Square telescopic tubes are a type of length-adjustable tubing made from multiple sections of precision square tubes that overlap. They are compact for transport when retracted and can be locked at the desired height or length when extended, eliminating the need for welding or drilling. Their main advantages are as follows:

- Fast assembly: Various locking methods such as pin locks, clamp locks, or spring buttons enable efficient on-site adjustment.

- Lightweight and high strength: Aluminum alloy materials (such as 6061, 6005, 6082) offer both light weight and torsional stiffness.

- Space-saving: The folded state occupies a small volume, reducing transportation and storage costs.

- Versatile applications: Widely used in scaffolding, display racks, sign supports, medical equipment, automated machinery, and more.

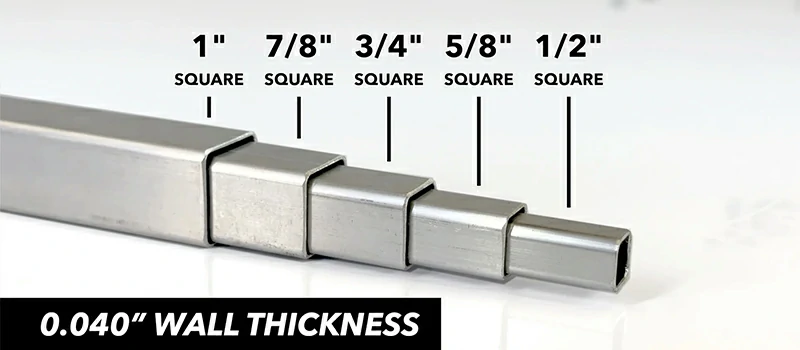

Chalco provides one-stop solutions for square telescopic tubes, offering multi-stage specifications from ½″→⅝″, ⅝″→¾″, ¾″→⅞″, ⅞″→1″, and supports customized surface treatments such as anodizing and powder coating, as well as a full range of locks and bracket accessories to meet all your needs from tubing to complete installation.

Instant QuoteClick to view[Square Telescopic Tube Imperial Size Chart]

Square Telescopic Tubes Product List

Square Telescoping Tube

Telescopic square tubes with smooth walls and no holes, featuring minimal gaps between sections for a clean appearance. Suitable for applications with requirements for aesthetics or sealing.

Contact us now

Telescopic square tubes with smooth walls and no holes, featuring minimal gaps between sections for a clean appearance. Suitable for applications with requirements for aesthetics or sealing.

Features

- Number of sections and travel: Supports single-section, dual-section, and multi-section structures, with a maximum extension of 60% of the original length.

- Wall thickness and dimensions: 0.040″ - 0.125″ (1.0 - 3.2 mm); outer diameter range ½″–2½″.

- Materials: Commonly used 6061 - T6, 6063 - T5, 6005A - T6 aluminum alloys; optional galvanized carbon steel.

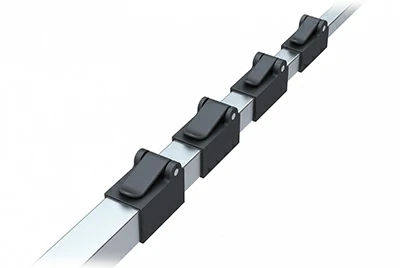

Locking methods

- Spring - Button Detent: Fast single-hand insertion, 0.125″ increments

- SQ - Lock: Lightweight adjustment, no metal friction noise

- Clamp Lock: No pre-drilling required, suitable for frequent fine-tuning

Supporting processing and services

- Fixed-length cutting: Length up to 6 m, customizable cutting

- End processing: Flanging, flaring, punching, threading

- Surface treatment: Anodizing (multi-color), powder coating

- Packaging & logistics: Special protective tube racks, supports overseas full container direct shipping

Typical applications

Photography tripods, outdoor flagpoles, adjustable furniture legs, medical infusion stands, lightweight display racks, etc., highlighting their simple, aesthetic, and lightweight advantages.

Pre - Drilled / Perforated Square Telescoping Tube

Telescopic tubes with pre-drilled standard holes on the tube walls, for direct use with pin locks or bolt fixation, enabling "plug-and-play" high-load-bearing modular assembly.

Contact us now

Features

- Hole specifications: 7/16″ diameter, 1″ (25 mm) standard spacing; optional four-sided, three-sided, or single-sided holes.

- Number of sections and travel: Also supports multi-stage structures, combining long travel with high strength.

- Materials & wall thickness: 6005A‑T6/6061‑T6 aluminum alloy or galvanized carbon steel, wall thickness 0.058″-0.135″.

Locking methods

- Pin & Hole: Quick and firm insertion, strong vibration resistance

- U‑Bolt: Suitable for heavy-duty or vibration conditions

Supporting hardware and systems

- Base Plate P90xx: Multi-hole base plate, directly bolted to the ground or frame

- Angle Bracket: Four-sided perforated, for rapid splicing at any angle

- T-Connector: Three-way branching, for building multi-branch structures

- Multi-head rivets / hooks / U-Nuts: High-load fastening, ensuring overall stability

Chalco provides integrated solutions, including tubes + bases + angle brackets + connectors, delivered in one package for on-site assembly according to drawings.

Typical applications

Traffic sign supports, safety railings, industrial assembly lines, warehouse shelves, supermarket displays, etc., in scenarios with high requirements for modularity, load-bearing capacity, and reusable disassembly and assembly.

Chalco Telescopic Tube Overall Solutions

Chalco provides one-stop telescopic tube system packages suitable for various scenarios such as scaffolding, shelves, signboards, and display systems:

- Tubes: Supports multi-stage telescoping combinations with various wall thicknesses (0.040″ - 0.135″) and imperial/metric dimensions, covering square and rectangular cross-sections.

- Locks & Accessories: Compatible with both non-perforated and pre-drilled solutions, offering spring buttons, SQ-Lock plastic latches, pin kits, 90° angle brackets, column bases, hooks, multi-head rivets, and more.

- Processing & Customization: Supports on-demand fixed-length cutting, pre-drilling/punching, flanging and flaring, end threading, anodizing or powder coating, and more.

- Design & Services: Supports customer drawing customization and small-scale design optimization, providing free 3D assembly drawings, rapid sample prototyping (3 - 5 days), and flexible logistics and distribution.

No matter the project size, Chalco can tailor the optimal telescopic tube solution for you.

Instant QuoteChalco Multi-Section Telescopic Tube Series

In addition to square telescopic tubes, Chalco can also provide round, rectangular, and oval telescopic tubes in three cross-sections to meet various application needs from lightweight handheld to industrial support.

The streamlined cross-section and uniform stress characteristics make it an ideal choice for lightweight applications such as selfie sticks, fishing rods, and handheld lighting brackets.

Telescoping Rectangular Tube

The rectangular cross-section provides excellent torsional stiffness and stability, and is widely used in telescopic table leg supports, billboard frames, warehouse shelf supports, and other structural parts.

Telescoping Oval Tube

The oval cross-section ensures lightweight while possessing good planar torsional performance, commonly used in adjustable lamp arms, sign pillars, and decorative support brackets.

If you require other cross-sectional shapes or personalized customization, please provide design drawings. Chalco can customize mold openings according to the drawings to accurately meet your project needs.

Instant QuoteChalco Square Telescopic Tube Material Selection

6061-T651 Telescoping Square Tube

6061 seamless aluminum square tube is one of the aluminum alloys with the best balance of strength and processability. It is widely used in industrial brackets, exhibition display racks, and outdoor advertising frame fields, combining welding and precision cutting performance.

Heavy-Duty Telescoping Square Tube 6005A-T6

6005A has excellent structural strength and rigidity. It is commonly used in scaffolding, pipe rack supports, and heavy-duty equipment frames, ensuring stability and safety during heavy-duty use.

7075-T6 Telescoping Square Tube

7075 is an aerospace-grade high-strength alloy with extreme lightweight and fatigue resistance characteristics. It is ideal for high-end photography brackets, extreme sports equipment, and model aircraft support structures.

Other Alloy Square Telescopic Tubes

6063 is known for its excellent anodizing and surface finish and is often used in decorative lightweight support scenarios such as indoor furniture legs, lamp arm supports, and display props.

Adjustable Square Tube 6082 exhibits excellent corrosion resistance and weather resistance and is suitable for high-corrosion environments such as ship deck supports, coastal sign posts, and chemical pipe racks.

7001 has excellent toughness and fatigue resistance and is often used in lightweight sports equipment such as tent poles, hiking poles, and outdoor leisure furniture.

7005 combines the advantages of strength and formability and is suitable for various outdoor equipment and sports equipment such as bicycle frames, windsurfing support tubes, and camping tools.

Square Telescopic Tubes of Other Materials

- Galvanized Steel Telescoping Square Tube

Made of G-90 hot-dip galvanized carbon steel, the surface zinc layer thickness is better than that of ordinary galvanized pipes, and it has excellent weather resistance and corrosion resistance. It is often used in heavy-duty scenarios such as outdoor scaffolding, traffic sign supports, and warehouse shelves.

- 4130 Chromoly Telescoping Square Tube

4130 alloy steel (Chromoly) is known for its high strength-to-weight ratio and excellent fatigue performance. It is suitable for adjustable structures with extremely high requirements for strength and reliability in racing roll cages, aviation test supports, and high-end industrial equipment.

If you need to know more about material specifications or obtain sample tests, please contact our engineering team, and we will provide you with one-on-one customized material solutions.

Instant QuoteSquare Telescopic Tube Specifications

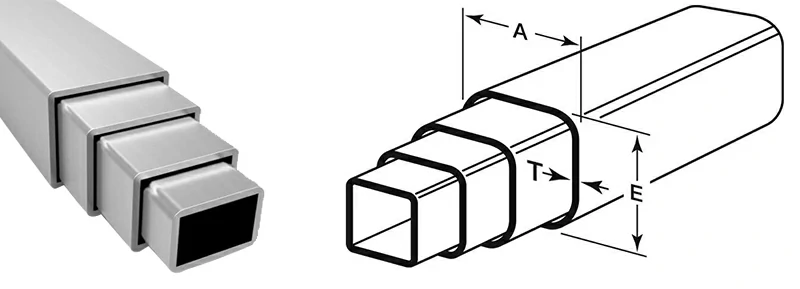

Before constructing any telescoping structure, the rationality of dimensional matching directly affects the telescoping performance, load-bearing capacity, and service life. The following is a summary of the core design elements for square telescopic tubes from Chalco:

Clearance

Appropriate sliding clearance is required between the outer tube's inner wall and the inner tube's outer wall:

- For small-diameter aluminum tubes (e.g., 1" → 7/8"), a total bilateral clearance of 0.013"–0.015" (0.33–0.38 mm) is recommended.

- For large-diameter aluminum tubes (e.g., 2" → 1¾"), a clearance of 0.030"–0.060" is recommended for easy insertion, removal, or perforation positioning.

Wall Thickness and Strength Matching

Common wall thicknesses for aluminum alloy telescopic tubes are:

- 0.040"–0.065": Suitable for lightweight equipment brackets, telescopic photography devices, and simple outdoor structures.

- 0.105"–0.125": Suitable for heavy-duty frames, sign supports, and traffic-grade structural needs.

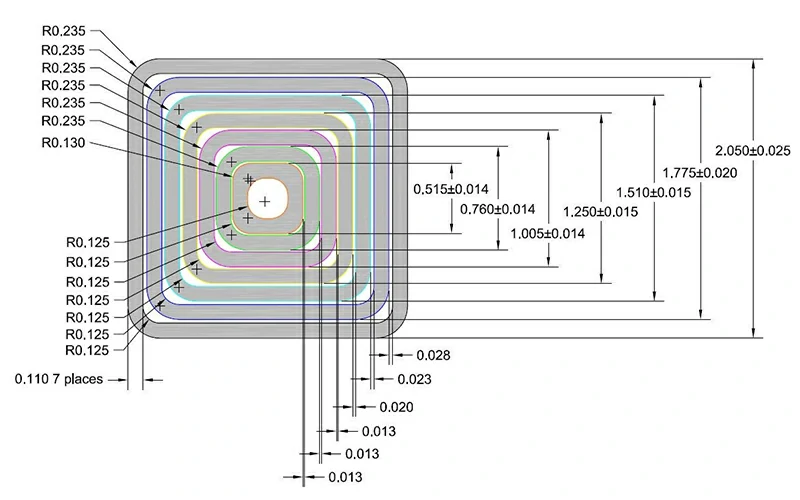

Corner Radius Consistency (R Matching)

Telescoping tubes must be extruded/roll-formed from the same set of molds to ensure interference-free "corner-to-corner" sliding. Mismatched R-values, even with matching outer diameters, can easily cause jamming.

Locking Method and Structure Selection

Sliding fit + plastic latches / spring buttons: Suitable for photography supports, telescopic rods, and portable devices.

Pre-drilled + pin/gravity pin systems: Suitable for traffic sign supports, scaffolding, and industrial support frames.

Number of Telescoping Stages

The standard 7-stage configuration includes 2", 1¾", 1½", 1¼", 1", ¾", and ½" sections from the outermost to the innermost, corresponding to different load levels and telescoping ratios.

Tolerance Control

To ensure smooth yet non-loose sliding, the OD of each stage must be matched within a tolerance range of ±0.014" to ±0.025".

Chalco can provide multi-stage structure customization, fit optimization design, and standard-grade paired sample services according to customer needs. Please click below to obtain exclusive size consultation and sample proofing services.

Instant QuoteSquare Telescopic Tube Imperial Size Chart

Square telescopic tubes with a wall thickness of 0.040″

Commonly used in lightweight structural parts and portable equipment, such as photography light stands, portable exhibition stands, outdoor folding table legs, and camping tool racks.

| Sequence | Nominal Size | Actual OD (in) | Wall Thickness t (in) | Tolerance ± (in) |

| 1-Outer Tube | 2″ | 2.050″ | 0.040″ | ±0.025″ |

| 2 | 1 ¾″ | 1.775″ | 0.040″ | ±0.020″ |

| 3 | 1 ½″ | 1.510″ | 0.040″ | ±0.015″ |

| 4 | 1 ¼″ | 1.250″ | 0.040″ | ±0.015″ |

| 5 | 1″ | 1.005″ | 0.040″ | ±0.014″ |

| 6 | ¾″ | 0.760″ | 0.040″ | ±0.014″ |

| 7 -Inner Tube | ½″ | 0.515″ | 0.040″ | ±0.014″ |

Square telescopic tubes with a wall thickness of 0.065″

Commonly used in medium-sized instrument supports, trolley structures, and laboratory workstation slide rail systems, requiring a balance of strength and sliding performance.

| Sequence | Nominal Size | Actual OD (in) | Wall Thickness t (in) | Tolerance ± (in) |

| 1 - Outer Tube | 2″ | 2.125″ | 0.065″ | ±0.025″ |

| 2 | 1¾″ | 1.875″ | 0.065″ | ±0.020″ |

| 3 | 1½″ | 1.625″ | 0.065″ | ±0.015″ |

| 4 | 1¼″ | 1.375″ | 0.065″ | ±0.015″ |

| 5 | 1″ | 1.125″ | 0.065″ | ±0.014″ |

| 6 - Inner Tube | ¾″ | 0.875″ | 0.065″ | ±0.014″ |

Square telescopic tubes with a wall thickness of 0.105″

Suitable for medium to heavy-duty applications such as industrial scaffolding, signpost supports, and mechanical structure reinforcement.

| Sequence | Nominal Size | Actual OD (in) | Wall Thickness t (in) | Tolerance ± (in) |

| 1 - Outer Tube | 2½″ | 2.625″ | 0.105″ | ±0.030″ |

| 2 | 2¼″ | 2.375″ | 0.105″ | ±0.025″ |

| 3 | 2″ | 2.125″ | 0.105″ | ±0.020″ |

| 4 | 1¾″ | 1.875″ | 0.105″ | ±0.015″ |

| 5 | 1½″ | 1.625″ | 0.105″ | ±0.015″ |

| 6 - Inner Tube | 1¼″ | 1.375″ | 0.105″ | ±0.015″ |

Square telescopic tubes with a wall thickness of 0.125″

Suitable for heavy-duty lifting systems, industrial fixed frames, and building reinforcement modules, with high requirements for bending resistance.

SequenceNominal SizeActual OD (in)Wall Thickness t (in)Tolerance ± (in)

| Sequence | Nominal Size | Actual OD (in) | Wall Thickness t (in) | Tolerance ± (in) |

| 1 - Outer Tube | 3″ | 3.125″ | 0.125″ | ±0.030″ |

| 2 | 2½″ | 2.625″ | 0.125″ | ±0.025″ |

| 3 | 2″ | 2.125″ | 0.125″ | ±0.020″ |

| 4 | 1½″ | 1.625″ | 0.125″ | ±0.015″ |

| 5 - Inner Tube | 1″ | 1.125″ | 0.125″ | ±0.015″ |

Whether it is a lightweight slide rail structure or a heavy-duty support frame, Chalco can provide square telescopic tubes with various wall thicknesses and matching sizes, covering a complete specification chain from ½″ to 2½″.

We support fixed-length cutting, multi-stage matching, and rapid prototyping to help you quickly construct the optimal structural solution.

Instant QuoteTypical Application Areas of Square Telescopic Tubes

Square telescopic tubes, with their structural stability, adjustability, and easy installation, play a crucial role in many industries. Chalco provides a variety of standard and customized specifications to fully meet the needs of the following scenarios:

Construction & Industrial Support

Pre-drilled structures + pin locks are recommended, combined with 0.105"-0.125" wall thickness aluminum tubes, to meet load-bearing and quick-assembly requirements.

Specific applications: formwork support, scaffolding frames, adjustable industrial support rods

Signage & Public Safety Systems

Four-sided pre-drilled telescopic tubes + column bases + U-shaped pin lock accessories are recommended to support rapid disassembly, assembly, and standardized replacement.

Specific applications: road signs, height limit frames, guide posts

Furniture & Exhibition Structures

Non-perforated telescopic square tubes + spring buttons / SQ-locks are used for lightweight and flexible adjustment.

Specific applications: exhibition supports, shelf supports, folding table legs, display stand frames

Photography & Lighting Equipment

Telescopic tubes with a wall thickness of 0.040"-0.065" are recommended, combined with plastic locks, to meet the dual requirements of portability and structural rigidity.

Typical applications: light stands, tripods, camera arms, track supports

Medical & Lab Equipment

Aluminum alloy tubes with anodized surfaces + spring buttons are recommended to ensure safety, corrosion resistance, and easy operation.

Typical applications: infusion hangers, mobile brackets, isolation frames

Sporting & Recreational Equipment

7001/7005 aluminum alloys are commonly used, which are lightweight and durable, and compatible with multi-stage telescopic structural designs.

Width:500mm--2800mm

Typical applications: adjustable fitness equipment, telescopic flagpoles, camping tent frames

Whether it is a building benchmark or a portable exhibition stand, Chalco square telescopic tubes can be customized in terms of structure, accessories, and surface treatment as needed, to help your products achieve rapid deployment and efficient application.

Manufacturing Process and Surface Treatment

Chalco has a complete integrated manufacturing chain, from aluminum ingot casting to profile extrusion, telescopic matching, surface treatment, and accessory assembly, providing precise, efficient, and customizable solutions for various telescopic structure projects.

Core Manufacturing Process Flow

Mold Design and Aluminum Ingot Casting: Supports customized square, rectangular, and oval cross-section molds to meet different matching structure needs.

Precision Extrusion Molding: Offers a variety of aluminum alloys, including 6061, 6063, 6005, and 7075, ensuring consistent wall thickness and sharp angles.

Stretching and Shaping: Utilizes multiple drawing and straightening processes to control dimensional deviations and wall thickness uniformity.

Matching Processing:

- Pre-drilling (7/16″ standard hole spacing)

- Punching positioning grooves

- End cap sealing and pre-riveted bases

- Length cutting & laser numbering

Tube Assembly and Testing: Each set of telescopic tubes is paired and test-assembled to ensure smooth sliding, no interference, and no shaking.

Optional Surface Treatment Methods

To adapt to different usage scenarios (outdoor exposure, high humidity, high friction, etc.), Chalco offers a variety of professional surface treatments:

High-pressure sandblasting or mechanical polishing can remove surface defects, forming a delicate matte or glossy texture and enhancing the overall aesthetics. It is commonly used in exhibition supports, consumer-grade electronic brackets, photography equipment, and other products with visual texture requirements.

Anodizing is the most commonly used anti-corrosion and decorative treatment for aluminum alloys, significantly enhancing surface hardness and wear resistance, and providing a variety of color options such as silver, black, and red. It is suitable for outdoor structures, display systems, sports equipment, and other applications with high requirements for appearance and weather resistance.

Electrostatic spraying of polymer powder forms a thick and wear-resistant coating, providing a rich variety of colors and textures with excellent UV and corrosion resistance. It is widely used in outdoor advertising structures, furniture systems, building components, and other long-lasting weather-resistant projects.

Round Telescopic Tubes vs. Square Telescopic Tubes

| Comparative dimensions | Telescoping Round Tube | Telescoping Square Tube |

| Structural characteristics | Smooth sliding, uniform friction, suitable for rotation and frequent adjustment | Anti-rotation structure with stronger stability, suitable for modular assembly and rigid frame structure |

| Ease of installation | Easy to plug and unplug, flexible operation, can be used for rapid extension and retraction | Adaptable to a variety of latches, connecting brackets, support bases, and high assembly standardization |

| Anti-torsion performance | Symmetrical structure, weak torsion resistance, suitable for light load and dynamic scenes | The four-sided support surface provides torsional strength, suitable for heavy-duty stable brackets |

| Accessory adaptability | Can be integrated with rotating buckles, hooks, rubber end plugs | Matching standard hardware such as latch locks, 90° angle pieces, T-connectors, etc. |

| Processing flexibility | Easy to roll and seal, suitable for automated equipment structure | Supports punching, cutting, anodizing spraying and other processing methods |

| Typical applications | Photographic brackets, fishing rods, tent poles, catheters, sliding rod systems, etc. | Display racks, sign posts, medical equipment racks, storage shelves, scaffolding, industrial support structures, etc. |

Round telescopic tubes excel in "smoothness and flexibility" and are commonly used in lightweight and dynamic application scenarios. In contrast, square telescopic tubes dominate in "structural stability and modular assembly" and are the preferred choice for heavy-duty industrial support structures. Chalco provides a full range of tube types, accessories, and processing services to meet your one-stop needs from design to installation.

Frequently Asked Questions (FAQ)

What are the typical applications of square telescopic tubes?

Square telescopic tubes are widely used in adjustable industrial supports, sign posts, display racks, medical booms, mobile equipment skeletons, and other structures, especially suitable for applications requiring repeated extension and retraction or high-strength support.

What locking methods do you offer? How should I choose?

Chalco offers a variety of locking mechanisms, including spring buttons (for lightweight quick assembly), clamping fixtures (for adjustable positioning), and pin systems (for heavy-duty applications). If you prioritize convenient adjustment, choose spring buttons; for high-load-bearing fixed structures, we recommend using a pin + pre-drilled hole combination.

Why is the "mating clearance" of telescopic tubes so important?

Mating clearance determines the smoothness of telescopic sliding and the structural stability. Too little clearance can cause jamming, while too much clearance can lead to shaking and looseness. Each set of telescopic tubes from Chalco undergoes strict tolerance and clearance control to ensure smooth insertion and removal without shaking, making them especially suitable for multi-stage high-precision structural designs.

Instant QuoteCan you customize different numbers of sections or non-standard sizes?

Yes! We support single-section, dual-section, three-stage, and multi-stage telescopic combinations. You only need to provide the target extended dimensions or a sketch, and we can assist in the design and provide sample testing services.

In addition to tubes, do you provide accessories and installation components?

Yes, Chalco provides complete "tube + lock + connector" integrated solutions, including column bases, angle brackets, rivets, spring buttons, clamps, etc., to meet various assembly needs, facilitating rapid assembly and improving efficiency.

What if the size I need is not in your existing list?

Welcome to contact us for customization! Chalco offers mold customization services, supports small-batch prototyping, and can adjust designs according to your mating structure or drawings.

Can I purchase only the inner or outer tubes?

Of course. We can provide inner or outer tubes of any stage separately and assist in checking mating dimensions to ensure compatibility with your existing structure.

Whether you are looking for standard parts or customized multi-stage telescopic systems and matching accessories, Chalco can provide you with efficient solutions and technical support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote