Materials are an important decision factor when we choose a bike. Both aluminum bikes and carbon fiber bikes have their place in the market, and they have their own strengths and weaknesses along multiple dimensions. Let’s compare these two types of bikes from different angles to help you understand them better.

1. Material

The frame material of aluminum bicycles is primarily aluminum alloy, which is a material composed of aluminum mixed with other metallic elements such as copper, zinc, magnesium, etc. The main aluminum alloys used for bicycles are 6061 and 7075.

Carbon fiber, on the other hand, is composed of fibers made from carbon elements. Typically, these fibers are produced from polyacrylonitrile fibers through processes like high-temperature carbonization and high-temperature graphitization.

2. Weight

Due to the low density of aluminum alloy, about 2.7g/cm3, the overall weight of the bicycle is relatively light, and the aluminum alloy frame

The weight of the car is generally 1500-1800g, and the weight of the whole vehicle is generally 9-11kg.

The weight of carbon fiber frame is only about half of that of aluminum alloy, usually 800-1200 grams, and the weight of the whole vehicle is about 7-9kg. Now for aluminum alloy, light weight is the biggest advantage of carbon fiber.

3. Tensile strength

The tensile strength of bicycles using 6061 and 7075 aluminum alloys is about 276-310 MPa, which can meet the requirements of most part of the daily needs of the bike.

The tensile strength of carbon fiber bicycles is excellent, reaching 1500-2500 MPa.

4. Comfort

The comfort level of aluminum alloy bicycles is generally lower than that of carbon fiber bicycles, because aluminum alloys have higher rigidity, and may feel more vibrations and impacts on uneven or rough roads. Vibration technology to reduce vibration.

Carbon fiber bikes generally perform better when it comes to comfort. The carbon fiber construction gives the bike excellent shock absorption properties, helping to dampen road vibrations. This makes carbon fiber bikes especially suitable for long rides, especially on uneven surfaces.

5. Safety

Aluminum bicycles generally have high durability and firmness, can resist external impacts, and generally will not break directly, which can improve riding safety to a certain extent.

The rigidity of carbon fiber bicycles is poor, and it is easy to crack or even break under unexpected impacts, which may affect the safety of riders.

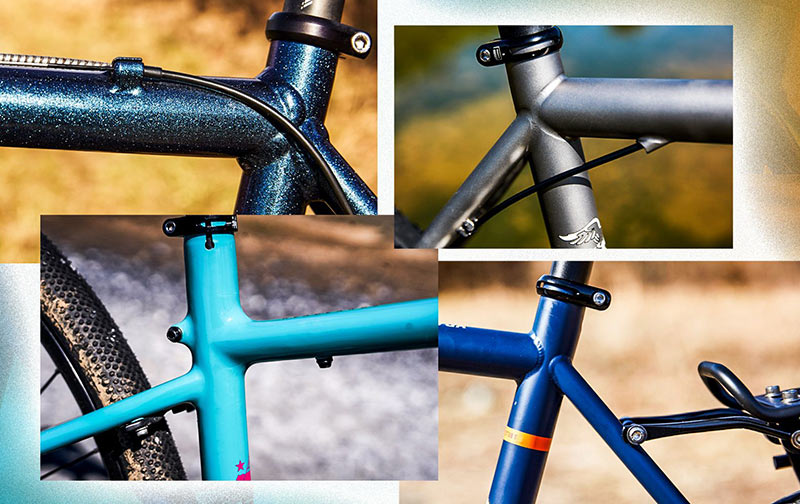

6. Appearance

The appearance of aluminum alloy bicycles usually presents a traditional and practical style. The surface treatment methods include polishing, sandblasting, painting, etc., but the overall color and pattern change is limited, mainly in silver gray, which is easy to leave scratches. Aluminum bikes can come in a variety of designs, but tend to be less streamlined and modern than carbon bikes, and the properties of aluminum can limit certain styling and detailing.

Carbon fiber bicycles are often more prominent in terms of appearance, because the material properties of carbon fiber allow for more diverse and modern designs to be manufactured. The lightness and malleability of carbon fiber allows bicycle manufacturers to create a streamlined, clean look that evokes high performance and speed. Carbon fiber bikes may more easily appeal to cyclists looking for sleek, progressive designs.

7. Production Process

The production process of aluminum bicycles involves the preparation of aluminum alloys. Aluminum tubes are joined together by welding, riveting or casting to form the structure of the frame, which is shaped by extrusion, forging and CNC machining to make other components. Things like handlebars, seatposts, and cranks are finally painted and assembled to form the complete bike.

The manufacturing process of carbon fiber bicycles is more complex, including steps such as carbon fiber preparation, prepreg treatment, mold making and forming, heat curing and curing, manual adjustment and trimming, and painting and assembly. Carbon fiber cloth is combined with resin, shaped and cured to form the structure of the frame and components.

8. Price

Aluminum bikes are usually relatively inexpensive. Aluminum alloy is a common and affordable material, and the production process of aluminum alloy parts required for bicycles is relatively mature, which can greatly reduce production costs. Aluminum bikes are primarily for urban riding, recreational riding and long-distance riding.

Carbon fiber is a high-performance material that is relatively expensive to manufacture and requires more complex manufacturing processes and technologies. This puts carbon fiber bikes at a premium price point. Carbon fiber bikes are for riders looking for high performance, competitive riding and speed who are willing to pay extra for lighter, stiffer and more advanced designs.

9. Daily maintenance

The repair and maintenance of the aluminum alloy frame is relatively simple, and minor problems in daily use can be quickly resolved by adjusting the assembled parts. Aluminum alloys can be partially repaired by welding and patching, and accessories and spare parts are also readily available.

The maintenance and repair of carbon fiber frame is relatively complicated and requires professional equipment and technology. Once the carbon fiber structure is damaged, it is difficult to effectively repair it, usually the whole part needs to be replaced, and the maintenance cost is high.

10. Environmental friendly

Aluminum alloy is a metal material that is easier to recycle and reuse. The scrapped frame and parts can enter the recycling cycle and be remade into new aluminum alloy products, which is more environmentally friendly.

The composition of carbon fiber composite materials is complex, and once it is scrapped, it is difficult to realize recycling, and most of them will directly enter the landfill. The environmental protection of carbon fiber is worse than that of aluminum alloy.