Copper clad aluminum is a bimetallic conductor that permanently bonds a layer of copper onto an aluminum core.

It combines the excellent conductivity of copper with the lightweight advantages of aluminum.

Compared to pure copper, it cuts material costs by over 40% and significantly reduces weight—making it an idealalternative for power, telecom, and new energy applications.

Contact us for copper clad aluminum solutions

- Free sample support to help you verify quality before ordering.

- Fast response—standard products quoted within 24 hours.

- Flexible OEM/ODM services to meet diverse project needs.

- Full-process follow-up from selection to delivery for a smoother, worry-free purchase.

Send us your specifications or drawings—we'll get back to you quickly with expert advice and a precise quote.

Instant QuotePopular copper clad aluminum products

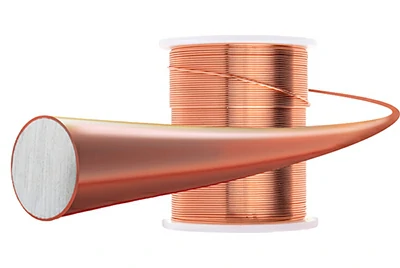

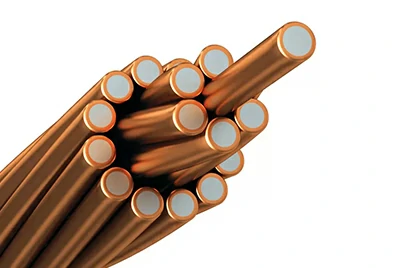

Copper Clad Aluminum Wire (CCA)

CCA wire has an aluminum core with 10% or 15% copper.It’s lightweight, highly conductive, and easier tosolder than pure copper.

Contact us now

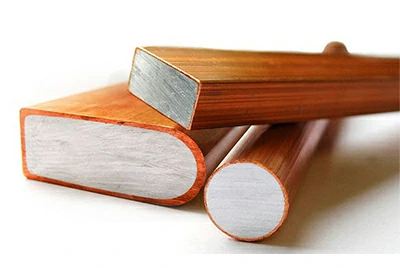

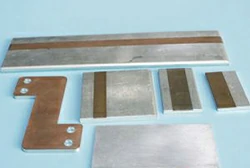

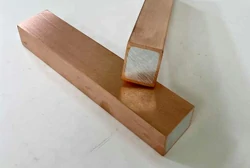

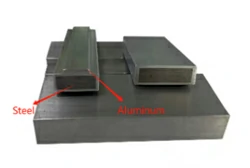

Copper Clad Aluminium Busbar CCA

CCA busbar is made by extruding a solid aluminum core with a high-conductivity copper layer.It combinesthe strengths of both metals—high conductivity with reduced weight.

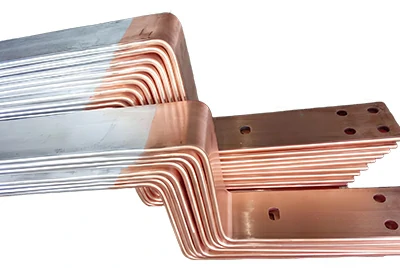

Contact us nowCopper Aluminum Transition Busbar

Copper-aluminum transition products prevent galvanic corrosion in power equipment and come inside-by-side or embedded structures, with customizable sizes from 0.2mm to 20mm thick.

Contact us now

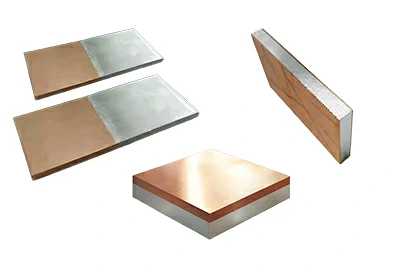

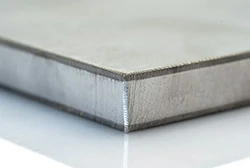

Copper clad aluminum plate offers over 92% conductivity, excellent strength, heat and corrosionresistance, and cost savings up to 64% compared to pure copper.

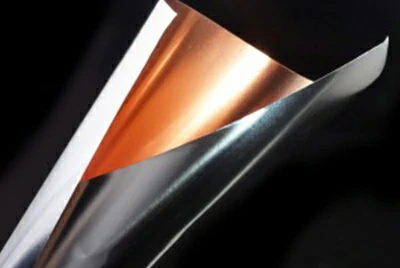

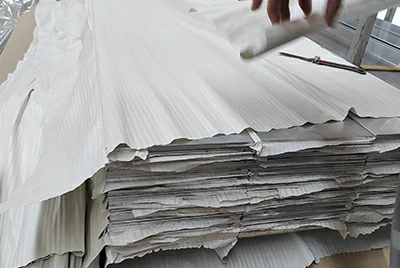

Contact us nowCopper clad aluminum strip delivers high conductivity, flexibility, and corrosion resistance withsignificant weight and cost savings.

Contact us now

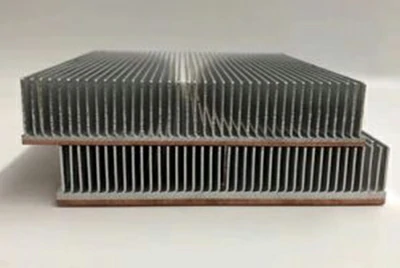

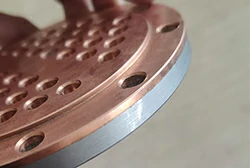

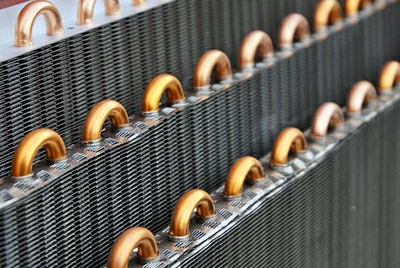

Copper Aluminum Heat Sink

Copper-aluminum heat sinks combine copper’s high thermal conductivity with aluminum’s lightweight,offering efficient and cost-effective cooling solutions.

Contact us nowCopper-Aluminium Bimetal Clad Cable Lugs

Copper-aluminium bimetal clad cable lugs ensure reliable conductivity and corrosion resistance foraluminum-copper cable transitions.

Contact us now

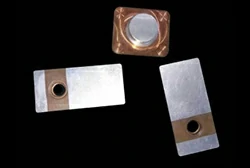

Copper-Aluminium Bimetal Clad Washer

This washer bonds copper and aluminum sides to ensure conductivity and prevent galvanic corrosion.

Contact us nowEnameled CCA wire combines the light weight of aluminum with the conductivity of copper and highinsulation performance, ideal for coils, motors, and transformers.

Contact us now

Copper clad aluminum cable offers high conductivity with reduced weight and lower cost.

Contact us nowCombining high conductivity and light weight, it's widely used in battery current collectors, EMIshielding, and flexible circuits.

Contact us now

We offer a wide range of copper-aluminum products and support custom solutions—contact us to discuss your specificrequirements.

Copper Aluminum Flexible Connector

High Speed Rail Grounding Block

Custom Shaped Copper Aluminum Composite

Copper Clad Aluminium Row

Copper Clad Aluminum Earthing Block

Copper Clad Aluminum Earthing Boss

Copper-Aluminum Composite Plate and Tube

Copper Aluminum Bimetallic Connector

Copper Aluminum Bimetallic LiB Terminal

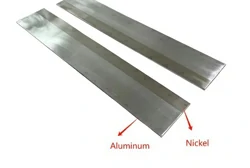

In addition to copper-aluminum composites, we offer a wide range of bimetallic products and accept custom orders ofall kinds.

Instant Quote

Aluminum-clad nickel

Nickel-clad copper

Aluminum-clad steel

Aluminum-clad titanium

Copper Aluminum Bimetal

Nickel Clad Steel

Product advantages: copper clad aluminum, the ideal balance of performance and cost

Choosing Copper Clad Aluminum means achieving the perfect balance between performance, cost, and efficiency:

- The copper layer provides stable conductivity, meeting the high electrical demands of power and electronicsapplications.

- Compared to pure copper, CCA is about 40% lighter, making it ideal for projects requiring weight reduction, suchas in new energy, automotive, and aerospace industries.

- Material costs are significantly lower than pure copper for the same volume, making it ideal for large-scaleprocurement and budget control.

- The aluminum core offers excellent mechanical strength and ductility, suitable for further processing such asbending and stamping.

- Supports various processing methods, including cutting, stretching, stamping, and surface treatment, adaptableto different product structures.

Copper clad aluminum applications

Copper Clad Aluminum, with its excellent conductivity, lightweight properties, and cost-effectiveness, is widelyused across multiple key industries.

We can customize copper clad aluminum solutions based on your application needs—contact us today to get started.

Instant QuotePower Systems

Used in cable conductors, busbars, and similar applications, it reduces wiring burden and material costswhile meeting high current carrying demands.

Contact us now

Telecommunication Equipment

Commonly used in coaxial cables, signal connection wires, and similar structures, the copper layerensures stable high-frequency transmission, while the aluminum core effectively reduces system weight.

Contact us nowNew Energy Vehicles

Used for battery tabs and conductive rails, such as copper clad aluminum wire for automotive, meetingthe dual demands of lightweight design and reliable conductivity.

Contact us now

HVAC & Heat Exchange

Copper-aluminum composite tubes offer excellent thermal conductivity, making them suitable for airconditioning condenser systems, heat dissipation modules, and more.

Contact us nowConsumer Electronics

Used in flexible circuit boards, connectors, and other precision electronic components, achieving theperfect integration of conductivity and mechanical performance.

Contact us now

Lithium Battery Manufacturing

Used as current collectors, such as copper clad aluminum battery cable, providing stable connections forpower batteries and improving energy conversion efficiency.

Contact us nowCopper Clad Aluminum Manufacturing Processes

Roll bonding

Suitable for continuous products such as strips, busbars, and foils, copper and aluminum are firmly bonded underhigh temperature and pressure, ensuring a uniform and dense bonding surface, ideal for large-scale, high-efficiencyproduction.

Explosive welding

Uses explosive shock waves to create instant high pressure, achieving molecular-level bonding between copper andaluminum.

This process provides extremely high bonding strength and is widely used for thick plates, structural components,and applications requiring high reliability.

Diffusion bonding

Involves high temperature and pressure in a vacuum or inert atmosphere to allow copper and aluminum atoms tointerdiffuse.

This results in a clean interface, making it ideal for industries with high corrosion resistance and long-termstability requirements (such as new energy and battery connections).

Co-extrusion

Copper and aluminum cores are simultaneously extruded through a mold, ideal for producing copper-clad aluminum wireand busbars, offering dense bonding and high extrusion efficiency.

Copper-Aluminum composite processing guide

Cutting

Saw cutting is recommended with fine-tooth blades and proper cooling. For punch cutting, use flat dies and keep theworkpiece level.

Drilling & Punching

Ensure proper die clearance to avoid burrs or delamination. Use multi-hole dies with stripper plates for multipleholes.

Support the workpiece when drilling, exit slowly, and apply coolant.

Bending

Follow the recommended bend radius, and adjust the die’s R angle based on thickness. Avoid sharp corners or folds toprevent conductivity issues.

Welding

Strip the copper layer to expose the aluminum before welding. Use AC TIG welding, followed by sandblasting andcopper thermal spraying.

Riveting

Use extended rivets. The hole diameter should be 0.15–0.2 mm smaller than the rivet.

Surface Treatment

Passivation and plating options include zinc, nickel, and silver. Protect exposed aluminum ends before acidtreatment to avoid corrosion.

Fastening

Use oversized washers and apply moderate torque to bolts.

Why Choose Chalco?

In the field of copper clad aluminum materials, we not only provide high-quality products but also strive to createlong-term, stable cooperation value for our customers:

High-quality bonding technology

We use advanced processes such as roll bonding, explosive welding, and diffusion bonding to ensure strong bondingand stable performance, certified by quality systems like ISO 9001.

Full range of specifications and custom solutions

We offer various forms including wire, strip, busbar, plate, and foil. Custom sizes, thicknesses, copper-aluminumratios, and surface treatments are available to meet specific industry needs.

Extensive export experience, serving global clients

We have established long-term partnerships with clients in North America, Europe, South America, the Middle East,and Southeast Asia.

We understand different national standards and packaging requirements, ensuring reliable delivery and efficientcommunication.

Original material reports and technical support

Each batch comes with an original material certificate (MTC). Third-party testing (e.g. SGS) is available uponrequest, along with technical support to assist with material selection and application, helping to drive projectsuccess.

Whether you're a large-scale power engineering contractor or a precision electronics component manufacturer, weprovide professional, efficient, and reliable copper-aluminum composite material solutions.

Instant QuoteTrusted by global partners

We are proud to be a trusted copper-aluminum solution provider for leading companies and contractorsworldwide—especially in power transmission, battery, and industrial sectors:

- ABB – global leader in electrification and automation

- Schneider Electric – advanced energy management solutions

- Siemens – power systems and smart infrastructure

- International cable manufacturers and EPC contractors across North America, Europe, Southeast Asia, and theMiddle East.

Transportation and packaging: safe, reliable, and worry-free global shipping

To ensure the surface integrity and dimensional stability of copper clad aluminum products during transportation, wehave established strict packaging standards:

- All products are wrapped with waterproof plastic film and foam padding for multi-layer protection, effectivelypreventing moisture, impact, and scratches.

- Products are cut to customer specifications, with labels including alloy grade, dimensions, batch number, andmore for easy identification and warehouse management.

- Bulk exports are packed in wooden boxes or pallets that meet international shipping standards, reinforced withstraps and stretch film, suitable for sea, air, or land transportation.

- We offer customized packaging solutions, including logo-branded packaging film, anti-counterfeit labels, andbarcode systems to enhance brand image and supply chain efficiency.

Frequently asked questions (FAQ)

Does copper clad aluminum oxidize easily?

Our copper clad aluminum products undergo strict interface bonding and anti-oxidation treatments, ensuring a denseand stable bond.

In dry or normal environments, electrochemical corrosion does not occur, making them ideal for long-term use inelectrical systems.

How does it compare to pure copper conductors in performance?

Copper clad aluminum achieves 85%–92% of the conductivity of pure copper but is lighter and more cost-effective.

It can fully replace pure copper in most electrical and telecom applications, making it ideal for customers seekingboth conductivity, lightweight design, and cost savings.

Do you offer custom sizes and copper-aluminum ratios?

Yes, as an experienced copper clad aluminum wire manufacturer, we offer custom wire diameters, thicknesses, copperlayer ratios, lengths, and other parameters to meet the unique needs of various projects.

What is the minimum order quantity (MOQ)?

We offer flexible MOQ options, with standard products available for orders as low as a few hundred kilograms.

MOQ for custom products depends on specifications, materials, and processes. Please contact us for exact details.

What is the copper clad aluminum wire price?

Prices vary depending on the copper layer thickness, product form (wire, strip, busbar), alloy type, and orderquantity.

Send us your specifications, and we will provide an accurate quote within 24 hours.