We offer a ready-die program for aluminum round bars designed for volume production and fast delivery. Side lengths cover 6.35–250 mm (inch / metric), with a focus on 6000 series alloys such as 6061 / 6082 / 6063 / 6005A. Paired with a 12,500 T extrusion press, we can stably produce large cross-sections and long lengths, and pre-process them so they are machine-ready (cut-to-length, chamfered, two- or four-side milling) to reduce preparation steps and waiting time.

- No Tooling Cost – Production using existing dies saves USD 300–1,500 per set

- Faster Delivery – Skip die development and trial runs; samples ship in as fast as 7–14 days

- Stable, Proven Dies – Avoid early-stage defects such as eccentricity, cracking, or poor forming

Download Aluminum Round Bar Mold List (PDF)

Aluminum Round Bar Mould Size Table

-

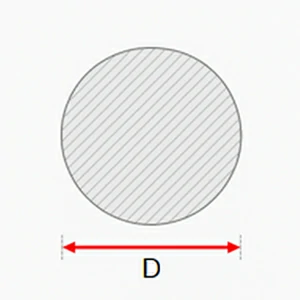

Standard aluminum round bar features a solid circular cross-section with diameter defined by outer diameter (D). Chalco supplies full-size coverage from Φ4–350 mm, available as extruded finished bars or as blanks for cold drawing, precision turning, or grinding.

Supported alloys include 6061, 6063, 6082, 6005A, 7075, 2011, 2014, 5083, selected based on required strength, machinability, or corrosion resistance, with matching tempers available.

Standard aluminum round bar features a solid circular cross-section with diameter defined by outer diameter (D). Chalco supplies full-size coverage from Φ4–350 mm, available as extruded finished bars or as blanks for cold drawing, precision turning, or grinding.

Supported alloys include 6061, 6063, 6082, 6005A, 7075, 2011, 2014, 5083, selected based on required strength, machinability, or corrosion resistance, with matching tempers available.

| Diameter (mm) | Linear Weight (Kg/m) | Alloy | Diameter (mm) | Linear Weight (Kg/m) | Alloy |

| 4 | 0.034 | 6082 | 80 | 14.074 | 5083-H112 |

| 5 | 0.053 | 6060-T66 | 80 | 14.074 | 7075-T6 |

| 5 | 0.053 | 1070 | 80 | 14.171 | 2011-T6/7075-T6 |

| 6 | 0.076 | 6060-T66 | 80 | 13.623 | 6082-T6 |

| 6 | 0.076 | 6063 | 81 | 13.913 | 6082-T6 |

| 6.1 | 0.079 | 6061-T6 | 82 | 14.259 | 6082-T6 |

| 6.35 | 0.088 | 6063 | 82.55 | 14.504 | 6061-T6511 |

| 7.94 | 0.134 | 6061-T6511 | 85 | 15.321 | 6082-T6 |

| 8 | 0.136 | 6060-T66 | 85 | 16.029 | 2011-T6/7075-T6 |

| 8.1 | 0.139 | 6063-T6 | 85 | 15.378 | 6082-T6 |

| 9.53 | 0.193 | 6061-T6 | 88.9 | 16.759 | 6061-T6 |

| 9.6 | 0.195 | 6063-T6 | 88.9 | 16.821 | 6061-T6511 |

| 10 | 0.212 | 6060-T66 | 90 | 17.177 | 6082-T6 |

| 10 | 0.212 | 6082-T6 | 90 | 17.244 | 6082-T6 |

| 10.5 | 0.234 | 6061-T6 | 90 | 17.311 | 5083-H112 |

| 10.7 | 0.243 | 6061-T6 | 90 | 17.950 | 7075-T6 |

| 11.7 | 0.293 | 6063 | 90 | 17.961 | 2011-T6/7075-T6 |

| 12 | 0.305 | 6060-T6 | 90 | 17.241 | 6082-T6 |

| 12 | 0.305 | 6082-T6 | 91 | 17.560 | 6082-T6 |

| 12 | 0.305 | 6061-T6 | 92 | 17.949 | 6082-T6 |

| 12 | 0.305 | 6063 | 95 | 19.138 | 6082-T6 |

| 12.7 | 0.343 | 6063 | 95 | 20.000 | 2011-T6/7075-T6 |

| 13.49 | 0.386 | 6262-T6511 | 95 | 19.340 | |

| 13.6 | 0.392 | 6061-T6 | 95.25 | 19.239 | 6061-T6511 |

| 14 | 0.416 | 6060-T6 | 97.2 | 20.035 | 440*260 |

| 14 | 0.416 | 6082-T6 | 100 | 21.206 | 6082-T6 |

| 14.29 | 0.433 | 6061-T6511 | 100 | 21.354 | 5083-H112 |

| 14.88 | 0.470 | 6005-T6 | 100 | 22.146 | 7075-T6 |

| 15 | 0.477 | 6082-T6 | 100 | 22.156 | 2011-T6/7075-T6 |

| 15 | 0.479 | 6082 T6 | 100 | 21.284 | 6082-T6 |

| 15.88 | 0.537 | 6061-T6511 | 101.6 | 21.890 | 6061-T6511 |

| 15.9 | 0.534 | 6061-T6511 | 101.6 | 21.971 | 6061-T6511 |

| 16 | 0.543 | 6060-T66 | 102 | 22.062 | 6082-T6 |

| 16 | 0.545 | 6005T5 | 103 | 22.497 | 6110A-T1 |

| 16.46 | 0.574 | 6262-T6511 | 104.775 | 23.279 | 6061-T6511 |

| 18 | 0.690 | 6063 | 105 | 23.379 | 6082-T6511 |

| 19 | 0.766 | 6082/6061 | 105 | 24.430 | 2011-T6/7075-T6 |

| 19.05 | 0.772 | 6061-T6511 | 107.95 | 24.711 | 6061-T6511 |

| 20 | 0.848 | 6061-T6 | 110 | 25.659 | 6082-T6 |

| 20 | 0.848 | 6063 | 110 | 25.764 | 6082-T6 |

| 21 | 0.935 | 6061-T6 | 110 | 25.846 | 5083-H112 |

| 22 | 1.030 | 6082-T6 | 110 | 26.800 | 7075-T6 |

| 23.00 | 1.122 | 6061 | 111.125 | 26.186 | 6061-T6511 |

| 23.81 | 1.202 | 6061-T6511 | 114.3 | 27.704 | 6061-T6511 |

| 24 | 1.267 | 2007-T4511 | 114.3 | 27.807 | 6061-T6511 |

| 24.3 | 1.252 | 6061-T6 | 115 | 28.045 | 6082-T6 |

| 25 | 1.330 | 6063 | 115 | 29.290 | 7075-T6 |

| 25.4 | 1.373 | 7075 | 115 | 28.154 | 6082-T6 |

| 25.4 | 1.373 | 6061-T6511 | 117 | 29.029 | 6082-T6511 |

| 26 | 1.434 | 6061-H112 | 120 | 30.536 | 6082-T6 |

| 26.19 | 1.476 | 6061-T6 | 120 | 30.651 | 6082-T6 |

| 26.5 | 1.489 | 120 | 30.740 | 5083-H112 | |

| 27 | 1.546 | 120 | 31.880 | 7075-T6 | |

| 28 | 1.663 | 120.65 | 30.868 | 6061-T6511 | |

| 28.4 | 1.710 | 6061-H112 | 120.65 | 30.982 | 6061-T6511 |

| 29 | 1.783 | 6082-T6 | 125 | 33.134 | 6082-T6 |

| 29 | 1.783 | 6061-T6 | 125 | 34.637 | 2011-T6/7075-T6 |

| 30 | 1.909 | 6110A-F | 125 | 33.293 | 6082-T6 |

| 30 | 1.909 | 6063 | 127 | 34.203 | 6061-T6511 |

| 31 | 2.038 | 6061-T6 | 127 | 34.329 | 6061-T6511 |

| 31 | 2.038 | 2014A T4 | 130 | 35.838 | 6061-T6 |

| 31.75 | 2.146 | 6082-T6 | 130 | 36.003 | 6082-T6 |

| 32 | 2.171 | 6082-T6 | 130 | 36.114 | 5083-H112 |

| 32 | 2.180 | 6082-T6 | 130 | 37.450 | 7075-T6 |

| 33 | 2.309 | 2014A T4 | 133.35 | 37.709 | 6061-T6511 |

| 33 | 2.395 | 2007-T4511 | 135 | 38.819 | 6082-T6 |

| 33 | 2.309 | 6082-F | 135 | 38.647 | 6101-T6 |

| 34.925 | 2.587 | 6082-T6 | 137 | 39.801 | 6082-T6 |

| 35 | 2.713 | 2011-T6/7075-T6 | 139.7 | 41.385 | 6061-T6511 |

| 35 | 2.598 | 6082-T6 | 140 | 41.563 | 6082-T6 |

| 36 | 2.748 | 6060-T66 | 140 | 41.861 | 5083-H112 |

| 36 | 2.748 | 6082 | 140 | 43.411 | 7075-T6 |

| 36.51 | 2.827 | 6262-T6511 | 145 | 44.585 | 2007-T4511 |

| 37 | 2.903 | 6061-T6 | 146.05 | 45.233 | 6061-T6511 |

| 37 | 2.903 | 2014A T4 | 150 | 47.713 | 6082-T6 |

| 38 | 3.062 | 150 | 47.713 | 7075-T6 | |

| 38.1 | 3.090 | 6061-T6511 | 150 | 47.904 | 6082-T6 |

| 39.69 | 3.340 | 150 | 48.032 | 5083-H112 | |

| 40 | 3.541 | 2011-T6/7075-T6 | 150 | 49.811 | 2011-T6/7075-T6 |

| 40 | 3.406 | 6082-T6 | 152 | 49.252 | 6082-T6 |

| 41 | 3.565 | 6082-T6 | 152.4 | 49.252 | 6061-T6 |

| 41.28 | 3.627 | 6061-T6511 | 152.4 | 51.076 | 2014-T6511 |

| 41.5 | 3.652 | 2014A T4 | 152.4 | 49.252 | 6082-T6 |

| 42 | 3.741 | 6082-T6 | 155 | 50.947 | 6A02-T6 |

| 43 | 3.921 | 6082(AS10) | 158.75 | 53.442 | 6082-T6 |

| 44 | 4.105 | AS10(6082)-F | 160 | 54.558 | 6082-T6 |

| 44.45 | 4.190 | 6061-T6 | 160 | 54.695 | 5083-H112 |

| 45 | 4.453 | 7075-T6 | 160 | 56.720 | 7075-T6 |

| 45 | 4.313 | 6082-T6 | 160 | 54.287 | 6082-T6511 |

| 46 | 4.487 | 6082-T6 | 162 | 55.652 | 6082-T6511 |

| 46 | 4.504 | 6082-T6 | 165 | 58.013 | 6082-T6 |

| 48 | 4.886 | 6082 | 170 | 61.573 | 6082-T6 |

| 49 | 5.092 | 6082-T6511 | 170 | 61.718 | 5083-H112 |

| 49.21 | 5.136 | 6061-T6511 | 170 | 64.004 | 2011-T6/7075-T6 |

| 50 | 5.498 | 5083-H112 | 171.45 | 62.335 | 6082-T6 |

| 50 | 5.531 | 2011-T6/7075-T6 | 175 | 64.943 | 6061-T6 |

| 50 | 5.321 | 6082-T6 | 177.8 | 67.037 | 6061-T6511 |

| 50.8 | 5.493 | 6061-T6511 | 180 | 69.012 | 6082-T6 |

| 51 | 5.516 | 6082(AS10) | 180 | 69.165 | 5083-H112 |

| 51.59 | 5.645 | 6061-T6511 | 180 | 71.727 | 7075-T6 |

| 52 | 5.755 | 6082T651 | 190 | 76.936 | 6082-T6 |

| 52.4 | 5.820 | 6061-T6511 | 190 | 79.932 | 2011-T6/7075-T6 |

| 55 | 6.415 | 6060-T66/6082-T6 | 190 | 76.553 | 6A02-H112 |

| 55 | 6.695 | 2011-T6/7075-T6 | 190.5 | 76.956 | 6061-T651 |

| 55 | 6.444 | 6082-T6 | 195 | 80.635 | 6082-T651 |

| 56 | 6.650 | 6082-T6 | 200 | 85.226 | 6082-T6 |

| 57.15 | 6.952 | 6082-T6 | 200 | 85.460 | 5083-H112 |

| 59 | 7.382 | 6082-T1 | 200 | 88.537 | 2011-T6/7075-T6 |

| 59 | 7.382 | 6082 | 200 | 84.823 | 6061-T6 |

| 60 | 7.634 | 6082-T6 | 203 | 87.387 | 6082-T651 |

| 60 | 7.917 | 5083-H112 | 205 | 89.117 | 6082-T6511 |

| 60 | 7.917 | 7075-T6 | 210 | 93.941 | 6082-T6 |

| 60 | 7.963 | 2011-T6/7075-T6 | 210 | 93.517 | 6082-T6511 |

| 61 | 7.891 | 6082-T6 | 210 | 93.517 | 5A02-H112 |

| 62 | 8.151 | 215 | 98.024 | 6082-T6511 | |

| 63 | 8.417 | 6082-T6511 | 215.9 | 98.846 | 6082-T6 |

| 63.5 | 8.582 | 6061-T6511 | 215.9 | 98.846 | 6061-T651 |

| 65 | 8.959 | 6082-T6 | 219 | 97.582 | 2011-T6/7075-T6 |

| 65 | 9.341 | 2011-T6/7075-T6 | 220 | 107.067 | 2011-T6/7075-T6 |

| 65 | 8.993 | 6082-T6 | 220 | 102.636 | 6A02-H112 |

| 66 | 9.237 | 6082-T6511 | 225 | 107.354 | 6082-T6511 |

| 66 | 9.579 | 7050-T6 | 228.6 | 110.817 | 6061-T6511 |

| 66.67 | 9.427 | 6061-T6 | 230 | 112.178 | 6082-T6511 |

| 66.68 | 9.427 | 6061-T6511 | 235 | 117.109 | 5A05-H112 |

| 67 | 9.872 | 2007-T4511 | 240 | 122.145 | 6A02-H112 |

| 68 | 9.806 | 6082 | 245 | 127.288 | 6063-H112 |

| 69 | 10.096 | 6082-T1/6110A-T1 | 254 | 136.811 | 6082-T6 |

| 69.85 | 10.346 | 6061-T6 | 255 | 137.890 | 6082-T6 |

| 70 | 10.391 | 6082-T6 | 265 | 148.917 | 5A05-H112 |

| 70 | 10.776 | 5083-H112 | 270 | 154.590 | 6A02-H112 |

| 70 | 10.860 | 2011-T6/7075-T6 | 275 | 160.368 | 6082-T6511 |

| 70 | 10.435 | 6082-T6 | 279.4 | 165.541 | 6082-T6 |

| 71 | 10.690 | 6082 T6 | 280 | 166.253 | 6A02-H112 |

| 72 | 10.993 | 6082-T6 | 290 | 178.340 | 6082-T6 |

| 73 | 11.308 | 6061-T6511 | 300 | 190.852 | 6061-H112 |

| 75 | 11.928 | 6082-T6 | 304.8 | 197.008 | 6082-T6 |

| 75 | 12.461 | 2011-T6/7075-T6 | 310 | 203.787 | 6A02-H112 |

| 75 | 12.017 | 6082-T6 | 320 | 217.147 | 6082-T6 |

| 76 | 12.248 | 6082-T6 | 323.85 | 222.403 | 6061-T6 |

| 76.2 | 12.313 | 6061-T6 | 330 | 230.931 | 6082-T6 |

| 76.2 | 12.359 | 6061-T6511 | 340 | 245.138 | 6082-T6 |

| 78 | 12.902 | 6082-T6 | 350 | 259.770 | 2A50-H112 |

| 80 | 13.572 | 6082-T6 | 355.6 | 268.150 | 6061-T651 |

Processing · Precision · Value-Added Machining

After extrusion, aluminum round bars can be supplied in different processing conditions depending on application and precision requirements—suitable for turned parts, structural components, guide shafts, hydraulic systems, and more.

We provide not only extruded blanks, but also straightened, cold-drawn, peeled/turned, or ground bars for enhanced dimensional consistency and machining stability.

Bar Form Options · Matched to Different Uses

-

Turned Aluminum Bar

• Suitable for Φ10–200 mm

• Removes oxide layer and surface defects

• Improves surface uniformity and cutting performance

Dimensional Accuracy & Quality Control

To meet machining and assembly requirements, aluminum round bars are process-controlled during extrusion and downstream finishing:

- Straightness ≤ 0.5 mm/m for smooth feeding and stable turning

- Diameter tolerance per EN 755 / ASTM B211; precision drawn and ground bars up to h9–h7

- Extruded surface roughness Ra 3.2–6.3 μm; peeled surfaces Ra 1.6–3.2 μm; ground surfaces Ra 0.2–0.8 μm

- EN 10204 3.1 certificates available, with optional reports for dimensions, mechanical properties, surface roughness, and roundness

Value-Added Machining & Pre-Processing

To reduce outsourcing steps and preparation time, aluminum round bars can be supplied with pre-machining services:

- Cut-to-length, chamfering, deburring, length tolerance ±0.5–1.0 mm

- Supports turning, drilling, tapping, slot milling, knurling, and CNC operations

- Laser marking for size, alloy, heat number, and batch traceability

- For exposed parts or high-appearance components, anodizing or sandblasting can follow machining

Featured Case Studies

Case 01|CNC Machining Plant · Precision Shaft Blanks

Customer Type / Region:German precision machining factory (CNC + automatic lathes)

Application:Small connecting shafts for robotic joints

Specification:6061-T6, Φ18 mm, length 1200 mm

Die Match:Existing Φ18 mm die → no tooling cost

Processing Route:Extrusion + cold drawing → diameter tolerance h9 (±0.03 mm), straightness ≤0.3 mm/m

Delivery Condition:Cut-to-length + end chamfering, no post-heat-treatment machining

Outcome:Saved approx. USD 800 in tooling, reduced lead time by 5 days, and improved turning efficiency by ≈12%

Case 02|Automotive Component Manufacturer · Torsion Rods / Support Shafts

Customer:U.S. automotive chassis system supplier

Application:Torsion rods and support shafts (pre-machining blanks)

Specification:7075-T6, Φ32 mm × 3 m

Die Status:Diameter matched to in-stock Φ32 mm die → no new die required

Processing Route:Extrusion → straightening → peeling/turning (oxide removal) → 0.5 mm machining allowance retained

Dimensional Performance:OD controlled +0 / –0.08 mm, roundness ≤0.12 mm

Outcome:Material went straight into machining without per-bar face-milling, with stable OD and roundness across batches. Scrap rate dropped, and the project saved about USD 1,200 in tooling while bringing forward the validation milestone by about 1 week.

Case 03|Hydraulic Equipment Manufacturer · Precision Ground Piston Rods

Customer:Italian hydraulic cylinder producer

Application:Medium-size piston rods (ground and chromium-plated later)

Specification:6082-T6, Φ25 mm × 2.5 m

Die Match:In-stock Φ25 mm die → no tooling fee

Processing Chain:Extrusion → cold drawing → precision straightening → centerless grinding to h8 → surface Ra 0.4 μm

Delivery Condition:Delivered after grinding; customer directly chromium-plates and assembles

Outcome:From order to mass production in 6 days; 30% weight reduction vs steel alternative and ≈9% cost reduction

More dies Libraries

We maintain a large and continuously updated die library covering round bars, square bars, profiles, micro-channel tubes, and more. Below are navigation entries to commonly used die tables — you may browse and request quotations directly.

Packaging & Logistics

Packaging Method:Square bar ends are protected with end caps, bundles are wrapped with anti-corrosion film or kraft paper, and secured with wooden pallets or wooden crates to prevent bending and impact—suitable for sea freight and air freight.

Labeling & Traceability:Each bundle or crate is labeled or marked with alloy, size, length, quantity, and heat/batch number. QR codes or customer-specific coding can be added upon request.

Documentation Included:Supplied with Commercial Invoice, Packing List, Bill of Lading or Air Waybill, and EN 10204 3.1 material certificate. Certificate of Origin or dimensional/mechanical reports can be added if required.

Trade Terms & Transport Support:Supports EXW / FOB / CIF / DDP, and can assist with customs clearance, delivery, and cargo insurance, with packing photos or video records provided for traceability.

FAQ

Should I Choose Extruded Bar, Cold Drawn Bar, or Ground Bar?

It depends on application and accuracy. Extruded bar is suitable as turning or sawing blanks. Cold drawn / precision drawn bar is used when you want to reduce machining allowance and need h9/h10 diameter tolerances. Precision ground bar is ideal for guide shafts, piston rods, and similar parts requiring h8/h7 precision and low surface roughness.

How Are Diameter Tolerance and Straightness Controlled? Is It Suitable for CNC or Shaft Fits?

Extruded bars follow EN 755 / ASTM B211 with straightness controlled to ≤0.5 mm/m. After cold drawing, tolerances can be tightened to h9/h10, and after grinding to h8/h7. For guide shafts, linear rails, or piston rods, we can provide precision straightening plus roundness and roughness reports as needed.

What Material Certificates and Test Documents Can You Provide?

Standard documentation includes EN 10204 3.1 MTC, covering heat number, chemical composition, and mechanical properties. On request, we can add dimensional inspection reports, straightness/roundness and roughness reports, as well as Certificate of Origin and REACH/RoHS compliance files.

How Is Pricing Calculated? What Factors Influence It?

Pricing is quoted per kg, per meter, or per piece, depending on the item, and mainly depends on alloy, condition (extruded / cold drawn / ground), size, tolerance level, cutting or machining requirements, and destination port.

What Are the MOQ and Sample Conditions? Can I Buy Just a Few Pieces for Testing?

Standard extruded bars typically start at around 500 kg. Cold drawn / ground bars have higher MOQs due to extra processes. We can supply samples or short lengths for trial machining with MTC and/or dimensional reports, with charges based on process route.

What Are the Lead Times? Do You Support Expedited or Split Shipments?

Typical lead time for standard extruded bars is about 7–15 days. Adding cold drawing, peeling, or grinding extends this to about 10–20 days. Depending on scheduling, we can offer expedited production or partial shipments, with lead time counted from drawing/requirement confirmation and payment.