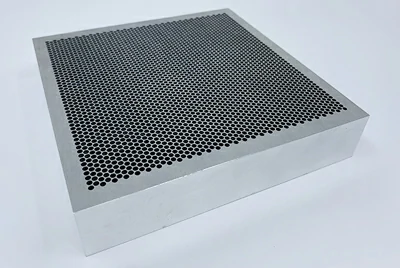

A honeycomb ventilation shield is a metal component that simultaneously meets the requirements of ventilation and heat dissipation as well as EMI/RFI attenuation. It is composed of regular honeycomb channels and reduces electromagnetic leakage while maintaining airflow through waveguide effect. It is widely used in industrial equipment, communication devices and various EMC enclosures.

Building on this, Chalco employs a combination of aluminum honeycomb and various frame structures, which can achieve a flexible balance between airflow performance and shielding performance through different aperture, thickness and material configurations, adapting to multi-level engineering needs from standard equipment vents to high-requirement shielding environments.

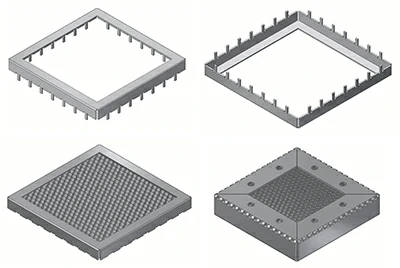

Chalco Honeycomb Vent Product Structure

Chalco honeycomb ventilation shielding panels are composed of an aluminum honeycomb core and an aluminum frame. By combining different pore sizes, thicknesses, and edging methods, stable and controllable engineering performance can be achieved in terms of ventilation efficiency, shielding performance, and installation methods. Standard products are made of lightweight aluminum alloy materials, suitable for most industrial and EMC scenarios; special alloys or special structures can be customized according to project requirements.

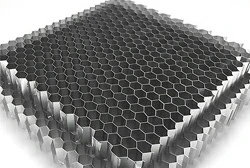

Honeycomb core structure

Border structure

Surface treatment

Chalco Aluminum Honeycomb Sizes and Styles

The honeycomb core consists of molded and electrically connected honeycomb cells, resulting in a lightweight yet strong structure that provides stable EMI/RFI attenuation while ensuring airflow. Aluminum honeycomb is the standard material, but materials with higher shielding or greater durability can be selected depending on the application.

| Cellular core specification range | |

| Aperture (Cell Size) | 1.6 mm / 3.2 mm / 4.8 mm / 6.4 mm |

| Thickness | 6 mm – 100 mm (larger available) |

| Material | 5052/3003 aluminum honeycomb, stainless steel, brass, and other honeycomb materials are available upon request. Please contact our sales department for inquiries. |

| Manufacturing method | Adhesive-free resistance welded honeycomb, flame-retardant adhesive film honeycomb (optional) |

| Detailed parameters | Jump to the [Parameters Section] |

Straight Cell Options

1.6 mm (1/16") small aperture

3.2 mm (1/8") standard aperture

6.4 mm (1/4") large aperture

Cellular core thickness : 6 mm – 25 mm

Custom apertures and thicknesses available on request.

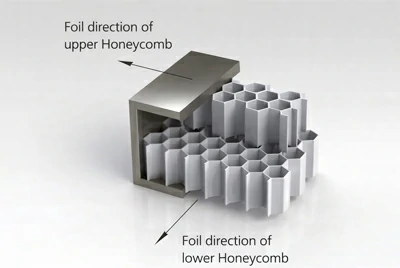

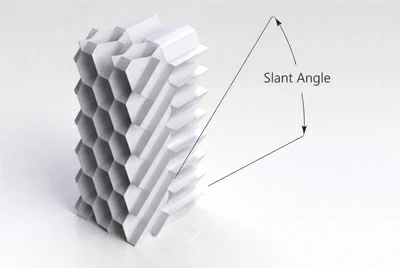

Slanted Cell (tilt structure: 30°/45°/ 60°)

3.2 mm cell × 6.35 mm thick × 30°

3.2 mm cell × 6.35 mm thick × 45°

3.2 mm cell × 6.35 mm thick × 60°

* Used to limit the line of sight, enhance waveguide effects, or for specific aesthetic structures.

In addition to standard straight-hole honeycomb cores, we also offer higher-level structural options to meet specific shielding, visual obstruction, or environmental adaptability requirements; related customized solutions need to be evaluated based on project requirements, please contact our sales staff to confirm feasibility.

-

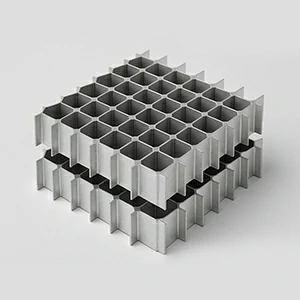

Double-Layer Honeycomb

The two-layer honeycomb rotation and stacking significantly improves EMI/RFI attenuation performance, making it suitable for systems with higher shielding levels .

-

Expanded Aluminium Style

The metal mesh structure formed by stretching aluminum plates has a higher shielding capacity, but the airflow is relatively reduced.

-

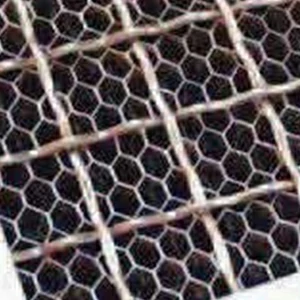

Woven / Mesh Vents

It uses a mesh structure woven from metal wires to provide shielding capabilities in specific frequency bands while maintaining better ventilation.

-

Honeycomb + Filter Composite

Honeycomb cores can be layered with dustproof mesh, waterproof membranes, or filter layers for ventilation and shielding in outdoor or high-dust environments.

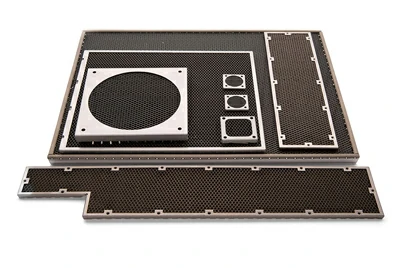

Chalco Honeycomb Vent Border Design

The frame is used to secure the honeycomb core and form a reliable connection with the equipment housing, making it a key component of the overall structure of the honeycomb ventilation panel. Chalco offers two main types of manufacturing solutions: extruded profile frames and molded frames, catering to various design needs from standard to complex structures, depending on the installation method, strength requirements, and shape requirements.

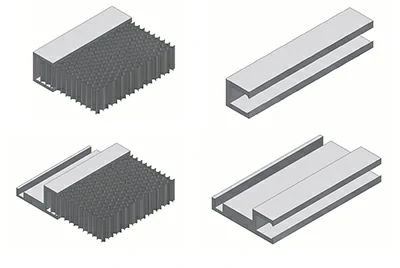

Extruded frames

Suitable for standard honeycomb ventilation panel assembly, it features a lightweight structure, stable dimensions, and allows for rapid integration by selecting different profiles based on honeycomb thickness.

Material: Aluminum Alloy 6063-T1 / T4 / T6 (ASTM B221)

Profiles: C-channel, U-channel, Chair-style extrusions

Formed Frames

For ventilation panels used in large, irregularly shaped applications or those requiring additional structural strength, diverse structures can be achieved through processes such as bending, stamping, and welding.

Material: 5052-H32 aluminum (AMS-QQ-A-250/8)

Frames: Bent / stamped / welded frames

Chalco's frame system offers flexible configuration options to suit various equipment interfaces, significantly enhancing the assembly stability, sealing, and compatibility of honeycomb ventilation panels to meet diverse applications from standard to high-requirement projects. All frames can be custom-made in terms of size, thickness, shape, and installation method; feasibility of special structures can be confirmed with our engineers.

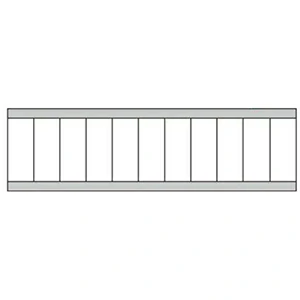

-

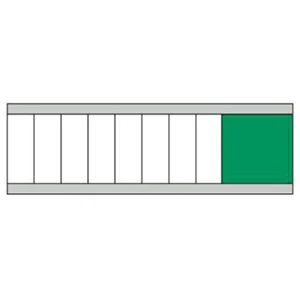

Straight Frame

Used for standard rectangular openings, it is the most common and universal border form.

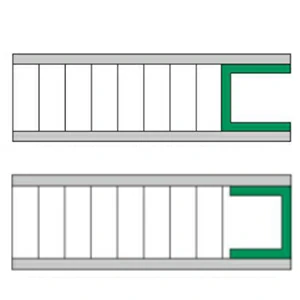

-

U-shaped cut-out frame

Suitable for structures that require avoiding internal components or side-mounted assembly.

-

Flange frame

Provides additional clamping surfaces or bolt mounting surfaces to improve fixation and sealing.

-

Chamfered/Rounded Corner Frame

Used to reduce structural interference, improve appearance continuity, or meet equipment safety requirements.

Chalco Honeycomb Vent Product Surface Finishes

To adapt to different application environments, conductivity requirements, and corrosion resistance requirements, Chalco's honeycomb ventilation panels offer a variety of surface treatments to improve the product's performance in terms of EMI shielding, structural reliability, and service life .

Chem-film (standard): Provide basic corrosion and electrical protection, suitable for standard environments in most industrial and electronic equipment.

Tin plating: Improve low-frequency EMI/RFI shielding performance and enhances conductivity at the contact point with the housing, making it suitable for systems with high requirements for contact resistance.

Nickel plating: Enhance surface corrosion resistance and significantly improves interfacial conductivity, making it suitable for high humidity, high corrosion, or scenarios requiring higher structural stability.

For applications such as blackening treatment (to meet matte visual requirements), stainless steel coating, and other special electroplating solutions, we can customize and develop solutions according to the project environment and interface requirements. Please contact our engineering team for a feasibility assessment.

Chalco Honeycomb Vent Applications & Selection Guide

Cellular ventilation panels are widely used in various fields such as communication equipment, power systems, medical electronics, and shielded rooms. The requirements for airflow, shielding levels, and structural compatibility vary significantly across industries. Leveraging its long-term experience in projects across multiple industries, Chalco has developed mature application configuration strategies and can provide you with more suitable combinations of cell core specifications, frame structures, and surface treatments based on typical scenarios.

Communication & Electronic Equipment (High-frequency EMI Applications)

Typical equipment: base stations, 5G gateways, switches, routers.

Requirements: high-frequency shielding + moderate airflow.

Recommended selection: 3.2 mm aluminum honeycomb (standard) or 1.6 mm small aperture; A single-layer structure is sufficient. Chem-film or nickel plating (if corrosion resistance is required)

Power / Industrial Control

Typical equipment: power modules, UPS, frequency converters.

Requirements: heat dissipation priority + low-to-medium frequency shielding.

Recommended selection: 6.4 mm large aperture honeycomb (high airflow); Thickened structure (>12mm) improves attenuation; Tin plating (improves low-frequency performance)

Medical / Imaging Systems

Requirements: Corrosion resistance + stable EMI shielding.

Recommended selection: 3.2 mm aluminum honeycomb; Nickel plating surface treatment; Rounded corner frame (for added safety)

Shielded Rooms and EMC Laboratories

Requirements: Dual shielding in H field + E field, high attenuation required.

Recommended selection: Steel or tin-plated honeycomb; Double-layer (cross-cell); Flange frame structure ensures a seal

Outdoor and Harsh Conditions

Requirements: Filtration + Shielding + Airflow

Recommended Selection: Honeycomb + Filter composite structure; Waterproof membrane/dustproof mesh superimposed; Nickel plating (outdoor corrosion resistant)

For equipment with special heat dissipation or environmental protection requirements, we can also assess and provide extended structures such as fan interface type and dust filter combination type according to project requirements. The specific feasibility shall be subject to confirmation by the engineering design.

Chalco Honeycomb Ventilation Panel Performance Specifications

Aluminum Honeycomb Shielding Performance (Pore Size 3.2 mm, Thickness 12.7 mm)

| Frequency | Lateral attenuation | Longitudinal attenuation |

| 100 MHz | 95 dB | 90 dB |

| 500 MHz | 85 dB | 85 dB |

| 1 GHz | 80 dB | 85 dB |

| 5 GHz | 80 dB | 85 dB |

| 10 GHz | 80 dB | 85 dB |

Typical Cellular Airflow Performance (Reference Values)

| Honeycomb thickness | Aperture (Cell Size) | Pressure drop (@1 m/s) | airflow rate |

| 6.4 mm | 4.8 mm | 18–25 Pa | high |

| 12.7 mm | 3.2 mm | 35–55 Pa | middle |

| 25.4 mm | 3.2 mm | 70–110 Pa | Low |

| Note: The greater the thickness and the smaller the aperture, the higher the shielding performance, but the lower the ventilation volume. | |||

Mechanical Properties of Honeycomb Structures (Typical Values)

| Project | Typical value | illustrate |

| compressive strength | 1.0–1.8 MPa | Related to thickness and alloy condition |

| Shear strength | 0.6–1.2 MPa | Stable load-bearing capacity after being combined with the frame |

| density | 48–80 kg/m³ | Lightweight structure, suitable for weight reduction design |

| Note: Specific parameters vary depending on the specifications and manufacturing method of the honeycomb core. | ||

Environmental Durability

| Test Project | Typical manifestations |

| Salt spray test (48–96 h) | No obvious corrosion on the surface |

| Temperature and humidity cycling (85°C / 85% RH) | Stable structure, no layering |

| Thermal shock (-40°C ↔ 85°C) | Keep it flat and free from cracks. |

| Long-term conductivity stability | High EMI attenuation retention rate |

| Note: Chem-film treatment, tin plating, nickel plating, and other treatments can further improve environmental durability. | |

Why Choose Chalco Honeycomb Vent

Commonly used material systems in engineering, with reliable structures

Utilizing 3003/5052 aluminum honeycomb and 6063 extruded aluminum frame (ASTM B221), it is available in aperture sizes of 1.6 / 3.2 / 6.4 mm and thicknesses of 6–25 mm to meet the opening requirements of most equipment.

Multi-process surface treatment enhances EMI and corrosion resistance

Optional treatments include MIL-DTL-5541 (Chem-film), electroless nickel plating, and tin plating, which are commonly used in the industry to improve contact conductivity and environmental adaptability.

Strong customization capabilities to match different equipment structures

It supports honeycomb structures such as double-layer, angled, stretched mesh, and filter composite; the frame can be made of extruded profiles, bent, welded and irregular structures to adapt to different cabinets and panel interfaces.

Stable batch production capability and dimensional consistency

The dimensional tolerances of the honeycomb and frame can be controlled within ±0.2–0.3 mm, the production process is traceable, and continuous supply from samples to batches can be supported.

Contact Chalco to obtain project samples and customized solutions. We will provide the most suitable configuration combination based on your application needs.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote