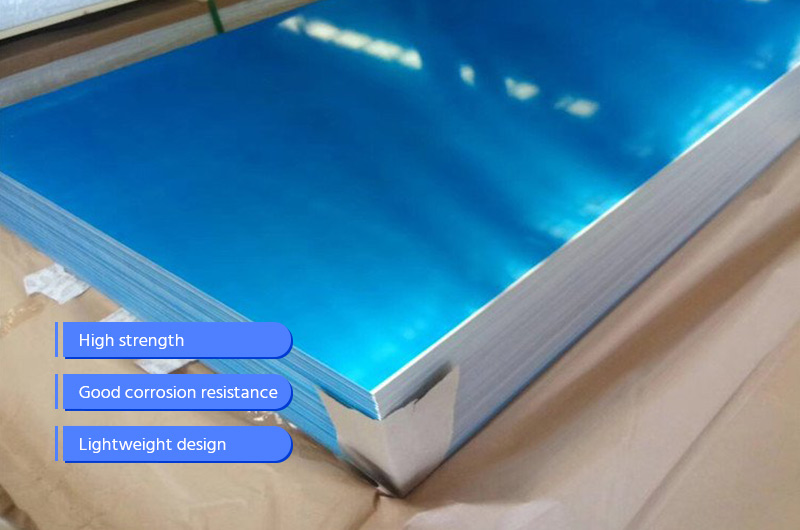

5454 aluminum plate is a medium-magnesium alloy designed for medium- and high-temperature service. It offers good corrosion resistance and weldability, making it ideal for asphalt, insulated, and chemical tank trucks.

- High-temperature suitability: Stable performance at 65–150 °C, ideal for hot asphalt, emulsions, and chemical liquids.

- Strength & corrosion resistance: 5454-H111 combines high tensile strength and excellent corrosion resistance to withstand vibration and fatigue during transport.

- Ready-to-ship stock: 5454-H111 plates available from stock, with cut-to-size and custom head/baffle fabrication to reduce weld seams and save assembly time.

View 5454-H111 plate stock and available sizes

Specifications of 5454 aluminum sheet plate for oil tanker

| Alloy | 5454 |

| Temper | 5454-H111 (in stock), 5454-O (made-to-order) |

| Thickness range | 3.0–12.0 mm (common: 5 / 6 / 8 mm) |

| Common widths | 1000–2600 mm (max 2600 mm helps reduce longitudinal seams) |

| Common lengths | 2000–12000 mm |

| Available surfaces | Mill, Mirror (better solar reflectance for hot-climate routes) — see surface grades |

| Tolerances | see permissible deviation |

| Standards | EN 14286, ASTM B209 (with EN 10204 3.1 MTC) |

Features of 5454 Aluminum Plate for Tank Trucks

5454 is a medium-magnesium alloy tailored for medium- to high-temperature tanker service. It balances strength, corrosion resistance, and weldability for asphalt, insulated, and chemical tank bodies.

Stable at elevated temperatures: Performs reliably around 65–150 °C, suitable for hot asphalt, emulsions, and selected chemical media.

Corrosion & weather resistance: Good resistance to salt spray and chemical environments, supporting long-term service on coastal and corrosive routes.

Wide plate reduces seams: Widths up to 2600 mm help cut longitudinal welds, improving leak-tightness and production efficiency.

Mirror surface option: Mirror sheets enhance solar reflectance to lower surface temperature—useful for hot-climate regions (e.g., Middle East/North Africa).

Selection note: For long-term cryogenic/LNG service, choose 5083 aluminum plate to ensure low-temperature toughness.

Recommended Applications and Tempers of 5454 Aluminum Plate

| Component | Recommended Temper | Thickness | Notes |

| Tank Body | 5454-H111 / 5454-H32 | 5–8 mm | H111 for standard service; H32 for high-temp or heavy load |

| Heads / Covers | 5454-O | Same or thicker than body | Soft temper, easy for spinning and forming |

| Baffles / Partitions | 5454-O | ≈1 mm thinner | Reduce weight, keep impact resistance |

| Bulkheads | 5454-O | 5–8 mm | Separate compartments, ensure independent transport |

Why Choose Chalco as Your 5454 Aluminum Tanker Plate Supplier

5454 aluminum plate is the preferred material for tankers carrying medium- and high-temperature media such as asphalt and chemical liquids, requiring stable mechanical properties and excellent corrosion resistance. Chalco supplies 5454 plates and components that meet international standards to ensure tanker safety, durability, and efficiency.

- Standards & Compliance: Supplied per EN 14286, ASTM B209 with EN 10204 3.1 material certificates, supporting third-party inspection and full traceability.

- Proven Tanker Experience: Long-term cooperation with well-known manufacturers (CIMC Lingyu, Almutlak, etc.), providing customized dimensions and cutting plans to reduce on-site cutting and welding.

- End-to-End Quality Control: Advanced smelting, rolling, heat treatment, and testing equipment ensure flat surface and stable mechanical properties from casting to finished product.

5454 Aluminum Plate Purchasing Guide

Pricing & delivery: priced per sheet or kg; EXW/FOB/CIF/DDP supported. A formal quotation is issued within 24h after receiving your specs and drawings.

Typical lead time: samples 5–7 days; bulk 2–3 weeks. Expedited production and partial shipments available.

- Submit specifications and drawings via message board or email

- Price factors: alloy/temper, thickness & tolerance, cutting/bevel, quantity, destination port

- MOQ & samples: mixed specs supported; samples with EN 10204 3.1 MTC

- Packing & compliance: PE film + ISPM 15–compliant crate; COO and REACH/RoHS on request

- Logistics & customs: sea/air/rail; DDP optional; insurance, customs docs, and packing list provided

5454 Mill Finish vs 5454 Mirror Finish

- Lower cost, ideal for large-scale tank body production

- Surface can be painted or further processed

- Meets general corrosion resistance and weldability requirements

- Suitable for oil and chemical media at normal temperatures

- High reflectivity, reduces surface temperature

- Premium appearance, enhances tanker aesthetics

- Preferred in Middle East and high-temperature regions

- Lowers heat absorption, reduces product evaporation risk

Tanker Plate Selection Guide (5182 | 5083 | 5454 | 5754)

| Dimension \ Alloy | 5182 | 5083 | 5454 | 5754 |

| Positioning / Scenario keywords | ADR hazardous goods; ambient–medium temperature; emphasis on elongation and welding stability | Cryogenic/LNG; marine/salt-spray; general corrosion resistance | Long-term medium–high temperature / insulated cargo (e.g., asphalt / emulsified asphalt) | General welded structures; food/personal care; everyday corrosion resistance |

| Typical parts & tempers | Shell: 5182-H111; Heads/Baffles: 5182-O | Shell: 5083-H111/H321; Heads/Bulkheads: 5083-O | Shell: 5454-H111/H32; Heads/Bulkheads: 5454-O | Shell/Internals: 5754-H111/O (per forming need) |

| Operating boundaries & risk control | For 5xxx under sustained higher temperature + stress, perform NAMLT assessment; for long-term higher temperature also evaluate 5454 | Excellent at low temperature and marine service; not recommended for long-term high temperature | Better stability at medium–high temperature than 5182/5083; still manage NAMLT risk | Moderate strength; verify media and regulatory fit per project |

| What customers value most | High elongation and weldability; wide plates reduce seams; drawing-based parts available | Proven corrosion/cryogenic performance; strong track record in LNG/coastal projects | Stable service life at medium–high temperature; suited to insulated cargo and hot routes | Good formability and cost profile; fits general tanker structures |

If your application is ADR hazardous goods at ambient–medium temperature, choose 5182 aluminum plate.

If it involves cryogenic/LNG or coastal salt-spray environments, choose 5083 aluminum plate.

If it requires long-term medium–high temperature or insulated cargo, choose 5454 aluminum plate.

If it is a general welded structure or food/personal care with common corrosion demands, choose 5754 aluminum plate.

5454 aluminum sheet plate in Stock

| Alloy | Temper | Thickness | Width | Length | Weight (KG) | Piece |

| 5454 | H111 | 5.6 | 2520 | 10100 | 4295 | 11 |

| 5454 | H111 | 5.6 | 2520 | 10100 | 1945 | 5 |

| 5454 | H111 | 5.6 | 2520 | 10100 | 1170 | 3 |

| 5454 | H111 | 5.6 | 2520 | 10100 | 1950 | 5 |

| 5454 | H111 | 5.6 | 2520 | 10900 | 1265 | 3 |

Chemical composition of 5454 aluminum sheet plate for oil tanker

| Element | Composition % |

| Si | 0.25 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.5-1.0 |

| Mg | 2.4-3.0 |

| Cr | 0.05-0.20 |

| Ni | --- |

| Zn | 0.25 |

| Ti | 0.20 |

| Al | Remainder |

Mechanical properties of 5454 aluminum sheet plate for oil tanker

| Temper | Thickness/mm | Tensile Strength /MPa | Specified non-proportional Tensile Strength/MPa | Elongation After Break/% | A50 mm | Bending Radius |

| O, H111 | 3.00-6.00 | 215-285 | ≥85 | ≥19 | - | 1.0t |

| >6.00-12.00 | 215-285 | ≥85 | ≥19 | - | 2.0t |

Surface grade of 5454 aluminum sheet plate for oil tanker

| Type | Standard Plate | High Class Plate | Bright Plate | Mirror Plate |

| Surface | ★★★☆☆ | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Roughness Ra/μm | 0.5-0.8 | 0.3-0.5 | 0.1-0.3 | ≤0.04 |

| Product Description | Smooth surface Defect deepness <Minus Tolerances Of Thickness | Fine and smooth surface No or only very little colour aberration and chatters | Bright, fine and Smooth surface No colour aberration and chatters | Mirror reflective Surface Reflectance ≥86% |

| Applicable Standards | GB/T 3880 | EN14286 ASTM B209 EN485 Customer special requirements | EN14286 ASTM B209 Customer special requirements | EN14286 ASTM B209 Customer special requirements |

| Application | Use directly or After brashing Tanker Body, Tanker Head Wall Partition, Resistance Plate | Use directly Tanker Body, Tanker Head Wall Partition, Resistance Plate | Use directly Tanker Body, Tanker Head | Use directly Tanker Body, Tanker Head |

Permissible deviation of 5454 aluminum sheet plate for oil tanker

| Thickness tolerances within the following width ranges | ||||

| Thickness | ≤1250 | >1250-1600 | >1600-2000 | >2000-2600 |

| 3.00-3.50 | +0.28 | +0.28 | +0.30 | +0.40 |

| >3.50-6.00 | +0.32 | +0.32 | +0.40 | +0.45 |

| >6.00-8.00 | +0.38 | +0.45 | +0.50 | +0.60 |

| >8.00-12.00 | +0.45 | +0.55 | +0.65 | +0.80 |

FAQ – 5454 Aluminum Tanker Plate

1. What tanker applications suit 5454 alloy?

5454 plate is ideal for hot asphalt, bitumen emulsion, and some chemical transport. It keeps strength at elevated temperatures and resists softening. For ambient oil transport, 5182 or 5083 may also be considered.

2. How does 5454 differ from 5083 and 5182?

5454 has slightly lower Mg and strength than 5083 but better stability under heat, with less strength loss after welding. 5083 is preferred for LNG and low-temperature service, 5182 for ADR hazardous goods tankers.

3. Can you supply heads, baffles, and other parts?

Yes. Chalco offers cutting, rolling, and forming services, delivering ready-to-install parts. This reduces onsite cutting, welding time, and scrap rates.

4. How is 5454 weldability?

Excellent. It matches well with ER5356/ER5183 wires for MIG/TIG welding and keeps good corrosion resistance after welding, suitable for tank body rolling welds.

5. What standards and certificates are provided?

Standards include EN 14286, ASTM B209, EN 485. EN 10204 3.1 MTC is standard; COO, REACH/RoHS can be provided. See standards for more.

6. How is pricing and MOQ?

Priced per sheet or kg. Factors include alloy/temper, thickness tolerance, finish, processing, and destination port. Mixed sizes allowed. Samples with MTC available. Request a quote via inquiry or upload-spec.

7. What are lead times and delivery terms?

Samples ship in 5–7 days, bulk in 2–3 weeks, rush and split shipments available. EXW/FOB/CIF/DDP supported. See packing-policy and logistics for packaging and logistics details.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote