Aluminum MIG Wire is an aluminum alloy solid-core wire engineered for the GMAW (Gas Metal Arc Welding) process. It supports DCEN push welding and seamlessly integrates with mainstream Aluminum MIG welding machines and automated systems.

Compared with manual-feed TIG Rods and self-shielded Flux-Core wires, Alu MIG Welding delivers higher welding speeds, lower labor intervention, and superior cost efficiency—making it the top choice for high-volume production and robotic welding.

Chalco Aluminum Welding Wire holds ISO 9001 and IATF 16949 dual quality certifications and complies with AWS A5.10 and ISO 18273 international standards. Drawn to a precision of ± 0.02 mm and vacuum-dried for sealed packaging, it's available for 72 h rapid shipment.

Instant QuoteAluminum MIG Wire Product Categories

ER4043 (Al-5%Si) MIG Wire

ER4043 contains 4.5–6.0 % Si, forming a eutectic aluminum–silicon filler metal with outstanding fluidity and heat-crack resistance. It produces a bright, minimal-discoloration weld bead. As a non-heat-treatable alloy, it's ideal where weld appearance and smoothness matter.

Contact us nowChemical Composition

| Element | Si | Fe | Cu | Mn | Zn | Ti | Be | Al |

| Value | 4.5–6.0% | ≤0.80% | ≤0.30% | ≤0.05% | ≤0.10% | ≤0.20% | ≤0.0003% | Rem |

Key Features

- Exceptional fluidity and wetting behavior, reducing porosity and lack-of-fusion

- Low hot-crack susceptibility, especially on 6xxx-series substrates

- Light-gray anodized finish, high compatibility with parent metal

- Smooth arc stability, minimal spatter, and no post-weld grinding required

Suitable Base Materials

1xxx / 3xxx / 6xxx series aluminium alloys, 5xxx-series aluminium alloys (Mg ≤ 2.5 %)

Typical Applications

- Automotive body panel welding

- Decorative parts for bicycles and motorcycles

- Architectural curtain walls and precision instrument housings

Car body

Bicycle

Precision instrument housing

ER5356 (Al-5%Mg) MIG Wire

ER5356 contains 4.7–5.5 % Mg, a high-strength aluminum–magnesium filler metal with excellent corrosion resistance and stable arc characteristics. It yields a light-white weld bead—ideal for structural welding in marine and chemical environments.

Contact us nowChemical Composition

| Element | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti | Be | Al |

| Value | 4.7–5.5% | ≤0.25% | ≤0.40% | ≤0.10% | 0.05–0.20% | 0.05–0.20% | ≤0.10% | ≤0.20% | ≤0.0003% | Reminder |

Key Features

- High tensile strength (~380 MPa) for superior load-bearing

- Exceptional marine and chemical corrosion resistance

- Stable arc with minimal spatter, producing clean weld profiles

- Optimized for high-speed automated welding of medium-thick plates

Suitable Base Materials

5083/ 5052 / 5454 high-Mg 5xxx-series alloys;Select 6xxx-series and 7xxx-series alloys

Typical Applications

- Ship decks and bulkheads

- Pressure vessels and high-pressure storage tanks

- Offshore platforms and chemical equipment

Ship deck

High pressure storage tank

Offshore platform

ER1100 MIG Wire

ER1100 MIG WireER1100 MIG Wire is nearly pure aluminum (≥ 99.5 %), offering superior electrical conductivity and thermal conductivity. Its welds have high ductility but limited strength, making it ideal for electronic heat sinks, busbars, and ultra-thin sheet welding where appearance is secondary.

AWS A5.10 ISO 18273 ER2319 MIG Wire

ER2319 MIG WireER2319 MIG Wire contains 6–7 % Cu, designed for 2xxx-series alloys (2014, 2219). It enables post-weld solution treatment plus age hardening, achieving weld strength nearly equal to the base metal—suited for aerospace structural components and high-strength pressure parts.

AWS A5.10 ISO 18273 AMS 4191 ER4047 MIG Wire

ER4047 MIG WireER4047 MIG Wire boasts 11–13 % Si, yielding a low melting point and exceptional fluidity—fills wide gaps and minimizes distortion. Weld beads appear gray-black, making it popular for brazing, seal welds, and heat exchanger fabrication, with excellent heat resistance.

AWS A5.10 ISO 18273 AMS 4190 ER4943 MIG Wire

ER4943 MIG WireER4943 MIG Wire contains 6.3–7.0 % Si and 0.45–0.9 % Mg, balancing fluidity and strength (≈ 270 MPa). Its color match is better than ER4047, suited for 6xxx-series high-fatigue parts requiring PWHT, such as rail transit components and high-pressure vessels.

AWS A5.10 ISO 18273 AMS 4185 ER5554 MIG Wire

ER5554 MIG WireER5554 MIG Wire enhances ER5356 with Mn and Zn for better ductility and crack resistance, offering 360–380 MPa strength. Good fluidity and color match suit chemical tanks, fuel tanks, and light-load aluminum frames.

AWS A5.10 ISO 18273 ER5556 MIG Wire

ER5556 MIG WireER5556 MIG Wire, derived from ER5356 with 0.5–1.0 % Mn, enhances weld ductility, crack resistance, and tensile strength (≈ 415 MPa). It maintains outstanding marine corrosion resistance, suitable for ship structures, high-load pressure vessels, and bridge construction.

AWS A5.10 ISO 18273 ER5654 MIG Wire

ER5654 MIG WireER5654 MIG Wire, containing 4–5 % Zn and Mn, resists heat and oxidation. Welds withstand 150 °F (66 °C) with 370–390 MPa strength. Dense, penetration-resistant beads fit harsh chemical and aerospace uses like peroxide vessels, exchangers, and pump housings.

AWS A5.10 ISO 18273 ER5183 MIG Wire

ER5183 MIG WireER5183 MIG Wire with 4.3–5.2 % Mg, 0.5–1.0 % Mn, and trace Cr offers excellent corrosion resistance, ductility, and ~410 MPa strength. Ideal for LNG tanks, offshore platforms, and rail parts in marine, cryogenic, and high-pressure uses.

AWS A5.10 ISO 18273

Aluminum MIG welding wire specifications & packaging

| Item | Parameter range |

| Diameter (mm) | 0.8 | 0.9 | 1.0 | 1.2 | 1.6 (0.6 & 2.0 & 2.4 can be customized) |

| Spool Weight | S100 0.5 kg | S200 2 kg | S300 7 kg | S360 20 kg | Drum 150 kg |

| Wire Diameter Tolerance / State | F condition; ISO 544 h9 ±0.02 mm |

| Welding Process | GMAW / MIG |

| Recommended Shielding Gas | 100% Ar or Ar + ≤ 30% He (for thick parts or high thermal conductivity substrates) |

| Implementation Standard / Brand Minimum Order Quantity / Delivery | AWS A5.10 (such as ER4043 / ER5356 / ER5556) |

| ISO 18273 | |

| Technical Support | S100 Minimum order of 0.5 kg; Regular stock shipped within 72 hours |

| Implementation Standard / Brand | Free welding parameter window, sample evaluation, COA/COC report and RoHS document; Engineers online to answer questions 24 hours a day |

Aluminum MIG Wire Technical Parameters

Typical Filler Metal Properties of Aluminum MIG Wire

| Alloy | Elongation% | Resistance to Crack Growth | Resistance to Solidification Cracking | Fillet WeldsLongitudinal / Transverse (ksi) | UTS(ksi) |

| ER1100 | High (55) | Good | Good | Low (7.5) / Low (7.5) | Low (13) |

| ER4043 | Low (5) | Low | Very Good | Low (11.5) / Low (15.0) | Med. (28) |

| ER4047 | Low (13) | Low | Excellent | Low (11.5) / Low (15.0) | High (38) |

| ER4643 | Low (15) | Low | Good | Med. (13.5) / Med. (20.0) | Med. (29) |

| ER4943 | Low (15) | Low | Very Good | Med. (15.5) / Med. (23.0) | Med. (35) |

| ER5087 | Good (25) | High | Good | High (20.0) / High (30.0) | High (42) |

| ER5183 | Good (25) | V. High | Good | High (18.5) / High (28.0) | High (41) |

| ER5356 | High (35) | Good | Good | High (18.0) / High (26.0) | High (38) |

| ER5554 | High (40) | Fair | Fair | Med. (17.0) / Med. (23.0) | Med. (33) |

| ER5556 | Good (25) | High | Good | High (20.0) / High (30.0) | High (42) |

MIG/GMAW Typical Process Parameters

| Wire Diameter (mm) / (") | Current Range (A) | Voltage Range (V) | Wire Feed Speed (ipm / m·min⁻¹) | Shielding Gas | Gas Flow (CFH) | Deposition Rate (lb/hr / kg/hr) |

| 0.8 (0.030) | 60–170 | 13–24 | 150–350 (3.8–8.9) | 100 % Ar | 20–25 | 4–8 (1.8–3.6) |

| 0.9 (0.035) | 70–180 | 15–26 | 200–400 (5.1–10.2) | 100 % Ar | 20–25 | 5–9 (2.3–4.1) |

| 1.0 (0.040) | 90–290 | 15–26 | 250–450 (6.4–11.4) | 100 % Ar | 20–25 | 6–12 (2.7–5.4) |

| 1.2 (0.047) | 140–260 | 20–29 | 300–500 (7.6–12.7) | Ar + 25 % He | 25–30 | 9–15 (4.1–6.8) |

| 1.6 (1/16) | 190–350 | 25–30 | 350–550 (8.9–14.0) | Ar + 25 % He | 25–30 | 12–20 (5.4–9.1) |

Aluminum MIG Wire Welding Positions

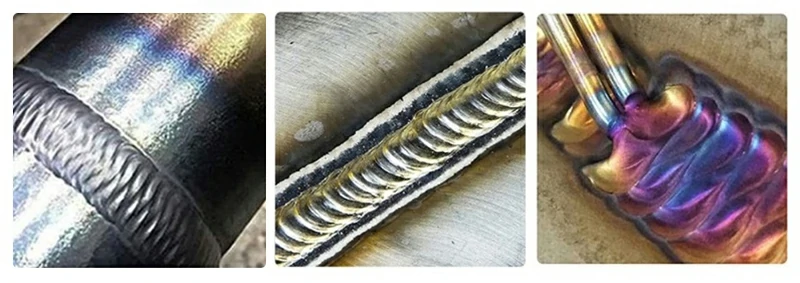

R4043 supports all welding positions except specialized downward vertical in furnace applications. Common positions include:

2G Horizontal Welding

Weld axis is horizontal in a vertical plane, ensuring stable pool and easy penetration. Ideal for side joints on medium plates or continuous pipe-to-plate welding.

4G Overhead Welding

Welds beneath the workpiece, needing precise droplet control to avoid sagging. Used for floor panels, ceilings, and reverse structural welding.

3G Vertical Down Welding

Torch moves downward along the joint for fast welding. Best for thin sheets to increase speed, but demands precise control to avoid droplet sag.

2F Horizontal Fillet Welding

Welds corner joints between horizontal and vertical plates, filling angles with smooth beads for strength and appearance—common in frames and structures.

1G Flat Welding

Weld lies on a horizontal plane. Offers optimal penetration and bead width for long, straight seam welding and large-area fabrication.

3F Vertical Up Fillet Welding

Fills vertical corner joint bottom-up, ensuring uniform penetration and tie-in—ideal for reliable fillet welds on load-bearing parts.

Arc transfer mode comparison

| Transfer Mode | Features | Applicable thickness/position | Advantages |

| Short-Circuit | Instantaneous jump after short circuit, minimum heat input, minimal spatter | Thin plates ≤ 3 mm; vertical welding, corner welding | Smooth weld formation, vertical welding to prevent dripping |

| Spray | Continuous small droplets, strong penetration | Medium and thick plates > 3 mm; flat welding, horizontal welding | High deposition efficiency, high weld accumulation rate |

| Pulse | High/low current alternation, reducing average heat input | Various thickness plates, fine welds | Both penetration and weld control are taken into account |

| Cold Metal Transfer (CMT) | Instant arc interruption + wire feeding retraction, near zero spatter | Ultra-thin plates, sheet metal; automated high-precision welding | Extremely low heat input, almost no spatter |

Shielding gas performance comparison

| Shielding gas | Weldability | Penetration | Weld appearance | Typical applications |

| 100 % Ar | Medium | Medium | Smooth, less spatter | Thin plate welding, indoor manual MIG |

| Ar + 25 % He | High | Strong | Weld slightly wider, deep enough | Medium and thick plates, high thermal conductivity substrates (such as 6XXX series) |

| Ar + 5–10 % CO₂ (optional) | Low | Low | Weld slightly thicker, more spatter | Low-cost occasions, not sensitive to spatter |

Equipment Setting Parameters for Aluminum MIG Wire

| Wire diameter (inch/mm) | Plate thickness (inch) | ER4043 Current (A) | ER5356 Current (A) | ER4043 Voltage (V) | ER5356 Voltage (V) | Wire feed rate (ipm) |

| 0.030″ / 0.8 mm | 1/16″ | 90 | 100 | 20 | 18 | 260 / 300 |

| 0.030″ / 0.8 mm | 3/32″ | 110 | 120 | 22 | 21 | 350 / 400 |

| 0.035″ / 0.9 mm | 1/16″ | 90 | 100 | 23 | 21 | 300 / 350 |

| 3/64″ / 1.2 mm | 3/32″ | 110 | 120 | 25 | 24 | 170 / 220 |

| 1/16″ / 1.6 mm | 1/4″ | 200 | 210 | 26 | 24 | 170 / 200 |

Typical mechanical properties of GTAW groove joint welds

| BASE ALLOY | AS WELDED | POST WELD HEAT TREAT AND AGE | |||||||

| BASE ALLOY | UTS (KSI) | UYS (KSI) | ELONG (%) | UTS (KSI) | UYS (KSI) | ELONG (%) | UTS (KSI) | UYS (KSI) | ELONG (%) |

| 2014-T6 | 70 | 60 | 13 | 34 | 28 | 4 | 50 | -- | 2 |

| 6061-T4 | 35 | 21 | 22 | 27 | 18 | 8 | 352 | -- | 82 |

| 6061-T6 | 45 | 40 | 12 | 27 | 18 | 8 | 44 | 40 | 5 |

| 6063-T4 | 25 | 22 | 22 | 20 | 10 | 12 | 30 | -- | 13 |

Why Choose Chalco?

Among many suppliers, Chalco ER4043 welding wire has the following four core advantages to help your project advance efficiently and ensure quality:

- Global Quality-Certified Production Line: Factory certified to ISO 9001 and IATF 16949, with an annual capacity of 8,000 tonnes and full batch traceability.

- Ultra-High Precision and Moisture Protection: Drawing tolerance strictly controlled at ± 0.02 mm, vacuum-dried and degassed before shipment, then sealed in aluminum-foil composite bags to ensure long-term moisture resistance.

- Rapid Delivery Capability: Stock wire diameters Ø 0.8–4.0 mm, with a minimum order of S100 (0.5 kg); all in-stock items ship within 72 h to your door.

- One-Stop Technical Support: Engineers respond within 24 h of order placement, providing dedicated welding parameter windows, base-metal comparison test plates, and COA/COC reports—truly "order online, worry-free offline.”

Click the Get Sample button on the right to let our professional team rapidly customize an ER4043 welding solution for you.

Instant Quote

ER4043 vs. ER5356

| Comparison items | ER4043 (Al-5%Si) | ER5356 (Al-5%Mg) |

| Chemical composition | Si 4.5–6.0 %; Fe ≤ 0.8 %; Cu ≤ 0.3 % | Mg 4.7–5.5 %; Si ≤ 0.25 %; Fe ≤ 0.4 % |

| Melting point range | 1065–1170°F (571–632°C) | 1190–1205°F (643–652°C) |

| Melting pool fluidity | ★★★★☆ (Excellent) | ★★☆☆☆ (General) |

| Penetration/penetration depth | Medium | Strong (deeper penetration) |

| Tensile strength (weld) | ~29 ksi (≈200 MPa) | ~38 ksi (≈260 MPa) |

| Elongation | ~6-12 % | ~18-25 % |

| Resistance to thermal cracking | Very low | Medium to high |

| Weld color difference | Light gray, good match to base material | Bright white, need to pay attention to post-processing |

| Compatible parent materials | 1xxx, 3xxx, 6xxx and low Mg 5xxx series | 5xxx (Mg ≤ 5%) and some 6xxx/7xxx series |

| Typical applications | Sheet trim, automotive panels, bicycle frames | Ship structures, pressure vessels, offshore platforms, storage tanks |

| Recommended shielding gas | 100 % Ar | Ar + 25 % He |

| AWS/ISO standards | AWS A5.10 ER4043; ISO 18273 S Al 4043 | AWS A5.10 ER5356; ISO 18273 S Al 5356 |

Want to learn more about the differences between ER4043 and ER5356?

Click to view the full comparison → ER4043 vs ER5356

Selection Guide—Six Steps to Pinpoint the Best MIG Wire

Step 1: Determine Base Metal Series

1xxx-series / 3xxx-series pure aluminum or low-alloy: recommend ER1100 (near-pure aluminum filler) or ER4043 (light-gray aesthetic weld).

5xxx-series (Mg ≤ 2.5 %) structural parts and tanks: prioritize ER5356 (high-strength, corrosion-resistant).

6xxx-series heat-treatable alloys: use ER4043 for weld appearance, ER4943 for strength.

7xxx-series (e.g., 7005): ER5356 also delivers high-toughness welds.

Step 2: Evaluate Welding Environment

Outdoor, windy conditions: choose Push-Pull or Spool Gun to ensure smooth, tangle-free feeding.

Marine or chemical corrosive environments: ER5183 and ER5556 offer exceptional corrosion resistance.

Industrial workshop or cleanroom: ER4043 produces minimal color mismatch with base metal.

Step 3: Define Weld Performance Requirements

Load-bearing or high-stress parts: select ER5356 (≈ 380 MPa UTS) or ER5556 (≈ 415 MPa UTS).

High weld appearance and post-anodizing: ER4043 yields light-gray, smooth, and uniform weld beads.

Gas-tight or large-gap joints: ER4047 provides optimal fluidity and pore-free fill.

Step 4: Match Wire Diameter to Plate Thickness

0.8–1.2 mm wire for 1–4 mm thin plate; combined with high-speed pulse for increased travel speed.

1.6–2.4 mm wire for 4–8 mm medium-thick plate; stable deposition suited for high-volume automated welding.

3.2–4.0 mm solid wire for > 8 mm thick plate multi-pass groove welds or heavy-duty structures.

Step 5: Verify Equipment Compatibility

Use U-groove aluminum drive rolls for adequate grip.

Employ PTFE-lined liners to reduce friction in the wire feed path.

Based on feed distance and welding method, decide on standard feed, Push-Pull, or Spool Gun.

Step 6: Cross-Check Industry Standards

All Chalco solid MIG wires comply with AWS A5.10 and ISO 18273.

For military or aerospace grades, select optional AMS 4190 (ER4043) or AMS 4191 (ER2319) certifications.

For a tailored recommendation, submit your base-metal grade, plate thickness, and production volume—Chalco engineers will deliver the ideal wire selection and process parameters within 24 hours.

Instant QuoteFAQs

Why does wire feeding jam or tangle occur during welding? How can I troubleshoot quickly?

Aluminum wire is soft and prone to oxidation. Common causes:

PTFE-lined liner wear or blockage by oxide film → use PTFE-lined liners and replace regularly.

Improper drive-roll tension → select high-hardness aluminum drive rolls and adjust to medium tension.

Excessive feed length or gravity pull → use Push-Pull or Spool Gun for smooth, tangle-free feeding.

How should I store aluminum wire to maintain optimal performance?

Chalco wire is vacuum-dried and sealed in aluminum-foil bags at the factory. For transport and storage, maintain 15–25 °C, RH < 60 %, and avoid direct sunlight, high temperatures, or humidity. No extra drying is needed before opening; once opened, reseal and use within 30 days.

My welds always show porosity and high rework costs—what can I do?

Porosity is usually caused by moisture and contamination:

Wire & base metal surfaces: vacuum-dry pre-weld (already done at factory); use within 30 days of opening; clean base metal of oil and oxides.

Shielding gas: choose ≥ 99.998% Ar or Ar+He mix, maintain 20–25 CFH.

Parameter fine-tuning: slightly increase voltage and wire-feed speed to reduce molten-pool exposure time.

I mainly weld 6061, 3003, and 5052 aluminum alloys—which wire should I choose?

6xxx-series (6061/3003): hot-crack sensitive → ER4043 (5 % Si) for low cracking and high weld appearance.

5xxx-series (Mg ≤ 2.5 % e.g., 5052): need high strength and corrosion resistance → ER5356 (5 % Mg).

For both: use ER5356 root pass (strength, seal) and ER4043 cap pass (appearance, color match).

I anodize after welding, but the weld bead is darker than the base metal—how can I minimize color mismatch?

Select ER4043 (light-gray weld) to match base metal.

Anodize the entire assembly or apply uniform local spray.

Use a dual-wire process: root pass ER4043, cap pass ER5356 or ER4943.

How should I store and maintain Chalco aluminum wire?

Unopened: store at 15–25 °C, RH < 60 %, away from light and moisture.

Opened: seal in a desiccant-packaged container and use within 30 days.

If overdue: bake at 120 °C for 1–2 h or re-vacuum-dry.

What is the minimum order quantity and delivery lead time?

Chalco offers a minimum order of S100 (0.5 kg) with stock wire diameters Ø 0.8–2.4 mm. All in-stock items ship within 72 h, and engineers provide welding parameters and test coupons within 24 h of order.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote