.

2017 precision ground aluminum bar

Tightly controlled tolerances, smooth surface, ideal for applications requiring high dimensional precision, such as shaft parts, measuring tools, or medical equipment.

2017 extruded aluminum bar

Good surface quality and uniform mechanical properties, commonly used in construction, transportation, and electronics industries.

2017 anodized aluminum bar

Enhanced surface protection and appearance, suitable for decorative or corrosion-sensitive applications.

Other hot selling products of Chalco 2017 aluminum bar

- 2017 aluminium cold finish round bars

- Astm b211 aluminium 2017 cold drawn bars

- 2017 aluminium half round bar

- 2017 aluminium hot rolled round bar

- Aluminium 2017 cold rolled round bar

- Aluminium 2017 pump shaft quality bar

- Aluminium 2017A threaded bar

- 2017a aluminium forged bar

- Aluminum alloy 2017A extruded rod

Available shapes, stock dimensions, and hot-selling sizes of Chalco 2017 aluminum bar

- Relying on Chalco production line and its subsidiaries, source procurement, lowest price guarantee.

- Chalco has the largest inventory and can allocate its subsidiary's inventory products at any time, seven-day delivery guarantee;

- The quality of large and small batches is the same, and be provided at the lowest price.

Customized sizes are available. Inventory is updated in real time, and lengths can be cut to your specifications. Click to inquire about custom production with free mold fees. Click the button below to get the latest stock details and the most competitive quote.

Instant Quote- 2017 aluminum round bar

Diameter: 3-600mm

Length: 1-12m

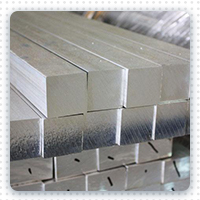

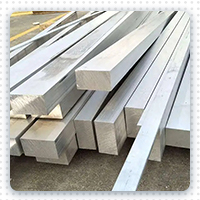

- 2017 aluminum square bar

Side length: 4-100mm

bar length: can be cut

- 2017 aluminum flat bar

size: thirty-three × 30mm-295 × 1066mm

Length: can be cut

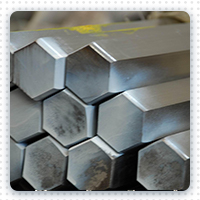

- 2017 aluminum hex bar

Size: 4-100mm A/F

Length: can be cut

| Hot selling 2017 round bar size table | ||

| Product | Metric diameter inventory mm | Inch diameter inventory (inch) |

| 2017-T4 | φ30 | 1 1/6 |

| 2017-T4 | φ40 | 1 1/2 |

| 2017-T4 | φ50 | 2 |

| 2017-T4 | φ60 | 2 3/8 |

| 2017-T4 | φ70 | 2 3/4 |

| 2017-T4 | φ80 | 3 1/8 |

| 2017-T4 | φ90 | 3 1/2 |

| 2017-T4 | φ100 | 4 |

| 2017-T4 | φ110 | 4 1/3 |

| 2017-T4 | φ120 | 4 3/4 |

| 2017-T4 | φ130 | 5 1/8 |

| 2017-T4 | φ140 | 5 1/2 |

| 2017-T4 | φ150 | 5 7/8 |

| 2017-T4 | φ160 | 6 1/4 |

| 2017A-T6 | φ43 | 1 11/16 |

Need to calculate the theoretical weight of your selected aluminum bar size?

To help you estimate order quantities and shipping costs more easily, we provide a dedicated [Aluminum Bar Weight Calculator] for quick and accurate results. Simply enter the diameter, length, and shape to get the weight instantly. You're also welcome to contact our sales representatives at any time for a quotation.

Instant QuoteTechnical specifications of Chalco 2017 aluminum alloy

| Equivalent Names of 2017 Aluminum Bar | ||||||

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlCu4MgSi | AU4G | 3.1325 | A92017 | AlCu4MgSi | 2017 | AlCuMg1 |

| Chemical Composition of Chalco 2017 Aluminum Alloy (wt%) | |

| Element | Content Range (%) |

| Copper (Cu) | 5.5 – 6.5 |

| Magnesium (Mg) | 0.2 – 0.8 |

| Manganese (Mn) | 0.4 – 1.0 |

| Iron (Fe) | ≤ 0.7 |

| Silicon (Si) | ≤ 0.2 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance (remainder) |

| Mechanical Properties (Approximate Values) | ||||

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T3 | 320 – 360 | 215 – 250 | 12 – 18 | 90 – 110 |

| T4 | 340 – 380 | 230 – 270 | 10 – 15 | 95 – 115 |

| T6 | 400 – 440 | 340 – 380 | 8 – 12 | 115 – 135 |

| T8 | 430 – 470 | 380 – 410 | 6 – 10 | 130 – 145 |

| CF (Cold Finished) | 360 – 400 | 270 – 320 | 10 – 14 | 105 – 120 |

- T3: Solution heat-treated and naturally aged to a stable condition; moderate strength and good machinability.

- T4: Solution heat-treated and naturally aged; higher strength than T3 with good formability.

- T6: Solution heat-treated and artificially aged; high strength and hardness for structural applications.

- T8: Solution heat-treated, artificially aged, and cold worked; maximum strength and hardness.

- T451: Solution heat-treated, stress-relieved by stretching, and naturally aged; improved dimensional stability and machining accuracy, ideal for precision applications.

Advantages of Chalco 2017 aluminum bar

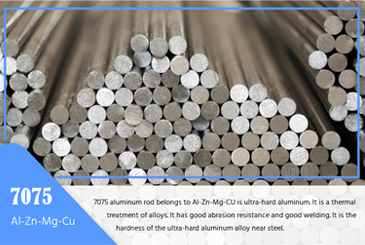

- Good cutting performance, high strength, excellent fatigue strength, and good machining performance.

- A certain degree of heat resistance, when the temperature is above 125 ℃, the strength of 2017 alloy is higher than that of 7075 alloy.

- The formability of the hot, annealed, and newly quenched states is good. The strengthening effect of heat treatment is obvious, and the process requirements are strict.

- Poor corrosion resistance, but using pure aluminum coating can effectively protect it.

- Cracks are prone to occur during welding, but special processes such as resistance welding or riveting can be used for welding.

Application field of Chalco 2017 aluminum bar

- 2017 alloy combines excellent cutting performance and high strength, making it one of the most widely used alloys in automatic screw machining.

- It is a tough and ductile alloy suitable for heavy-duty structural components.

- It has high strength (slightly lower than 2014), excellent fatigue strength, and excellent processing characteristics.

- 2017-T451 T6 aluminum rods are widely used in high-strength structures such as aerospace, machine manufacturing, military equipment, rivets, and sports equipment.

Chalco 2017 aluminum bar related products recommendation

2017 aerospace aluminum bar

2017 auto aluminum profile

2017 rivet aluminum rod

2017A fastener wire rod

2024 aluminum bar

2014 aluminum bar

7075 aluminum bar

6061 aluminum bar

5052 aluminum bar

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote