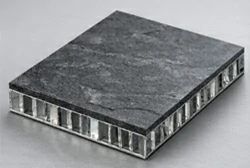

Stone honeycomb panels combine natural stone veneers with aluminum honeycomb cores, preserving the authentic stone appearance while significantly reducing weight and improving bending stability. They are ideal for ultra-large curtain walls, façade systems, and high-end interior applications requiring long-term flatness and flexible processing.

Leveraging proprietary honeycomb core manufacturing and controlled composite processes, Chalco supplies high-flatness, durable stone honeycomb panels with consistent quality and reliable structural performance for both exterior and interior building projects.

Chalco Stone Honeycomb Panel Product Details

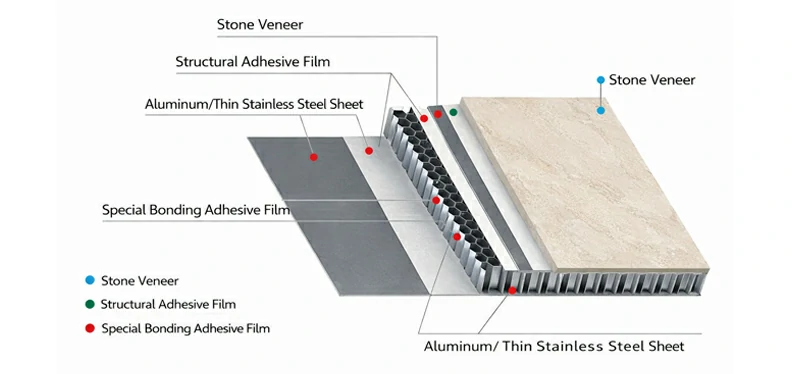

Chalco stone honeycomb panels are composed of natural stone sheets and an aluminum honeycomb core. Various stone surface materials, such as marble, granite, and quartzite, can be selected according to project requirements, and different structural systems can be formed by combining them with aluminum or FRP back panels. Through controllable honeycomb core density, stone thickness (3–10 mm), and back panel reinforcement configurations, the panels can be adapted for back-bolt, tongue-and-groove, folded edges, and irregular shapes, covering a wide range of applications including exterior curtain walls and interior decoration.

60–80% weight reduction

High bending stability

Weather & UV resistant

A2/B1 fire rated

Flexible machining

Contact us now

Chalco Stone Honeycomb Panel Product Structure and Technical Specifications

| Project | Parameter range | Illustrate |

| Stone thickness | 3–8 mm (marble), 5–10 mm (granite) | Customizable according to project requirements |

| Total thickness | 12–25 mm | Determined by structural configuration |

| Maximum size | 1500 × 3000 mm, 1200 × 3000 mm | Large sizes require evaluation based on stone type. |

| unit weight | 14–20 kg/m² | Depending on the type of stone and back panel |

| Cellular core density | 48–75 kg/m³ (commonly used) | Highly customizable |

| Backplate type | Aluminum sheet/FRP | Applicable to various indoor and outdoor scenarios |

| Adhesive system | Epoxy or structural adhesive | Compatible with a variety of stone materials |

| Fire rating | A2 / B1 | Determined by the back panel system |

-

Stone + aluminum honeycomb + aluminum back panel (standard curtain wall structure)

Most commonly used in exterior curtain walls and high-rise facades. High strength and excellent weather resistance, suitable for large panel sizes and long-term outdoor use.

-

Ultra-thin stone veneer system

The stone can be as thin as 2–3 mm, and it still maintains high strength and stability after being honeycomb composited, making it suitable for furniture, decorative panels, and large-area interior decoration.

-

Stone + aluminum honeycomb + fiberglass backing (FRP) (lightweight interior structure)

It is lighter and more corrosion-resistant, making it suitable for use in weight-sensitive applications such as commercial spaces, interior walls, and elevator cars.

-

Translucent Stone System

Using special stone and backlighting technology, it is used for illuminated background walls, display devices, and artistic decorative surfaces.

Chalco Stone Honeycomb Panel - Available Stone Types

Stone honeycomb panels are composed of a stone surface layer, an aluminum honeycomb core, and a back panel structure. The stone, as the outer cladding, is a key component determining the building's visual effect and texture. To meet diverse architectural styles and performance requirements, Chalco can combine various natural stones with honeycomb structures. We can also provide color swatches, texture options, and sample support based on project requirements.

Marble

is suitable for interior and exterior facades and large-format decoration, with a prominent high-end natural texture effect.

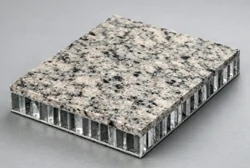

Granite

is strong and weather-resistant, making it suitable for exterior walls, curtain walls, and other high-durability applications.

Limestone

has a soft texture and is suitable for public buildings, commercial spaces, and high-end interior finishes.

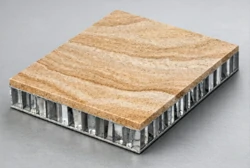

Sandstone

has a natural color and a warm finish, making it suitable for cultural buildings and personalized designs.

Quartzite

offers greater hardness and durability, making it suitable for high-wear or demanding projects.

Slate

Naturally waterproof, durable, and with a deep, stable color.

Chalco Stone Honeycomb Panel Production Capacity and Quality Assurance

Manufacturing capacity:

- Independent manufacturing of honeycomb cores (density, pore size, and foil thickness are controllable)

- The constant pressure lamination process ensures a uniform and stable adhesive layer without delamination

- Curtain wall level flatness control, large panels without bulging or warping

- Multiple backplate configurations: aluminum backplate / FRP backplate / reinforcing rib system

- Large-scale production capacity: Maximum 1500 × 3000 mm

- High batch consistency, suitable for continuous supply of large-scale projects

Quality and Testing:

- Bond strength test

- Bending and shear mechanical property testing

- Flatness and dimensional accuracy inspection

- UV, damp heat, and freeze-thaw resistance tests

- Fire protection systems can reach A2 / B1

- Test reports, parameter files, and application documents can be provided

Chalco Stone Honeycomb Panel Project Cooperation

Chalco stone honeycomb panels are widely used in high-rise curtain walls, large commercial buildings, hotels, convention centers, and high-end interior spaces. We can provide customized structural configurations, stone surface layer combinations, and engineering detailing support based on the structural requirements, load limits, processing methods, and installation systems of different projects.

To ensure the smooth progress of the project, Chalco provides a complete range of services, from solution selection to processing and refinement.

- System processing services for bolt holes, folded edges, grooves, etc.

- Installation node and keel system compatibility recommendations

- Stone & Backing Panel System Selection Support (Exterior/Interior Walls)

- Structural parameters, load data and project approval documents

- Large-format batch supply and color difference control

- Transportation, Packaging and On-site Protection Solutions

Chalco Stone Honeycomb Panel Outdoor Curtain Wall Collaboration Project Showcase

Chalco stone honeycomb panels have been used in a wide range of building projects worldwide, including high-rise curtain walls, large public buildings, commercial complexes, and high-end interior decoration projects. We provide customized structural systems, stone combinations, and processing services for different projects to ensure that engineering requirements are met in terms of aesthetics, safety, and durability.

Typical structural system: Aluminum back skin ; stronger and more weather-resistant, it is the mainstream choice for exterior curtain walls.

Stone thickness characteristics: Thicker stone (5–10 mm) is commonly used for outdoor use, offering higher safety and durability.

Construction method:

- Back-mounted tethering system (mainstream)

- Hanger / Keel Fixing System

Chalco Stone Honeycomb Panel Interior Curtain Wall Collaboration Project Showcase

Chalco stone honeycomb panels, with their lightweight, flexible processing, and high-end natural texture, are widely used in interior projects such as commercial spaces, hotel lobbies, conference centers, exhibition halls, and high-end residences. The honeycomb composite structure ensures aesthetics while making the stone surface lighter and easier to process, suitable for large-area interior designs.

Typical structural system: FRP back panel (lightweight interior system) ; lighter and better suited for styling and interior structure.

Stone thickness characteristics: Ultra-thin stone (2–6 mm) can be used ; significant lightweight advantages.

Construction method:

- Adhesive installation (common)

- Pendant System

- Local keel fixation

Chalco Stone Honeycomb Panel Selection Guide and FAQ

Which back panel system should be chosen for exterior curtain walls?

For exterior walls (especially high-rise curtain walls), aluminum back panel structures are recommended, as they have higher wind pressure resistance and weather resistance, and are suitable for large panels and long-term outdoor use.

Which structure should be used for interior applications?

For lightweight applications such as interior facade decoration, feature walls, and elevator cars, FRP back panel systems are more suitable, as they are easier to process and shape and have a smaller installation load.

How to choose the thickness of the stone?

- Exterior walls: 5–10 mm is recommended to improve safety and durability.

- For indoor use: 2–6 mm ultra-thin stone is available, resulting in a more significant reduction in weight.

- Design and Furniture: Prioritize ultra-thin veneer structure

How are the slab sizes determined?

The maximum size can reach 1200–1500 × 3000 mm, but it needs to be evaluated based on the type of stone, installation method and project load.

How to match processing methods such as back bolts, tongue and groove joints, and folded edges?

- Back bolts → Mainstream for exterior curtain walls

- Tongue and groove/plug-in joint → Quick installation of indoor large panels

- Folding → Shaping, Binding, Corner Nodes

Are honeycomb stone panels safer than solid stone panels?

Yes. The honeycomb core structure significantly improves bending strength, making it less prone to cracking or complete detachment. Exterior wall systems can achieve A2/B1 fire resistance ratings.

Will there be color difference issues with exterior wall stone honeycomb panels?

We can provide the same batch of stone surface material and conduct pre-layout and color difference control to ensure a consistent visual effect across the entire facade.

How are stone honeycomb panels installed?

For exterior walls, a back-bolt + keel system is primarily used; for interior walls, adhesive, hanging brackets, or partial keel systems can be used. Chalco can provide detailed joint suggestions.

Can stone honeycomb panels be used in elevator cars or old building renovations?

Yes. Lightweight structures are particularly suitable for load-bearing spaces, such as elevator interiors and old building renovations.

Can you provide product samples? What is the delivery time?

Standard stone samples and structural samples can be provided. The standard delivery time is 2–4 weeks depending on the project size.

What factors influence prices?

- Stone type and thickness

- Backplate system (aluminum / FRP)

- Number of machining operations (back bolt, hemming, tongue and groove)

- Specifications, dimensions, and order quantity (an accurate quote can be provided based on the drawings).

Can Chalco provide project approval documents?

Yes. These include test reports, fire protection system descriptions, mechanical parameters, dimensional standards, etc.

If you are undertaking a curtain wall facade, interior panel decoration, or lightweight renovation project, please send us your drawings or requirements. Chalco can provide stone samples, structural selection advice, system processing solutions, and project quotation support, offering reliable stone honeycomb panel solutions for your project.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote