5083 aluminum plate is magnesium-alloyed with good weldability, corrosion resistance, and fabrication performance. Its moderate strength makes it well suited for liquid tanker manufacture—especially for low-temperature media (e.g., LNG) and coastal/salt-spray environments in long-haul service—which is why it is one of the preferred materials for aluminum tankers.

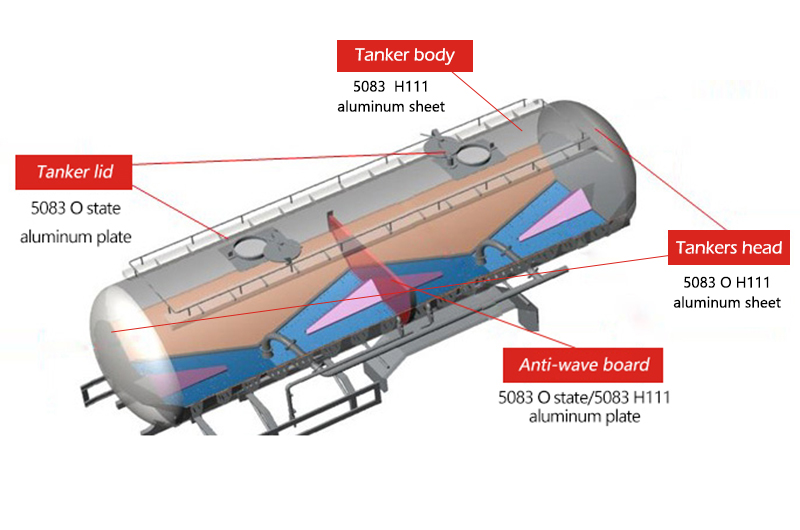

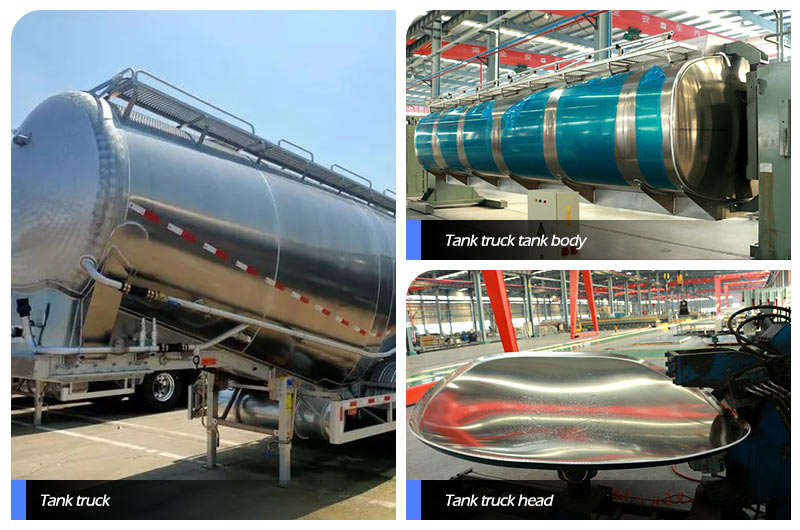

A tanker body comprises side panels, baffles, manholes, and other parts. The shell typically uses 5083-H111 plate, while the tank lid and internal partitions use softer 5083-O plate for easier bending, helping ensure sealing and structural strength.

For tanker use, plate width is generally below 2.2 m, with common thicknesses of 5, 6, 7, and 8 mm. A complete shell usually requires 4–6 plates welded together, so welding performance and joint elongation are critical to structural integrity and leak-tightness.

View 5083 aluminum plate stock and available sizes

Specifications of 5083 aluminum sheet plate for oil tanker

| Alloy | 5083 |

| Temper | O, H111 |

| Thickness | 3.00-12.00mm |

| Width | 1000-2600mm |

| Length | 2000-12000mm |

| Surface grade | Click to view detailed surface treatment |

| Permissible deviation | Click to view detailed Permissible deviation |

| Standard | EN14286, ASTM B209 |

Features of 5083 Aluminum Plate for Oil Tanker

Excellent Low-Temperature Toughness: Performs reliably at LNG temperatures (-162 °C), maintaining strength and ductility, ideal for cryogenic transport and storage.

Outstanding Corrosion Resistance: High magnesium content provides strong resistance to salt spray and marine environments, lowering maintenance costs.

Good Weldability: Supports gas welding, TIG/MIG, and spot welding with high joint elongation and tight, durable seams.

Wide Plate Advantage: Up to 2600 mm wide plates reduce longitudinal welds and improve tank integrity.

Lightweight Design: Higher strength-to-weight ratio than steel, reducing vehicle weight and increasing payload capacity.

High-Temperature Note: Strength drops at >65 °C; not recommended for asphalt or hot-medium tankers. Consider 5454 aluminum plate for such applications.

Recyclable & Sustainable: Fully recyclable, supporting green manufacturing and lifecycle cost efficiency.

5083 Aluminum Plate Applications & Temper Selection

The table below summarizes typical 5083 aluminum plate tempers and thicknesses for different tanker parts, helping you quickly select the right material for your project.

| Part | Recommended Temper | Typical Thickness | Notes / Application |

| Tank Body (Shell) | 5083-H111 | 5–6 mm | Main shell plate; good weldability and strength |

| Tank Head (End Cap) | 5083-H111 / 5083-O | ≥ shell thickness | End sealing parts; plasticity and weldability required |

| Baffle / Partition | 5083-O | ~1 mm thinner than shell | Stamped forming; suppresses liquid sloshing |

| Bulkhead | 5083-O | 5–8 mm | Divides independent compartments; high ductility |

| Manhole Cover | 5083-O | - | Easy bending/forming; ensures sealing |

|

High-Stress Parts (e.g., level gauge, air inlet) |

5083-H321 | 3–6 mm | Stabilized temper; SCC resistance |

For custom dimensions, beveling, or complete kit supply (head plates, baffles, bulkheads), please use the quote or drawing upload buttons below.

Instant Quote

Tanker Plate Selection Guide (5182 | 5083 | 5454 | 5754)

| Dimension \ Alloy | 5182 | 5083 | 5454 | 5754 |

| Positioning / Scenario | ADR hazardous goods; ambient–medium temp; elongation & welding stability | Cryogenic/LNG; coastal salt-spray; marine corrosion resistance | Long-term medium–high temp; insulated/hot cargo (e.g., asphalt) | General welded structures; food/personal care; everyday corrosion |

| Typical parts & tempers | Shell: 5182-H111; Heads/Baffles: 5182-O | Shell: 5083-H111; Heads/Baffles/Bulkheads: 5083-O | Shell: 5454-H111/H32; Heads/Bulkheads: 5454-O | Shell/Internals: 5754-H111/O (per forming need) |

| Operating boundaries & risk | For sustained temp + stress, manage NAMLT; evaluate 5454 for hotter service | Excellent at low temp & marine service; not advised for long-term high temp | Better stability at medium–high temp vs 5xxx peers; manage NAMLT | Moderate strength; verify media/regulatory fit per project |

| What customers value | High elongation & weldability; wide plates reduce seams; drawing-based parts | Proven cryogenic & coastal performance; LNG/coastal references | Stable life at higher temp; suited to insulated/hot routes | Good formability & cost profile; broad applicability |

For ADR hazardous goods at ambient–medium temperature, choose 5182 Aluminum plate.

For cryogenic/LNG or coastal salt-spray environments, choose 5083 tanker plate.

For long-term medium–high temperature or insulated cargo, choose 5454 Aluminum plate.

For general welded structures or food/personal care applications, choose 5754 Aluminum plate.

Durability and Low Maintenance Costs: The Economic Benefits of Aluminum Tankers

First, aluminum alloy tank trucks excel in safety, boasting a solid accident record. Their low center of gravity enhances braking stability, and the use of non-combustible materials reduces the risks of sparks and static electricity buildup. Additionally, the lighter weight of aluminum alloy bodies allows for higher effective payloads, which can decrease the number of transport trips and improve return on investment.

In terms of fuel efficiency, aluminum alloy tank trucks help lower carbon dioxide emissions, making them more environmentally friendly. Their strong corrosion resistance ensures a lifespan of 15 to 20 years, while maintenance costs remain low, as they do not require painting and have a durable appearance that is easy to clean. Finally, the high recyclability of aluminum provides additional revenue after the truck is decommissioned.

Instant QuoteWhy Choose Chalco as Your 5083 Aluminum Tanker Plate Supplier

Compliance & Safety Assurance: Tanker transport is strictly regulated as it involves hazardous goods. Chalco’s 5083 aluminum plates fully comply with EN 14286 and ASTM B209 standards, with EN 10204 3.1 mill test certificates provided for every batch to ensure traceability and compliance.

Stable Supply & Processing Capability: With an integrated production system covering melting, hot rolling, leveling, and inspection, we can steadily supply 3–12 mm × 1000–2600 mm wide plates, cut-to-length up to 12 m. We also provide drawing-based cutting, beveling, marking, and kit-packing services to help reduce on-site cutting, lower the number of weld seams, and improve assembly efficiency.

Proven Applications & Customer Trust: Chalco partners with leading tanker manufacturers such as CIMC Lingyu, pt.geluran adikarya, and Almutlak. Our 5083 plates have been proven in LNG low-temperature transport and coastal salt-spray environments, helping customers extend tanker service life and reduce maintenance costs.

5083 Aluminum Plate Procurement Guide

Pricing is based on weight or pieces, available with EXW/FOB/CIF/DDP terms. Submit your specifications to receive a formal quotation. Typical lead time: 5–7 days for samples, 2–3 weeks for bulk orders; expedited or partial shipments available.

- Quote: Submit specs → Get a quote (/inquiry/) or upload drawings (/upload-spec/)

- Price factors: Alloy/temper, thickness, tolerance, quantity, destination port

- MOQ & Samples: Mixed sizes supported; samples with MTC available

- Packing & Compliance: ISPM15 fumigation, COO, REACH/RoHS documents available

- Logistics: Sea/air/rail freight, DDP option, insurance & customs support

Get an accurate price and lead time for 5083 aluminum plates by submitting your requirements now.

5083 H111 aluminum sheet plate stock list

| Description | Thickness(mm) | size/mm | Spec |

| 5083 H111 aluminum sheet | 1 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 1 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 1.5 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 1.5 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 2 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 2 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 2.5 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 2.95 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 3 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 3 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 4 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 4 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 5 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 5 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 6 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 6 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 16 | 2000x4000 | EN 485, ASTM B209 |

Chemical composition of 5083 aluminum sheet plate for oil tanker

| Element | Composition % |

| Si | 0.40 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.40-1.0 |

| Mg | 4.0-4.9 |

| Cr | 0.05-0.25 |

| Ni | - |

| Zn | 0.25 |

| Ti | 0.15 |

| Al | Remainder |

Mechanical properties of 5083 aluminum sheet plate for oil tanker

| Temper | Thickness/mm | Tensile Strength /MPa | Specified non-proportional Tensile Strength/MPa | Elongation After Break/% | A50 mm | Bending Radius |

| O, H111 | 3.00-6.00 | 290-370 | ≥145 | ≥17 | ≥4930 | 1.5t |

| >6.00-12.00 | 290-370 | ≥145 | ≥17 | ≥4930 | 4.0t | |

| H116 | 3.00-6.00 | 305-370 | ≥220 | ≥12 | - | 3.0t |

| >6.00-12.00 | 305-370 | 220 | ≥12 | - | 6.0t | |

| H321 | 3.00-6.00 | 305-370 | ≥220 | ≥l2 | - | 3.0t |

| >6.00-12.00 | 305-370 | ≥220 | ≥12 | - | 6.0t |

Surface grade of 5083 aluminum sheet plate for oil tanker

| Type | Standard Plate | High Class Plate | Bright Plate | Mirror Plate |

| Surface | ★★★☆☆ | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Roughness Ra/μm | 0.5-0.8 | 0.3-0.5 | 0.1-0.3 | ≤0.04 |

| Product Description | Smooth surface Defect deepness <Minus Tolerances Of Thickness | Fine and smooth surface No or only very little colour aberration and chatters | Bright, fine and Smooth surface No colour aberration and chatters | Mirror reflective Surface Reflectance ≥86% |

| Applicable Standards | GB/T 3880 | EN14286 ASTM B209 EN485 Customer special requirements | EN14286 ASTM B209 Customer special requirements | EN14286 ASTM B209 Customer special requirements |

| Application | Use directly or After brashing Tanker Body, Tanker Head Wall Partition, Resistance Plate | Use directly Tanker Body, Tanker Head Wall Partition, Resistance Plate | Use directly Tanker Body, Tanker Head | Use directly Tanker Body, Tanker Head |

Permissible deviation of 5083 aluminum sheet plate for oil tanker

| Thickness tolerances within the following width ranges | ||||

| Thickness | ≤1250 | >1250-1600 | >1600-2000 | >2000-2600 |

| 3.00-3.50 | +0.28 | +0.28 | +0.30 | +0.40 |

| >3.50-6.00 | +0.32 | +0.32 | +0.40 | +0.45 |

| >6.00-8.00 | +0.38 | +0.45 | +0.50 | +0.60 |

| >8.00-12.00 | +0.45 | +0.55 | +0.65 | +0.80 |

FAQ — 5083 Aluminum Plate for Tank Trucks

1. Can 5083 be used for cryogenic or LNG tankers?

Yes. 5083 maintains strength and toughness down to LNG temperatures (≈ −162 °C), making it suitable for cryogenic transport and storage tanks. Compared with many steels, it offers lower weight with good formability and weldability for tanker fabrication.

2. How does 5083 perform in coastal or salt-spray environments?

5083 is a high-magnesium alloy with strong resistance to salt spray and marine atmospheres. It fits coastal, port, and chemical routes and helps reduce long-term corrosion maintenance.

3. What should I pay attention to when welding the shell?

Use ER5183 (preferred) or ER5356 filler, control heat input and interpass temperature, and clean oxide/oil before welding. Ensure proper shielding to avoid porosity and cracking and verify joints via NDT as required (PT/RT/UT).

4. Which tempers are commonly used for tanker parts?

Typical mapping: 5083-H111 for shells; 5083-O for heads, baffles, bulkheads, and manhole covers; 5083-H321 for selected high-stress parts. Choose temper by balancing strength, ductility, and forming needs.

5. When should I choose 5083 vs. 5454?

Choose 5083 for cryogenic/ambient media and marine routes where ductility and corrosion resistance are key. For long-term hot media (e.g., asphalt/insulated cargo), 5454 is usually preferred due to better high-temperature stability.

6. MOQ and samples?

Mixed specifications are supported. Samples can be supplied with measurement reports and EN 10204 3.1 MTC; special cutting and kit supply are quoted by process.

7. Lead time, packing, and documents?

Typical lead time is 5–7 days for samples and 2–3 weeks for bulk orders, with options for expedited or partial shipments. Export packing uses PE film plus crate/pallet; documents can include EN 10204 3.1, COO, and REACH/RoHS upon request.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote