Welded Aluminum Tubes are made by roll-forming aluminum strips and welding the seam using High-Frequency Welding (HFW), Electric Resistance Welding (ERW), or Spiral Welding. Compared to seamless tubes, welded tubes offer higher material efficiency, broader size ranges, and greater design flexibility—ideal for medium- to low-pressure fluid transport and lightweight structures.

Chalco provides one-stop welded aluminum tube solutions, covering alloy selection, forming, heat treatment, surface finishing, and testing. We offer alloys like 3003, 5052, 6061, 5083 and shapes including round, square, and custom profiles. Whether for manifold tubes, thick-walled structural tubes, or special-shaped profiles, we deliver high-quality products with fast turnaround and tailored services for diverse industries.

Instant QuoteWelded Aluminum Tube Types, Alloys & Applications

To meet diverse needs in equipment frames, heat exchanger manifolds, automotive structures, and architectural supports, Chalco offers a full range of welded aluminum tubes. Tubes can be classified by welding method, wall thickness, and cross-section, and are available in custom alloys and sizes to match design requirements for strength, formability, corrosion resistance, and joining methods.

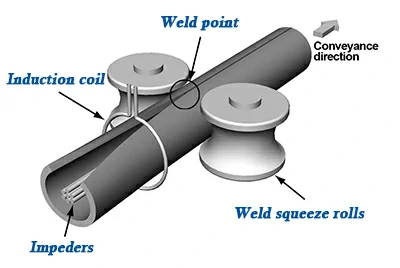

High-Frequency Welded Aluminum Tube

Process: 100–400kHz current, continuous seam welding

Alloys: 3003, 3105, 4343/3003/4343 composite

Standards: ASTM B313, ASTM B547

Contact us nowOD: φ8 mm – φ80 mm

Wall: 0.3 mm – 3.0 mm

Length: ≤6000 mm (custom cutting available)

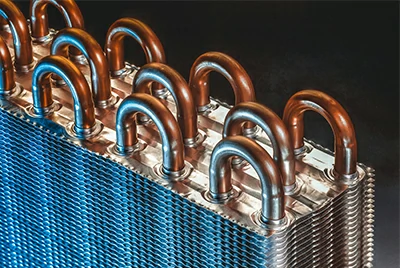

Applications: Automotive coolant manifolds, condenser headers, HVAC tubing, new energy thermal systems

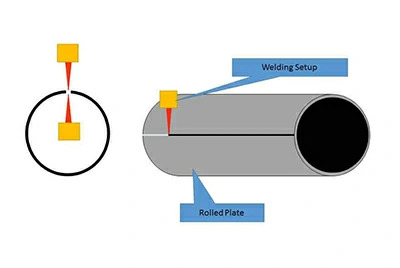

ERW (Electric Resistance Welding) Aluminum Tube

Process: Uses the metal's electrical resistance to fuse strip edges without filler wire or shielding gas, ideal for continuous high‑volume production.

Alloys: 3003, 5052, 5083, 6061

Standard: ASTM B313

Contact us now

Outer Diameter (OD): φ20 mm – φ150 mm

Wall Thickness (WT): 1.0 mm – 5 mm

Length: ≤ 6000 mm (customizable)

Applications: Industrial structural tubing (frames, supports), Rail transit piping, Automated equipment frameworks, High‑precision structural components requiring deep processing or cold drawing

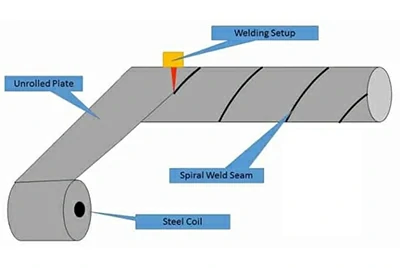

Spiral Welded Aluminum Tube

Process: 25–45° spiral forming and welding of aluminum strip

Alloys: 3004, 5052, 5083, 6061

Standards: ASME B36.10M, customized specs

Contact us nowOD: φ200 mm – φ2000 mm+

Wall: 1.0 mm – 6.0 mm

Length: ≤18000 mm (cut per transport needs)

Applications: Large ventilation pipes, aluminum chimneys, air separation systems, marine water pipelines, lightweight exhaust systems

Welded Tubes by Wall Thickness

WA: 0.3 - 3 mm

Alloys: 1100, 3003, 4343/3003

Mainly high-frequency welded with clad options; brazing-compatible; internal flash ≤0.1 mm. Used in heat exchangers, decorative tubes, and flow components.

WA: 3 - 6mm

Alloys: 5052,5083,6061

Made by HFW or ERW with heat treatment and UT testing, these tubes reach ≥90% base metal strength, ideal for structural supports, frames, and marine piping.

Welded Tubes by Cross Section

Round Welded Aluminum Tube

Round Welded Aluminum Tube Alloys: 3003, 4343/3003/4343, 5052, 5083, 6061

OD: 20 mm - 300 mm

Wall: 1.5 mm - 6 mm

The most common tube shape, offering balanced structure, easy forming and connection, widely used in heat transfer, HVAC systems, lightweight supports, railings, etc.

Square Welded Aluminum Tube

Square Welded Aluminum Tube Alloys: 6061, 6063

Size: 25 mm - 200 mm

Wall: 2 mm - 6 mm

Equal-length sides for easy welding, modular assembly, and excellent torsional rigidity, ideal for symmetric load-bearing in energy storage racks, equipment guards, lighting trusses, exhibition structures, window frames, and storage shelves.

Rectangular Welded Aluminum Tube

Rectangular Welded Aluminum Tube Alloys: 6061, 6063

Size: 25 mm - 200 mm

Rectangle shape enhances directional strength, ideal for tight spaces or directional load structures like EV battery cooling, PV inverter frames, HVAC joints, curtain wall systems, etc.

Custom/Special-Shaped Welded Aluminum Tube

Custom/Special-Shaped Welded Aluminum Tube Alloys: 3003, 3105, 5052, 6063

Includes D-shaped, oval, flat tubes and more, typically custom-designed with dedicated tooling. Used in EV battery trays, flat tube A/C systems, duct connectors, sliding frame structures, etc.

No matter if you need thin-walled tubes for heat transfer, thick-walled structural tubing, or custom complex profiles for tight spaces, Chalco delivers precise, tailored welded aluminum tube solutions.

Instant QuoteWelded Aluminum Tube Alloy Selection Guide

Different welded aluminum tube applications require different levels of strength, corrosion resistance, and workability. Chalco offers a full range of alloys from the 1xxx, 3xxx, 5xxx, to 6xxx series, covering both general industrial materials and aerospace-grade structures. All products can be delivered according to ASTM B313 and B547 standards.

1100 Welded Aluminum Tube|Commercially Pure Aluminum

1100 Welded Aluminum Tube|Commercially Pure Aluminum1100 is a high-purity aluminum with excellent ductility and corrosion resistance. It is ideal for non-load-bearing decorative structures, pipe jacketing, and HVAC outer shells, especially where formability is more important than strength.

ASTM B313 ASTM B547 3003 Welded Aluminum Tube|Anti-Rust Aluminum

3003 Welded Aluminum Tube|Anti-Rust Aluminum3003 is a typical Mn-based anti-rust aluminum with excellent welding and corrosion resistance. It is widely used in air conditioning heat exchangers, ventilation systems, and architectural trim. Its good bendability also makes it suitable for complex curved structures.

ASTM B313 ASTM B547 5052 Welded Aluminum Tube|Medium Strength

5052 Welded Aluminum Tube|Medium Strength5052 offers higher strength and corrosion resistance, especially in coastal or industrial atmospheres. It is commonly used in traffic barriers, light pole frames, and engineering supports, offering good weldability and moderate fatigue strength.

ASTM B313 ASTM B547 5083 Welded Aluminum Tube|High Corrosion Resistance

5083 Welded Aluminum Tube|High Corrosion Resistance5083 is ideal for structures exposed to high humidity or salt spray, such as marine cooling pipes, offshore platforms, and port structures. It retains high strength after welding and is a top choice for heavy-duty environments.

ASTM B313 ASTM B547 6061 Welded Aluminum Tube|High Strength

6061 Welded Aluminum Tube|High Strength6061 is widely used in mechanical frames, equipment supports, and automated structures. It offers strong heat-treatable properties and maintains good strength after welding. After anodizing, it also delivers a clean appearance, making it suitable for both functional and decorative uses.

ASTM B313 ASTM B547

Other Available Alloys

3004 Welded Aluminum Tube

Based on 3003 with enhanced strength. Suitable for pressure vessels, piping systems, and light structural loads.

5050 Welded Aluminum Tube

Balanced between 3003 and 5052. Offers moderate strength and corrosion resistance, ideal for light-duty frames, retail displays, and outdoor structures.

Similar to 5083 but with better stress corrosion resistance. Recommended for ship frames, harbor components, and coastal structures.

5154 Welded Aluminum Tube

Suitable for tanks, marine frames, and environments requiring high structural stability and post-weld strength retention.

5454 Welded Aluminum Tube

Designed for petrochemical and liquid transport systems where high temperature resistance is critical.

Optional alloys and performance comparison table

| Alloy | Temper | Weldability | Tensile strength (MPa) | Corrosion resistance | Typical application |

| 1100 | O / H14 | ★★★★★ | 90 MPa | ★★★★★ | Low-strength molded structures, ventilation sleeves, decorative pipes |

| 3003 | H14 / O | ★★★★☆ | 130 MPa | ★★★★☆ | Manifolds, condensers, light structural parts, furniture frames |

| 3004 | H34 / O | ★★★★☆ | 160 MPa | ★★★★☆ | Pressure vessels, pipeline exteriors, structures with high molding requirements |

| 5050 | H34 / O | ★★★★☆ | 175 MPa | ★★★★☆ | Commercial display structures, general supports, box frames |

| 5052 | H32 / O | ★★★★☆ | 215 MPa | ★★★★★ | Ship structures, outdoor brackets, railings, industrial housings |

| 5083 | H111 / O | ★★★☆☆ | 290 MPa | ★★★★★ | High-humidity environments, heavy-load supports, marine duct structures |

| 5086 | H32 / O | ★★★☆☆ | 275 MPa | ★★★★★ | Port facilities, dock railings, offshore platform components |

| 5154 | H34 / O | ★★★☆☆ | 240 MPa | ★★★★☆ | Liquid storage structures, marine frames, chemical containers |

| 5454 | H32 / O | ★★★☆☆ | 260 MPa | ★★★★★ | High-temperature manifolds, chemical barrels, heat exchange shells |

| 6061 | T6 / T4 | ★★★★☆ | 310 MPa | ★★★★☆ | Engineering frames, vehicle frames, industrial structural parts |

No matter your priorities—cost-effectiveness, structural strength, or corrosion resistance—Chalco delivers high-performance welded aluminum tube solutions that meet international standards. Share your project details with us, and we'll help match the best alloy and welding process for your needs.

Instant QuoteTypical Applications of Welded Aluminum Tubes

With their balanced strength, corrosion resistance, and lightweight properties, welded aluminum tubes are ideal for construction, thermal systems, industrial assemblies, and transport manufacturing. Chalco offers multi-alloy, multi-spec solutions—from standard structural pipes to specialized manifold tubes.

Automotive & New Energy Vehicles

Welded aluminum tubes help reduce overall vehicle weight while improving cooling and structural strength. Widely used in battery cooling pipes, heat exchangers, and chassis supports.

Recommended Products:

- 3003 HFW welded tube: Great formability and brazability, ideal for heat exchangers

- 4343/3003/4343 composite tube: Clad composite tube for battery cooling manifolds

- 6061 ERW welded tube: High bending rigidity, suitable for EV frames and subframes

- 5052 welded tube: Medium strength, used in vehicle structures and support pipes

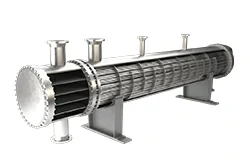

HVAC & Heat Exchange Systems

Aluminum welded tubes offer good formability and brazing compatibility, ideal for condensers, evaporators, and heat exchange headers in AC, refrigeration, and energy management systems.

Recommended Products:

- 3003 HFW welded tube: Widely used in condenser headers and manifold systems

- 3102 thin-wall tube: Excellent thermal conductivity, used in heat dissipation modules

- 4343 clad composite tube: Superb brazing with clad layers, perfect for refrigerant flow channels

Building Structures & Industrial Frames

Welded aluminum tubes provide high strength, weather resistance, and easy fabrication, making them ideal for curtain walls, handrails, and scaffolding platforms.

Recommended Products:

- 6061 ERW welded tube: High strength, used in industrial platforms and stairs

- 5083 structural tube: Excellent salt spray resistance for outdoor and coastal supports

- 5052 anodized welded tube: Corrosion-resistant and aesthetic, ideal for decorative structures

Shipbuilding & Offshore Equipment

Aluminum welded tubes are highly resistant to salt spray and provide strong structural stability, widely used in ship frames, walkways, and support elements in high-humidity, corrosive environments.

Recommended Products:

- 5083 ERW welded tube: High strength for main structural parts

- 5454 H32 welded tube: Heat- and corrosion-resistant, ideal for offshore fluid transport

- 5052 marine-grade tube: Lightweight and durable, used in interior marine components

Industrial Equipment & Automation Frames

Used in automated lines and conveyor platforms, aluminum welded tubes support high strength and precision assembly, ideal for frames and load-bearing parts.

Recommended Products:

- 6061 ERW welded tube: Great workability for machine frame structures

- 5083 spiral welded structural tube: Strong load capacity for heavy-duty automation frames

- 5052 welded assembly tube: Good ductility for multi-point connections

Furniture & Lightweight Outdoor Structures

Lightweight, aesthetic, and cost-effective, aluminum welded tubes are ideal for outdoor furniture, display racks, and portable equipment.

Recommended Products:

- 3003 round welded tube: Lightweight and economical for furniture and displays

- 6063 decorative welded tube: Surface anodizing-ready, great for decorative columns

- 5052 frame tube: Flexible and durable for mobile frames and load-bearing parts

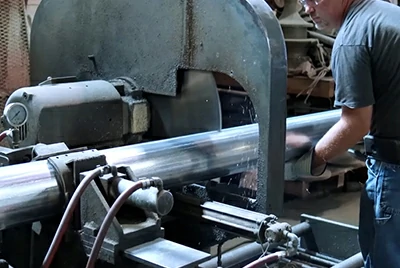

Chalco Welded Aluminum Tube Manufacturing Process & Quality Assurance

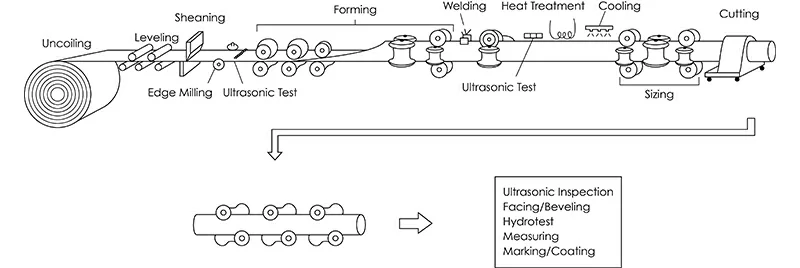

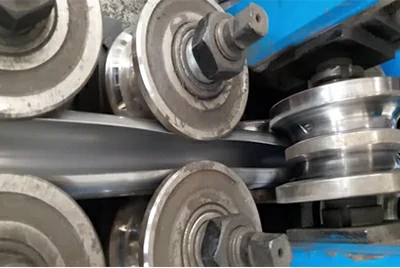

The manufacturing process plays a critical role in the performance of welded aluminum tubes. Chalco adopts an advanced, integrated production system, strictly controlling every step from raw material preparation to final delivery to ensure consistent mechanical properties, excellent weld quality, and precise dimensional accuracy.

Manufacturing Overview: From Aluminum Strip to Finished Welded Tube

Material Preparation & Cleaning: Pre-rolling and shaping of aluminum strip; ensures weld area is oil-free and oxide-free.

Welding Execution:

- HFW: Used for clad strips like 4343/3003/4343, HFW enables continuous, high-speed welding with clean, strong seams. It's widely applied in heat exchanger tubes and thin-walled precision tubes.

- ERW: ERW suits standard welded aluminum tubes for fluid transport and structural applications, offering stable, efficient seam welding with excellent mechanical strength and corrosion resistance.

- Spiral Welding: Ideal for large-diameter or heavy-wall tubes, spiral welding forms strong, reliable seams with high material utilization and design flexibility, commonly used in HVAC, marine, and structural systems.

Cooling & Heat Treatment: Air or natural cooling post-weld; T6 heat treatment for alloys like 6061

Shaping & Cutting: Precision sizing + laser/flying saw cutting + chamfering

Surface Finishing: Options include anodizing, electrophoresis coating, or mechanical polishing; weld zones are polished/pickled as needed

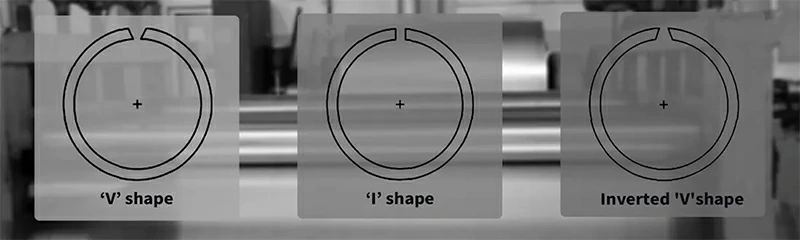

High-Frequency Welding Forming Control: Ensuring Optimal Weld Geometry

In high-frequency welded aluminum tube production, weld seam geometry is critical to overall weld quality. Chalco ensures precise seam formation by controlling forming parameters and tooling design, achieving ideal "I" or small "V" butt joints at the welding zone:

- "I" joints ensure simultaneous contact of inner and outer walls, promoting uniform heating and dense, defect-free welds.

- Slight "V" joints help slag discharge and facilitate proper weld filling.

- Avoiding large or inverted "V" joints is essential, as they can cause uneven heating or slag entrapment, leading to porosity, lack of fusion, and inclusions.

With strict forming control, Chalco eliminates weld defects at the source and lays a solid foundation for downstream inspection and seam reliability.

Weld Quality Assurance: Chalco's Five Core Control Mechanisms

To ensure reliability and consistency in every welded aluminum tube, Chalco implements comprehensive quality measures across the entire process:

1.Weld integrity monitoring: Automated imaging to detect porosity/inclusions/lack of fusion

2.Dimensional consistency: Laser measurements accurate to ±0.1mm

3.Surface quality inspection: Optical + manual inspection

4.Non-destructive testing: X-ray / UT for critical applications

5.Microstructural analysis: Optional metallographic reports available

Value-Added Machining & Surface Treatment Capabilities

To support ready-to-use delivery, Chalco offers full-service processing for welded aluminum tubes:

- Custom sizing & end processing: High-precision (±0.2mm) laser/flying saw cutting, chamfering, expanding/reducing ends

- Integrated assemblies: Pre-welded flanges, connectors for modular systems

- Surface treatments: Anodizing, electrophoresis, brushed finish to enhance corrosion resistance and appearance

- Internal weld bead removal: For thin-wall HFW tubes, ensuring smooth fluid passage with burrs ≤0.1mm

Certifications & Documentation Available

- Compliance with ASTM B313 / B547

- Material Test Certificate (MTC) + Mechanical property report

- ISO 9001 / ISO 14001 quality certifications

- RoHS / REACH compliance declarations

- Optional: Weld inspection report, surface appearance record, anodizing thickness report

Chalco's integrated welding system and strict QC processes ensure every tube delivers superior strength, weld stability, and consistent appearance. Submit your drawings or specs – we'll recommend the best process and alloy combination.

Welded vs Seamless Aluminum Tubes: Which to Choose?

Each option has its strengths. Understanding the differences in structural behavior, manufacturing characteristics, and application suitability helps you make the right choice and reduce costs.

| Comparison dimensions | Welded Tube | Seamless Tube |

| Manufacturing process | Aluminum strip is rolled and formed by high-frequency/TIG/MIG/laser welding | Solid aluminum rod is formed by hot extrusion or cold drawing in one step |

| Weld structure | There is a weld, HAZ control <2mm, and internal burrs need to be removed | No weld, uniform and continuous inside and outside |

| Dimensional capability | Outer diameter φ10–2000mm (spiral welding), length up to 18m | φ5-420mm, length ≤6m |

| Wall thickness range | 0.3-6mm (high-frequency welding), 3-25mm (TIG/MIG) | 1-50mm (cold drawing is thinner but the cost is high) |

| Surface treatment | Welds need to be pickled/polished, and the thickness difference of the anodic film is ±2μm | Good anode consistency, Ra≤0.8μm |

| Mechanical properties | Weld strength 90~95%, suitable for light and medium load structures | High overall strength, better fatigue life |

| Cost efficiency | Low cost, fast delivery, high material utilization (≥95%) | Cost 2~3 times, special mold required, long cycle |

| Recommended applications | HVAC, automotive cooling, engineering brackets, headers | Hydraulic pipes, aircraft fuel lines, precision instrument structures |

For mass production, lightweight structures, and thermal systems, welded aluminum tubes offer great cost-effectiveness and customization.

For high-pressure, high-precision, or critical-load applications, seamless aluminum tubes remain the preferred solution.

Interested in seamless tube performance? Visit our [Chalco Seamless Aluminum Tube page] for technical details and selection guidance.

Is Welded Aluminum Tube Right for You?

Compared with seamless or cold-drawn tubes, welded aluminum tubes offer the following key advantages, especially for large-size, non-high-precision applications:

- Cost-effective: Simplified production and high material yield reduce costs—up to 50% less than seamless tubes

- Large diameter & custom shapes supported: Tubes up to φ2000mm and beyond for structures like ventilation or collectors

- Faster delivery & better availability: Efficient welding methods enable lead times as fast as 3–5 days

- Ideal for non-critical applications: Perfect for items like display racks, scaffolds, structural connectors

- Flexible customization: Alloy, shape, surface treatment—all tailored to your needs

Not sure if welded aluminum tube suits your project? Contact Chalco for free evaluation and expert recommendations.

Instant QuoteFAQs

What types of aluminum coils are used for welded tubes? How is weldability evaluated?

Welded aluminum tubes are mainly made from single-alloy strips and clad composite strips (e.g., 4343/3003/4343). Single-alloy types are suitable for structural applications, while clad types are used for brazed heat exchangers. The base material must meet the following criteria:

- Clean, burr-free edges to prevent uneven welds;

- Oil-free, oxide-free surface to avoid porosity;

- Good alloy compatibility: 3003/3102 for HFW, 5083 for MIG, and 6061 for TIG (followed by heat treatment).

All strips used by Chalco undergo leveling, degreasing, and cleaning to ensure consistent weld quality.

How are weld seams treated after welding? Will they affect product performance?

Proper weld seam treatment is essential for tube safety. For HFW tubes, Chalco uses internal deburring blades (residual burr ≤ 0.1mm) and inline eddy current testing. For TIG/MIG welded tubes, weld seams can be ground, pickled, polished, or passivated based on customer needs, enhancing corrosion resistance and appearance.

Optional metallographic samples and NDT reports are available for all shipped products.

What is the pressure capacity of welded aluminum tubes? Can they be used for medium-pressure fluid systems?

The pressure capacity depends on weld quality, alloy strength, and wall thickness:

- HFW tubes made from 3003 alloy can withstand low-pressure systems (0.8–1.5MPa);

- TIG-welded 6061-T6 tubes with ≥3mm wall thickness can handle 8–12MPa, suitable for load-bearing and medium-pressure pipelines.

Burst and pressure testing can be conducted per ASTM B313/B547 and ASME B31.3 standards.

How does Chalco prevent porosity, inclusions, and other common weld defects?

Chalco uses 99.99% pure argon shielding, acetone pre-cleaning, and real-time weld imaging to reduce the risk of hydrogen pores and inclusions. For thin-wall TIG welding, pulse or laser welding is used with controlled heat input, beveled edges, and airflow direction to prevent burn-through and distortion.

Can anodized aluminum tubes be welded? How is post-weld treatment handled?

Anodized layers are non-conductive and must be removed (by grinding or chemical stripping) before welding. After welding, micro-arc oxidation or surface sealing is recommended to avoid corrosion.

Chalco can weld pre-anodized tubes and apply localized oxide film repair with thickness variation controlled within ±2μm to meet decorative and corrosion-resistance needs.

How can I determine if welded aluminum tubes meet strength or corrosion-resistance requirements?

Chalco offers the following services based on your project parameters:

- Material selection consulting: optimal alloy + weld type + surface treatment

- Weld seam microstructure evaluation: crack/inclusion checks via metallography

- ASTM/ISO/GB compliance reports

- RoHS/REACH declarations + anodic film thickness tests

Chalco has experience providing SGS and X-ray inspection reports for aerospace clients.

Is it expensive to customize non-round welded tubes? How to manage tooling costs?

Custom shapes (e.g., oval, D-shape, dual-channel) require special roll-forming dies. Chalco maintains a shared mold library with hundreds of options; if your design is similar, existing dies can be shared at no or low cost.

Standard MOQ is 500kg. Simple shapes can also be formed via stamping and seam folding without welding dies.

Still searching for a cost-effective and high-performance welded aluminum tube solution? Submit your drawings and technical requirements—Chalco will recommend the most suitable alloy, welding process, and fabrication solution to help move your project forward efficiently.

Click below to request a quote or technical support!

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote