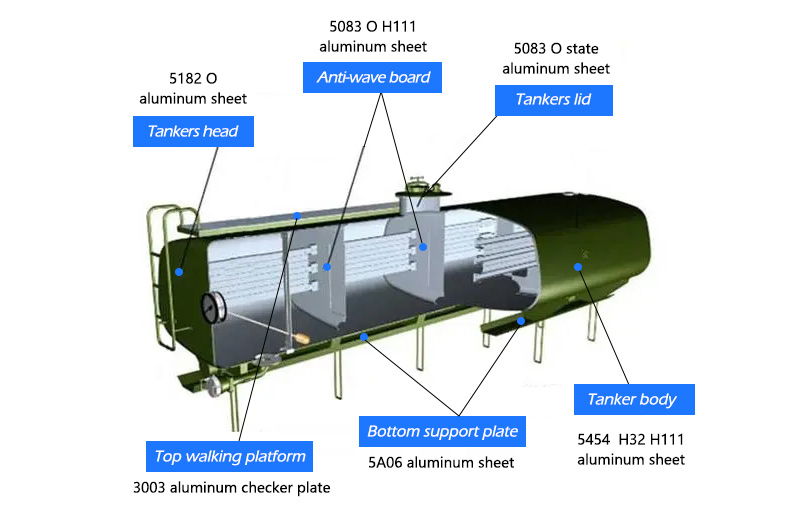

Aluminum alloys are widely used in modern tanker trucks for weight reduction, durability, and international compliance. Compared with steel, aluminum tankers carry more payload and require less maintenance.

Chalco supplies a full range of materials for tanker manufacturing—plates, tubes, bars, profiles, and CNC machined parts. With stock and custom sizes, global delivery, and certified quality, we provide reliable aluminum solutions for fuel, chemical, and gas transportation.

Tanker Aluminum Alloy Grades Supplied by Chalco

-

5083 Tanker Aluminum Alloy

Can be used in nearly all parts of the tanker body, including tank barrels, gas cylinders, and LNG storage tanks.

O, H111, H116, H321

-

5182 Tanker Aluminum Alloy

High-Mg alloy meeting ADR requirements; used for dangerous goods transportation tankers and end plates/heads.

O, H111

-

5454 Tanker Aluminum Alloy

Mainly for oil & gas tankers; maintains strength at higher service temperatures with stable corrosion resistance.

O, H111

-

5754 Tanker Aluminum Alloy

Used for side and bottom plates of oil tankers and chemical liquid transportation vehicles.

O, H111

-

5383 Tanker Aluminum Alloy

High-strength option mainly used as tank body plate for transporting liquid goods.

O, H111, H116, H321

-

5086 Tanker Aluminum Alloy

Applied in freshwater oil tankers and environments with relatively lower corrosion demands.

O, H111

-

3003 Checkered Tanker Aluminum Alloy

Anti-slip and decorative surface; suitable for walkways and operating platforms on tanker bodies.

-

5052 Tanker Aluminum Alloy

Often used for manufacturing fuel tank plates and auxiliary components; good formability.

O, H114

-

5059 Tanker Aluminum Alloy

For harsh service: pressure vessels, chemical storage tanks, and other high-strength sections.

O, H111, H112

-

5088 Tanker Aluminum Alloy

Good bending strength and corrosion resistance; used in structural parts of the tank body.

O, H111

-

5186 Tanker Aluminum Alloy

High bending strength and corrosion resistance; ideal for side and bottom plates.

-

6061 Tanker Aluminum Alloy

Can be stamped/machined for internal partitions and interior components; good overall machinability.

-

7075 Tanker Aluminum Alloy

Used at critical connection points and components requiring very high strength.

-

5356 Tanker Welding Alloy

Widely used filler alloy for tanker body welding; offers high strength and corrosion resistance, suitable for 5xxx series plates.

Wire Ø1.6–5.0mm, coils or rods

-

5183 Tanker Welding Alloy

High-strength welding alloy for joining 5083, 5383 and other high-Mg plates; ensures excellent toughness and seawater resistance.

Wire Ø1.2–5.0mm, ABS/DNV certified

Chalco processes these tanker alloys into a wide range of product forms, including plates, tubes, bars, and profiles, with optional CNC machining to meet different tanker applications.

Tanker Aluminum Plates

For tanker truck manufacturing, Chalco mainly supplies plate products made from 5083, 5182, 5454, 5754, 5383, 5086, and 5059 alloys. These alloys are widely recognized in the industry for their corrosion resistance, strength, and compliance with ADR and DOT standards.

Applications: Tank body shells, bulkheads, anti-wave plates, end plates, side and bottom plates, and fuel tank panels.

Chalco Supply Advantages:

- Thickness range: 4.0–10.0 mm, width up to 2650 mm; Click to check the aluminum tanker plate stock

- Available tempers: O, H111, H116, H321, H114

- Certified to EN 10204 3.1, with SGS, DNV, BV reports available

- Stock and custom sizes, global delivery with export packaging

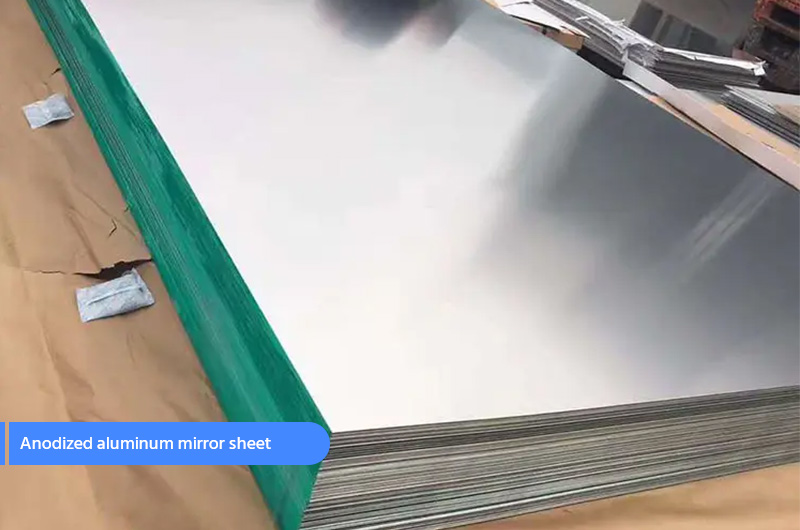

- In addition to standard plates, Chalco also produces special tanker plates such as mirror high-reflection plates, ultra-wide plates, porous aluminum foam plate, and 3003 checkered anti-slip plates.

Lightweight, energy-absorbing foam panels for noise/vibration damping and thermal buffering in tanker compartments.

Aluminum Checkered Plate

Anti-slip tread sheets for tanker walkways and platforms, offering durable traction and easy cleaning.

Mirror Finish Aluminum Plate

High-reflection plates to lower tank surface heat gain and reduce fuel evaporation, with consistent cosmetic appearance.

Explore Chalco's full range of tanker aluminum plate available stock or request a quick quote today.

Tanker Aluminum Tubes

Chalco processes the listed tanker alloys into high-quality aluminum tubes for fuel loading/unloading lines, vent/return pipes, and onboard piping systems. Common tube alloys: 5083 (corrosion-resistant service) and 6061 (strength + machinability), with tempers such as O, H112, T6.

Applications: Fuel transfer and delivery lines, vent, breather and return lines, as well as piping for measurement, drainage and auxiliary circuits.

Chalco Supply Advantages:

- Seamless and extruded tubes, straight lengths or cut-to-size

- Typical capability: OD 20–500 mm, wall 2–20 mm (custom on request)

- Tempers for tanker service: O / H112 / T6; EN 10204 3.1 certification available

- CNC support: precision cutting, drilling, beveling; simple end prep for welding and assembly

Aluminum tube for fuel delivery systems

Aluminum tube for vent and breather lines

Aluminum tube for measurement and drainage lines

Contact Chalco today to get a quick quote for tanker aluminum tubes tailored to your specifications.

Tanker Aluminum Bars

Chalco supplies aluminum bars in tanker-grade alloys such as 5182, 6061, and 6082, available as round, square, and flat bars. These bars are widely used for reinforcement ribs, connectors, and support structures in tanker manufacturing.

Applications: Reinforcement ribs and stiffeners for tanker bodies, connectors and couplings, as well as support brackets and welded assemblies.

Chalco Supply Advantages:

- Forged and extruded bar products in stock and custom dimensions

- Typical diameters from 10–500 mm

- Tempers available: O, H112, T6, T651

- CNC machining options for cutting, drilling, and surface finishing

All bar products are supplied on a made-to-order basis. Request a custom quote today for your tanker aluminum bar needs.

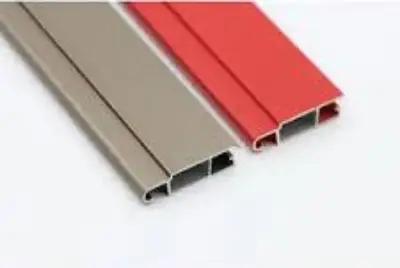

Tanker Aluminum Profiles

Chalco produces aluminum profiles for tanker manufacturing in alloys such as 6061 and 6063. These profiles are extruded into customized shapes and dimensions to support structural and accessory parts of tanker trucks.

Applications: Ladders and guardrails, frames and edge reinforcements, as well as accessory components and safety fittings.

Chalco Supply Advantages:

- Custom extrusions available in L-shape, U-shape, T-slot, and other profiles to meet specific tanker design requirements

- Alloy options: 6061 / 6063 with O, T5, T6 tempers

- Surface finishes: anodizing, powder coating, polishing

- CNC machining support: cutting, drilling and simple fabrication

All profiles are supplied on a custom-made basis. Contact Chalco to discuss your tanker aluminum profile requirements.

Machined Tanker Parts

In addition to plates, tubes, bars and profiles, Chalco also provides machined parts made from tanker-grade aluminum alloys. With in-house CNC capabilities, we can deliver semi-finished and finished components according to customer drawings.

Applications: Flanges and pipe joints, custom brackets and mounting parts, as well as simple partitions, covers and structural fittings.

Chalco Machining Advantages:

- CNC cutting, drilling, beveling and light milling

- Custom dimensions and tolerances based on customer design

- Integration with plate, bar, and profile supply for one-stop service

- Inspection and export-ready packaging available

All machining work is carried out upon request. Send your drawings to Chalco and get a tailored machining solution for tanker parts.

One-Stop Tanker Aluminum Solutions

- Advanced SMS rolling mill ensures wide-width plates up to 2650mm with optional surface finishes such as embossing, patterning, polishing, or mirror treatment.

- Complete range of extrusion dies for tanker profiles, with in-house mold development to reduce costs and support customized cross-sections.

- Full welding capability including TIG, MIG, FSW, and EBW processes, supported by matching filler rods and MIG wires for complete joint solutions.

- Integrated supply covering alloys, plates, profiles, welding consumables, machining, and assembly—backed by certified production lines and global delivery.

Partner with Chalco for reliable tanker aluminum solutions from raw material to finished assembly.

Specification of Chalco aluminum products for tank truck

| Alloy | 5083 5454 5182 3003 6061 6063 |

| Welding wire | ER5183 ER5356 |

| Aluminum plate thickness | 3--10mm |

| Aluminum plate width | 1000---2650mm |

| Aluminum plate length | 2000---16000mm |

| Aluminum profile product shape | L type, T type, round tube, triangular beam etc. |

| Surface treatment | Mill finish, bright mirror finish |

| Tanker material aluminum thickness | 6mm,5mm |

| Bulkhead and baffle thickness | 7mm |

| Tanker shell thickness | 6mm & 5mm |

| Shape of tanker Ellips | double "d" |

| Manhole 20" aluminum alloy manhole cover | C801-560 |

Chalco tank truck aluminum material parameter table

| Element | Chemical composition (%) | |||||

| 5083 | 5454 | 5182 | 3003 | 6061 | 6063 | |

| Si | 0.40 | 0.25 | 0.60 | 0.20 | 0.40--0.80 | 0.20--0.60 |

| Fe | 0.40 | 0.40 | 0.70 | 0.35 | 0.70 | 0.35 |

| Cu | 0.10 | 0.10 | 0.05--0.20 | 0.15 | 0.15--0.40 | 0.10 |

| Mn | 0.40--1.00 | 0.50--1.00 | 1.00--1.50 | 0.20--0.50 | 0.15 | 0.10 |

| Mg | 4.0--4.9 | 2.4--3.0 | --- | 4.0--5.0 | 0.80--1.20 | 0.45--0.90 |

| Cr | 0.05--0.25 | 0.05--0.20 | --- | 0.10 | 0.04--0.35 | 0.10 |

| Ni | --- | --- | --- | --- | --- | --- |

| Zn | 0.25 | 0.25 | 0.10 | 0.25 | 0.25 | 0.10 |

| Ti | 0.15 | 0.20 | --- | 0.10 | 0.15 | 0.10 |

| Al | Remainder | Remainder | Remainder | Remainder | Remainder | Remainder |

| Mechanical Property | ||||

| Alloy | Temper | Tensile strength Rp0.2/MPa | Yield strength Rm/MPa | Elongation A50mm/% |

| 5083 | O/H111 | 290--370 | ≥145 | ≥17 |

| 5454 | O/H111 | 215--285 | ≥85 | ≥19 |

| 5182 | O/H111 | 280--350 | ≥125 | ≥26 |

| 3003 | H14/H24 | 145--185 | ≥125 | ≥4 |

| 6061 | T4 | 180 | 110 | 13 |

| T5 | 240 | 205 | 7 | |

| T6 | 260 | 240 | 8 | |

| 6063 | T4 | 130 | 65 | 12 |

| T5 | 160 | 110 | 5 | |

| T6 | 215 | 170 | 6 | |

Available Stock Dimensions of Tanker Aluminum Plates & Coils

| Available Stock Dimensions of Tanker Aluminum Plates & Coils | |||

| Product | Alloy | Temper | Size (W × L, mm) |

| Medium Thick Plate | 5182 | O | 5.5 × 1900 × 6600 |

| Medium Thick Plate | 5182 | O | 10 × 1500 × 6000 |

| Medium Thick Plate | 5182 | O | 5.5 × 2620 × 2650 |

| Medium Thick Plate | 5182 | H111 | 10 × 1600 × 6000 |

| Medium Thick Plate | 5182 | O | 8 × 2580 × 5160 |

| Medium Thick Plate | 5182 | O | 5.5 × 2580 × 2880 |

| Medium Thick Plate | 5059 | H111 | 5.5 × 2000 × 6772 |

| Medium Thick Plate | 5059 | H111 | 5.5 × 2000 × 7400 |

| Medium Thick Plate | 5059 | H111 | 5.5 × 1400 × 7830 |

| Medium Thick Plate | 5059 | H111 | 5.5 × 2000 × 7830 |

| Medium Thick Plate | 5059 | H111 | 5.5 × 2000 × 6960 |

| Medium Thick Plate | 5088 | O | 7 × 2000 × 2950 |

| Medium Thick Plate | 5454 | H111 | 5.6 × 2520 × 10100 |

| Medium Thick Plate | 5454 | H111 | 5.6 × 2520 × 10900 |

| Hot Rolled Coil | 5182 | H111 | 5.5 × 2520 × C |

| Hot Rolled Coil | 5182 | O | 6 × 2390 × C |

| Hot Rolled Coil | 5182 | H111 | 6 × 2200 × C |

| Hot Rolled Coil | 5454 | O | 6 × 2000 × C |

Tips for purchasing and using aluminum plates for tank trucks

1.Welding is very important for the manufacturing of tank cars. How to avoid welding failure?

Welding failure may lead to leaks and structural issues. Problems such as incomplete penetration, porosity, and improper welding techniques may damage the integrity of the storage tank. Choosing the correct welding material is the primary condition for successful welding. Chalco ER5183 and ER5356 can fully meet the welding requirements and have a price advantage, reducing production costs for customers.

2.How to minimize the problem of tank body corrosion in tank trucks?

Tank trucks are usually used to transport goods such as oil, gas, and hazardous chemicals, so they have high requirements for corrosion resistance. When selecting aluminum plates, manufacturers should not only pay attention to selecting 5000 series corrosion-resistant alloys, but also choose partners with quality requirements that meet the standards, in order to strive for long-term cooperation and avoid unnecessary losses caused by substandard quality.

3.How to avoid cracking of aluminum plates during the production of tank cars?

Due to the special nature of transporting goods, tank trucks must avoid problems such as tank body cracks. This requires aluminum plates to have strong resistance to stress cracking. The Chalco cold rolling project adopts a German Simark six high cold rolling mill, which eliminates internal stress and does not deform during cutting, effectively avoiding cracking issues.

4.Why do tank car manufacturers increasingly favor using aluminum plates as the production material for tank cars?

With the demand for lightweight vehicle bodies and the requirements for corrosion resistance, weldability, heat dissipation, and surface treatment methods of tank car body materials, aluminum alloys are increasingly used in the field of tank car manufacturing, greatly reducing fuel utilization. And aluminum, as a recyclable material, can be used in tank cars using aluminum products, which can effectively save energy and protect the environment.

5.Need welding and CNC processing?

Welding, deep-draw, stamping, and rolling forming are all important steps in the production and processing of aluminum plates. Chalco not only provides tank car aluminum plates, but also provides additional services such as welding, cutting, and CNC processing, providing overall solutions for customer projects.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote