Aluminum flanges are widely used in pipeline engineering and industrial manufacturing to connect pipes, valves, pumps and equipment. Compared with steel flanges, aluminum flanges are lightweight, corrosion-resistant and easy to machine, ensuring reliable sealing, safety and long-term efficiency. With advanced forging and CNC machining capabilities, Chalco manufactures and customizes a full range of aluminum flange solutions to meet global industry standards.

Our product range covers multiple types of aluminum flanges, including pipe flanges, ductwork flanges, structural flanges and large-diameter flanges up to 5–7 meters. These options allow us to support diverse projects from HVAC ventilation systems to marine engineering and heavy industrial equipment.

Chalco Aluminum Pipe Flange Hot Selling Products

Aluminum pipe flanges are widely used to connect pipelines, valves, pumps and pressure vessels, ensuring secure sealing and reliable flow control. Compared with steel flanges, they offer lower weight, excellent corrosion resistance, and easier installation. Chalco manufactures aluminum pipe flanges in 6061, 7075, 5083, 5086 and other alloys, using advanced forging, machining and anodizing processes to meet ASME, EN, JIS and other international standards.

-

Large-Diameter Aluminum Pipe Flanges

Large-Diameter Aluminum Pipe Flanges

Chalco supplies large-diameter aluminum flanges up to 7 meters for petrochemical, offshore and wind-power projects. With heavy forging, CNC machining and automated welding, we deliver precise tolerances, high strength and reliable performance in harsh conditions.

Instant Quote -

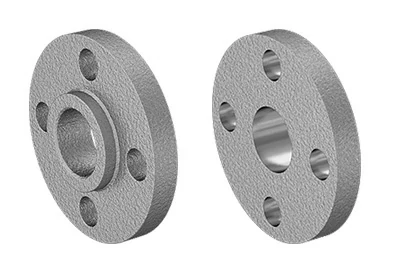

Aluminum Loose Plate Flanges

Aluminum Loose Plate Flanges

Also called lap joint flanges, aluminum loose plate flanges work with stub ends or flaring rings, allowing rotation for easy alignment. They simplify assembly, prevent bolt mismatch, and suit corrosive or frequently dismantled pipelines. Click to view detailed [Size Parameters].

Instant Quote -

Aluminum Slip-On Flanges

Aluminum Slip-On Flanges

Easy to install and cost-effective, aluminum slip-on flanges slide over the pipe and are welded on both sides. They are widely applied in low-pressure and low-temperature systems such as air, oil and water pipelines. Pressure class: 125. Click to view detailed [Size Parameters].

Instant Quote -

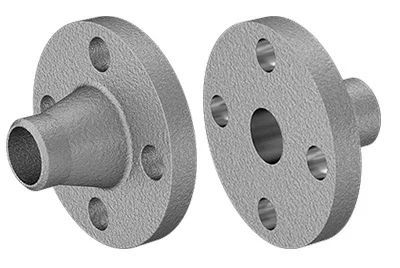

Aluminum Butt-Weld Flanges

Aluminum Butt-Weld Flanges

Seamlessly welded to the pipe, aluminum butt-weld flanges provide high-strength, leak-proof connections. They are suitable for high-pressure and high-temperature applications in oil & gas, chemical processing and marine systems. Pressure class: 125. Click to view detailed [Size Parameters].

Instant Quote -

Aluminum Welding Neck Flanges

Aluminum Welding Neck Flanges

Featuring a long tapered hub, aluminum welding neck flanges reduce stress concentration at the base and ensure reliable sealing under severe service. Common in petrochemical plants, power stations and pressure vessels.

Instant Quote -

Aluminum Socket Weld Flanges

Aluminum Socket Weld Flanges

In aluminum socket weld flanges, the pipe is inserted into the socket bore and fillet welded, producing high-strength, leak-tight joints. They are recommended for small-diameter, high-pressure pipelines with vibration or fatigue concerns.

Instant Quote -

Aluminum Blind Flanges

Aluminum Blind Flanges

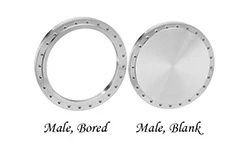

Aluminum blind flanges are solid discs used to block or terminate pipelines, nozzles or vessels. They are widely applied in system isolation, hydrostatic testing and maintenance, with optional customized drilling for different gasket styles. Click to view detailed [Size Parameters].

Instant Quote -

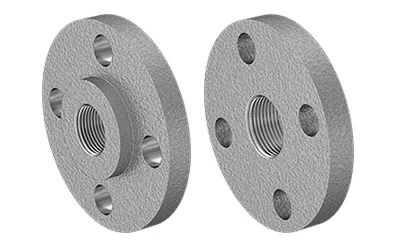

Aluminum Threaded Flanges

Aluminum Threaded Flanges

With threaded bores, aluminum threaded flanges connect to externally threaded pipes without welding. Ideal for low-pressure, small-diameter pipelines, they allow fast assembly and disassembly. Click to view detailed [Size Parameters].

Instant Quote -

Aluminum Collar Flanges

Aluminum Collar Flanges

Used together with loose flanges, aluminum collar flanges are welded or flared at pipe ends. They offer excellent corrosion resistance and are suitable for chemical, marine and seawater service where dismantling and reassembly are frequent.

Instant Quote

Chalco Aluminum Ductwork Flanges

Chalco supplies aluminum ductwork flanges for HVAC, ventilation and exhaust systems. Lighter than galvanized steel, they offer corrosion resistance, easy installation and reliable sealing. Our range includes rectangular, round and spiral duct flanges, with TDC, TDF and duct mate systems. Standard sizes such as 4", 8", 12" and 150 mm duct flanges are available, along with custom dimensions.

-

Aluminum Rectangular Duct Flanges

Aluminum Rectangular Duct Flanges

Designed for square and rectangular ducts, these flanges ensure rigid frame connections and high airtightness. Rectangular duct flanges are widely used in commercial buildings, factories and public infrastructure, providing stable support for large HVAC duct systems.

Instant Quote -

Aluminum Round & Spiral Duct Flanges

Aluminum Round & Spiral Duct Flanges

Suitable for circular ducts and spiral duct flanges, these connections guarantee proper alignment, low vibration and minimal air leakage. They are ideal for high-speed air flow systems such as cleanrooms, hospitals and industrial workshops.

Instant Quote -

Aluminum TDC / TDF Duct Flanges

Aluminum TDC / TDF Duct Flanges

TDC and TDF systems are standardized flange frames for rectangular ducts. Aluminum TDC / TDF duct flanges provide fast assembly, consistent sealing and reliable connections, widely adopted in modern HVAC projects for modular construction efficiency.

Instant Quote -

Aluminum Companion & Duct Mate Flanges

Aluminum Companion & Duct Mate Flanges

Companion flanges and duct mate flange systems enable quick, bolt-together connections with excellent sealing. They are popular in field installation, retrofitting and maintenance projects where flexibility and time savings are crucial.

Instant Quote

Chalco Aluminum Base Flange Hot Selling Products

Chalco supplies a complete range of aluminum base flanges for railings, fences, flooring systems and custom assemblies. Compared with steel base flanges, aluminum offers lighter weight, excellent corrosion resistance and easier installation. Our product range covers wall base flanges, floor base flanges, fence base flanges, threaded base flanges and weld-on base flanges, available in both round, square and customized sizes.

Aluminum Wall Base Flanges

Aluminum wall base flanges are designed for fixing handrails or railings to walls, ensuring stability and safety. Options include round wall base flanges and offset wall base flanges, suitable for residential, commercial and industrial projects.

Instant Quote

Aluminum Floor Base Flanges

Aluminum floor base flanges are used to secure railing posts or fence posts to the ground, providing vertical load-bearing support. Popular choices include square floor base flanges and rectangular floor base flanges, widely used in balconies, staircases and outdoor decks.

Instant Quote

Aluminum Fence Base Flanges

Aluminum fence base flanges are specifically designed for aluminum fence posts, providing strong structural support while keeping installation simple. Options include standard fence base flanges and reinforced fence post base flanges for heavy-duty applications.

Instant Quote

Aluminum Threaded & Weld Base Flanges

For special assembly needs, Chalco provides aluminum threaded base flanges and aluminum weld-on base flanges. These flanges are suitable for tanks, tubing connections, custom railing systems and industrial piping, ensuring leak-tight, durable performance.

Instant Quote

Chalco Aluminum Flange Finished Products Gallery

Below is a selection of Chalco's finished aluminum flange products. From weld neck and blind flanges to orifice, lap joint and special-shaped designs, we provide a complete range of solutions to meet different pipeline and structural requirements.

Weld neck flange

Long weld neck flange

Spectacle blind flanges

Socket weld flanges

Orifice flanges

Lap joint flanges

Square flanges

Ring type joint flanges

Expander flanges

Reducing flanges

Male & female flanges

Weldolet flange

Nipolet flange

Backing ring flanges

Ring spacer flanges

Paddle blind flanges

Plate flange

High hub blind flange

Swivel ring flange

Exhaust flanges

Wire seal flange

Aluminum Flange Specifications & Standards

Chalco supplies aluminum flanges in a wide range of alloys, dimensions and connection types to meet international pipeline, HVAC and structural engineering standards. Our flanges are available for pipe, ductwork and base mounting applications, ensuring reliable performance across industries.

Aluminum alloys: 7075, 6061, 5086, 5083, 3003, 1100

Other materials such as titanium, stainless steel or nickel alloy flanges are also available on request.

Nominal pipe sizes: NPS 1/2” to NPS 48” (DN15 to DN1200), plus customized ductwork and base flange dimensions.

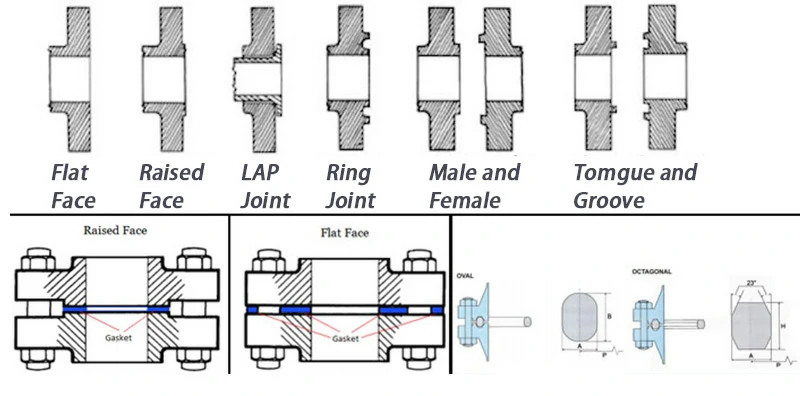

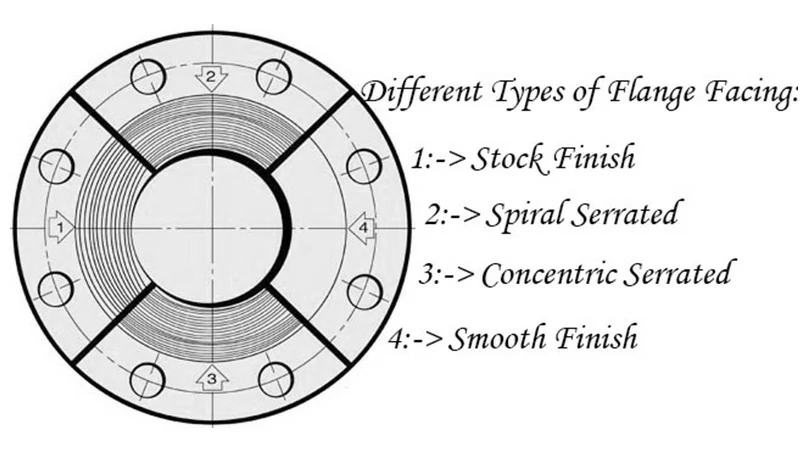

Flange face types: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ), Concentric Serrated, Spiral Serrated

Surface treatments: Stock finish, smooth surface, spiral serration, concentric serration, anodized [View details]

Standards supported:

- ASME: B16.5, B16.47 Type A/B, ANSI/ASME B16.1

- European: EN 1092-1, DIN 2633, UNI

- Japanese: JIS B2220

- Russian: GOST 12820 / 12821-80

- Korean: KS 1503

- South African: SANS/SABS

Chalco Aluminum Flange Manufacturing & Processing Capabilities

Forged Aluminum Flanges

Produced under high temperature and pressure, forged aluminum flanges feature dense grain structure, superior mechanical strength, and excellent fatigue resistance. Suitable for high-pressure and high-temperature environments in oil & gas, marine and chemical industries.

- Heavy forging presses up to XXXX tons ensure integrity for large-diameter flanges.

- Heat treatment options (T6, T651, etc.) optimize strength and toughness.

Cast Aluminum Flanges

Cast aluminum flanges allow complex shapes and cost-efficient production. While lower in strength than forged types, they are ideal for HVAC, low-pressure pipelines and structural connections.

- High-precision casting molds guarantee smooth surfaces and dimensional accuracy.

- Strict quality control system ensures compliance with EN and ASTM standards.

Machined / Cut Aluminum Flanges

CNC-machined aluminum flanges are cut from plate or bar stock, offering quick delivery and high dimensional accuracy. Best suited for medium and small-size customized projects.

- Equipped with multi-axis CNC lathes and milling centers for precision drilling and facing.

- Flexible production for one-off prototypes or batch runs.

Rolled Aluminum Flanges

Rolled flanges are formed by rolling plate into ring sections, then welded and machined. This process enables the production of large-diameter flanges up to 5–7 meters for offshore, wind energy and heavy equipment projects.

Backed by advanced forging, casting, machining and rolling technologies, Chalco delivers aluminum flanges that combine high strength, precision tolerances and reliable performance for diverse industries. Contact us today for technical support or to request a tailored quotation.

Instant QuoteChalco flange face types explained

Raised face flange (RF)

Raised face flanges (RF) are easily identifiable because the gasket surface area is above the flange bolt line. Raised face flanges are compatible with a wide range of flange gaskets, from flat face to semi-metallic and metallic types (e.g., jacketed and spiral wound gaskets), whether annular or full flat face.

Flat flange (FF)

The contact surface of a flat face flange (FF) is at the same height as the bolt line of the flange. A full-face gasket, usually a soft gasket, is used between two flat face flanges. According to ASME B31.3, a flat face flange should never be mated with a raised face flange because the resulting flange joint is certain to leak.

Ring joint flange (RTJ)

Ring Joint Flanges (RTJ) are used when a metal-to-metal seal between mating flanges is required (conditions for high pressure and high temperature applications, i.e. above 700/800 C°). Ring Joint Flanges have a circular groove that accommodates a Ring Joint Gasket (oval or rectangular ). RTJ flanges can be sealed by RTJ gaskets of different styles (R, RX, BX) and profiles (e.g. R style is octagonal/oval).

Lap flange

Lap joint flanges have flat faces that are not used to seal the flange joint, but simply carry the back side of the stub end. The sealing surface is actually on the stub end itself and can be either flat or convex.

Tongue and groove flange (T and G)

The two tongue-and-groove flanges (T&G faces) fit perfectly into each other: one flange has a raised ring, the other has a groove, and they fit together easily ( the tongue goes into the groove and seals the joint).

Inner and outer flanges (M and F)

Similar to tongue and groove flanges, the male and female flanges (M&F face type) also match each other. One flange has an area that extends beyond its face area, the male flange, and the other flange has a matching depression machined into the facing surface, the female flange. The female face is 3/16 inch deep, while the male face is 1/4 inch high, and both are smoothed. The outer diameter of the female face retains the gasket.

Chalco flange surface processing

Inventory complete

It is the most widely used of all flange finishes because it is suitable for virtually all common service conditions. Under compression, the soft face of the gasket will dig into this finish, which helps to form a seal and creates a high level of friction between the mating surfaces. The finish on these flanges is produced by a 1.6 mm radius round head tool at a feed rate of 0.8 mm per revolution up to size 12". For sizes 14 inches and larger, the finish is completed by a 3.2 mm round head tool at a feed rate of 1.2 mm per revolution .

Spiral sawtooth

This is also a continuous or phonograph spiral groove, but it differs from the original finish in that the groove is usually produced using a 90° tool, creating a "V" shaped geometry with 45° angle teeth.

Concentric sawtooth

As the name implies, this surface consists of concentric grooves. With a 90° tool, the teeth are evenly spaced across the surface.

Smooth surface

This surface finish has no visible tool marks. These finishes are commonly used on gaskets with metal surfaces such as double jackets, flat steel and corrugated metal. Smooth surfaces mate to form a seal and rely on the flatness of the opposing surfaces to achieve the seal. This is usually achieved by having the gasket contact surface formed by a continuous spiral groove formed by a rounded tool with a radius of 0.8 mm at a feed rate of 0.3 mm per revolution and a depth of 0.05 mm. This will result in a roughness between Ra 3.2 and 6.3 microns (125 – 250 micro inches).

Applications of Aluminum Flanges

Aluminum flanges are valued for their lightweight, corrosion resistance, and cost-efficiency, making them a reliable choice across multiple industries. Chalco supplies customized aluminum pipe flanges, ductwork flanges, and base flanges for a wide range of engineering projects.

- Oil & Gas / Petrochemical – Aluminum flanges are used in offshore platforms, refineries, and pipeline systems where resistance to seawater and chemicals is critical, reducing weight compared with traditional steel flanges.

- Marine & Shipbuilding – Ideal for seawater pipelines, ballast systems, and exhaust ducts. Aluminum's natural corrosion resistance extends service life and lowers maintenance costs in harsh marine environments.

- HVAC & Ventilation – Ductwork flanges made from aluminum provide excellent air-tightness, easy installation, and long-term stability for ventilation, smoke exhaust, and cleanroom systems.

- Construction & Structural Engineering – Base flanges are applied in handrails, fences, and architectural supports, ensuring lightweight yet strong connections for modern building projects.

- Power & Renewable Energy – Large-diameter aluminum flanges are widely used in wind power towers and power station piping, delivering high strength while reducing overall structural weight.

- Chemical & Industrial Equipment – Corrosion-resistant aluminum flanges are suitable for low-pressure pipelines, tanks, and process equipment in chemical plan

Chalco flange product partial stock size reference table

|

Loose plate flange aluminum | ||||||

| DN | d1 | Typ | b | O | kg | Price | |

| 10 | 17,2 | C | 12 | blank | 0,196 | request | |

| 15 | 21,3 | C | 12 | blank | 0,180 | request | |

| 15 | 21,3 | C | 12 | coated | 0,180 | request | |

| 20 | 26,9 | C | 12 | blank | 0,235 | request | |

| 20 | 26,9 | C | 12 | coated | 0,240 | request | |

| 25 | 29,0 | A | 12 | blank | 0,260 | request | |

| 25 | 29,0 | A | 12 | coated | 0,280 | request | |

| 25 | 33,7 | C | 12 | blank | 0,240 | request | |

| 25 | 33,7 | C | 12 | coated | 0,260 | request | |

| 32 | 35,0 | A | 16 | blank | 0,500 | request | |

| 32 | 35,0 | A | 16 | coated | 0,560 | request | |

| 32 | 42,4 | C | 16 | blank | 0,520 | request | |

| 32 | 42,4 | C | 16 | coated | 0,524 | request | |

| 40 | 44,0 | A | 16 | blank | 0,593 | request | |

| 40 | 44,0 | A | 16 | coated | 0,600 | request | |

| 40 | 48,3 | C | 16 | blank | 0,580 | request | |

| 40 | 48,3 | C | 16 | coated | 0,580 | request | |

| 50 | 54,0 | A | 16 | blank | 0,780 | request | |

| 50 | 54,0 | A | 16 | coated | 0,760 | request | |

| 50 | 57,0 | B | 16 | blank | 0,770 | request | |

| 50 | 57,0 | B | 16 | coated | 0 | request | |

| 50 | 60,3 | C | 16 | blank | 0,700 | request | |

| 50 | 60,3 | C | 16 | coated | 0,690 | request | |

| 50 | 60,3 | D | 18 | blank | 0,640 | request | |

| 65 | 70,0 | A | 16 | blank | 0,860 | request | |

| 65 | 70,0 | A | 16 | coated | 0,920 | request | |

| 65 | 76,1 | C | 16 | blank | 0,850 | request | |

| 65 | 76,1 | C | 16 | coated | 0,860 | request | |

| 65 | 76,1 | D | 18 | blank | 0,797 | request | |

| 80 | 84,0 | A | 18 | blank | 1,099 | request | |

| 80 | 84,0 | A | 18 | coated | 1,100 | request | |

| 80 | 88,9 | C | 18 | blank | 1,038 | request | |

| 80 | 88,9 | C | 18 | coated | 1,060 | request | |

| 80 | 88,9 | D | 20 | blank | 0,951 | request | |

| 100 | 104,0 | A | 18 | blank | 1,247 | request | |

| 100 | 104,0 | A | 18 | coated | 1,240 | request | |

| 100 | 108,0 | B | 18 | blank | 1,240 | request | |

| 100 | 108,0 | B | 18 | coated | 0 | request | |

| 100 | 114,3 | C | 18 | blank | 1,180 | request | |

| 100 | 114,3 | C | 18 | coated | 1,120 | request | |

| 100 | 114,3 | D | 20 | blank | 1,014 | request | |

| 125 | 129,0 | A | 18 | blank | 1,475 | request | |

| 125 | 129,0 | A | 18 | coated | 1,540 | request | |

| 125 | 133,0 | B | 18 | blank | 1,650 | request | |

| 125 | 133,0 | B | 18 | coated | 0 | request | |

| 125 | 139,7 | C | 18 | blank | 1,430 | request | |

| 125 | 139,7 | C | 18 | coated | 1,439 | request | |

| 125 | 139,7 | D | 22 | blank | 1,538 | request | |

| 150 | 154,0 | A | 18 | blank | 1,874 | request | |

| 150 | 154,0 | A | 18 | coated | 1,920 | request | |

| 150 | 159,0 | B | 18 | blank | 1,870 | request | |

| 150 | 159,0 | B | 18 | coated | 0 | request | |

| 150 | 168,3 | C | 18 | blank | 1,700 | request | |

| 150 | 168,3 | C | 18 | coated | 1,680 | request | |

| 150 | 168,3 | D | 22 | blank | 2,054 | request | |

| 200 | 204,0 | A | 20 | blank | 2,660 | request | |

| 200 | 204,0 | A | 20 | coated | 2,680 | request | |

| 200 | 219,1 | C | 20 | blank | 2,486 | request | |

| 200 | 219,1 | C | 20 | coated | 2,420 | request | |

| 200 | 219,1 | D | 24 | blank | 2,216 | request | |

| 250 | 254,0 | A | 22 | blank | 3,570 | request | |

| 250 | 254,0 | A | 22 | coated | 3,298 | request | |

| 250 | 267,0 | B | 22 | blank | 3,300 | request | |

| 250 | 267,0 | B | 22 | coated | 0 | request | |

| 250 | 273,0 | C | 22 | blank | 3,240 | request | |

| 250 | 273,0 | C | 22 | coated | 3,220 | request | |

| 250 | 273,0 | D | 26 | blank | 3,480 | request | |

| 300 | 304,0 | A | 22 | blank | 4,240 | request | |

| 300 | 304,0 | A | 22 | coated | 3,700 | request | |

| 300 | 323,9 | C | 22 | blank | 3,720 | request | |

| 300 | 323.9 | C | 22 | coated | 3,680 | request | |

| 300 | 323.9 | D | 26 | blank | 3,380 | request | |

| 350 | 355.6 | A/C | 22 | blank | 5,100 | request | |

| 350 | 355.6 | A/C | 22 | coated | 5,200 | request | |

| 350 | 368,0 | B | 22 | blank | 4,200 | request | |

| 350 | 368,0 | B | 22 | coated | 0 | request | |

| 400 | 406,4 | A/C | 25 | blank | 6,940 | request | |

| 400 | 406,4 | A/C | 25 | coated | 7,020 | request | |

| 450 | 457,2 | A/C | 25 | coated | 0 | request | |

| 450 | 457.2 | A/C | 25 | blank | 7,300 | request | |

| 500 | 508.0 | A/C | 28 | blank | 9,320 | request | |

| 500 | 508.0 | A/C | 28 | coated | 0 | request | |

| 600 | 609.6 | A/C | 30 | blank | 12,130 | request | |

| 600 | 609.6 | A/C | 30 | coated | 14,500 | request | |

| 700 | 711.2 | A/C | 40 | blank | 21,000 | request | |

| 700 | 711.2 | A/C | 40 | coated | 0 | request | |

| 800 | 812.8 | A/C | 44 | blank | 29,200 | request | |

| 800 | 812.8 | A/C | 44 | coated | 30,000 | request | |

| 900 | 914.4 | A/C | 44 | blank | 37,000 | request | |

| 900 | 914.4 | A/C | 44 | coated | 0 | request | |

| 1000 | 1016.0 | Air conditioning | 44 | blank | 43,000 | request | |

| 1000 | 1016.0 | A/C | 44 | coated | 0 | request | |

| 1200 | 1232.0 | Air conditioning | 60 | blank | 75,000 | request | |

|

Slip-on weld flanges | ||||||

| Pipe size | Flange OD | For Bolt Dia | Dia | No. of | Bolt Circle Dia. | Max. Pressure | |

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 150 psi @ 72° F | |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 150 psi @ 72° F | |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 150 psi @ 72° F | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 psi @ 72° F | |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 150 psi @ 72° F | |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 150 psi @ 72° F | |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 150 psi @ 72° F | |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 150 psi @ 72° F | |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 150 psi @ 72° F | |

| 6 | 11" | 3/4" | 7/8" | 8 | 9 1/2" | 150 psi @ 72° F | |

| 8 | 13 1/2" | 3/4" | 7/8" | 8 | 11 3/4" | 150 psi @ 72° F | |

|

Butt-weld flanges | ||||||

| Pipe size | Flange OD | For Bolt Dia | Dia | No. of | Bolt Circle Dia. | Max. Pressure | |

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 150 psi @ 72° F | |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 150 psi @ 72° F | |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 150 psi @ 72° F | |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 150 psi @ 72° F | |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 150 psi @ 72° F | |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 150 psi @ 72° F | |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 150 psi @ 72° F | |

| 6 | 11" | 3/4" | 7/8" | 8 | 9 1/2" | 150 psi @ 72° F | |

|

Aluminum blind flange | ||||

| Size (in) | Bolt Circle Diameter (in) | Bolt Hole Diameter (in) | Flange Diameter (in) | Flange Thickness (in) | Number of Bolt Holes |

| 1/2 | 2.38 | 0.63 | 3.5 | 0.44 | 4 |

| 3/4 | 2.75 | 0.63 | 3.88 | 0.5 | 4 |

| 1 | 3.13 | 0.63 | 4.25 | 0.56 | 4 |

| 1-1/4 | 3.5 | 0.63 | 4.63 | 0.63 | 4 |

| 1-1/2 | 3.88 | 0.63 | 5 | 0.69 | 4 |

| 2 | 4.75 | 0.75 | 6 | 0.75 | 4 |

| 2-1/2 | 5.5 | 0.75 | 7 | 0.88 | 4 |

| 3 | 6 | 0.75 | 7.5 | 0.94 | 4 |

| 3-1/2 | 7 | 0.75 | 8.5 | 0.94 | 8 |

| 4 | 7.5 | 0.75 | 9 | 0.94 | 8 |

| 5 | 8.5 | 0.88 | 10 | 0.94 | 8 |

| 6 | 9.5 | 0.88 | 11 | 1 | 8 |

| 8 | 11.75 | 0.88 | 13.5 | 1.13 | 8 |

| 10 | 14.25 | 1 | 16 | 1.19 | 12 |

|

Aluminum threaded pipe flange | ||||||

| Pipe size | Flange OD | For Bolt Dia | Dia | No. of | Bolt Circle Dia. | Max. Pressure | |

| 1/2 | 3 1/2" | 1/2" | 5/8" | 4 | 2 3/8" | 150 psi @ 72° F | |

| 3/4 | 3 7/8" | 1/2" | 5/8" | 4 | 2 3/4" | 150 psi @ 72° F | |

| 1 | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/8" | 150 psi @ 72° F | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 psi @ 72° F | |

| 1 1/2 | 5" | 1/2" | 5/8" | 4 | 3 7/8" | 150 psi @ 72° F | |

| 2 | 6" | 5/8" | 3/4" | 4 | 4 3/4" | 150 psi @ 72° F | |

| 2 1/2 | 7" | 5/8" | 3/4" | 4 | 5 1/2" | 150 psi @ 72° F | |

| 3 | 7 1/2" | 5/8" | 3/4" | 4 | 6" | 150 psi @ 72° F | |

| 4 | 9" | 5/8" | 3/4" | 8 | 7 1/2" | 150 psi @ 72° F | |

| 6 | 11" | 3/4" | 7/8" | 8 | 9 1/2" | 150 psi @ 72° F | |

| 8 | 13 1/2" | 3/4" | 7/8" | 8 | 11 3/4" | 150 psi @ 72° F | |

Frequently Asked Questions About Aluminum Flanges

How to choose the right flange type?

Select based on system requirements such as pressure, temperature, medium characteristics, and ease of installation. Common options include slip-on, welding neck, blind, threaded and socket weld aluminum flanges.

Why choose aluminum instead of steel flanges?

Aluminum flanges are lightweight, corrosion-resistant, thermally conductive and non-magnetic. They are widely used in aerospace, marine, HVAC and food processing where weight reduction and durability are critical.

How to choose the flange material?

For non-corrosive, lightweight systems aluminum alloys such as 6061, 5083 and 7075 are recommended. For high-pressure or specialized media, stainless steel or titanium flanges may also be considered.

How to ensure quality of aluminum flanges?

- Alloys with EN 10204 3.1 material certificates

- Dimensional accuracy and surface treatment inspection

- ISO, ASME, CE and marine classification approvals available

What is the lead time when ordering?

- Standard sizes: usually in stock, 1–3 days shipping

- Custom or large-diameter: 10–30 days depending on complexity

Can Chalco produce customized aluminum flanges?

Yes, we support non-standard sizes, large diameters up to 7 meters, special face types and surface finishes, tailored for specific project needs.

Which industries use aluminum flanges?

Aluminum flanges are widely applied in petrochemical, marine, HVAC, aerospace, automotive and structural construction projects where corrosion resistance and lightweight are essential.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote