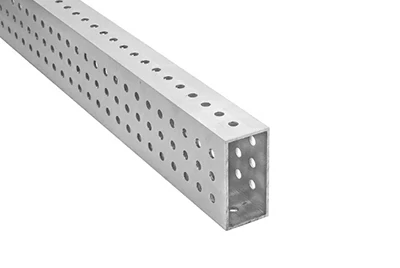

Perforated Aluminum Tube is a functional tubing product made by punching precise holes into aluminum sheets, followed by rolling, welding, deburring, and surface finishing. It combines ventilation, filtration, and aesthetic appeal in a single solution.Click to view[Perforated Aluminum Sheet]

- Open Area Ratio: 20% – 65%, directly impacts fluid flow and pressure drop

- Hole Type & Diameter: Available in round holes, square holes, and slots, with customizable diameters from 0.5 mm to 50 mm

- Tube Diameter & Wall Thickness: Outer diameter ranges from 10 mm to 650 mm; wall thickness from 0.4 mm to 5 mm

Leveraging the lightweight, high strength, and corrosion-resistant nature of aluminum, perforated aluminum tubing offers smooth airflow in HVAC systems and precise filtration in hydraulic applications—delivering a solution that is more efficient, more durable, and more adaptable.

Instant QuoteClick to view[Explore more Chalco perforation patterns]

Specifications of Perforated Aluminum Tube

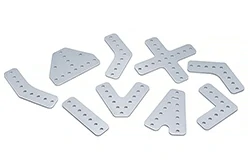

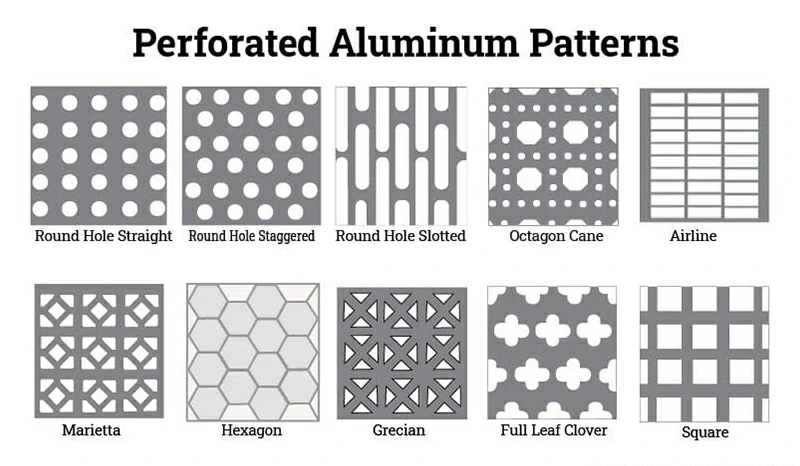

Common Hole Patterns

Round Hole

Most versatile; ideal for ventilation, filtration, and sound insulation.

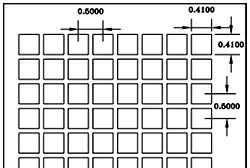

Square Hole

Clean and uniform appearance with high breathability; commonly used in architectural facades and cladding.

Slotted Hole

Supports directional airflow or drainage; widely used in HVAC systems and hydraulic shielding.

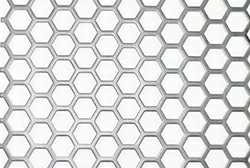

Hexagonal Hole

Enhances both strength and open area; balances aesthetics and functionality—suitable for high-precision filtration or decorative use.

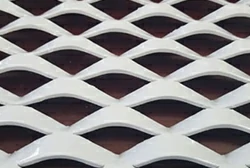

Diamond Hole

Diagonal layout combines fluid flow with visual appeal; popular for modern building facades and functional partitions.

Fish Scale Hole

Distinctive design for premium aesthetics; ideal for high-end ceilings and interior architectural finishes.

Specifications

| Open Area | 20% - 65% |

| OD | 10 mm - 650 mm |

| WA | 0.4 mm - 5 mm |

| Hole Diameter | 0.5 mm - 50 mm |

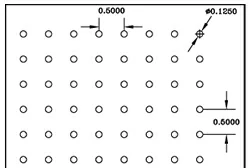

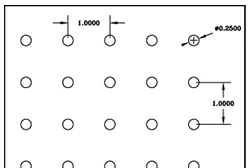

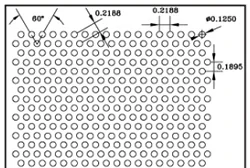

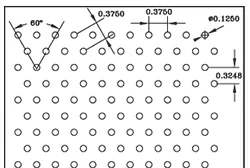

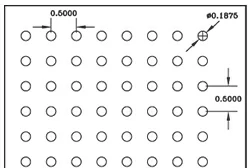

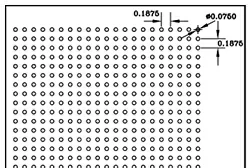

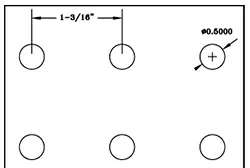

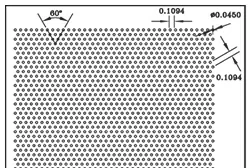

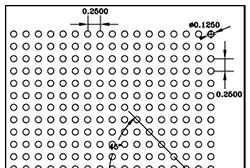

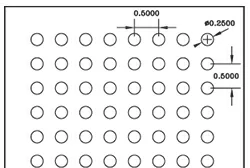

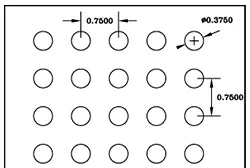

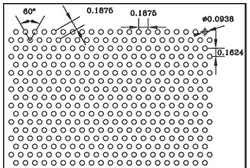

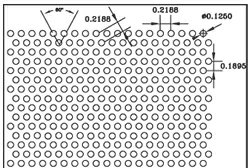

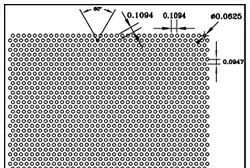

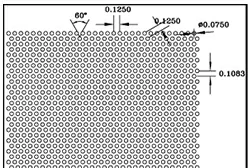

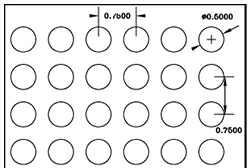

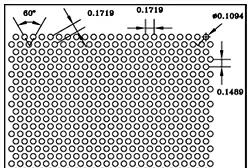

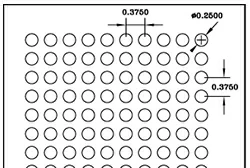

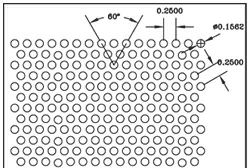

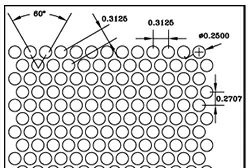

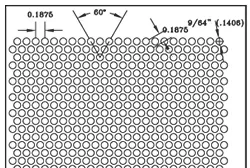

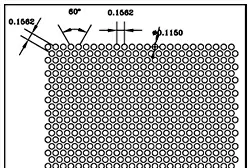

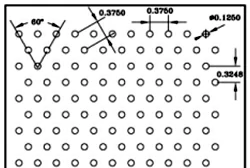

| Arrangement | In-line arrangement, staggered arrangement (45° / 60°) |

| Material | 1100, 3003, 5052, 6060, 6061, 6063 |

| Surface Finish | Anodizing, powder coating, brushing, polishing |

| Quality | The hole edge should be deburred and smooth, and the tube body should have no obvious scratches or deformation |

| Industry Certification | ISO 9001 / CE / RoHS / FDA |

Customization Capabilities

- Hole shape, hole diameter, and open area can be tailored to your drawings (OEM/ODM services)

- Tube diameter, wall thickness, and length can be cut or machined to specific sizes

- Customizable punching direction and hole arrangement to meet special fluid dynamics or decorative design requirements

- Precision welding and assembly processing available to reduce your downstream labor and time costs

Looking for application solutions of different perforated aluminum tube designs and specifications?

Click the button below to explore customization options that help you achieve more efficient, visually appealing design goals!

Instant QuoteTypes of Perforated Aluminum Tubes

Round Perforated Aluminum Tube

The most common type, featuring uniform and stable tube structure, available in various hole types, open area ratios, and surface treatment options.

Outer Diameter: 10mm - 650mm

Wall Thickness: 0.4mm - 5mm

Perforated Aluminum Square Tubing

High section rigidity and excellent load-bearing performance, ideal for curtain wall systems, structural supports, mechanical frames, and furniture manufacturing.

Common Sizes: 20×20mm, 30×30mm, 50×50mm

Wall Thickness: 0.5 - 5mm

Rectangular Perforated Aluminum Tube

Combines the structural benefits of square tubes with more flexible aspect ratios, commonly used in ventilation ducts, machine guards, billboard frames, and custom decoration projects.

Smooth and aesthetic appearance, low wind resistance, and high space efficiency. Suitable for lighting housings, traffic equipment, art installations, and other special design scenarios.

Custom-Shaped Perforated Aluminum Tube

Tailored to customer drawings to meet unique functional and decorative needs. Widely used in high-end architecture, exhibition displays, and custom industrial design projects.

Chalco also offers other perforated aluminum materials

Features of Perforated Aluminum Tube

- Made from 6061-T6, 7075, and other high-performance aluminum alloys, offering strength comparable to carbon steel, while weighing only 1/3 to 1/4 as much—significantly reducing self-weight and transportation costs.

- Aluminum naturally forms a dense oxide film. After anodizing, PVDF coating, or powder coating, it resists salt spray and humidity, making it ideal for long-term outdoor or harsh environment use.

- Open area adjustable from 20% to 65%, with hole diameters from 0.5 mm to 50 mm customizable—ensuring high airflow while enabling micron-level filtration and balancing breathability and pressure loss.

- Supports various hole patterns including round, square, slotted, hexagonal, and fish scale; available in straight or staggered arrangement. Suitable for both ventilation and heat dissipation as well as curtain walls and suspended ceilings, combining function and aesthetics.

- Formed through stamping, CNC machining, or laser cutting, with smooth, burr-free edges. After roll forming and welding, tubes can be directly assembled or connected via flanges or threading, allowing flexible assembly and on-site reprocessing.

- Aluminum is 100% recyclable with low energy consumption in production and processing. Compared with stainless steel or plastic, it offers more competitive costs for products of the same dimensions.

Material Options for Perforated Aluminum Tube

1060 Perforated Aluminum Tube

1060 Perforated Aluminum Tube Commercially pure aluminum with aluminum content ≥99.6%. Soft texture, excellent ductility, outstanding machinability, and superior corrosion resistance. Commonly used in indoor decoration, lighting structures, lightweight protective covers, and ventilation/exhaust systems where high machinability is needed but strength requirements are low.

1100 Perforated Aluminum Tube

1100 Perforated Aluminum Tube Nearly pure aluminum with excellent corrosion resistance, workability, and weldability. Smooth surface with high reflectivity. Widely applied in architectural decoration, signage, protective railings, low-load filters, and exhaust ducts.

3003 Perforated Aluminum Tube

3003 Perforated Aluminum Tube Manganese added, stronger than pure aluminum, with excellent corrosion resistance and good formability. High cost-effectiveness. Suitable for exterior curtain walls, screening and filtration equipment, mechanical ventilation ducts, and hydraulic systems where certain mechanical performance is required.

5052 Perforated Aluminum Tube

5052 Perforated Aluminum Tube Magnesium-aluminum alloy with high strength, excellent corrosion resistance (including salt spray), and good weldability. Commonly used in marine protective covers, chemical liquid filters, premium ventilation systems, and mechanical components requiring corrosion resistance and medium to high strength.

6060 Perforated Aluminum Tube

6060 Perforated Aluminum Tube Medium strength, excellent extrusion performance, and superior surface finish (high aesthetic value after anodizing). Often used in architectural railings, posts, lightweight structural frames, and ventilated curtain wall systems requiring both appearance and weight reduction.

6061 Perforated Aluminum Tube

6061 Perforated Aluminum Tube Excellent mechanical properties and corrosion resistance, good weldability, and high strength, which can be further enhanced by heat treatment. Widely used in high-load ventilation/filter system supports, industrial exhaust piping, and equipment protective covers.

6063 Perforated Aluminum Tube

6063 Perforated Aluminum Tube Outstanding extrusion performance, smooth surface, strong corrosion resistance, and decorative appeal. Commonly used in architectural curtain walls, indoor and outdoor decorative grilles, acoustic panel systems, and lightweight equipment enclosures.

Typical Applications of Perforated Aluminum Tube

HVAC & Ventilation Systems

Perforated aluminum tubes are used in air conditioning and ventilation systems as air supply ducts, return air outlets, and diffuser housings. They ensure efficient ventilation and air distribution while effectively reducing airflow noise. Anodized surface treatment enhances durability and aesthetic appeal.

Liquid & Gas Filtration

In water treatment, oil and gas transportation, and hydraulic systems, perforated tubes serve as filter core supports, hydraulic oil filters, water filtration cartridges, mesh frames, and inner shells of pressure vessels. They offer excellent strength and permeability. Various hole patterns and open area designs enable precise fluid control and high-efficiency filtration.

Architectural Decoration & Structural Support

In curtain wall cladding, column covers, interior partitions, and ceiling systems, perforated aluminum tubes combine a modern appearance with lightweight structure, delivering both decorative and load-bearing performance. Widely used in commercial spaces, airports, exhibition halls, and subway stations.

Acoustic Engineering & Sound Absorption Systems

Paired with sound-absorbing cotton or cavity structures, perforated aluminum tubes significantly reduce noise in sound barriers, acoustic ceilings, and machine noise enclosures. They are widely applied in roads, factories, theaters, conference rooms, and other acoustically optimized environments.

Agricultural & Industrial Equipment

Used as components like ventilation ducts, screening barrels, and machinery enclosures, perforated aluminum tubes are widely applied in agricultural greenhouses, grain drying systems, and screening equipment—supporting durable, automated farming and industrial systems.

Automotive & Transportation

In vehicle ventilation systems, heat exchanger covers, and onboard storage units, perforated aluminum tubes offer weight reduction, corrosion resistance, good ventilation, and structural aesthetics. Also used in sound insulation and ventilation systems of rail transit equipment.

Lighting & Home Furnishings

Perforated aluminum tubes are commonly used in lamp housings, protective light tubes, and heat dissipation components, combining aesthetics with functionality. They are also used in furniture frames, speaker grilles, and display racks for modern industrial-style interiors.

Custom Industrial Systems

Based on specific industry needs, perforated aluminum tubes are customized for use in chemical pipeline supports, solar component frames, protective railings, machine safety guards, and other functional structural parts—enabling lightweight, modular, and easy-to-maintain industrial system designs.

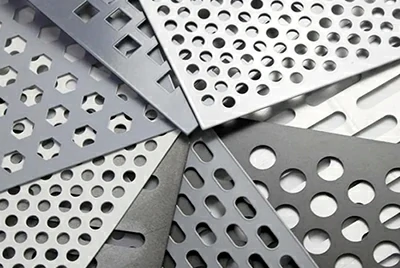

Manufacturing Process of Perforated Aluminum Tube

The manufacturing of Perforated Aluminum Tubes involves a precise process covering sheet perforation, tube forming, and surface finishing. It ensures hole pattern and dimensional consistency while maintaining tube structural integrity and surface aesthetics. The main process steps are as follows:

Material Selection & Preparation

Aluminum alloys (such as 1060, 3003, 5052, 6061, etc.) are selected based on customer requirements and cut into appropriate sheet sizes or pre-extruded tubes.

For high-precision customization, annealing or pre-flattening treatments may be applied to enhance subsequent perforation accuracy.

Perforation

High-precision CNC perforating equipment (e.g., CNC punch press, turret punch) is used to punch round holes, slots, square holes, diamond holes, and other patterns on the aluminum surface.

Typical open area ranges from 20% to 65%, with minimum hole diameters as small as 0.5 mm.

Hole arrangements can include straight line, staggered, or fish scale layouts based on design requirements.

Flatness, hole positioning tolerance, and edge burrs must be strictly controlled.

Tube Forming

For tubes made from perforated sheets, the material is roll-formed and welded into tube structures.

Common welding methods include TIG welding, laser welding, and seam welding, with welds optionally polished or made seamless.

- Straight seam welding

- Spiral seam welding

Tubes can be formed into round, square, rectangular, oval, or custom cross-sectional shapes.

If using pre-extruded aluminum tubes, perforation is done post-forming (e.g., Perforated aluminum square tubing), often used for telescoping structural supports in thick-walled or high-strength applications, requiring tube punching machines.

Deburring & Shaping

All tubes undergo internal and external deburring and chamfering to ensure safe handling, unblocked flow, and no damage to internal components.

For precision applications, additional processes like roundness correction, straightening, and end-face squaring are performed to ensure dimensional accuracy.

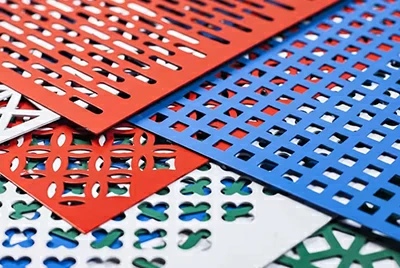

Surface Finishing

To enhance corrosion resistance, weatherability, and visual appeal, Perforated Aluminum Tubes can undergo various surface treatments including anodizing (silver, black, gold, etc.), painting/powder coating, and brushing, polishing, or matte finishing—meeting both functional and decorative needs.

Inspection & Packaging

Every batch of perforated tubes is inspected for appearance, dimensions, and hole pattern accuracy. Strength or corrosion resistance testing is conducted when required.

Finished products are securely packed using anti-scratch films, bubble wrap + woven bags, wooden cases, or steel frames based on transport needs, ensuring delivery quality.

Through rigorous perforation, forming, surface treatment, and inspection processes, we manufacture high-performance Perforated Aluminum Tubes tailored to diverse industrial and architectural needs.Whether you prioritize filtration efficiency, ventilation performance, structural strength, or decorative effect, we provide highly customized solutions to help you achieve your project goals.

Contact us now to get professional recommendations, technical drawings, and real-time quotes for your perforated aluminum tube applications!

Instant QuoteSurface Treatment Methods

To enhance the corrosion resistance, weatherability, aesthetic appeal, and service life of perforated aluminum tubes, the following common surface treatments can be selected based on specific application needs:

1. Anodizing

Anodizing is an electrochemical process widely used for aluminum, in which a dense oxide layer is formed on the surface to significantly improve corrosion resistance, hardness, and appearance.

Common colors: silver, black, champagne gold, bronze, etc.

Application areas: building facades, decorative panels, lighting housings, electronic enclosures, etc.

2. Powder Coating

Through electrostatic spraying or thermal curing of thermosetting powders, a hard and uniform organic coating is formed on the aluminum tube surface. This treatment offers rich color options and strong visual diversity, along with excellent UV resistance, chemical resistance, and scratch protection.

Application areas: outdoor railings, architectural trims, traffic infrastructure, etc.

3. Polishing, Brushing, Mirror Finishing

Mechanical or chemical surface treatments are used to achieve various levels of gloss and texture.

- Polishing enhances mirror-like reflectivity

- Brushing creates a textured metallic grain finish

- Matte finishing offers a soft and subtle touch

Application areas: ideal for high-end decorative uses such as furniture components, display racks, and interior design elements.

Perforated Aluminum Tube vs. Perforated Stainless Steel Tube vs. Perforated Carbon Steel Tube

| Comparison items | Perforated Aluminum Tube | Perforated Stainless Steel Tube | Perforated Carbon Steel Tube |

| Material | Aluminum alloy (such as 6061, 6063) | Stainless steel (commonly used 304, 316) | Carbon steel (such as Q235/SS400) |

| Density/weight | ~2.7 g/cm³ (lightweight) | ~7.9 g/cm³ | ~7.85 g/cm³ |

| Corrosion resistance | Good, with oxide film; excellent after anodizing | Excellent, self-healing chromium oxide layer | Poor, requires anti-corrosion treatment such as galvanizing or painting |

| Tensile strength | ~200–300 MPa (6061-T6) | ~500–700 MPa (304/316) | ~400–550 MPa (Q235) |

| Bending/formability | Excellent (good ductility, easy to punch and form) | Good (slightly hard but can be stamped and bent) | Medium (can be stamped in large quantities, but local forming requires preheating) |

| Welding performance | Fair (need to use aluminum-specific welder, pay attention to heat input) | Excellent (both TIG/MIG, good joint strength at high temperatures) | Excellent (MIG/manual welding is possible, low cost) |

| Thermal/electrical conductivity | High (thermal conductivity ≈235 W/m·K; excellent electrical conductivity) | Medium (thermal conductivity ≈16 W/m·K; average electrical conductivity) | Low (thermal conductivity ≈60 W/m·K; poor electrical conductivity) |

| Surface treatment | Anodizing, spraying, brushing, polishing | Wire drawing, mirror polishing, sandblasting or electrolytic polishing | Galvanizing, painting, powder coating |

| Cost | Medium to low | High | Minimum |

| Typical applications | Ventilation/air conditioning ducts, filter element brackets, curtain wall decoration, acoustic sound absorption panels | Food/pharmaceutical/chemical filter support, high temperature exhaust, clean room equipment | Machinery guards, heavy-duty structural supports, outdoor fences |

In summary, perforated aluminum tubes are lightweight, corrosion-resistant, and easy to process—ideal for ventilation and decorative applications and light-duty filtration; perforated stainless steel tubes offer high strength and superior corrosion resistance, commonly used in food equipment and medical systems; perforated carbon steel tubes are structurally robust and cost-effective, suitable for industrial support structures and other high-strength environments. Choosing the right material depends on your specific application scenario and performance requirements.

Perforated Aluminum Tube Selection Guide

When selecting perforated aluminum tube for your engineering project or product design, first identify the intended application:

- HVAC ducts or filter support frames?

- Curtain wall or partition decorative profiles?

- Acoustic panels requiring noise attenuation?

Only with a clear primary use can you accurately choose tube shape, hole pattern, material, and other key parameters.

Round Perforated Aluminum Tube

Best for ventilation and fluid conveyance due to its symmetric, streamlined structure, minimal flow resistance, and strong mechanical performance.

Ideal for air ducts, powder sieving, and muffler housings.

Square / Rectangular Perforated Aluminum Tube

Offers higher section rigidity and easy flange or clip installation—perfect for modular assemblies, load-bearing structures, or decorative grilles.Commonly used in telescoping profiles, display racks, and curtain wall panels.

Oval & Custom-Shaped Perforated Aluminum Tube

Provides unique aesthetics and design flexibility; integrates seamlessly into lighting housings, art installations, and display columns.

Hole Style, Hole Diameter & Open Area Ratio

Hole patterns—from round, square, to slots, diamond, hexagon, or fish-scale layouts—dictate both airflow and visual appeal.

Hole diameter ranges from 0.5 mm up to 50 mm, open area typically controlled between 20%–65%.

Layout options (straight, staggered, flower, fish scale) fine-tune fluid resistance and decorative effect while preserving structural strength.

Material Selection

Not all alloys suit perforation:

- 1060, 1100 (high ductility for light decorative use)

- 3003, 5052 (corrosion-resistant, medium strength for indoor/outdoor filters and marine environments)

- 6060, 6063 (excellent extrudability and surface finish for architectural facades and light frameworks)

- 6061 (heat-treatable, high strength—preferred for mechanical supports and premium filter racks)

Each alloy endures punching processes and meets diverse strength and corrosion requirements.

Size Specifications

Round tubes: OD from 10 mm to 650 mm

Square/rectangular: cross-sections from 20×20 mm to 200×100 mm

Wall thickness: 0.4 mm–5 mm

Standard lengths: 1–6 m, cut-to-length per site or transport needs

Surface Treatment

To extend service life and meet aesthetic requirements, choose from anodizing (silver, black, champagne, etc.), powder coating/painting (weather-resistant, rich color options), polishing/brushing/mirror finishing (high-end decorative effect), electrophoretic coating, or sandblasting pre-treatment.

Installation Methods & End Treatment

Tube ends can be prepared for flange connections, threaded fittings, weld-butt joints, or snap-in assemblies, with optional pre-drilled mounting holes, chamfers, or reinforced flanges to suit suspended ceilings, fixed supports, pipe flanges, and other installation scenarios.

Precision & Tolerance

High-end projects often demand hole position accuracy (± 0.1 mm – ± 0.3 mm), length and end-face squareness (± 0.5 mm), and strict control of surface flatness and burrs. Our CNC punching presses and laser-cutting equipment ensure consistent, repeatable batch production.

Special Environments & Certification

For high-temperature service (recommended ≤ 204 °C) or chemical exposure, options include thicker anodic films, PVDF coating, or specialized high-temperature alloys. Food-grade or fire-safety projects can also be supplied with FDA, UL, and other certification reports.

Still Unsure Which Perforated Aluminum Tube to Choose?

Let our engineers tailor a solution that perfectly matches every detail of your project requirements.

Instant QuoteFAQs

Will perforated aluminum tube rust in high-humidity or corrosive environments?

No. Aluminum inherently offers excellent corrosion resistance, and after surface treatments like anodizing, it can be used long-term in marine climates or chemical plants without rust concerns.

Is a higher open area ratio always better for perforated aluminum tube?

Not necessarily. While a high open area improves ventilation and filtration efficiency, it also reduces structural strength. In practice, you should balance airflow requirements and load-bearing needs—common open area ratios range between 20%–45%.

Will aluminum’s lower hardness make perforated aluminum tube prone to deformation?

Aluminum alloys vary widely in strength. Alloys like 5052 and 6061 provide good rigidity and flexural strength, meeting most structural demands. Proper alloy selection is critical for design integrity.

Can the hole patterns of perforated aluminum tube be customized?

Yes. Standard patterns include round, elongated, square, hexagonal, and diamond holes. Custom shapes can also be produced per your drawings to satisfy filtration, decorative, or noise-reduction requirements.

Will welding perforated aluminum tube affect its appearance or strength?

With professional welding techniques (e.g., TIG welding) plus proper cleaning and finishing, weld seams remain smooth, aesthetically pleasing, and retain full strength. We offer customized welding services for both decorative and structural applications.

Do you support small-batch customization or prototyping of perforated aluminum tube?

Yes. We accommodate low minimum order quantities and fast prototyping to support design validation, sample testing, and small-scale projects—responding flexibly to varied procurement needs.

Will perforated aluminum tube deform during transport, and how is it packaged?

No. We use foam + kraft paper + wooden crates or steel strapping to protect tubes from crushing or scratching—suitable for long-distance ocean or land transport.

Chalco Perforation Patterns Overview