In modern bicycle manufacturing, aluminum alloy is one of the most widely used metal materials. Among them, 6061-T6 aluminum tubing stands out for its excellent strength-to-weight ratio, good weldability and machinability, and outstanding corrosion resistance, making it a mainstream choice for frames of mountain bikes, road bikes, and urban commuter bikes.

Why choose Chalco 6061 T6 aluminum tube for bicycle frame?

Chalco provides 6061-T6 aluminum alloy tubing specially designed for high-performance bicycle manufacturing, balancing structural strength, manufacturing efficiency, and cost-effectiveness. It offers the following core advantages:

Free samples for quality evaluation

We offer free samples to help you verify material quality and compatibility before placing bulk orders.Click the button on the right to send us an email and get your free sample

Instant QuoteLow minimum order quantity

Whether you're a prototype builder or a small-batch manufacturer, our low MOQ makes it easy to get started.

Ready-to-ship inventory

Standard sizes and popular profiles are kept in stock, ensuring fast lead times and smooth delivery.

Custom processing available

We support CNC cutting, hydroforming, bending, slotting, and other value-added processing tailored to your design.

Diverse surface treatments

Available finishes include anodizing, sandblasting, polishing, brushing, or custom powder coating.

Extensive mold library

Our wide range of existing extrusion dies helps reduce tooling cost and speed up custom profile development.

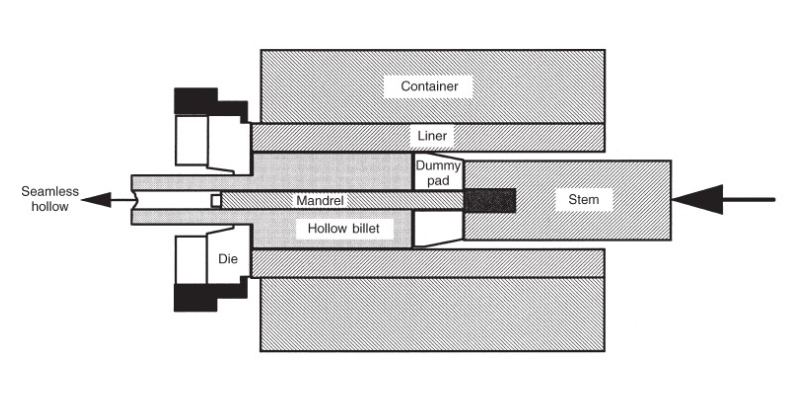

Advanced extrusion line

Chalco operates multiple advanced production lines, equipped not only for precision aluminum tube extrusion but also for bending and forming processes. We specialize in manufacturing high-quality seamless aluminum tubes for lightweight, high-strength bicycle frames, as well as premium aluminum hubs—offering comprehensive solutions to meet diverse cycling component needs.

Instant QuoteProduct quality assurance

Chalco's 6061 aluminum tubing strictly meets ASTM F2711-08 standards, ensuring high strength and precise dimensions. Advanced manufacturing processes and rigorous quality control provide stable and reliable quality assurance for your bicycle frames, making your products more competitive.

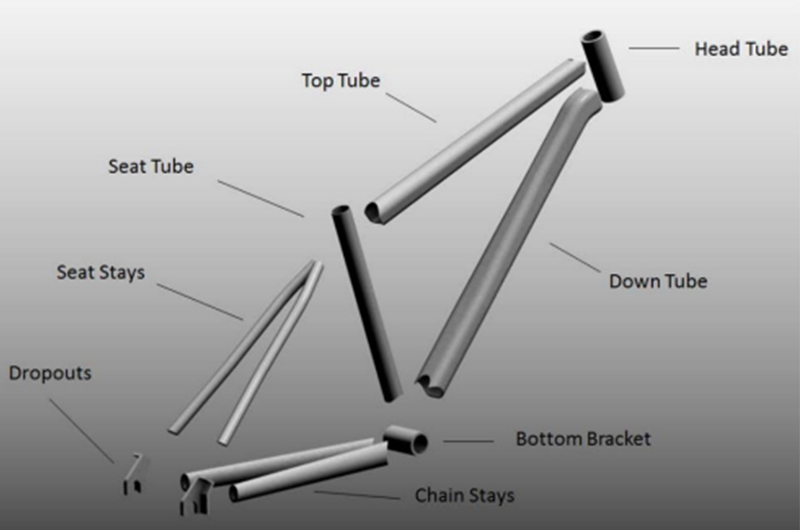

Common types of 6061-T6 aluminum tubing for bicycle frames

A high-performance bicycle frame is composed of various types of tubing, each with specific functions, dimensions, and performance characteristics. Chalco offers a full range of 6061 tubing for bicycle frames, providing a one-stop solution.

6061 Top Tube

OD: 35mm – 45mm

Wall: 0.8mm – 2.0mm

Features: Provides rigidity and riding comfort; commonly round or oval shaped.View more sizes

Contact us now

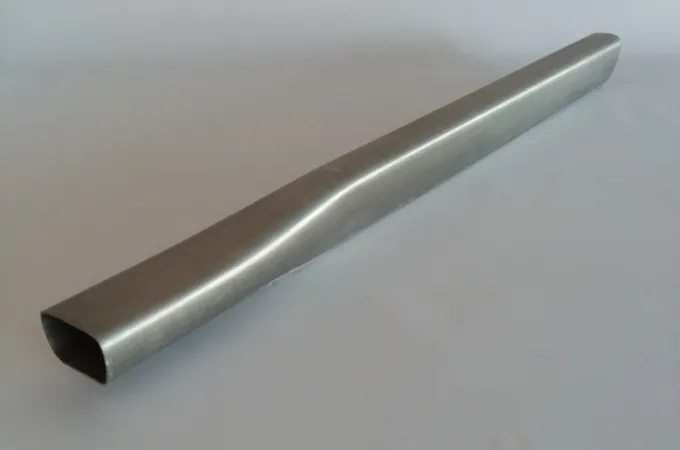

6061 Down Tube

OD: 34.9mm – 50mm

Wall: 1.5mm – 2.0mm

Features: Carries main frame stress; often hydroformed or shaped for increased rigidity. View more sizes

Contact us now

6061 Seat Tube

Diameter: Matches common seat posts (27.2mm or 31.6mm)

Features: Supports seat post insertion with accurate sizing. View more sizes

Contact us now

6061 Head Tube

Function: Connects top and down tubes; houses steering system

Specifications: Various sizes; typically thick-walled or reinforced for strength. View more sizes

Contact us now

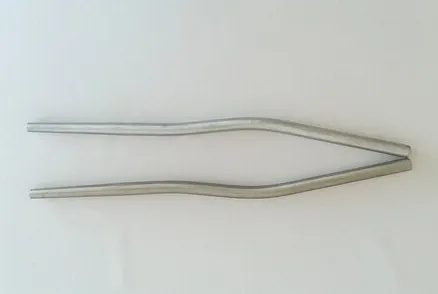

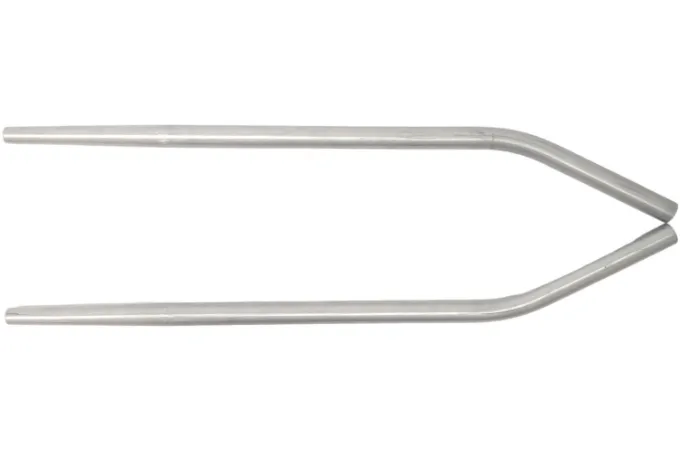

6061 Seat Stays

OD: 12mm – 18mm

Wall: 0.8mm – 1.2mm

Features: Thin or curved design to improve rear shock absorption. View more sizes

Contact us now

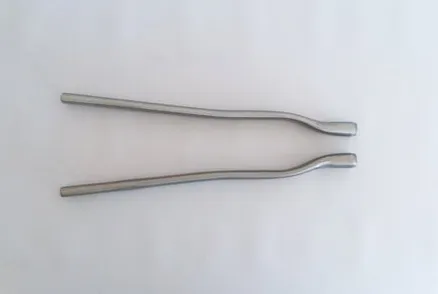

6061 Chain Stays

OD: 18mm – 25mm

Wall: 1.2mm – 1.6mm

Features: Transfers pedaling force; shaped to clear tires and cranks. View more sizes

Contact us now

Types and dimensions of 6061 aluminum tubes used in different bicycle frame components

6061 top tube sizes

35mm round top tube, 6061 aluminum, 1.4/1.1mm wall thickness, 600mm length

35mm butted top tube, 6061 aluminum, wall 2.0/1.3/1.8mm, 610mm length

Elliptical top tube, 6061 aluminum, 42×26.5mm profile, 1.4/1.1mm wall, 600mm

Curved elliptical top tube, 6061 aluminum, 42×26.5mm profile, 1.4/1.1mm wall, 600mm

36mm triple-butted top tube, 6061 aluminum, 1.3/0.9/1.3mm wall, 620mm length

Shaped top tube, 6061 aluminum, tapered 41mm to 31mm, 1.3/0.9/1.3mm wall, 620mm

35mm lightweight butted top tube, 6061 aluminum, 1.2/0.8/1.2mm wall, 600mm length

38mm triple-butted round top tube, 6061 aluminum, 1.6/1.2/1.6mm wall, 660mm

38mm ultra-thin butted top tube, 6061 aluminum, 0.8/0.7/1.0mm wall, 600mm

Tapered top tube, 6061 aluminum, 42.6mm to 34mm, 1.4/1.1mm wall, 680mm length

6061 down tube sizes

38mm round down tube, 6061 aluminum, 1.6/1.2/1.6mm wall thickness, 660mm length

42mm round down tube, 6061 aluminum, 1.9/1.1/1.3mm wall thickness, 680mm length

42.6mm round down tube, 6061 aluminum, 1.5/1.2mm wall thickness, 670mm length

44mm bent down tube, 6061 aluminum, 2.0/1.0/1.4mm wall thickness, 750mm length, 14° bent

44mm oval down tube, 6061 aluminum, 1.2/0.9mm wall thickness, 670mm length

48mm down tube, 6061 aluminum, 1.5/1.0/1.3mm wall thickness, 660mm length

48mm down tube, 6061 aluminum, 1.5/1.0/1.3mm wall thickness, 670mm length

48mm shaped down tube, 6061 aluminum, 2.0/1.1/1.4mm wall thickness, 680mm length

48mm round down tube, 6061 aluminum, 2.0/1.1/1.4mm wall thickness, 680mm length

48mm round down tube, 6061 aluminum, 1.9/1.3mm wall thickness, 820mm length

48mm bent down tube, 6061 aluminum, 1.9/1.3mm wall thickness, 820mm length

50.8mm round down tube, 6061 aluminum, 1.6/1.0/1.4mm wall thickness, 750mm length

60mm aero-shaped down tube, 6061 aluminum, 77/39.5mm profile, 1.35mm wall thickness, 680mm length

6061 seat tube sizes

31.7mm round seat tube, 6061 aluminum, for 27.2mm seat post, 2.2/1.6mm wall, 620mm length

35mm round seat tube, 6061 aluminum, for 31.6mm seat post, 1.65mm wall, 650mm length

35mm round seat tube, 6061 aluminum, for 31.6mm seat post, 1.7/0.9/1.5mm wall, 650mm length

35mm round seat tube, 6061 aluminum, for 31.6mm seat post, 1.7/1.2/1.5mm wall, 520mm length

35mm round seat tube, 6061 aluminum, for 34.9mm seat topper, 2.2/1.5mm wall, 800mm length

31.7mm round seat tube, 6061 aluminum, for 27.2mm seat post, 2.2/1.0/1.6mm wall, 650mm length

6061 head tube sizes

52/64mm Ø × 95–127mm tapered head tube, 6061 aluminum

50mm Ø × 200mm head tube, 6061 aluminum

85mm tapered head tube, 46/56mm Ø, 6061 aluminum

96mm tapered head tube, 46/56mm Ø, 6061 aluminum

110mm tapered head tube, 46/56mm Ø, 6061 aluminum

120mm tapered head tube, 46/56mm Ø, 6061 aluminum

135mm tapered head tube, 46/56mm Ø, 6061 aluminum

155mm tapered head tube, 46/56mm Ø, 6061 aluminum

180mm tapered head tube, 46/56mm Ø, 6061 aluminum

6061 seat stays sizes

16mm Ø round seat stay, 6061 aluminum, 1.2mm wall, 550mm length

19mm Ø round taper seat stay, 6061 aluminum, 1.0mm wall, 560mm length

19mm Ø round taper seat stay, 6061 aluminum, 1.2mm wall, 560mm length

22mm Ø round taper seat stay, 6061 aluminum, 1.0mm wall, 550mm length

19mm Ø S-bend seat stay for cross/gravel, 6061 aluminum, 1.2mm wall, 560mm length

19mm Ø S-bend seat stay for MTB/gravel, 6061 aluminum, 1.2mm wall, 560mm length

19mm Ø single 25° bend round taper seat stay, 6061 aluminum, 1.2mm wall, 560mm length

19mm Ø single bend seat stay for fatbike/plus tire, 6061 aluminum, 1.2mm wall, 560mm length

6061 chain stays sizes

24mm Ø oval/round chain stay, 6061 aluminum, 1.6mm wall, 440mm length

24mm Ø oval/round chain stay, 6061 aluminum, 1.6mm wall, 405mm length

24mm Ø oval/round S-bend chain stay, 6061 aluminum, 1.6mm wall, 440mm length

24mm Ø CX bend chain stay, 6061 aluminum, 1.8/1.5/1.8mm wall, 440mm length

24mm Ø MTB/gravel bend chain stay, 6061 aluminum, 1.8/1.5/1.8mm wall, 440mm length

24mm Ø S-bend chain stay for plus tire/fatbike, 6061 aluminum, 1.8/1.5/1.5mm wall, 445mm length

25.4mm Ø oval/round chain stay, scandium alloy, 1.2/0.8mm wall, 410mm length

25.4mm Ø road/track/chrono chain stay, scandium alloy, 1.2/0.8/1.0mm wall, 410mm length

Anodized 6061-T6 Aluminum Tubes for High-End Bicycle Frames

To meet the dual demands of high-end bicycle manufacturers for frame aesthetics and durability, Chalco offers a wide range of anodized 6061-T6 aluminum tubes. Whether for brand customization or structural corrosion resistance, anodizing significantly enhances both the performance and visual appeal of aluminum tubing.

To enhance the appearance and corrosion resistance of bicycle frame tubing, anodizing has become one of the most widely used surface treatments for aluminum. Chalco offers anodized 6061-T6 aluminum tubes in a variety of colors—black, silver, red, blue, gold, and more—widely used in high-end bike frame designs.

If you're interested in understanding how the anodizing process works, including how colors are formed and how the finish affects material performance, you can read our in-depth guide on aluminum anodizing techniques. To explore different shapes, sizes, and use cases of anodized tubing, visit our comprehensive anodized aluminum tubing product overview.

Chalco offers a wide range of anodized 6061-T6 aluminum tubes for bicycle frames, available in multiple colors and finishes. Below are real product samples showcasing our standard anodized options.

If you need a quotation for our bicycle frame aluminum tubes, please click the button below to send us an email and receive a detailed offer.

Instant Quote

Advantages of 6061 aluminum tubes for bicycle frame

Strength and lightweight: Chalco 6061 aluminum tubes maintain sufficient strength while having a low density, resulting in a high strength-to-weight ratio for bicycle frames. This helps reduce the overall weight of the bicycle, making cycling more effortless and efficient.

Corrosion resistance: Chalco 6061 aluminum tubes exhibit excellent corrosion resistance, ensuring that bicycle frames can maintain their optimal condition even under various weather and environmental conditions. This is particularly crucial for riders who frequently cycle in humid or rainy regions.

Machinability and ductility: Chalco 6061 aluminum alloy tubes are easy to machine and shape, allowing manufacturers to design bicycle frames in various shapes and structures to meet different needs and riding styles.

Affordability: compared to some high-end materials such as carbon fiber, Chalco 6061 aluminum alloy tubes are more cost-effective, providing good performance at a competitive price point.

Different butted for bicycle frames using 6061 aluminum tubes

Single butted: in a single butted tube, the thickness changes only at one end of the tube, usually at one of the ends. The butting process involves reducing the thickness at both ends of the tube while maintaining a constant thickness in the middle section of the tube. This helps save weight while retaining reasonable strength. Single butting tubes are typically used in lower-end bicycles.

Double butted: double butted tubes have thickness variations at both ends, creating a tube with different thicknesses at each end. The ends of the tube are thicker, while the middle section is thinner. Double butting tubes offer better weight reduction and higher toughness compared to single butting tubes. They are commonly used in mid-range and higher-end bicycles.

Triple butted: triple butted tubes have three different thicknesses along their length. The ends of the tube are thicker, the middle section is thinner, and there is a third intermediate thickness section between the ends. Triple butting tubes are designed to provide the best combination of weight reduction, strength, and riding quality. They are typically used in high-end and performance-oriented bicycles.

Production process of 6061 aluminum bicycle frame

Extrusion of aluminum tubes: the thickness of the aluminum tube, and therefore its weight, is determined according to the geometry of the bicycle frame, the maximum mechanical expected load, and the minimum mechanical properties achievable by the alloy.

Annealing: the extruded tube is annealed to increase its ability to deform without breaking, thereby increasing the material elongation A to a higher level than extruded tube without annealing. Extruded profiles usually have an elongation of around 10-15%, but after annealing, the elongation can reach around 25%.

Butting and/or hydroforming: annealed tubing is tapered or hydroformed to achieve the final frame geometry. These tubes can deform up to 60% before reaching their final geometry and, therefore, may require multiple annealing/reducing production cycles. Newer bicycles have increasingly complex geometries that require materials with high deformation without failure. For higher strength alloys, an intermediate annealing process prior to the butt joint process may not be necessary.

Welding: the individual components of the frame are joined together by welding to form a complete frame.

Post-weld heat treatment and aging: as a result of the welding process, the mechanical properties of the heat-affected zone decrease. In order to restore these properties, the frame must be heat treated. This heat treatment must include solution annealing, quenching and aging.

Surface treatment: after heat treatment, anodizing, liquid coating, powder coating, decals, laser engraving, etc. are performed on the frame to meet the appearance required by customers.

Instant Quote

Specifications of 6061 aluminum tube for bicycle frame

| Alloy | 6061 |

| Temper | T6 |

| Diameter | 25.4-28.6mm |

| Length | 400-700mm |

| Surface treatment | color coating, polishing, anodizing |

| Color | Silver or customized according to requirements |

| Package | Bundling, plastic film, wooden box or as per customer requirements |

Chemical composition of 6061 aluminum tubes for bicycle frame

| Element | Composition (%) |

| Al | Remainder |

| Mg | 0.8-1.2 |

| Si | 0.4-0.8 |

| Fe | 0-0.7 |

| Cu | 0.15-0.4 |

| Cr | 0.04-0.35 |

| Zn | 0-0.25 |

| Mn | 0-0.15 |

| Ti | 0-0.15 |

| Other(each) | 0-0.05 |

| Other(total) | 0-0.15 |

Mechanical properties of 6061 aluminum tubes for bicycle frame

Chalco's 6061-T6 aluminum bicycle frame tubes are manufactured in strict accordance with ASTM B221 and QQ-A-200/8F standards. This ensures that all mechanical properties—such as tensile strength, yield strength, and elongation—meet or exceed the minimum requirements specified for high-performance structural applications. Our tubing delivers consistent quality, reliable strength, and excellent formability for lightweight, durable bicycle frames.

| Temper | Wall Thickness Range | Tensile Strength (ksi / MPa) | Yield Strength (ksi / MPa) | Elongation (%) |

| 6061-T6 | ≤ 0.249 inch (6.32 mm) | 38.0 ksi / 262 MPa | 35.0 ksi / 241 MPa | 8% |

| 6061-T6 | ≥ 0.250 inch (6.35 mm) | 38.0 ksi / 262 MPa | 35.0 ksi / 241 MPa | 10% |

FAQ

Q: Are you a manufacturer? Do you have your own factory?

A: We are a manufacturer with our own factory with many years of production experience and established a good reputation.

Q: Can you produce extruded aluminum tubing?

A: We have several advanced extruded aluminum pipe production lines, which can produce high-quality extruded aluminum pipes.

Q: What colors can powder coatings be made of?

A: We have several advanced powder coating production lines, and can customize any color you need according to your requirements.

Q: Can you send me samples?

A: We can send samples, and the specific cost needs to be negotiated according to the actual situation.

Q: Do you have after-sales service for your products?

A: Our products have after-sales service. If there is any problem with the product you ordered, please contact us, and we will give you a satisfactory solution as soon as possible.