Aluminum is the preferred material for modern heat exchanger applications thanks to its excellent thermal conductivity, corrosion resistance, and lightweight nature. Chalco supplies brazing clad strip and coil in customized dimensions, engineered for condenser tubes, radiator header plates, evaporator end plates, and EV battery cooling plates. With multi-layer alloy combinations such as 4343/3003, 4045/6061, and 4343/6951/7072, our aluminum brazing materials ensure stable brazing performance, long service life, and cost-effective manufacturing across automotive, HVAC, industrial, and power electronics heat exchangers.

-

Product Overview →

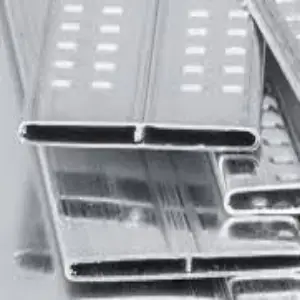

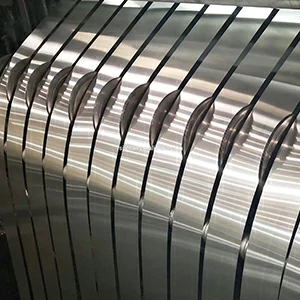

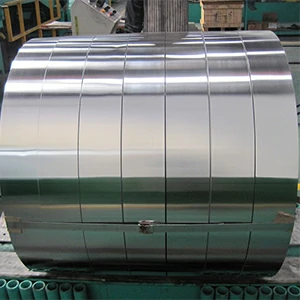

Products: Brazing clad aluminum sheet · strip · coil

Specs: t 0.05–3.0 mm · w ≤ 1500 mm

Alloys: 4343/3003 · 4045/6061 · 4343/6951 · 4343/7072

-

Heat Exchanger Components →

Tubes: Fin & flat tubes

Plates: Header & side plates

Cooling: EV battery cold plates

Process: CAB & vacuum brazing

-

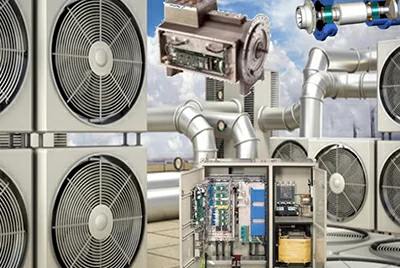

Industry Applications →

Automotive: Radiators, condensers, intercoolers

HVAC: Evaporators, coil systems

Industrial: Process coolers & electronics

Energy: EV thermal & power cooling

| Specifications of Aluminum Brazing Coil & Strip | ||||||||

| Brazing layer grade | Base grade | State | Coverage rate (%) | Thickness(mm) | Width(mm) | Plate length (mm) | Coil inner diameter (mm) | Coil outer diameter (mm) |

|

4A13 4A17 4A43 4A45 4045 4045 4047 4104 4343 |

3A11 3003 3003 6A02 6060 6082 6951 7A11 7072 |

O H12 H22 H14 H24 H24 H16 H26 |

3.0 ~ 25.0 | 0.050 ~ 6.000 | 7.0 ~ 1600.0 | ≤10,000 |

75.0 150.0 200.0 250.0 300.0 400.0 500.0 505.0 |

2500.0 |

| The order of alloy structure is "brazing layer/substrate layer", such as 4343/3003 | ||||||||

| The 7072 grade is an anodic anti-corrosion layer, which is usually used as an outer layer in a three-layer or multi-layer structure. | ||||||||

Heat Exchanger Components and Matching Aluminum Brazing Materials

-

Condenser & Radiator Tubes

Material form: Brazing clad aluminum strip or coil, optimized for precision tube forming.

Recommended clad alloys: 4343/3003, 4045/6060 → product details

Key advantages: Excellent formability, stable brazing flow, leak-tight joints, and long service life in automotive radiators and condensers.

-

Header & Side Plates

Material form: Brazing clad aluminum sheet with thickness up to 6 mm.

Recommended clad alloys: 4343/3003, 4343/6951 → product details

Key advantages: High strength, reliable brazing joints, and strong corrosion resistance to ensure structural stability of heat exchangers.

-

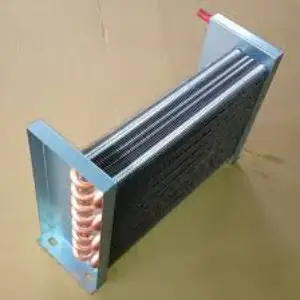

Evaporator End Plates

Material form: Brazing clad sheet or strip, often supplied in multilayer structures.

Recommended clad alloys: 4343/3003, 4343/7072 → product details

Key advantages: Compact design compatibility, 7072 layer as sacrificial anti-corrosion protection, long-term durability in HVAC applications.

-

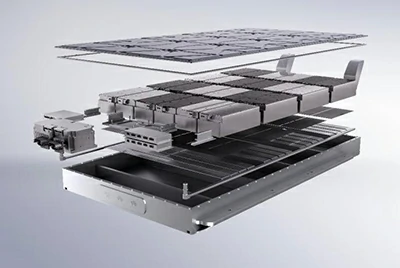

EV Battery Cooling Plates

Material form: Brazing clad sheet and coil engineered for battery cooling assemblies.

Recommended clad alloys: 4343/3003/7072 multilayer clad structures → product details

Key advantages: Excellent brazing reliability, high thermal conductivity, and enhanced corrosion protection for safe and efficient EV battery thermal management.

By partnering with Chalco, you gain more than just clad sheet, strip and coil — we deliver a complete heat exchanger materials solution. From brazing foil for high-efficiency fins to aluminum brazing wires and rods for reliable joining, Chalco provides integrated products that ensure your entire project runs smoothly with consistent quality and supply.

Industry Applications — Aluminum for Heat Exchangers (Brazing Sheet, Strip & Coil)

Automotive Heat Exchangers

Parts: Radiators, condensers, intercoolers

Forms: Coil for tubes; sheet for header/side plates

Alloys: 4343/3003, 4045/6060

Features: Formability, uniform braze, long service life

HVAC & Refrigeration

Parts: Evaporators, condenser coils, header plates

Forms: Double-clad strip; multilayer sheet

Alloys: 4343/7072, 4045/3102/4045

Features: Corrosion resistance, stable joints

New Energy / EV Thermal Management

Parts: Battery cooling plates, liquid channels

Forms: Clad sheet & coil for plate assemblies

Alloys: 4343/3003/7072, 4343/3102

Features: High conductivity, sacrificial anti-corrosion

Industrial & Power

Parts: Process coolers, steam condensers, plate-fin cores

Forms: Wide strip & sheet for heavy-duty exchangers

Alloys: 4343/6951/7072, 4045/3102/7072

Features: Multilayer integrity, cycle durability

Beyond heat exchangers, Chalco brazing sheet, strip and coil are also engineered for liquid cold plates and heat spreaders, power-electronics baseplates (IGBT/inverter), battery trays and housings with integrated cooling channels, HVAC distributors/manifolds, microchannel manifolds and fluid lines, as well as oil/transmission cooler shells and charge-air cooler tanks. Share your drawings/specs and we’ll recommend the right clad stack-up and provide a rapid quotation.

Aluminum for Heat Exchangers — Brazing Sheet, Strip & Coil Product Detail

-

Single-sided brazing clad aluminum strip

Use: one-side brazed joints for header/end plate edges and compact subassemblies; cost-efficient with good formability.

Alloys: 4343/3003, 4343/3102, 4343/6951, 4045/6061 → technical parameters

Applications: header/end plates, localized structural joints, compact heat-exchanger parts.

-

Double-side clad brazing strip

Use: double-sided brazing to ensure joint integrity and stiffness in plates and cores.

Alloys: 4343/3003/4343, 4045/3102/4045, 4343/6951/4343, 4343/6061/4343 → technical parameters

Applications: sandwich cooling plates, channel plates, intercooler/radiator cores.

-

Functional brazing strip

Use: harsh or high-performance conditions with 7072 sacrificial layer, Zn-modified cores, high-conductivity cores or surface pretreatments.

Alloys: 4343/3003+Zn/7072, 4045/3102/7072, 4343/6951/7072, 4343/6061/PET → technical parameters

Applications: salt-mist environments, EV cooling modules, precision electronic plates.

-

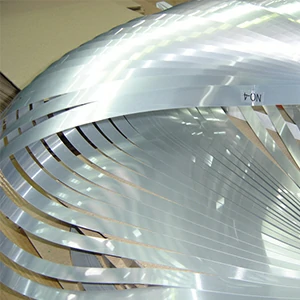

Clad brazing strip for tube forming

Use: HFW/flat/microchannel tube making; excellent ductility, clean surface and welding compatibility.

Alloys: 4343/3003/7072, 4045/3003+Zn/7072, 4343/3102/7072, 4343/6061/4343, 4343/6951/7072 → technical parameters

Applications: condenser/radiator flat tubes, EV microchannels, HVAC structural tubes.

-

Core alloy strip for brazing foil & strip

Use: high-quality cores for self-lamination or multilayer stacks; optimized for tube stock and intermediate plate layers.

Alloys: 3003, 3003+Zn, 3102, 6061, 6951, 8011, 7072 → technical parameters

Applications: multilayer composite cores, HFW tube core (fin stock), heat-exchange plate base layers.

Supply form:

- Aluminum coil

- The surface can be anodized, degreased, and pre-treated

- Supports fixed width and fixed thickness (thickness tolerance can be controlled within ±0.01mm)

Manufacturing Capabilities & Quality — Why Choose Chalco

For aluminum heat exchanger projects, Chalco delivers end-to-end material capability and quality assurance. We provide brazing clad sheet, strip and coil with precise clad coverage control, tight dimensional tolerances and surface readiness for CAB and vacuum brazing. Backed by engineering support, testing documentation and export-grade logistics, we help you shorten validation cycles and achieve stable, repeatable production at scale.

Overview of Main Production Capabilities

| Project | Capability parameters |

| Alloy Support | 1100, 3003, 3102, 6061, 6951, 4343, 4045, 7072, etc. |

| Aluminum Strip Thickness Range | 0.05 mm – 3.0 mm (supports three-layer composite structure) |

| Width range | Max coil base width > 1500 mm; slit per project requirements |

| Composite structure | Single-/Double-side cladding, 3-layer composite, Zn-modified strip |

| Interlayer uniformity | Clad thickness tolerance ±0.003 mm; edge alignment ≤ ±0.2 mm |

| Surface state | O / H14 / H18 / H22 / H24 |

| Coating method | Roll-pressed, cladding, directional symmetric, zoned cladding |

| Cutting accuracy | ±0.3 mm; fit for high-speed automated lines |

- Process compatibility: CAB (NOCOLOK) and vacuum brazing ready; matched stacks for HFW/flat/microchannel tubes.

- Engineering support: alloy stack-up & coverage ratio selection, brazing window matching, DFM for plates/tubes.

- Quality assurance: lot traceability, repeatable batches, metallography & coverage% reports on request.

- Surface readiness: degreasing / pretreatments for clean wetting and stable fillets.

- Packaging & logistics: export-grade packing for global shipments; documentation set (COA/test reports).

- Lead time: regular specs 7–10 working days; customized structures confirmed per order.

Chalco brazing composite belt product technical parameters and performance indicators

Chalco can provide single-sided/double-sided coated and three-layer composite brazing aluminum strips . Its mechanical properties, composite layer accuracy and welding adaptability meet or exceed industry standards and are widely used in high-demand brazing structures.

Chalco brazing aluminum strip coverage deviation

| Coverage rate (%) | Coverage rate tolerance (%) |

| 3.0~6.0 | ±1.2 |

| >6.0~8.0 | ±1.5 |

| >8.0~13.0 | ±2.0 |

| >13.0~25.0 | ±3.0 |

Chalco brazing aluminum strip thickness deviation

| Thickness(mm) | ≤1000 mm width deviation | >1000~1320 mm width deviation | >1320~1600 mm width deviation |

| 0.050~0.100 | ±0.006 | ±0.006 | ±0.006 |

| >0.100~0.200 | ±0.015 | ±0.015 | ±0.015 |

| >0.200~0.400 | ±0.020 | ±0.030 | ±0.040 |

| >0.400~0.700 | ±0.030 | ±0.040 | ±0.050 |

| >0.700~1.000 | ±0.040 | ±0.050 | ±0.060 |

Room temperature tensile mechanical properties of Chalco composites

| Temper | Thickness(mm) | Tensile strength Rm (N/mm²) | Specified non-proportional elongation strength Rp0.2 (N/mm²) | Elongation after fracture A50mm (%) |

| O | 0.050~0.100 | 95~160 | 35 | ≥6.0 |

| >0.100~0.200 | 95~160 | 35 | ≥10.0 | |

| >0.200~1.300 | 95~160 | 35 | ≥18.0 | |

| >1.300~6.000 | 95~160 | 35 | ≥20.0 | |

| H12 | 0.050~0.100 | 120~170 | 90 | ≥1.0 |

| >0.100~0.200 | 120~170 | 90 | ≥3.0 | |

| >0.200~1.300 | 120~170 | 90 | ≥4.0 | |

| >1.300~6.000 | 120~170 | 90 | ≥5.0 | |

| H22 | 0.050~0.100 | 120~170 | 80 | ≥2.0 |

| >0.100~0.200 | 120~170 | 80 | ≥6.0 | |

| >0.200~1.300 | 120~170 | 80 | ≥6.0 | |

| >1.300~6.000 | 120~170 | 80 | ≥7.0 | |

| H14 | 0.050~0.100 | 150~200 | 125 | ≥0.5 |

| >0.100~0.200 | 150~200 | 125 | ≥1.0 | |

| >0.200~1.300 | 150~200 | 125 | ≥2.0 | |

| >1.300~6.000 | 150~200 | 125 | ≥5.0 | |

| H24 | 0.050~0.100 | 150~200 | 115 | ≥1.0 |

| >0.100~0.200 | 150~200 | 115 | ≥3.0 | |

| >0.200~1.300 | 150~200 | 115 | ≥3.0 | |

| >1.300~6.000 | 150~200 | 115 | ≥5.0 | |

| H16 | 0.050~0.100 | 170~230 | 150 | ≥0.5 |

| >0.100~0.200 | 170~230 | 150 | ≥1.0 | |

| >0.200~1.300 | 170~230 | 150 | ≥2.0 | |

| >1.300~6.000 | 170~230 | 150 | ≥2.0 | |

| H26 | 0.050~0.100 | 170~230 | 140 | ≥1.0 |

| >0.100~0.200 | 170~230 | 140 | ≥2.0 | |

| >0.200~1.300 | 170~230 | 140 | ≥3.0 | |

| >1.300~6.000 | 170~230 | 140 | ≥5.0 | |

| H18 | >0.100~0.200 | ≥200 | 170 | ≥0.5 |

| >0.200~6.000 | ≥200 | 170 | ≥1.0 |

Room temperature tensile mechanical properties of composite materials

| Temper | Thickness(mm) | Tensile strength Rm (N/mm²) | Specified non-proportional elongation strength Rp0.2 (N/mm²) | Elongation after fracture A50mm (%) |

| O | 0.050~0.100 | 95~165 | 35 | ≥6.0 |

| >0.100~0.200 | 95~165 | 35 | ≥10.0 | |

| >0.200~1.300 | 95~165 | 35 | ≥18.0 | |

| >1.300~6.000 | 95~165 | 35 | ≥20.0 | |

| H12 | 0.050~0.100 | 125~205 | 90 | ≥1.0 |

| >0.100~0.200 | 125~205 | 90 | ≥2.0 | |

| >0.200~1.300 | 125~205 | 90 | ≥3.0 | |

| >1.300~6.000 | 125~205 | 90 | ≥6.0 | |

| H22 | 0.050~0.100 | 125~205 | 80 | ≥2.0 |

| >0.100~0.200 | 125~205 | 80 | ≥3.0 | |

| >0.200~1.300 | 125~205 | 80 | ≥7.0 | |

| H14 | 0.050~0.100 | 145~225 | 125 | ≥1.0 |

| >0.100~0.200 | 145~225 | 125 | ≥2.0 | |

| >0.200~1.300 | 145~225 | 125 | ≥4.0 | |

| H24 | 0.050~0.100 | 145~225 | 115 | ≥2.0 |

| >0.100~0.200 | 145~225 | 115 | ≥3.0 | |

| >0.200~1.300 | 145~225 | 115 | ≥5.0 |

Room temperature tensile mechanical properties of composite materials

| Temper | Thickness(mm) | Tensile strength Rm (N/mm²) | Specified non-proportional elongation strength Rp0.2 (N/mm²) | Elongation after fracture A50mm (%) |

| O | 0.200~6.000 | ≤160 | 85 | 16.0 |

Typical grades, states, coverage and dimensions of composite strips for pipe making

| Brazing layer grade | Base grade | state | Thickness (mm) | Width (mm) | Coverage rate (%) |

| 4A13, 4A17, 4A43, 4A45, 4004, 4045, 4047, 4104, 4343 | 3B11, 3003, 3005, 7072 | H14 | >0.200~ 3.000 | 7.0~ 1400.0 | 3.0~20.0 |

| H24 |

FAQ

Q: Can you customize clad coverage and temper?

A: Yes. Coverage 3–25% and O/H tempers can be tuned to your forming route and brazing window.

Q: When should we add a 7072 sacrificial layer?

A: For salt-mist or condensate-prone environments (coastal HVAC, EV cooling plates) to enhance corrosion resistance and service life.

Q: 4343/3003 vs. 4045/3102 — how to choose?

A: 4343/3003 is the universal stack for condenser/evaporator cores; 4045/3102 helps when higher conductivity or specific flow/wetting behavior is required.

Q: Do you support vacuum brazing applications?

A: Yes. We offer degreased surfaces and suitable stacks (e.g., 4343/3003/7072) for flux-free, clean joints in vacuum brazing.

Q: MOQ and lead time?

A: MOQ 1 ton for standard stacks. Regular specs ship in 7–10 working days; customized structures are confirmed per order.

Ordering & Sample

- Process: Send drawings/specs (stack-up, coverage %, sizes, temper, surface, CAB/vacuum) → we provide technical proposal & quotation → trial/sample validation → finalize spec → production & shipment.

- Quote & lead time: Include qty, coil/sheet, tolerances, any mechanical targets; regular specs ship in 7–10 working days; standard stacks MOQ 1 ton.

- Packing & docs: Moisture-proof vacuum film + stretch film + export wooden case; lot traceability with COA/test reports on request.

Share your drawings/specs to our email box for a tailored stack-up and rapid quotation.

Instant QuoteChalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote