Still Searching for Lightweight Yet High-Strength Materials to Boost Efficiency and Reduce Weight?

At Chalco, we have years of expertise in aluminum extrusion technology and a deep understanding of the increasing demands across industries—for lighter weight, better corrosion resistance, and enhanced aesthetics. Whether it's mechanical engineering, architectural, automotive, or electronic heat dissipation, round aluminum extrusions meet all these critical requirements.

Instant QuoteWhether you need Solid Round Bar or Hollow Round Tube, we provide high-quality, customizable aluminum solutions to help your projects break through the limits of traditional design.

Below, we'll introduce our offerings across four major product categories:

- Solid Round Aluminum Extrusions

- Hollow Round Aluminum Extrusions

- Structural Round Aluminum Extrusions

- Functional Round Aluminum Extrusions

Solid Round Aluminum Extrusions

Solid round aluminum extrusions refer to solid cylindrical aluminum profiles produced through the extrusion process. Compared to hollow tubes, these products offer higher structural strength and impact resistance, making them widely used in machinery, industrial equipment, and architectural components.

Diameter: 5–420mm

Alloys: 6061, 6063, 6082, 7005

Features: High load-bearing capacity, impact resistance, excellent machinability

Applications: Transmission shafts, bearing housings, structural support columns, fixing rods

Aluminum Half Round Bar

These bars are cut along the centerline of a round bar, resulting in a solid profile with a 180° arc cross-section.

Alloys: 6061, 6063

Features: Material-saving, lightweight, strong decorative appeal

Applications: Decorative trims, furniture edges, stair corner guards

Whether used in high-strength structural components or as critical transmission elements in industrial equipment, solid round aluminum extrusions deliver outstanding stability and machining flexibility.

If you have specific size requirements or need special alloys, Chalco offers both ready-made and customized aluminum solutions to help accelerate your project with efficiency.

Instant QuoteHollow Round Aluminum Extrusions

Diameter: 5–420mm

Alloys: 6061, 6063, 6082, 7005, 7075

Features: Lightweight, high strength, easy to machine

Applications: Railings, handrails, machinery columns, automotive chassis tubing, tent poles

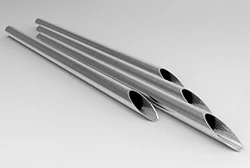

Aluminum Half Round Tube

Also known as D-shaped tube, it features a 180° curved section combined with a flat side. This design retains the load-bearing advantages of a round tube while offering a flat surface for easy mounting or installation.

Alloys: 6061, 6063, 6082

Applications: Drainage channels, cable raceways, decorative trims, wire conduits, automotive/mechanical interior tracks

Aluminum Quarter Round Tube

A hollow profile with a 90° arc-shaped cross-section, often designed with a flat edge or flange at the curved side or opening for secure mounting.

Alloys: 6061, 6063

Applications: Corner protectors, trim edges, equipment housings, cabinet transitions, interior decoration

Hollow round aluminum extrusions, including round tubes, half-round tubes, quarter-round tubes, and multi-chamber profiles, are circular hollow profiles produced via the aluminum extrusion process. Known for their lightweight structure, even stress distribution, and customizability, these extrusions are widely used in architectural decoration, mechanical equipment, and transportation systems.

Hollow round aluminum extrusions combine strength and lightweight performance, making them ideal for applications requiring both structural stability and reduced weight. If you're looking for a reliable supplier of aluminum tubing profiles, Chalco offers a wide selection of standard dies and supports custom manufacturing based on your drawings.

Instant QuoteSpecialty Round Aluminum Extrusions

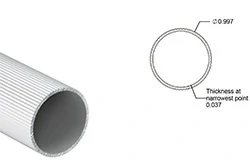

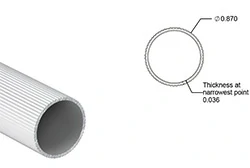

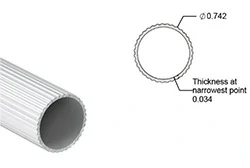

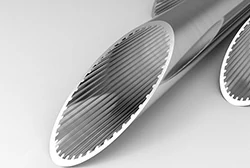

Aluminum Ribbed Round Tube

By adding axial ribs or reinforcement fins along the inner or outer walls of the tube, this design enhances overall strength and torsional resistance, allowing the tube to withstand greater loads with the same wall thickness. It is commonly used in high-load mechanical components, as well as in the automotive and military industries where impact resistance is required.

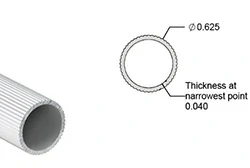

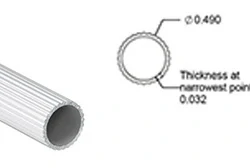

1” Aluminum Ribbed Round Tube

7/8” Aluminum Ribbed Round Tube

5/8” Aluminum Ribbed Round Tube

3/4” Aluminum Ribbed Round Tube

1/2” Aluminum Ribbed Round Tube

1/4” Aluminum Ribbed Round Tube

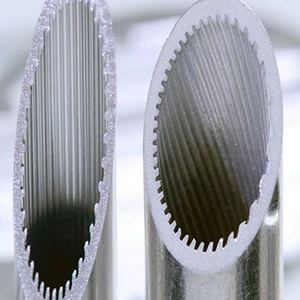

Aluminum Inner Grooved Tube (Internal Toothed Tube)

Aluminum Inner Grooved Tubes feature thread-like or trapezoidal grooves extruded on the inner surface. These grooves promote turbulent flow and enhance heat exchange efficiency for fluids or gases traveling through the tube. Compared to smooth-walled tubes, this design significantly improves internal heat transfer, making it ideal for air conditioning systems, heat exchangers, and high-efficiency condensers.

Multi-Hollow Round Extrusion

Multi-Chamber Round Aluminum Extrusions are circular profiles formed through aluminum extrusion, featuring multiple independent cavities or channels within the cross-section. While maintaining the basic outer shape of a round tube, their multi-hollow interior delivers superior strength, rigidity, and functionality. These extrusions are suited for a variety of high-performance applications.

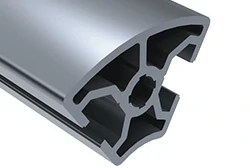

Round T-Slot Profile

Round T-Slot Aluminum Extrusions integrate a circular exterior with a T-slot channel system, offering enhanced modularity, compatibility, and structural flexibility. Manufactured through precision extrusion, they enable rapid assembly and multifunctional integration, making them ideal for industrial automation, equipment framing, workbenches, and guardrail systems.

For applications with more complex functional or structural requirements, Chalco offers comprehensive customization services. From unique cross-sectional designs to multi-chamber, ribbed, or high-thermal-conductivity structures, we provide expert engineering support to help bring your innovative designs to life.

Instant QuoteTypical Applications of Round Aluminum Extrusions

Round Slot Handrail Extrusion

Round Slot Handrail Extrusion is a type of aluminum profile that combines a round tube structure with slot design.

Contact us now

These profiles typically feature one or two slots on the side of the round tube, which can accommodate glass, acrylic panels, or other panel materials. They are widely used in glass railings, stair railings, balcony guardrails, and protective railings in public buildings. Not only do they enhance structural stability, but they also deliver a modern and minimalist decorative effect.

Key Features:

- The round profile offers better bending strength and uniform stress distribution.

- Optional single-slot or double-slot designs for flexible and secure assembly.

- Compatible with tempered glass, acrylic, PC boards, aluminum composite panels, etc.

- Made from 6061 T6 or 6063 T5 high-quality aluminum, with surface treatments like anodizing for corrosion resistance and durability.

Round Single-Slot Handrail Profile

Round Double-Slot Handrail Profile

Round Grooved Tube for Top Rail

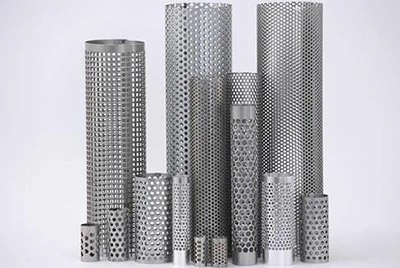

Perforated Aluminum Round Tube

Perforated Aluminum Round Tube

Perforated Round Tube refers to aluminum tubing that has been perforated in a regular pattern through extrusion or post-processing.

Contact us now

The perforations can be round, square, slot, oval, diamond-shaped, or custom-designed. The hole size, spacing, and layout can be tailored to specific application needs. This design significantly improves ventilation and heat dissipation, while also enhancing functionality for decoration, filtration, and noise reduction. Commonly used in acoustic equipment, filtration systems, ventilation systems, architectural decoration, and agriculture/irrigation.

Key Features

- A wide range of hole patterns to meet diverse requirements.

- Excellent airflow and heat dissipation, suitable for radiators, silencers, or drainage pipes.

- Significantly reduced weight while maintaining sufficient mechanical strength and stability.

Round Hole Perforated Tube

Slot Hole Perforated Tube

Square Hole Perforated Tube

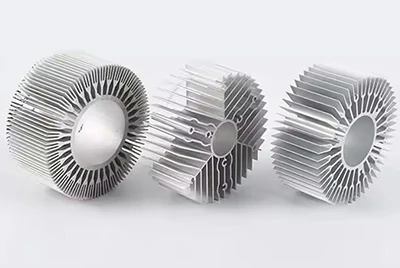

Round Heat Sink Extrusions

Round Heat Sink Extrusions

Round Heat Sink Extrusions are circular aluminum profiles formed through the aluminum extrusion process, featuring radially arranged heat-dissipating fins.

Contact us now

These profiles are typically made from high thermal conductivity aluminum alloys such as 6063-T5, 6061-T6, or 6005, offering excellent thermal conductivity, lightweight structure, stability, and ease of machining. Thanks to their 360° fin arrangement, they provide all-around cooling performance and are widely used in LED lighting, electronic devices, motor housings, and other thermal management systems.

Core Features

- Fins symmetrically arranged around the central axis ensure uniform 360° heat dissipation, solving issues caused by localized overheating.

- Various fin structures available, including straight fins, angled fins, and pin fins, to meet different performance requirements.

- Aluminum construction ensures light weight while maintaining structural strength, effectively reducing overall equipment weight and improving energy efficiency.

- Easy to perform CNC machining, drilling, tapping, cutting, and other secondary processing operations.

Types of Round Heat Sink Extrusions

Straight Fins

Traditional vertical fins for efficient heat transfer.

Angled Fins

Slanted fins to optimize airflow and cooling performance.

Pin Fins

Dense, needle-like fins ideal for compact designs with high thermal demands.

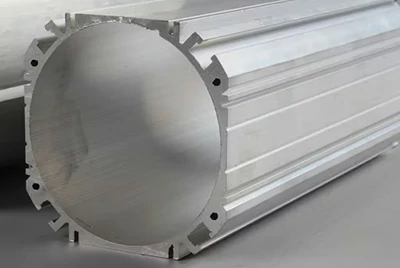

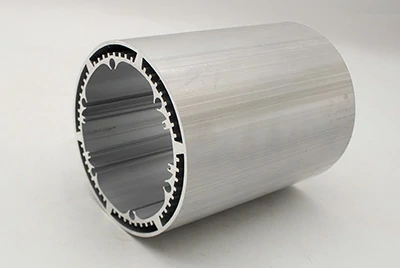

Round Motor Housing Extrusions

Round Motor Housing Extrusions refer to cylindrical aluminum profiles manufactured using the aluminum extrusion process, featuring precise internal cavity designs. These housings are widely used as enclosures and protective shells for motors, generators, fans, and other rotating mechanical equipment.

Contact us now

Produced through integrated extrusion forming, these aluminum motor housings offer high strength, lightweight construction, corrosion resistance, and excellent thermal performance. They effectively protect critical internal components, extend equipment lifespan, and enhance system heat dissipation.

Typical Application Areas

- EV Motors (Electric Vehicle Motors)

- Industrial Motors & Fans

- Inverter & Servo Motors

- Home Appliances & HVAC Compressors

Types of Round Motor Housing Extrusions

Aluminum Profiles for Missile Tail Fins

Aluminum Profiles for Missile Tail Fins are critical structural components used in the tail fin assemblies of missiles, rockets, and aerospace weapon systems.

Contact us nowManufactured through precision extrusion and CNC machining, these aluminum profiles are engineered to withstand aerodynamic loads during high-speed, high-temperature flight while maintaining lightweight and corrosion-resistant properties. They are widely used in tactical missiles, cruise missiles, air-to-air missiles, unmanned aerial vehicles (UAVs), and rocket systems.

Aluminum Finned Tube

The aluminum finned tube is produced using the Integral Extrusion Process, where the fins are seamlessly integrated with the tube wall, eliminating the need for welding or bonding. This integration removes interface thermal resistance, significantly enhancing heat transfer efficiency.

Contact us nowKey Advantages

- High Thermal Conductivity: The seamless connection between the fins and tube body enhances heat transfer performance.

- Strong Structure: The fins are securely attached, preventing detachment and ensuring a long service life.

- Corrosion Resistance: Made from high-strength aluminum alloys like 6063 and 6061, suitable for harsh environments.

Typical Applications

- Heat Exchangers

- HVAC Systems (Air Conditioning Evaporators)

- Industrial Condensers

- Petrochemical Equipment

Extruded Cylinder Tube

The extruded cylinder tube is a high-precision round tube manufactured using the hot extrusion process, specifically designed for pneumatic and hydraulic systems. Its inner wall is processed through Honing & Skiving to ensure smooth piston movement, reduce friction, and enhance sealing performance and durability.

Contact us nowKey Advantages

- Made from 6061, 6063, 7075 aluminum alloys, offering rust and wear resistance, ideal for harsh environments.

- 50% lighter than traditional steel cylinder tubes, making them more suitable for portable and high-response systems.

- Extrusion strengthened and anodized, capable of withstanding up to 30 MPa (300 bar) working pressure.

Typical Applications

- Pneumatic Actuators — Automation equipment, robotic joints, etc.

- Hydraulic Cylinders — Construction machinery, ship equipment, etc.

- Automotive Shock Absorbers — Electric vehicle, motorcycle suspension systems.

- Medical Devices — Precision fluid control systems.

The applications of the round aluminum extrusions above are just a few representative scenarios. The applications of round aluminum extrusions are far broader than these. With rich industry experience and strong engineering support capabilities, Chalco can provide precise and tailored round aluminum extrusion solutions for customers in various fields. Please feel free to contact us for more customized suggestions and reference cases.

Instant QuoteWhy Choose Chalco?

Full-Process Aluminum Processing Base for Consistent Quality

From aluminum ingot smelting, extrusion molding, precision processing to surface treatment, our integrated production system ensures consistent product quality and excellent material performance.

Advanced Extrusion Equipment to Meet Diverse Needs

Chalco owns advanced aluminum extrusion production lines capable of producing round aluminum extrusions from small to large diameters, suitable for various industrial applications.

Rich Alloy Selection to Meet Different Application Scenarios

We offer a variety of aluminum alloys, including 6061, 6063, 6082, and 7075, covering high strength, corrosion resistance, and high-temperature resistance to meet the needs of aerospace, rail transportation, electronic devices, and other industries.

Strict Quality Control Conforming to International Standards

All products comply with international quality standards such as ASTM, EN, JIS, and GB, and are subject to rigorous testing to ensure dimensional accuracy, mechanical properties, and surface quality meet industry-leading levels.

Stock Standard Profiles and Custom Complex Sections

For standard round aluminum extrusions, Chalco has ready molds for quick matching and supply, reducing costs and shortening delivery cycles. For complex cross-sections and multi-chamber structures, we support custom mold development to meet specific customer needs and provide personalized solutions.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote