We turn ultra-wide thin-wall microchannel profiles into reliable mass production, IATF 16949 certified and trusted in EV battery and HVAC cooling.

Why choose wide thin-wall microchannel tubes

Traditional round extrusion struggles to produce stable wide and thin-wall microchannel tubes. Our flat-extrusion one-piece process turns "hard to make" into scalable production.

This meets the demands of battery trays, microchannel cooling plates, and other large lightweight structures.

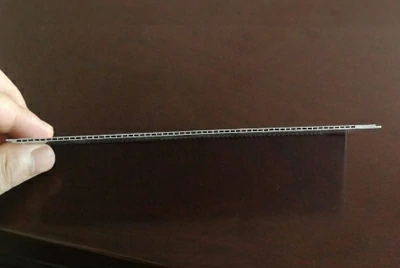

Our flat-extruded microchannel tubes achieve up to 550 mm width, 0.3–3.0 mm wall thickness, and 1.5–70 mm height.

- One-piece extrusion replaces welding, with fewer seams and shorter processes.

- At the same width, our tubes can be made thinner, cutting overall weight.

- Improved flatness and dimensional consistency ensure higher strength and sealing reliability.

- Wide thin-wall microchannel design boosts heat transfer efficiency.

- Production possible on small-tonnage flat extrusion presses, lowering equipment cost and giving customers a price advantage.

Each batch comes with full material certificates and inspection reports. We also offer fast sampling and customized design support.

If you are looking for a trusted wide thin-wall microchannel tube supplier, our flat-extrusion solutions are ready to help you.

Specifications of wide thin-wall microchannel tubes and profiles

- Standards: EN 573-3, EN 755-2, ASTM B221, EN 755-9, EN 12020-2

- Certifications: IATF 16949, ISO 9001, RoHS / REACH / ELV, IMDS

Each batch of profiles is supplied with a material certificate issued by a third-party or our in-house laboratory.

Key dimensions, thickness, tolerances, flatness, and wall consistency are fully inspected with written reports.

For microchannel tubes, we conduct hydrostatic or airtightness tests to check leakage rate and pressure resistance. These tests verify cooling circuit safety and ensure long-term reliability.

Popular wide thin-wall microchannel tube products

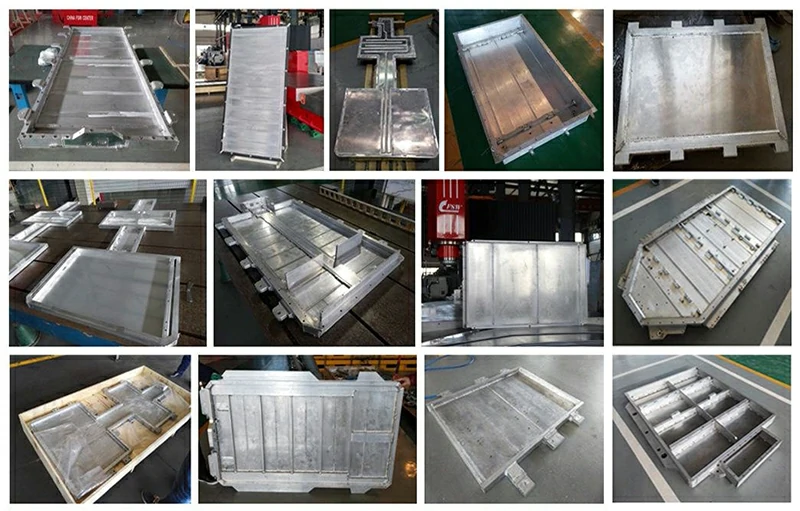

With advanced flat-extrusion technology, we have developed more than 50 complex profile designs for our customers.

All these products are wide thin-wall profiles and custom microchannel structures that are difficult—or even impossible—to achieve with conventional round extrusion. This proves our strong capability in die design and mass production.

Explore our product application cases with one click — click the text in the images below to view detailed content.

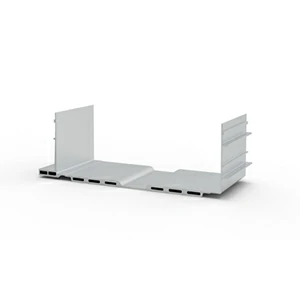

Automotive battery tray microchannel tubes

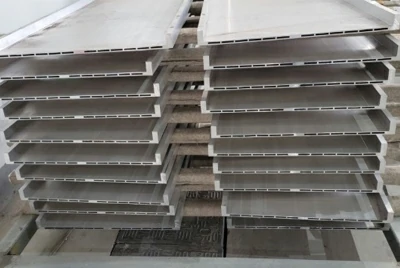

Battery tray base plates and cooling plates are usually welded from multiple profiles, but flat-extruded ultra-wide thin-wall profiles allow one-piece forming with higher efficiency and lower cost.

Contact us now

- Products: water-cooled plates, base plates, integrated modules

- Alloys: 6061, 6063

Flat-extrusion forming reduces friction welds, cuts weight, and improves strength and dimensional accuracy.

The process also simplifies manufacturing and lowers overall production costs.

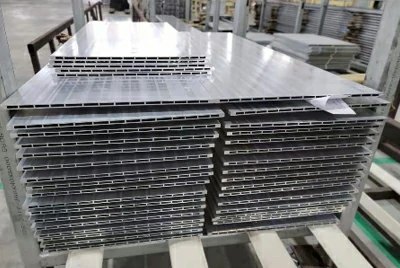

We have multiple stock dies for battery tray profiles, covering common base plates, water-cooled plates, and rib sections.

Customers can place orders directly without bearing the high cost of developing wide thin-wall dies, greatly reducing delivery time.

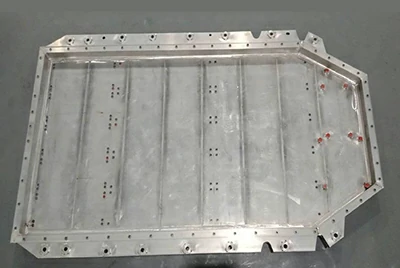

Battery tray mold dimension display.

-

6063 T6 automotive battery base plate microchannel tube

Width: 538 mm

Height: 33 mm

Wall thickness: 2.0 mm

-

6061 T6 automotive battery water-cooled plate microchannel tube

Width:500 mm

Height:10 mm

Wall thickness:1.5 mm

-

6063 T6 automotive battery water-cooled plate microchannel tube

Width:584 mm

Height:10 mm

Wall thickness:1.0 mm

-

6063 T6 automotive battery integrated module profile

Width:355 mm

Height:60 mm

Wall thickness:1.5 mm

-

6063 T6 automotive battery base plate microchannel tube

Width:405 mm

Height:35 mm

Wall thickness:1.5 mm

-

6063 T6 automotive battery base plate microchannel tube

Width:517 mm

Height:11 mm

Wall thickness:2.5 mm

Below are finished battery tray base plates, cooling plates, and integrated module profiles from our existing molds.

Automotive battery cooling microchannel tubes

Tesla 4680 battery serpentine cooling tubes

The 4680 battery has high energy density and generates significant heat. It requires efficient and uniform cooling to prevent individual cells from overheating.

CATL Kirin battery angled-hole cooling tubes

The Kirin battery features a compact layout and high energy utilization. It needs cooling channels that closely fit the cells to maximize space efficiency.

Our heat-exchange battery microchannel tubes are designed with ultra-thin walls. The thinner the wall, the higher the heat transfer efficiency, while also reducing material and processing costs.

If you need special designs, we can quickly customize on the basis of existing dies to meet the unique requirements of different projects.

Heat exchange micro-channel extrusion die display.

-

3003 capillary integrated plate

Width:160 mm

Height:2.6 mm

Wall thickness:0.4 mm

-

3003 module cooling plate

Width:250 mm

Height:4.0 mm

Wall thickness:0.5 mm

-

3003 RF module cooling plate

Width:186 mm

Height:1.5 mm

Wall thickness:0.4 mm

-

3003 energy storage battery cooling plate

Width:180 mm

Height:7.7 mm

Wall thickness:0.8 mm

-

3003 energy storage battery cooling plate

Width:180 mm

Height:8.0 mm

Wall thickness:0.8 mm

-

4680 battery cooling tube

Width:70 mm

Height:4.6 mm

Wall thickness:0.3 mm

If you are looking for a supplier of wide thin-wall microchannel tubes and complex profiles, Chalco’s proven technology and successful projects make us a partner you can trust.

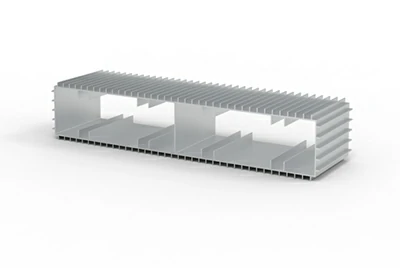

Wide thin-wall microchannel tubes for heat exchange applications

Our wide thin-wall profiles have been successfully used in projects such as 5G base station cooling and energy storage system thermal management, helping customers achieve significant gains in energy efficiency and reliability.

Heat exchange application mold display.

We have multiple dies ready for the heat exchange industry. These wide thin-wall microchannel tube molds can go directly into production, eliminating the high cost of new die development.

-

6063 5G base station cooling microchannel

Width:336 mm

Height:6.8 mm

Wall thickness:1.8 mm

-

3003 photovoltaic cooling microchannel

Width:450 mm

Height:16.25 mm

Wall thickness:0.8 mm

-

3003 BYD blade battery box microchannel

Width:105 mm

Height:45 mm

Wall thickness:0.45 mm

-

6063 display back cover cooling profile

Width:336 mm

Height:20.3 mm

Wall thickness:3.0 mm

-

6063 toolbox accessory profile

Width:501 mm

Height:11.3 mm

Wall thickness:1.0 mm

-

6005 integrated front frame profile

Width:330 mm

Height:55.7 mm

Wall thickness:2.0 mm

Refrigerated truck microchannel tubes

Our company participated in the design and manufacturing of CRRC refrigerated vehicles, successfully developing cooling profiles for energy storage refrigerant systems.

6005 T5 refrigerated truck cooling profile mold

Width:450 mm

Height:70 mm

Wall thickness:1.5 mm

Compared with traditional fan-based cooling solutions, this profile uses energy storage refrigerant to complete cold storage in a short time and deliver long-term stable cooling. Overall energy consumption is reduced by more than 60%.

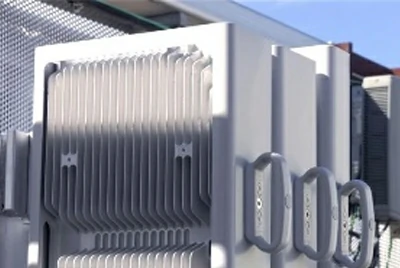

Finished CRRC refrigerated vehicle display

Through continuous mold innovation, we have helped many customers solve problems that "others can't do" and delivered lighter, stronger and more efficient aluminum profile solutions.

Aluminum microchannel ultra-wide flat extrusion: lighter, cheaper, more reliable

The following two case studies show how ultra-wide flat extrusion achieves weight reduction, cost savings, and performance improvement in real products.

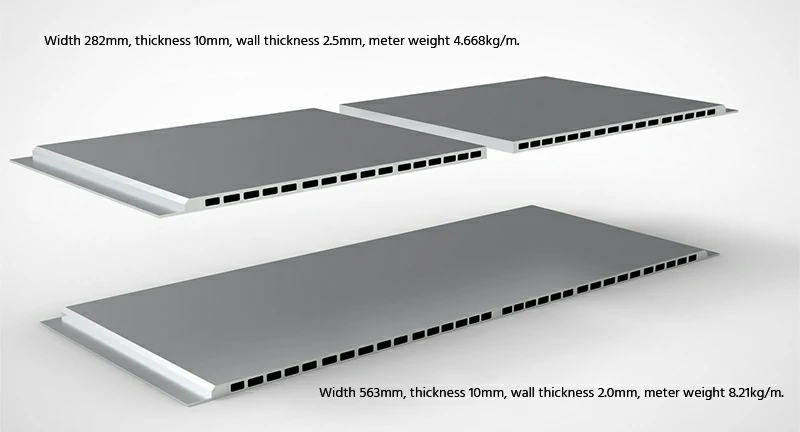

Case 1: battery tray water-cooled plate microchannel profile

Original design: two friction-welded pieces, 282 × 10 × 2.5 mm each, with unit weight 9.336 kg/m (4.668 × 2).

New design: one-piece ultra-wide flat extrusion, 563 × 10 × 2.0 mm, with unit weight 8.21 kg/m.

- Weight reduction of 1.126 kg/m, about 12%.

- Middle weld seam removed, resulting in a flatter surface and more reliable sealing.

- Fewer processes, faster efficiency, and overall lower cost.

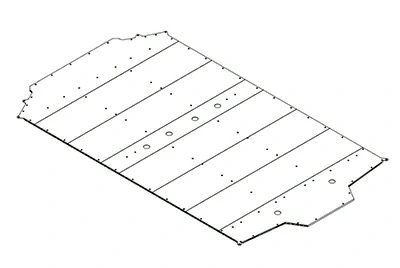

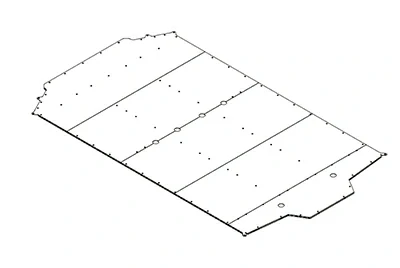

Case 2: automotive underbody protection microchannel profile

Option 1: 4 different profiles, 8 welded pieces

Option 2: 1 wide flat-extrusion profile, 5 welded pieces

| Option | Profile quantity | Die quantity | Die cost | Total weight | Friction weld length |

| 1 | 8 pieces | 4 sets | RMB 145,000 | 36.4 kg | 9.695 m (7 seams) |

| 2 | 5 pieces | 1 set | RMB 65,000 | 35.3 kg | 5.54 m (4 seams) |

- Option 2 reduces profile count by 3, giving a simpler structure and higher overall strength.

- Option 2 saves 3 die sets, cutting one-time tooling cost by RMB 80,000.

- Option 2 reduces weight by 1.1 kg, saving about RMB 29.7 per piece (at RMB 27/kg).

- Option 2 shortens weld length by 4.155 m, saving about RMB 41.55 per piece (at RMB 10/m).

- Option 2 achieves total savings of about RMB 71.25 per piece.

- Fewer welds mean lower leakage and rework risks, with better appearance and consistency.

Choose our wide thin-wall profiles. Send us your drawings or target weight/weld plan, and we can provide manufacturability feedback and cost-reduction evaluation within 48 hours.

Available alloys and customization capability

Microchannel heat exchange applications (battery cooling plates / HVAC / condensers)

-

3003 (H14 / H16 / H24)

Composite options: 3003+4343/4045, 3003+707

Excellent corrosion resistance and extrudability

Suitable for multi-channel microchannel tubes and thin-wall designs

-

3102

High thermal conductivity

Commonly used for fins and flow channels

Standards: EN 573-3 / EN 755 / EN 12020

-

1060 / 1070 / 1100 (O / H14)

Excellent electrical and thermal conductivity

Ideal for cooling circuits sensitive to heat transfer

Standards: EN 573-3, ASTM B221, GB/T 3190

Structural load-bearing applications (wide thin-wall plates / profiles / vehicle and electromechanical structures)

-

6061 (T5 / T6 / T651)

Balanced strength and machinability

Suitable for battery tray base plates, reinforcements, and assembly surfaces

Standards: EN 755-2/-9, ASTM B221, GB/T 6892

-

6082 (T6 / T651)

Higher strength alternative to 6061

Suitable for high-load structural parts, top and bottom plates

Standards: EN 755-2/-9, ASTM B221, GB/T 6892

-

6005A / 6060 / 6063 (T5 / T6)

Excellent extrudability, stable thin-wall forming, good surface finish

Suitable for wide exterior cover plates and interior partition panels

Standards: EN 755 / EN 12020, ASTM B221, GB/T 6892

We also support special alloys and non-standard cross-section customization. Performance requirements, application scenarios, and dimensional tolerances can all be developed according to your drawings.

Send us your drawings or parameters, and we will work with you to provide the best solution, delivery time, and quotation quickly.

Customized coatings for aluminum microchannel tubes

Microchannel aluminum tubes are prone to corrosion in salt spray, humid heat, and chemical environments. Surface coatings significantly slow the corrosion rate, ensuring long-term heat transfer performance and service life.

Pre-flux coating

Applied before vacuum or furnace brazing on fins and tubes. Improves wetting and filling, reduces manual fluxing and rework, and ensures stable quality.

NOCOLOK Si flux coating

Enhances wetting and joint strength during brazing. Improves tube-to-fin bonding, ideal for aluminum-to-aluminum brazing systems.

Zinc arc spray (zinc-rich coating)

Provides cathodic protection on the outer surface. Offers better cut-edge and edge corrosion resistance, suitable for marine and high salt-spray conditions. Can be combined with sealing coats for improved durability.

Electrophoretic coating (E-coat)

Uniform and dense anti-corrosion layer. Ideal for mass production with consistent appearance and protection. Can also serve as a primer for later spraying or bonding.

Selection tips:

- For brazing: choose pre-flux or NOCOLOK Si.

- For heavy corrosion protection: choose zinc arc spray (+ sealing coat).

- For appearance and corrosion resistance: choose E-coat.

We provide full reports on coating thickness, adhesion, and salt spray resistance. For microchannel tubes, we also offer airtightness and pressure tests to ensure traceability and production consistency.

Chalco equipment and production capacity

We are a lightweight solutions supplier, specializing in wide thin-wall aluminum profiles with integrated flat extrusion and custom production.

Our goal is to deliver high-strength and cost-effective innovations for our customers.

- 1000 t standard extrusion line × 1

- 1800 t dedicated flat-extrusion line × 1

- 2500 t dedicated flat-extrusion line × 1

- 3600 t flat-extrusion line × 1

Extruder technical parameters

| Tonnage | Max extrudable width | Min wall thickness |

| 1000 t | 250 mm | 0.3 mm |

| 1800 t | 350 mm | 0.8 mm |

| 2500 t | 580 mm | 1.0 mm |

| 3600 t | 750 mm | 1.0 mm |

| 5000 t | 1000 mm | 1.5 mm |

| 8000 t | 1500 mm | 2.0 mm |

We are also equipped with a full set of mold-making facilities, including CNC machining, EDM, and wire cutting.

For quality assurance, we use spectrometers, metallographic microscopes, and tensile testing machines.

Why choose chalco

Technology leadership

We are the first in China to achieve full-process flat extrusion for wide thin-wall profiles. This enables mass production of integrated multi-channel microchannel tubes up to 550 mm wide, 0.3–3.0 mm wall thickness, and 1.5–70 mm height.

One-stop engineering support

From structural design, metallurgy and alloy development, die and extrusion processes, to surface coatings (pre-flux, NOCOLOK Si, zinc-rich, e-coat), we deliver DFM analysis, cost-reduction plans, validation programs, and production rhythm matching.

Send us your drawings or target parameters, and receive manufacturability review, proposal, and quotation within 48 hours.

Tolerances and consistency

Tight tolerances and batch consistency ensure reliable fit for battery cooling plates, trays, and vehicle panels.

Processing and assembly

High-speed precision cutting (≤6 m) with options for end flattening, chamfering, and flanging. All designed for easier brazing and sealing.

Systems and compliance

Certified to IATF 16949 and ISO 9001.

Each order comes with EN 10204 3.1 certificates, dimensional inspections, and airtightness/pressure reports.

Quality assurance

Inline high-resolution visual inspection combined with spectrometer, metallography, and tensile testing.

Microchannel parts are tested according to drawings for airtightness, pressure, and leakage rate, with full records archived.

Related products of wide thin-wall microchannel tubes

We are a supplier of aluminum and titanium materials, able to provide matching products and services for a convenient one-stop selection and validation.

Automotive Microchannels

Aluminum Microchannel Tube

Aluminum Condenser Header Pipe

Automotive Brazing Composite Foils

Aluminum Brazing Welding Material

Aluminum Finned Tubes

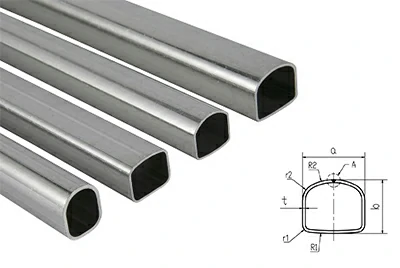

We also offer new products: microchannel folded tubes.

Microchannel folded tubes are manufactured using precision rolling of aluminum tube billets.

One type is the two-piece folded tube, where the outer tube and inner fins are formed separately and then assembled into a complete tube.

FAQ on wide thin-wall microchannel tubes

Q: What is a wide thin-wall extrusion profile?

A: An aluminum profile with large width and thin wall, beyond the capacity of conventional round extrusion. For example, width 500 mm with wall thickness only 2.5 mm.

Q: Can microchannel aluminum tubes be bent?

A: Yes, but proper processing is required. The bending radius should be ≥ 3–5 times the section height to maintain strength and sealing.

Q: What is the extrusion ratio?

A: It is the difficulty index of extrusion, calculated as billet cross-sectional area ÷ profile cross-sectional area. The typical limit for standard presses is 70–80; higher ratios are difficult to produce.

Q: What materials are used for microchannel tubes?

A: Mainly all-aluminum (3003+4343). They are lightweight, thermally conductive, and corrosion resistant.

Q: What certificates can you provide?

A: EN 10204 3.1 material certificates, dimensional inspection reports, and airtightness/pressure/leakage test reports.

Q: What are your dimensional capabilities?

A: Width up to 550 mm, wall thickness 0.3–3.0 mm, height 1.5–70 mm. One-piece extrusion, suitable for battery trays, cooling plates, and heat exchangers.