6061 aluminum is one of the most widely used aluminum alloys, offering an excellent balance of strength, corrosion resistance, machinability, and weldability. It can be heat-treated to high strength levels and anodized for enhanced surface protection. Typical uses include aerospace structures, automotive components, marine hardware, hydraulic systems, electrical connectors, bicycle frames and precision CNC parts.

Common Trade Names

UNS A96061, AA6061, ISO AlMg1SiCu, 6061-T4, 6061-T6, 6061-T651, 6061-T6511

Specifications — Aluminum 6061

ASTM: B209, B210, B211, B221, B308

AMS: QQ-A-200/9, QQ-A-225/8, 4027, 4082, 4117, 4150

ASME: SB-221

Product Guide

Application Fields

6061 Aluminum Quick Specs & Technical Parameters

| 6061 Aluminum Quick Specs | |||

| Product Type | Size Range | Common Tempers | Standards |

| Sheet & Plate | 0.2 – 250 mm | O, T4, T6, T651 | ASTM B209, AMS 4027, GB/T 3880 |

| Bar & Rod | Ø4 – 1350 mm | T6, T651, T6511 | ASTM B211, AMS 4115, GB/T 3191 |

| Tube & Pipe | Ø5 – 1320 mm | O, T6, T651 | ASTM B241, AMS 4082, GB/T 4437 |

| Extrusion Profiles | Custom shapes & sizes | T5, T6 | ASTM B221, EN 755-2, GB/T 6892 |

| Forgings | Up to Ø10 m | T6, T651 | ASTM B247, AMS 4128, GB/T 6619 |

| Wire | Ø1 – 20 mm | O, T4, T6 | ASTM B233, AMS 4185, GB/T 3195 |

| Alloy 6061 chemical composition Spec: BS EN 573-3:2009 | |

| Chemical Element | % Present |

| Manganese (Mn) | 0.0 - 0.15 |

| Iron (Fe) | 0.0 - 0.70 |

| Magnesium (Mg) | 0.80 - 1.20 |

| Silicon (Si) | 0.40 - 0.80 |

| Copper (Cu) | 0.15 - 0.40 |

| Zinc (Zn) | 0.0 - 0.25 |

| Titanium (Ti) | 0.0 - 0.15 |

| Chromium (Cr) | 0.04 - 0.35 |

| Other (Each) | 0.0 - 0.05 |

| Others (Total) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

| Physical Property of 6061 aluminum alloy | |

| Density | 2.70 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 23.4 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 166 W/ mK |

| Electrical Resistivity | 0.040 x10^-6 Ω .m |

| Mechanical Property of 6061 aluminum alloy | |

| Proof Stress | 240 Min MPa |

| Tensile Strength | 260 Min MPa |

| Hardness Brinell | 95 HB |

| Extrusions - Up to 200mm Dia. & A/F, 5mm WT for Tube and Prof Spec: BS EN 755-2:2008 | |

Chalco 6061 Aluminum Products

We focus on the most requested 6061 aluminum product forms for industrial buyers. Explore the quick overview below and jump into the details of each category.

6061 Aluminum Sheet & Plate

Size range: 0.2–250 mm | Standards: ASTM B209, AMS 4027, AMS-QQ-A-250/11, EN 485-2, GB/T 3190

Finishes & processing: anodizing, coating, brushing, polishing, mirror; CNC cutting, drilling, welding.

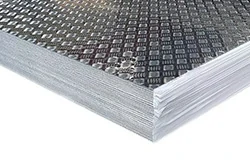

6061 aluminum tread/diamond plate

Anti-slip, high strength; floors, stairs, industrial platforms, truck boxes.

High precision & stability for molds, jigs, CNC base plates.

Standard 4x8 size, good strength, corrosion resistance and machinability.

Learn more stock sizes: [6061 sheet & plate stock pdf]

6061 Aluminum Tube & Pipe

Extruded: Ø3–450 mm | Cold drawn: Ø5–260 mm | Forged: Ø200–1000 mm

Standards: WW-T-700/6, ASTM B241/B429, AMS-QQ-A-200/8, ASTM B221, AMS 4079/4081/4082/4083, MIL-T-7081, EN 2392

OD up to 1320 mm

6061 thin wall tube

OD 90–300 mm; wall 0.25–50 mm

6061 seamless tube

OD 90–400 mm; wall 5–20 mm

Download stock sizes: [Tube & pipe stock PDF]

6061 Aluminum Bar & Rod (Round / Square / Hex / Flat)

Round bar: Ø4–300 mm (max up to Ø1350 mm) | Square bar: 6–50 mm | Hex bar: AF 12–65 mm | Flat bar: 2–250 mm (thickness), 5–300 mm (width)

Standards: ASTM B211, AMS 4115/4116/4117/4128, AMS-QQ-A-225/8; ASTM B221, AMS 4150/4160/4161, AMS-QQ-A-200/8

6061 cold drawn bar

6061 threaded bar

More sizes & stock list: [6061 bar details] [Bar stock PDF]

6061 Aluminum Extrusion

High-strength, corrosion-resistant, weldable profiles for frames and structures.

Standards: ASTM B221, EN 755.

6061 industrial profile

Machine frames, automation brackets, assembly lines.

6061 building profile

Curtain walls, doors & windows, structural supports.

6061 radiator profile

Heat sinks, LED radiators, power equipment.

Explore more extrusion profiles: [6061 extrusion details]

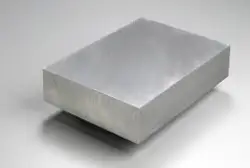

6061 Aluminum Block

Typical thickness: up to 250 mm+ (custom on request) | Applications: molds, fixtures, CNC tooling.

Related: 6061 tooling plate & block

6061 Aluminum Coil

Typical thickness: 0.2–3 mm | Width: up to 2650 mm (ultra-wide)

Standards: ASTM B209; Finishes: anodized, coated, brushed, mirror.

We also supply 6061 forging products, wire, busbar and custom profiles — contact us now for tailored solutions and fast delivery.

Chalco 6061 aluminum temper detailed explanation

Chalco 6061 aluminum alloy can show different mechanical properties, processing properties and application fields according to different heat treatment (Temper) states. The heat treatment methods of 6061 aluminum alloy mainly include T series (T4, T5, T6, T651, etc.) and O state (annealing state). These different treatment methods affect the strength, hardness, toughness and machinability of the alloy.

- T6: Highest strength, widely used, excellent corrosion resistance.

- T651: Stress-relieved version of T6, ideal for precision machining.

- T6511: Extruded + straightened, better dimensional stability.

- T62: Similar to T6, but improved toughness after cold work.

- T4: Good processability, better bending/welding performance.

- O (Annealed): Softest state, excellent ductility & weldability.

6061 aluminum alloy temper selection guide

| Temper Status | strength | Machinability | Bending properties | Corrosion resistance | Main Applications |

| O (Annealed) | Low | high | excellent | excellent | Aviation, automobile, welding structure |

| T4 (Natural Aging) | medium | high | excellent | good | Automobile, building, aviation structure |

| T6 (highest strength) | Highest | generally | Difference | excellent | Aviation, automobile, machinery, shipbuilding |

| T651 (Stress Relief T6) | Highest | medium | Difference | excellent | Precision machinery, molds, aerospace |

| T6511 (upgraded version of T651) | Highest | high | Difference | excellent | Rail transit, construction, ships |

| T62 (heat treatment after cold working) | high | high | excellent | good | Aviation, Automobile, Shipbuilding |

Chalco 6061 aluminum cooperation areas

6061 Aluminum for Aerospace

Chalco supplies AMS, ASTM and GB-certified 6061 aluminum for major aerospace projects. It is trusted in fuselage skins, wings, engine parts, cabin structures and electronic systems.

Contact us now

6061 Aluminum for Marine Ships

Certified by CCS, DNV and ABS, Chalco 6061 aluminum is widely used in hulls, decks, handrails, accessories and propulsion systems, offering seawater corrosion resistance and reliable strength for shipbuilding.

Contact us now6061 Aluminum for Automobile

Meeting ISO/TS 16949 standards, Chalco 6061 aluminum is used in car bodies, chassis, powertrain components and wheels. Its lightweight and high-strength help improve fuel efficiency and safety for vehicles.

Contact us now

6061 Aluminum for Sporting Goods

With excellent strength-to-weight ratio, durability and machinability, 6061 aluminum is widely used in bicycles, outdoor gear and high-end sports equipment, ensuring lightweight performance and reliability.

Contact us now6061 Aluminum for Power & Energy

6061 aluminum provides good conductivity, mechanical strength and environmental corrosion resistance, making it suitable for busbars, support structures and high-load power transmission applications.

Contact us now

6061 Al for Architectural Decoration

6061 aluminum combines weather resistance, machinability and surface finish adaptability, meeting the lightweight, aesthetic and structural stability requirements of modern buildings.

Contact us nowChalco 6061 Aluminum Production Capabilities

Chalco has established a complete production chain for 6061 aluminum, equipped with advanced casting, extrusion, rolling, and forging lines. With comprehensive heat treatment and strict testing systems, we deliver stable quality materials that meet global aerospace, automotive, marine, and industrial standards.

- Casting & Rolling: Stable alloy composition, high-precision hot & cold rolling for wide plates and thick plates

- Extrusion & Forging: 800T–10,000T extrusion presses and forging equipment for bars, tubes, profiles, and large aerospace forgings

- Heat Treatment: Full range of O, T4, T6, T651 processes to optimize strength, toughness, and machinability

- Testing & Certification: Ultrasonic inspection, tensile and hardness tests, full traceability; compliant with ASTM, AMS, ISO standards

Why Choose Chalco 6061 Aluminum

Choosing Chalco means securing not only high-quality 6061 aluminum, but also a reliable long-term partner with proven supply capacity and technical expertise.

- Full Product Range: Sheet, plate, bar, tube, extrusion, forging, coil, and block — all in one place

- Proven Industry Experience: Trusted by aerospace, marine, automotive, energy, and construction projects worldwide

- One-Stop Processing: Cutting, CNC machining, anodizing, surface coating, welding, stamping, forming

- Global Delivery: Extensive stock, flexible customization, and fast logistics service

6061 Aluminum Knowledge Center & FAQs

6061 aluminum and 7075 aluminum

6061 aluminum has higher strength, better weldability and corrosion resistance, and is suitable for aviation, automobiles, and building structures.

7075 aluminum has extremely high strength, but poor corrosion resistance and weak weldability. It is suitable for aerospace, high-end machinery, and military applications.

6061 aluminum and 6063 aluminum

6061 aluminum has stronger mechanical properties and is suitable for load-bearing structures, automotive parts, and industrial frames.

6063 aluminum is mainly used for building profiles, doors and windows, decorative frames, and has better processing and surface treatment performance.

6061 aluminum and 5083 aluminum

6061 aluminum has high mechanical strength and is suitable for aviation, automobile and industrial structural parts.

5083 aluminum has strong seawater corrosion resistance and is suitable for ships, marine equipment, and chemical storage tanks.

6061 aluminum and 5052 aluminum

6061 aluminum has higher strength and is suitable for structural parts, machining, and aerospace

5052 aluminum has stronger corrosion resistance and is suitable for highly corrosive environments such as ocean, chemical industry, and oil tanks.

What's the difference between 6061 and 7075 aluminum?

6061 has better corrosion resistance and weldability, while 7075 offers much higher strength but lower corrosion resistance.

How does 6061 compare to 6063 aluminum?

6061 is stronger and used for structural parts, while 6063 is softer, easier to extrude, and mainly used in architectural profiles.

Can 6061 aluminum be welded?

Yes, 6061 is weldable with common filler wires such as 4043 or 5356, widely used in structural and automotive welding.

Is 6061 aluminum good for machining?

Yes, it has excellent machinability and is one of the most popular alloys for CNC parts, molds, and fixtures.

What industries commonly use 6061 aluminum?

Aerospace, automotive, marine, construction, machinery, electronics, and sporting goods.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote