Why choose Chalco 7003 T5 auto aluminum profile?

Chalco auto aluminum profile production capacity

Chalco Aluminum has an aluminum alloy profile extrusion production line, and can produce seamed aluminum tubes and seamless aluminum tubes at the same time, which can meet the production requirements of various automotive profiles.

Automotive IATF16949 standard

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Well-known brand material certifications

Serving Tesla, Ford, Shanghai Automobile, Weilai Automobile, BAIC New Energy, Changan Automobile and other famous new energy automobile manufacturers, confirmed the material certification relationship, and completed the parts of many automobile factories such as BAIC New Energy and Weilai Automobile Model car plate material certification.

Specs of 7003 T5 auto aluminum profile

| Alloy Status | Cross-Sectional Shape | Size Range (mm) |

| 7003-T5 | Square Tube | 10×10-150×150 |

| 7003-T5 | Round Tube | Φ10-Φ150 |

| 7003-T5 | Rectangular Tube | 10×20-100×200 |

| 7003-T5 | Other Shaped Tubes | Customized according to customer requirements |

| 7003-T5 | Solid Round Bar | Φ6-Φ80 |

| 7003-T5 | Hollow Round Bar | Φ10-Φ80 |

| 7003-T5 | Solid Square Bar | 6×6-60×60 |

| 7003-T5 | Hollow Square Bar | 10×10-70×70 |

| 7003-T5 | U-shaped Profile | Customized according to customer requirements |

| 7003-T5 | Angle Aluminum | Customized according to customer requirements |

Chemical composition of 7003 T5 auto aluminum profile

| Elements | Composition |

| Al | 90.1 - 94.2 % |

| Cr | <= 0.20 % |

| Cu | <= 0.20 % |

| Fe | <= 0.35 % |

| Mg | 0.50 - 1.0 % |

| Mn | <= 0.30 % |

| Si | <= 0.30 % |

| Ag | 0.25 - 0.40 % |

| Ti | <= 0.20 % |

| Zn | 5.0 - 6.5 % |

| Zr | 0.05 - 0.25 % |

| Other(each) | <= 0.05 % |

| Other(total) | <= 0.15 % |

Mechanical property of 7003 T5 auto aluminum profile

| Alloy State | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Shear Strength (MPa) |

| 7003-T5 | 350 | 300 | ≥11 | 210 |

Features of 7003 T5 auto aluminum profile

High strength: 7003 aluminum alloy is a high-strength material from the 7xxx series. In T5 temper, its yield strength typically reaches 300 MPa, with tensile strength up to 350 MPa. It also has good fatigue resistance, making it suitable for automotive structural parts requiring higher load-bearing capacity.

Lightweight: Compared with traditional steel, 7003 aluminum alloy is significantly lighter. This helps reduce overall vehicle weight, lower fuel consumption, and improve fuel economy and performance.

Good machinability: 7003 aluminum alloy can be processed by extrusion, forging, and rolling. It also offers decent weldability (though not as easy as 6xxx series) and good cutting performance, allowing for efficient assembly and forming.

Moderate corrosion resistance: 7003 aluminum alloy has moderate corrosion resistance and is suitable for most atmospheric environments. However, for long-term use in humid or marine conditions, surface treatments such as anodizing or coating are recommended.

Environmental protection: 7003 aluminum alloy is recyclable and eco-friendly. Its use in automotive applications helps reduce lifecycle carbon emissions.

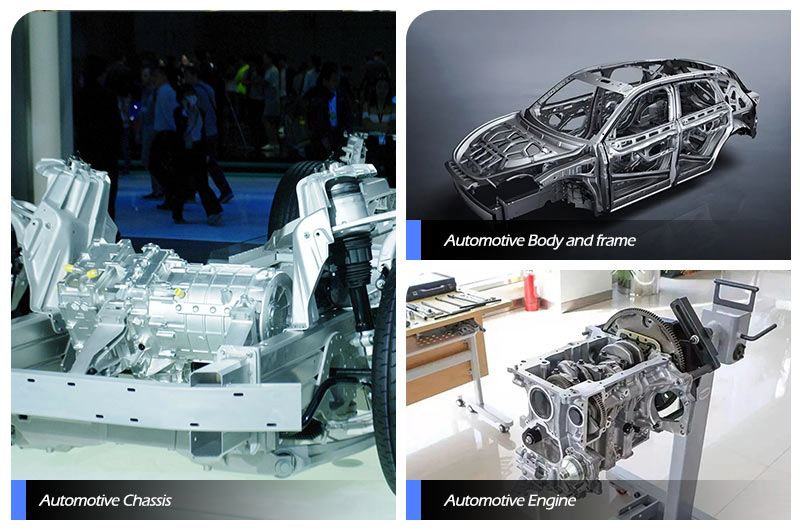

Usage of 7003 T5 auto aluminum profile

Body and frame: The high strength and lightweight characteristics of 7003 aluminum alloy make it an ideal material for automotive body structures and frames. Its use helps reduce vehicle weight, enhance fuel efficiency, improve handling stability, and increase overall body rigidity and crash safety.

Chassis: With its good corrosion resistance and strength, 7003 aluminum alloy is suitable for manufacturing structural parts in the automotive chassis, such as suspension arms, subframes, and mounting brackets. Surface treatments can enhance its durability in harsh environments.

Support components: While not typically used for core engine parts, 7003 aluminum alloy can be applied to lightweight support components near the engine bay or in battery tray structures for EVs, where high strength and rigidity are required without direct exposure to high temperatures.

Precautions for using 7003 T5 auto aluminum profile

Welding considerations: Although 7003 aluminum alloy has moderate weldability, it is more prone to hot cracking than 6xxx series alloys. Specialized welding techniques such as TIG or MIG welding with appropriate filler materials (e.g., ER5356) are recommended to ensure joint strength and avoid defects.

Corrosion protection: 7003 aluminum alloy has only moderate corrosion resistance compared to 6xxx series alloys. In harsh environments such as coastal or high-humidity areas, it is advisable to apply surface treatments like anodizing, powder coating, or electrophoresis to enhance corrosion resistance and extend service life.

Heat treatment sensitivity: The mechanical properties of 7003-T5 are sensitive to heat exposure. Overheating during welding or post-processing may degrade the alloy’s strength. Proper temperature control during forming and joining processes is critical.

Forming limitations: Compared to softer aluminum grades, 7003 alloy is less ductile and has limited formability. Complex bending or deep drawing may cause cracking or require special tooling and pre-heating to prevent failure.

Galvanic corrosion risk: When 7003 aluminum alloy is used in contact with dissimilar metals (such as steel or copper), galvanic corrosion may occur, especially in humid environments. It is important to use insulating layers or anti-corrosion coatings between dissimilar metals.