ER4043 (AlSi5) is a eutectic aluminum-silicon welding wire with 4.5–6.0% silicon, offering excellent fluidity, minimal spatter, and strong resistance to hot cracking.

It’s compatible with 1xxx, 3xxx, 6xxx, and low-Mg 5xxx alloys (e.g., 3003, 5052, 6061, 6063), making it a top choice for MIG/GMAW and TIG/GTAW welding.

Instant QuoteER4043 Aluminum Welding Wire Specifications and Packaging

| Item | Parameter range |

| Diameter (mm) | Coiled wire (MIG): 0.8 / 0.9 / 1.0 / 1.2 / 1.6 (0.6 & 2.0 mm can be customized) |

| Straight strip (TIG): 1.6 / 2.4 / 3.2 | |

| Packaging form / Net weight | Coiled wire: S100 0.5 kg | S200 2 kg | S300 7 kg | S360 20 kg | Drum 150 kg |

| Straight strip: 1 m long, 5–10 kg/box | |

| Wire diameter tolerance / Status | F;ISO 544 h9 ±0.02 mm |

| Welding process | GMAW / MIG (coiled wire) |

| GTAW / TIG (straight strip) | |

| Recommended shielding gas | 100% Ar or Ar + ≤30% He (thick parts/high thermal conductivity substrates) |

| Implementation standard / Brand | AWS A5.10 ER4043 | AMS 4190 | ISO 18273 S Al 4043 |

| Applicable parent material | 3003/3004/5052/6061/6063, etc. 1xxx·3xxx·6xxx series and 5xxx with Mg ≤ 2.5 % |

| Minimum order quantity / Delivery | Minimum order of S100 0.5 kg or TIG 1 kg; Regular spot goods are shipped within 72 hours |

| Technical support | Free welding parameter window, sample evaluation, COA/COC report and ROHS documents are provided, and engineers are available online 24 hours to answer questions |

Product Categories of ER4043 Aluminum Welding Wire

ER4043 MIG Wire

Suitable for automated and manual MIG (GMAW) welding, with good flowability and compatibility with various wire feeding devices.

Specifications: Ø 0.8 / 0.9 / 1.0 / 1.2 / 1.6 mm

Packaging: S100 0.5 kg | S200 2 kg | S300 7 kg | S360 20 kg | Drum 150 kg

ER4043 TIG Rod

Used for GTAW/TIG precision welding, suitable for thin plates and decorative parts. Straight rods are convenient for manual wire feeding and torch changes.

Specifications: Ø 1.6 / 2.4 / 3.2 mm

Length: 1000 mm

Packaging: 5 kg/box | 10 kg/box

ER4043 Metal-Cored Wire

For high-productivity MIG machine welding applications, the combination of filler alloy and inert gas core structure provides both high deposition rate and low spatter characteristics.

Specifications: Ø 1.2 / 1.6 mm

Packaging: S300 7 kg | S360 20 kg

ER4043 Flux-Cored Wire

For manual brazing and semi-automatic flame welding, containing flux internally, suitable for on-site repair or quick fixes without external flux.

Specifications: Ø 1.6 / 2.0 mm

Packaging: S200 2 kg | S300 7 kg

ER4043 Small Spools/Coiled Ring

Convenient for use with portable welding machines or hand-held push-pull guns, reducing downtime for spool changes, suitable for maintenance and on-site operations.

Features of ER4043 Aluminum Welding Wire

ER4043, with its excellent formulation and process advantages, has become the preferred filler material for aluminum welding in many industries. The following points not only reflect its technical performance but also directly translate into your production benefits:

- Balanced Silicon Content (4.5–6.0%): This range improves molten pool wettability, making the weld bead smooth, while ensuring the melting point is not too low, which is beneficial for molten pool control in vertical and overhead welding, reducing rework.

- Excellent Crack Resistance: For heat-crack-sensitive base materials such as the 6xxx series (e.g., 6061, 6063), the cracking rate is about 70% lower than that of 5xxx series filler wires, significantly improving weld reliability.

- Light Gray Weld, Minimal Color Difference: After welding and anodizing, it appears light gray, closely matching the base material, eliminating the need for secondary spraying or powder coating, saving post-processing costs.

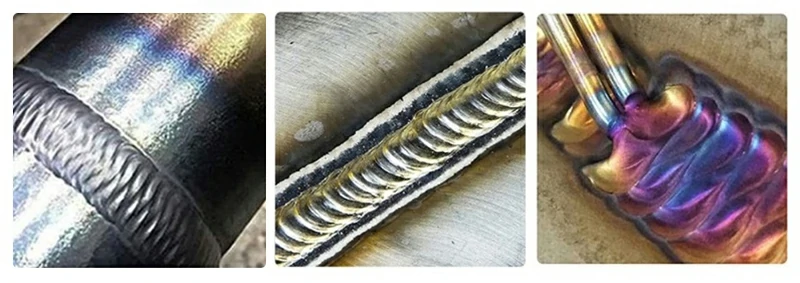

- Low Spatter, Beautiful Weld Bead: The arc is stable with minimal spatter, and the weld bead formation is good, requiring almost no grinding or slag removal, improving operator comfort and production efficiency.

- Economical and Efficient: Without Mg/Cu alloying elements, the smelting cost is low; the cost performance is better than similar aluminum-silicon welding wires, which can help customers reduce overall welding material expenses by 15–20%.

- Good Process Compatibility: Suitable for GMAW/MIG, GTAW/TIG, and high-speed pulsed MIG (Ø1.2 mm can achieve a deposition rate of 9–12 kg/h), meeting the requirements for precision welding of thin plates and high-productivity welding of thick plates.

- Good Corrosion and Thermal Conductivity: The weld is resistant to atmospheric and humid heat corrosion, and the thermal conductivity is approximately 130 W/m·K, suitable for high thermal conductivity applications such as heat exchangers, battery trays, and electronic heat sinks.

Application Fields of ER4043 Aluminum Welding Wire

Automotive & Trailer Bodies

Splicing and reinforcement of car body outer panels

Welding of trailer side walls and floor panels

Interfaces of fuel tanks and fuel pipelines

Ship Interior Panels & Honeycomb Curtain Walls

Cabin partitions and ceilings of ships

Bulkheads and door frames for ships

Splicing of honeycomb aluminum panels for building curtain walls

Bicycle / Motorcycle Frames

Main beam and cross beam of bicycle frames

Brackets and crash bars of motorcycles

Connection of electric scooter chassis

Casting Repair

Repair welding of blowholes in automotive engine blocks

Repair of shrinkage cavities in turbine housings and pump bodies

Restoration of local damage to molds

Pressure Vessels & Airtight Welding

Joints and flanges of hydraulic pipelines

Sealing of high-pressure gas storage tanks

Welding of cryogenic storage tanks

Why Choose Chalco?

Among many suppliers, Chalco ER4043 welding wire helps your projects proceed efficiently and ensures quality with the following four core advantages:

- Globally Certified Quality Production Lines: The factory is certified by ISO 9001 and IATF 16949 dual quality management systems, with an annual production capacity of 8,000 tons and full batch traceability.

- Ultra-High Precision and Moisture Protection: Wire drawing tolerance is strictly controlled within ±0.02 mm. Before leaving the factory, it undergoes vacuum drying and degassing, and is then packaged in aluminum foil composite bags to ensure long-term storage without moisture absorption.

- Ultra-Fast Delivery Capability: Common wire diameters ranging from Ø 0.8–4.0 mm are in stock, with a minimum order quantity starting from S100 (0.5 kg). All in-stock items are shipped to your door within 72 hours.

- One-Stop Technical Support: Enjoy 24-hour response from engineers upon placing an order, providing exclusive welding parameter guidance, base material comparison test plates, and COA/COC reports, truly achieving "online ordering, offline worry-free."

Click the "Get a Sample" button on the right to let our professional team quickly customize an ER4043 welding solution for you.

Instant Quote

Technical Reference for ER4043 Aluminum Welding Wire

Chemical Composition of ER4043 Aluminum Welding Wire

| Element | ER4043 |

| Si | 4.50 – 6.00 |

| Fe | 0.80 max |

| Cu | 0.30 max |

| Mn | 0.05 max |

| Mg | 0.05 max |

| Zn | 0.10 max |

| Ti | 0.20 max |

| Al | Balance |

| Others* | 0.15 total max |

Others*0.15 total max

Welding Positions for ER4043 Aluminum Welding Wire

ER4043 supports all-position welding (except for specialized vertical-down in-furnace welding). The six common posture diagrams are shown below:

2G Horizontal Welding

Weld axis is horizontal in a vertical plane, ensuring stable pool and easy penetration. Ideal for side joints on medium plates or continuous pipe-to-plate welding.

4G Overhead Welding

Welds beneath the workpiece, needing precise droplet control to avoid sagging. Used for floor panels, ceilings, and reverse structural welding.

3G Vertical Down Welding

Torch moves downward along the joint for fast welding. Best for thin sheets to increase speed, but demands precise control to avoid droplet sag.

2F Horizontal Fillet Welding

Welds corner joints between horizontal and vertical plates, filling angles with smooth beads for strength and appearance—common in frames and structures.

1G Flat Welding

Weld lies on a horizontal plane. Offers optimal penetration and bead width for long, straight seam welding and large-area fabrication.

3F Vertical Up Fillet Welding

Fills vertical corner joint bottom-up, ensuring uniform penetration and tie-in—ideal for reliable fillet welds on load-bearing parts.

Process Base Material Compatibility of ER4043 Aluminum Welding Wire

To ensure welding quality and weld reliability, Chalco ER4043 is recommended for use on the following aluminum alloy base materials, with notes on materials that are not recommended or require careful welding:

| Base material category | Recommended grades | Not recommended / use with caution |

| 1xxx series | 1060,1100 | — |

| 3xxx series | 3003,3004,3005 | — |

| 5xxx series | 5052 (Mg ≤ 2.5 %),5005 | 5083, 5456 (Mg > 3 %) |

| 6xxx series | 6061,6063,6082 | 6005A, 6101 (thin-wall weldable, high thickness requires preheating) |

| 7xxx series | 7005 | 7075, 7050 and other high Zn/Cu alloys |

| Casting alloy | A356,319,355,214 | Castings prone to thermal cracking (such as complex high-stress structural parts) |

Typical Mechanical Properties of ER4043 GTAW Butt Joint Welds

| BASE ALLOY | AS WELDED | POST WELD HEAT TREAT AND AGE | |||||||

| BASE ALLOY | UTS (KSI) | UYS (KSI) | ELONG (%) | UTS (KSI) | UYS (KSI) | ELONG (%) | UTS (KSI) | UYS (KSI) | ELONG (%) |

| 2014-T6 | 70 | 60 | 13 | 34 | 28 | 4 | 50 | -- | 2 |

| 6061-T4 | 35 | 21 | 22 | 27 | 18 | 8 | 352 | -- | 82 |

| 6061-T6 | 45 | 40 | 12 | 27 | 18 | 8 | 44 | 40 | 5 |

| 6063-T4 | 25 | 22 | 22 | 20 | 10 | 12 | 30 | -- | 13 |

ER4043 MIG/GMAW Technical Parameters

| Wire diameter (mm) / (") | Current range (A) | Voltage range (V) | Wire feed speed (ipm / m·min⁻¹) | Shielding gas | Gas flow rate (CFH) | Deposition rate (lb/hr / kg/hr) |

| 0.8 (0.030) | 60–170 | 13–24 | 150–350 (3.8–8.9) | 100 % Ar | 20–25 | 4–8 (1.8–3.6) |

| 0.9 (0.035) | 70–180 | 15–26 | 200–400 (5.1–10.2) | 100 % Ar | 20–25 | 5–9 (2.3–4.1) |

| 1.0 (0.040) | 90–290 | 15–26 | 250–450 (6.4–11.4) | 100 % Ar | 20–25 | 6–12 (2.7–5.4) |

| 1.2 (0.047) | 140–260 | 20–29 | 300–500 (7.6–12.7) | Ar + 25 % He | 25–30 | 9–15 (4.1–6.8) |

| 1.6 (1/16) | 190–350 | 25–30 | 350–550 (8.9–14.0) | Ar + 25 % He | 25–30 | 12–20 (5.4–9.1) |

ER4047 vs ER4043 vs 4943 – Selection Comparison of Aluminum-Silicon Filler Wires

| Comparison items | ER4047(Al-Si 12) | ERER4043(Al-Si 5) | ER4943(Al-Si 6.5-Mg 0.6) |

| Main alloying elements (wt %) | Si 11 – 13 | Si 4.5 – 6.0 | Si 6.3 – 7.0, Mg 0.45 – 0.9 |

| Solidus / liquidus ≈ °C | 532 / 571 | 566 / 582 | 565 / 574 |

| Pot fluidity | ★★★★☆ (highest) | ★★★☆ | ★★★☆ |

| Hot cracking tendency (weld 6xxx) | ★☆☆☆ (lowest) | ★★☆☆ | ★★☆☆ |

| Weld shrinkage | Minimum | Medium | Medium |

| Anodized color | Dark grey-black, maximum color difference | Light grey, easier to match the parent material | Between the two, with minimal color difference |

| Typical tensile strength (6061-T6 base metal, single pass / PWHT) | ~ 140 MPa/ 210 MPa | ~ 150 MP/ 220 MPa | ~ 170 MP/ 260 MPa |

| Shear strength (fillet weld) | Highest | High | High |

| Can be re-aged with 6xxx | No | No | Can be aged (Mg + Si) |

| Thermal / electrical conductivity | ★★★☆ | ★★★☆ | ★★☆☆ |

| Advantages | Lowest melting point | Most versatile | Significant improvement in post-weld strength |

| Typical applications | Excellent fluidity | Price friendly | Replaces 5356/ER4043 to reduce weight |

| Compatible with base metal | Preferred for brazing, hermetic sealing | Small color difference of decorative parts | High-strength welding of 6xxx structural parts |

- If you require airtight brazing, thin-walled heat exchangers, or crack-sensitive castings, choose ER4047.

- If you require general structural/decorative welding, cost sensitivity, and minimal color difference, consider ER4043.

- If you require high-strength 6xxx series or structural components needing PWHT for strength recovery, ER4047 can be an option for the root pass with a cap of ER4943 or ER5356.

Still hesitating? Tell me the base material grade, thickness, and target strength, and Chalco engineers will provide exclusive filler wire recommendations and welding parameter guidance within 24 hours.

Instant QuoteFAQ

I was originally using ER5356. Why should I consider ER4043 now?

ER5356 has a lower silicon content and higher magnesium content. Although it has slightly better strength, its melting point and shrinkage rate are higher, making it difficult to fill brazing gaps and increasing the risk of hot cracking. ER4043's balanced 5% Si formulation can significantly improve fluidity, reduce cracking, and produce light gray welds while retaining sufficient strength, making it suitable for scenarios with higher requirements for weld appearance and airtightness.

When anodizing after welding, the weld color is always darker than the base material. How can I minimize this?

4043 itself has fewer precipitates and does not easily form a dark oxide layer. However, to make the color difference imperceptible to the naked eye, you can:

Choose a formulation with a lower silicon content (4.5% lower limit).

Anodize the entire part together after welding or apply uniform local spraying.

For fillet welds, use a dual-wire approach with 4043 for the root pass and 5356/4943 for the outer layer to balance airtightness and color difference.

Our factory has high humidity in winter. I'm worried about the welding wire absorbing moisture and causing porosity. How should it be stored?

Chalco ER4043 is vacuum-dried, packaged in aluminum foil bags, and comes with a desiccant. Before opening, it can be stored at room temperature for 12 months. After opening, it is recommended to use it within 30 days. If it exceeds this period, brief heating (120 °C × 2 h) or secondary vacuum pumping can restore its low hydrogen characteristics.

Can ER4043 weld 5xxx series alloys with Mg content >3% (such as 5083)?

Not recommended. 5xxx series alloys with Mg >3% will form brittle Mg₂Si phases with Si, leading to a high risk of hot cracking and porosity. If it is necessary, you can: first use ER5356/ER5556 for root pass compensation, and then use ER4043 for the surface pass; or use preheating + multi-pass procedures to strictly control heat input.

The post-weld strength is only 60–70% of the base material. Is solution aging necessary?

ER4043 is a non-aging alloy, so it can be used after welding without heat treatment. However, if higher strength is desired, consider using 4943 as an overlay and performing short-term T6 aging, or choose the ER4047 + 4943 dual-wire approach to balance sealing and strength.

We only want a small number of samples to verify the process. What is the minimum order quantity and delivery time?

Chalco supports small batch sampling of 0.5 kg (S100) or 1 kg TIG straight rods for verification. Regular stock items are shipped within 72 hours. We also provide your process window parameters, comparison test plates, and quality inspection reports for free, allowing you to "test in small quantities and put into production quickly."

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote