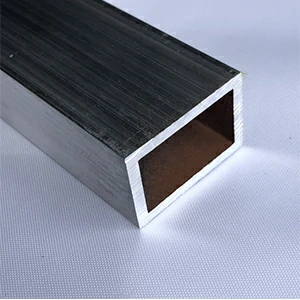

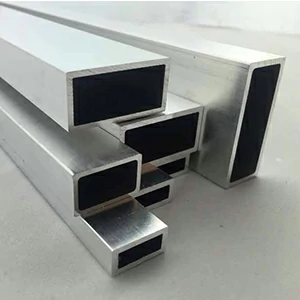

Chalco's aluminum rectangular tubing is favored by global engineering clients for its lightweight, high strength, excellent corrosion resistance, and seamless structure. We utilize high-precision extrusion processes to provide smooth-surfaced, clean-edged rectangular aluminum profiles, widely used in structural frameworks, fences, transportation equipment, shipbuilding, and other industries. Choose Chalco, and you'll benefit from:

- A selection of high-performance alloys, including 6061, 6063, 6082, and 7075

- Support for various wall thicknesses and custom cutting lengths

- Availability of multiple surface treatments, including anodizing, spraying, and mill finish

- Fast delivery + technical support + comprehensive quality inspection

Get a Quote or contact our technical team to customize a cost-effective solution for you!

Instant QuoteQuick Navigation

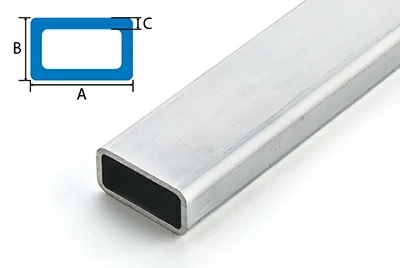

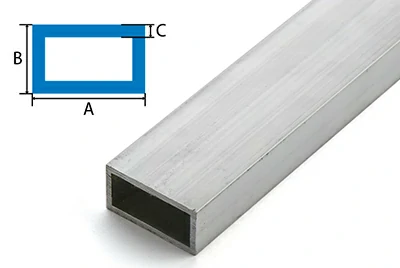

Aluminum Rectangular Tubing Specifications

Chalco offers a wide range of standard-sized aluminum rectangular hollow sections and supports non-standard size customization. We possess large-tonnage extrusion equipment and multiple die resources to meet diverse needs, from lightweight structures to heavy-duty industrial frameworks.

| Item | Metric Size (mm) | Imperial Size (Inches) |

| Width | 12.7 – 300 | 0.5" – 12" |

| Height | 12.7 – 200 | 0.5" – 8" |

| Wall | 1.5 – 12.0 | 0.058" – 0.5" |

| Length | ≤6000(cut-to-length available) | ≤24ft(cut-to-length available) |

| Corners | Square / Radius | |

| Tolerance | ±0.02" (standard), supports precise tolerance | |

| Surface Treatment | Sandblasting / Anodizing (silver, black) / Powder coating / Electrophoresis | |

| Further Processing | Cutting to length / Punching / Bending / CNC machining / Welding groove / Chamfering / Deburring | |

| Standard | ASTM B221 / EN 755-9 / AMS-QQ-A-200/8, 200/9 | |

| Certification | ISO 9001 / IATF 16949 / SGS / RoHS / REACH | |

Contact us now for samples, drawing evaluations, or bulk quotations. We will quickly match the optimal rectangular aluminum tubing solution for your project.

Instant QuoteChalco's Aluminum Rectangular Tubing Categories

Chalco offers various types of aluminum rectangular profiles to meet the diverse needs of different industries in terms of structural strength, appearance treatment, installation methods, and processing depth. The following are common product type classifications:

Thin Wall Aluminum Rectangular Tubing

Thin Wall Aluminum Rectangular Tubing Suitable for lightweight frames, decorative structures, and bending applications, with a thickness generally ≤1/8", light weight, easy to process, and supports batch fast-length cutting.

Structural Aluminum Rectangular Tubing

Structural Aluminum Rectangular Tubing Possesses medium to high strength levels, suitable for load-bearing structures, industrial equipment support, and connection frames, and can be used with welding and mechanical connections.

Large Aluminum Rectangular Tubing

Large Aluminum Rectangular Tubing The maximum outer diameter can reach 350mm, suitable for heavy equipment, mechanical equipment, transportation skeletons, and other occasions with high requirements for cross-sectional dimensions.

Metric Aluminum Rectangular Tubing

Metric Aluminum Rectangular Tubing Supports European standard EN specifications and is delivered in millimeter dimensions, suitable for global projects or customers using standardized accessory systems.

Anodized Aluminum Rectangular Tubing

Anodized Aluminum Rectangular Tubing Provides silver-white/black anodized aluminum rectangular tubing, suitable for decorative structures, display racks, window frame systems, and other occasions with high visual requirements.

Telescoping Aluminum Rectangular Tubing

Telescoping Aluminum Rectangular Tubing Features an inner and outer matching design, with precisely matched wall thickness/dimensions, suitable for adjustable structures, support frames, mobile component systems, and supports high-precision processing.

Seamless Aluminum Rectangular Tubing

Seamless Aluminum Rectangular Tubing Conventional rectangular tubes are mainly formed by extrusion, and some high-strength structural parts can be customized with drawing or seamless processes to enhance overall mechanical performance and stability.

Different projects can choose the corresponding product type according to the required strength, appearance, connection method, etc. For technical advice or structural adaptation support, please contact us for recommended solutions.

Chalco Aluminum Rectangular Tubing Common Alloy Selection Guide

Aluminum rectangular box sections can be selected based on the project's strength, weldability, corrosion resistance, surface treatment requirements, etc. The following are several commonly used aluminum alloys promoted by Chalco:

6061 Rectangular Aluminum Tubing

6061 rectangular aluminum tube offers a strong, easily workable solution for structural use. Its good weldability makes it ideal for brackets and mechanical connections.

Temper: T6, T4, T651

Tensile Strength: ≥290 MPa, Yield Strength: ≥240 MPa

Applications: Heavy-duty frames, engineering machinery, automotive structural parts

6063 Rectangular Aluminum Tubing

6063 rectangular aluminum tube is the first choice for building decoration applications, with high surface finish and good anodizing effect. It has good processing performance and is easy to cut, drill, and bend.

Temper: T5, T52

Tensile Strength: ≥190 MPa, Yield Strength: ≥160 MPa

Applications: Window frames, handrails, display racks, lightweight structures

Other Optional Aluminum Alloys

In addition to mainstream alloys such as 6061 and 6063, Chalco also offers a variety of aluminum rectangular hollow sections with specialized performance advantages to meet the differentiated needs of various industrial fields for strength, corrosion resistance, formability, etc.:

Higher strength than 6061, excellent welding performance, and good corrosion resistance. It is widely used in high-strength structural fields such as heavy-duty frames, vehicle chassis, and bridge components.

- 6005A Rectangular Aluminum Tubing

Possesses good extrusion processability and medium strength, suitable for manufacturing complex cross-sections and automated structures, such as conveying equipment, mechanical guides, and support components.

Has a balanced comprehensive performance and is particularly suitable for anodizing decorative treatment. It is often used in furniture profiles, display systems, and light-load structural parts.

Belongs to ultra-high-strength aerospace alloys and is suitable for applications with extremely high strength/rigidity requirements, such as aircraft structures, fixtures, and high-performance vehicle components.

Known for its high fatigue strength and good processing performance, it is mainly used in the aerospace field for skins, joints, and high dynamic load structures.

Has excellent corrosion resistance and welding performance, suitable for hulls, storage tanks, vehicle guards, etc.

Has stronger corrosion resistance and is particularly suitable for structural profiles in extreme environments such as marine, deep-sea engineering, and chemical equipment.

Alloy Selection Overview Table

| Alloy | Intensity | Weldability | Anodized | Formability | Recommended applications |

| 6061 | High | Yes | Fair | Good | Industrial structural parts, mechanical frames, transportation equipment |

| 6063 | Medium | Yes | Excellent | Excellent | Door and window profiles, architectural decoration, display structures |

| 6082 | High | Yes | Good | Fair | Heavy-duty frames, robotic arms, vehicle chassis |

| 6005A | Medium | Yes | Fair | Excellent | Automation systems, curtain wall frames, transmission structures |

| 6060 | Medium | Yes | Excellent | Excellent | Exhibition equipment, decorative structures, light applications |

| 7075 | Very high | No | Fair | Poor | Aerospace structural parts, fixtures, sports equipment |

| 2024 | High | No | Fair | Fair | Aircraft structures, fasteners, high fatigue situations |

| 5052 | Medium | Yes | Anodized | Excellent | Storage tanks, hulls, pipe shields |

| 5083 | Medium | Yes | Anodized | Fair | Ship decks, chemical containers, pressure vessels |

Whether you need high-strength structural rectangular aluminum sections or decorative profiles with excellent surface treatment performance, Chalco can match you with suitable alloys and customized solutions.

Instant QuoteApplication Industries and Solutions for Aluminum Rectangular Tubing

Chalco's aluminum rectangular tubing is widely used across various industries, standing out not only for its lightweight, high strength, and corrosion resistance but also for providing reliable integrated solutions through diverse alloy selections, deep processing capabilities, and customized options.

Aerospace

Widely used in aircraft supports, ground test platforms, lightweight truss systems, and other fields, with extremely high requirements for material specific strength, fatigue life, and corrosion resistance.

Alloys: 7075, 2024, 6061

Military and Defense Equipment

Used in military vehicle structures, equipment frames, communication system supports, etc., requiring a balance of mechanical strength, impact resistance, and long-term service environment stability.

Alloys: 6061, 6082, 7075

Industrial Equipment and Engineering Structures

Suitable for assembly line racks, mechanical outer frames, transmission equipment supports, etc., with uniform requirements for structural strength, welding performance, and dimensional accuracy.

Alloys: 6061, 6005A, 6082

Marine and Energy Engineering

Applied in ship hulls, pontoons, offshore platforms, and energy equipment frames, requiring materials with excellent salt spray corrosion resistance and welding performance.

Alloys: 5083, 5052, 6061

Automotive and Rail Transit

Frequently used in lightweight systems such as battery trays, structural beams, and guide rails, with high requirements for material formability and batch processing performance.

Alloys: 6061, 6005A, 6060

For industry-specific customized cases or exclusive aluminum alloy structural design advice, please contact the Chalco engineering technical team.

Instant QuoteChalco's Stock Size Chart for Aluminum Rectangular Tubing

≤ 1/8" Thin Wall Aluminum Rectangular Tubing (bendable/punchable/cut-to-length)

Common Alloys: 6061-T6, 6063-T5, 6063-T52, 6082-T6

Suitable for lightweight structural parts, decorative frames, and display racks, supporting efficient processing with bending, punching, and cut-to-length ±0.5mm.

| Wall thickness | Dimensions | Other |

| 1/16" | 0.5" × 1" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/16" | 1" × 2" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 0.5" × 1" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 0.75" × 1" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 0.75" × 1.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 1.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 2" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 2.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.25" × 2.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.5" × 2" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.5" × 2.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.75" × 3" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.75" × 3.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.75" × 4" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 2" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.5" × 2" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 2.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 3" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 4" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 2.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.25" × 2.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.5" × 2.5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 3" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.5" × 3" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.75" × 3" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 3" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 4" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.5" × 4" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1.75" × 4" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 4" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 3" × 5" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 1" × 6" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 6" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 4" × 6" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 8" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

| 1/8" | 2" × 10" aluminum rectangular tubing | Bending / Perforating / Custom Length Cutting |

3/16"–1/4" Medium Wall Aluminum Rectangular Tubing (slotted/chamfered/deburred)

| Wall thickness | Dimensions | Other |

| 3/16" | 1.5" × 3" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 3/16" | 2" × 3" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 3/16" | 2" × 4" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 3/16" | 3" × 4" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 3/16" | 3" × 6" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 3/16" | 4" × 2" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 3/16" | 6" × 2" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 3/16" | 6" × 3" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 2" × 3" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 2" × 4" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 3" × 2" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 3" × 4" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 3" × 6" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 4" × 3" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 4" × 6" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 6" × 3" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 6" × 4" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

| 1/4" | 8" × 4" aluminum rectangular tubing | Slotting / Chamfering / Deburring |

≥ 1/2" Thick Wall Aluminum Rectangular Tubing (CNC machined / precision assembly)

| Wall thickness | Dimensions | Other |

| 1/2" | 1" × 2" aluminum rectangular tubing | CNC Machining / Precision Assembly |

| 1/2" | 2" × 4" aluminum rectangular tubing | CNC Machining / Precision Assembly |

| 1/2" | 2" × 6" aluminum rectangular tubing | CNC Machining / Precision Assembly |

| 1/2" | 2" × 8" aluminum rectangular tubing | CNC Machining / Precision Assembly |

For a complete stock size specification table or customized solution quotations, please contact our engineering team for a quick response to your project needs.

Instant QuoteChalco's Rectangular Aluminum Tubing Production Capacity and Delivery Guarantee

Chalco possesses strong manufacturing capabilities and rapid response capabilities in the aluminum box section production field, providing comprehensive guarantees for the large-volume supply and customized processing of rectangular aluminum tubing.

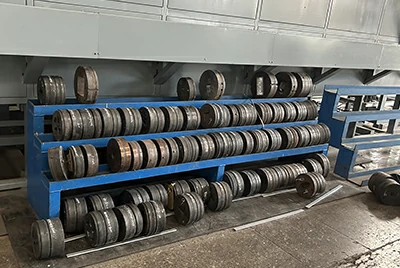

Abundant Mold Resources

We have over 1,000 sets of dedicated extrusion dies for rectangular tubes, covering common sizes from lightweight to heavy-duty structures, enabling rapid matching of existing molds, reducing mold opening costs and cycles.

High-Tonnage Extrusion Equipment

Equipped with more than 10 aluminum profile extrusion production lines, with extruder tonnage ranging from 600T to 12500T, we can produce rectangular aluminum tubes with a maximum outer diameter of 350mm, meeting large-size customization needs.

Inventory and Minimum Order Advantages

6061 and 6063 series alloy rectangular hollow aluminum are stocked year-round, and regular sizes support low minimum order quantities, shortening delivery cycles.

Flexible Customization Services

For non-standard sizes or special alloys (such as 6082, 7075, 5083, etc.), we can customize mold openings according to drawings or usage needs, supporting cut-to-length and complex structure extrusion solutions.

Supporting Processing System

Chalco has a complete downstream processing production line, including CNC precision machining, weld beveling, chamfering, punching, anodizing, electrophoresis, etc., adapting to a one-stop supply model for structural parts.

For real-time inventory status or customized delivery cycles, please contact the Chalco sales and technical team for a professional response.

High-Difficulty Rectangular Aluminum Tubing Customization Solutions

Chalco not only provides standard rectangular aluminum tubing products but also excels in solving high-difficulty customization needs that conventional manufacturers struggle with. We are committed to providing structural profile solutions for challenging scenarios, meeting the material requirements of special projects, complex assembly, and extreme working conditions.

- Special Cross-Section Structures: Develop complex cross-sections with ultra-high width-to-height ratios (>4:1), asymmetry, oblique edges/special shapes, adapting to high-precision systems such as solar brackets and aircraft components.

- Non-Standard Wall Thickness Customization: Support directional wall thickness structures as thin as 1.2mm and as thick as 12mm, used for lightweight systems or impact-resistant load-bearing structures.

- Complex End Processing: Achieve complex end-face processing such as oblique cutting (±45°), arc cutting (minimum R10), special-shaped interfaces, and weld beveling.

- Multi-Cavity Nested Structures: Possess dual-cavity/triple-cavity/nested extrusion capabilities, suitable for complex structural assembly such as module tracks, mobile support systems, and clamping systems.

- Precision Fixed Length and Cutting: The shortest segment supports 50mm, the longest can reach 6m, cutting accuracy is ±0.5mm, and CNC cutting is optional.

- Mold Collaborative Development: If customers have special cross-sectional drawings, complete the mold development cycle from drawing review to sample output within 15-20 working days, supporting proofing and repeated debugging.

If you are facing structural design challenges or need to break through the standard rectangular aluminum tubing limit specifications, please send drawings and technical requirements. The Chalco engineering team will quickly match you with feasible customized solutions and quotation plans.

Frequently Asked Questions (FAQ)

Chalco understands that customers not only focus on the product performance itself when choosing aluminum rectangular tubes but also consider issues such as processing compatibility, delivery timeliness, and cost control. The following is a summary of answers to common customer pain points:

Can rectangular aluminum tubes be customized according to drawing dimensions? Will it incur high mold opening costs?

Chalco has a mold library of thousands of rectangular aluminum tubes, covering mainstream specifications. Most common sizes can be directly matched with existing molds, eliminating the need for repeated mold opening. For special sizes, we also support low-cost customized mold opening and assist in optimizing the design structure to reduce the number of mold modifications and costs.

What alloy grades can Chalco provide? What are the delivery cycle and minimum order quantity requirements?

6061 and 6063 aluminum box sections are sufficiently stocked, and some specifications support ordering from 1 piece, with delivery within 2-3 days. For special alloys such as 6082, 6005A, 7075, and 5083, customized mold opening and initial batch delivery can usually be completed within 7-15 days. We support flexible production scheduling and project proofing services and welcome small-batch trial production cooperation.

Can you provide subsequent processing services, such as cutting, punching, surface treatment, etc.?

We have a complete processing and surface treatment system, supporting one-stop services such as fixed-length cutting, CNC machining, slotting, weld beveling, punching, anodizing, electrophoresis, and spraying. It is especially suitable for centralized procurement of export structural parts and assembly structure projects.

Do Chalco's products comply with international standards? How is dimensional accuracy and quality ensured?

Chalco's products comply with international standards such as ASTM B221, EN 755, and AMS QQ-A-200. The entire production process is equipped with an online testing system and a professional quality inspection team, supporting factory dimension tolerance reports, material certificates, and third-party testing (such as SGS, BV, etc.). The regular cutting accuracy is ±0.5mm, which can be controlled to ±0.2mm according to requirements.

Do you support exports? Can you assist with international transportation and customs clearance?

We have extensive international export experience and support various trade methods such as FOB, CIF, and DDP. We can provide logistics solutions such as sea, air, and rail transportation and assist customers in preparing customs clearance documents, certificates of origin, certification certificates, etc., to ensure smooth project delivery.

Rectangular Aluminum Tubes vs. Aluminum Round Tubes

Compared with traditional round aluminum tubes, rectangular aluminum tubes have many advantages in structural performance, processing adaptability, and installation efficiency, making them suitable for more load-bearing and directional force scenarios.

矩形管+圆管截面对比图

| Comparative dimensions | Rectangular aluminum tube | Round aluminum tube |

| Flexural stiffness | Better, suitable for structures with clear force direction | Overall balance, but not dominant in directional force structure |

| Torsional strength | Higher, especially after the cross-section design is optimized | Medium |

| Installation/connection | Flat structure is easy to weld, drill and fix | Circular surface connection requires customized clamps, poor adaptability |

| Space utilization | High, can be installed against the wall/corner, saving space | Circular structure has wasted corner space |

| Force design flexibility | Wall thickness can be designed in different directions, taking into account strength and lightness | Uniform wall thickness, not conducive to structural optimization |

| Application preferences | Industrial frames, brackets, track systems, mechanical skeletons, etc. | Fluid transportation, rotating structure, simple support rods, etc. |

Chalco can recommend the most suitable profile structure and cross-sectional parameter design according to different project needs. In addition to rectangular aluminum tubes, we also provide series products such as round aluminum tubes and square aluminum tubes. Welcome to click to view:

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote