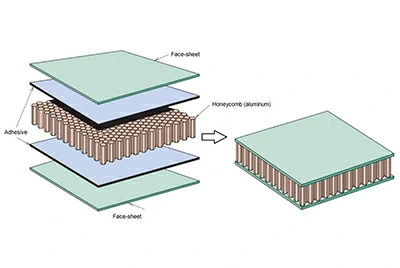

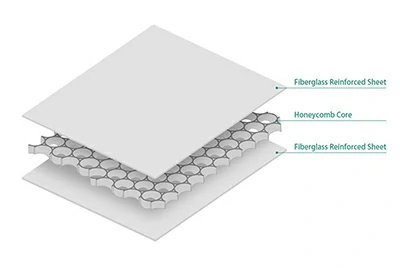

Chalco fiberglass honeycomb panels are lightweight, high-strength sandwich panels designed for engineering-grade structural applications. They consist of fiberglass face sheets bonded to a honeycomb core.

Compared with conventional FRP lightweight panels using PP or paper honeycomb cores, these panels provide higher load capacity, structural rigidity, and long-term stability, making them suitable for transportation, prefabricated buildings, ship interiors, and industrial equipment enclosures.

Chalco Fiberglass Honeycomb Panel Product Overview

Chalco fiberglass honeycomb panels use a sandwich structure consisting of an epoxy fiberglass surface layer, an aluminum honeycomb core, and a structural adhesive system.

Panel (FRP):Fiberglass cloth + epoxy resin, high strength and corrosion resistance.

Core material (aluminum honeycomb):3003/5052 aluminum honeycomb, lightweight and high rigidity.

Adhesive system:Epoxy structural adhesive composite, stable adhesion and no delamination.

| Panel thickness (FRP) | 0.5–1.0 mm epoxy fiberglass (customizable) |

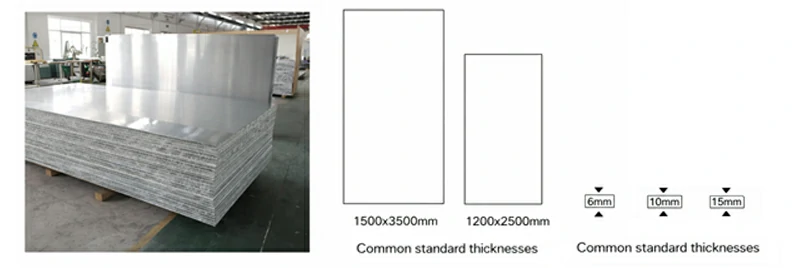

| Honeycomb core material thickness | 6 / 10 / 15 / 20 / 25 mm |

| Honeycomb core material | AA3003H18 / AA5052H18 Aluminum Honeycomb |

| Aperture (Cell Size) | 6 mm / 8 mm / 10 mm |

| Total thickness of standard sheet metal | 8–30 mm (depending on structural configuration) |

| Structural form | Single-sided FRP + aluminum honeycomb / Double-sided FRP + aluminum honeycomb |

| Standard size | 1220 × 2440 mm (standard) |

| Maximum size | 1500 × 4000 mm (customizable) |

| weight range | 2.5–6.0 kg/m² (depending on thickness) |

| Enhanced options | Fiberglass/Stainless Steel Flame Retardant Type (Reinforced Structure and Flame Retardant Properties) |

| Heat resistance | –40°C ~ +90°C (Long-term operating temperature range) |

| Flame retardant properties | Flame-retardant reinforced structures are available (specific grades can be customized to meet requirements). |

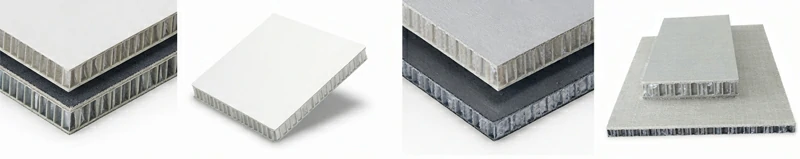

| Surface Options | Glossy, matte, gel coat, anti-slip, anti-corrosion coating |

Complete performance parameters such as elastic modulus, tensile strength, yield strength, coefficient of thermal expansion, and temperature range can be viewed in "Technical Parameter Details" or provided according to project requirements.

Surface treatment reference image:

Key Features and Advantages of Chalco Fiberglass Honeycomb Panel

- With high structural strength, aluminum honeycomb offers superior load-bearing capacity compared to PP and paper honeycomb, and is less prone to creep and deformation.

- Combining lightweight design with high flatness, it is suitable for large-size wall panels, ceiling panels, and flooring.

- Epoxy fiberglass is corrosion-resistant, impact-resistant, and can be used stably in the range of -40°C to +90°C.

- Flame-retardant structures are available to meet the safety requirements of transportation and public buildings.

- It has strong processing adaptability, can be cut and edge-sealed, and can be used in conjunction with a variety of system structures.

Why Choose Aluminum Honeycomb Core Instead of PP or Paper?

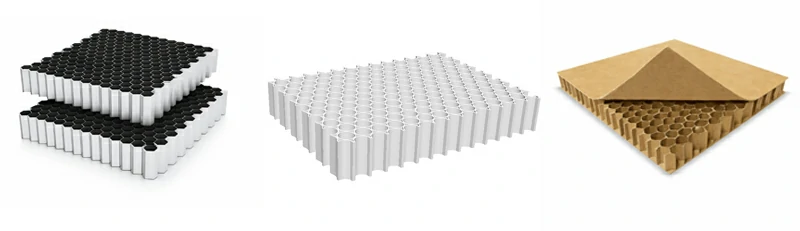

Higher structural strength: Aluminum honeycomb has compressive and bending strength that is about 3–5 times that of PP honeycomb, making it suitable for load-bearing structural panels.

No creep or deformation: PP and paper honeycomb are prone to sinking or creeping under long-term loads, while aluminum honeycomb can maintain long-term stability.

It has better temperature resistance: it can be used reliably in the range of –40°C to +90°C, while PP is prone to softening at high temperatures and cracking at low temperatures.

Stable dimensions and flatness: The regular hexagonal structure of the aluminum honeycomb is suitable for large-size wall panels, ceiling panels, floors and other scenarios with high flatness requirements.

Adaptable to a wider range of engineering applications: It can withstand structural loads and can be used in more demanding applications such as vehicle floors, equipment housings, industrial partitions, and cabin structures.

Chalco Fiberglass Honeycomb Panel Collaboration Project Showcase

Chalco fiberglass honeycomb panels have been successfully applied in real-world projects across multiple industries, meeting the structural requirements of various scenarios thanks to their advantages of lightweight, high strength, corrosion resistance, and dimensional stability.

The transportation project

uses van bodies, refrigerated car bodies, and interior panels for rail vehicles to meet the structural requirements of high rigidity and lightweight.

Prefabricated buildings and public facilities

are used in prefabricated wall panels, partition systems, building ceilings, and structural panels for large public spaces to ensure flatness and long-term stability.

Marine and offshore equipment

uses bulkheads, deck coverings, cabin furniture base plates, etc., to maintain good durability in humid and salt spray environments.

Industrial equipment and machinery protection,

as structural components such as equipment shells, maintenance platforms, and industrial partitions, combines strength and corrosion resistance.

Special structures and mobile buildings

are used in projects that require lightweight and impact resistance, such as mobile homes, equipment containers, and modular combined structures.

Chalco Fiberglass Honeycomb Panel Manufacturing and Engineering Capabilities

Chalco possesses a systematic manufacturing capability encompassing FRP surface molding, aluminum honeycomb structure configuration, and integrated sandwich composite, enabling it to stably output high-flatness, large-size engineering-grade honeycomb panels.

It supports processing methods such as cutting, edge sealing, grooving, hole drilling, and inserting, providing customers with semi-finished panels that can be directly used for assembly or secondary processing.

Customizable panel thickness, honeycomb core structure, surface treatment, and flame retardant system to meet the structural requirements and technical parameters of different projects.

Chalco Fiberglass Honeycomb Panel Technical Specifications

| Dimensions and Tolerances | |

| project | parameter |

| Standard size | 1220 × 2440 mm |

| Maximum size | 1500 × 4000 mm (customizable) |

| Plate thickness range | 8–30 mm (depending on structural configuration) |

| Thickness tolerance | ±0.2–0.5 mm |

| Length and width tolerances | ±2 mm |

| flatness | ≤ 1.5 mm/m |

| weight range | 2.5–6.0 kg/m² |

| Mechanical properties | |

| Performance items | Typical values/range |

| Compressive strength | Customizable based on core thickness and structure |

| Bending performance | Testing can be provided according to project requirements. |

| elastic modulus | ~70,000 N/mm² (aluminum honeycomb) |

| 0.2% yield strength | ≥130 MPa (FRP surface layer reference) |

| tensile strength | ≥220 MPa |

| Fatigue performance | No creep or collapse under long-term load |

| Environmental durability | |

| project | parameter |

| Operating temperature | -40°C ~ +90°C |

| Moist heat resistance | Through damp heat cycling test |

| Salt spray resistance | Suitable for coastal and corrosive environments |

| Water absorption rate | Both FRP and aluminum honeycomb do not absorb water. |

| Flame retardant properties | Customizable flame-retardant structure |

| Lifetime stability | Maintaining dimensional stability under long-term environmental changes |

Chalco Fiberglass Honeycomb Panel Engineering-Grade Delivery & Project Consulting

Each batch of products undergoes tests for bond strength, flatness, dimensional stability, and resistance to damp heat and corrosion. For key items, flame retardancy performance and related verification documents are available to ensure the reliability of engineering applications.

Before leaving the factory, the boards are coated with film and have their edges and corners protected. They are also secured with wooden pallets and reinforced structures to ensure the safety of the boards during domestic transportation and overseas export shipping.

We handle packaging, labeling, and shipping according to the project delivery process, and can provide suitable transportation and loading solutions based on on-site hoisting and installation conditions.

Feel free to contact us for engineering selection advice, structural configuration solutions, and project quotations.

FAQ (Frequently Asked Questions)

What are the maximum sizes that fiberglass honeycomb panels can be made in?

The standard size is 1220×2440 mm, and it can be customized up to 1500×4000 mm. Larger sizes can be evaluated according to project requirements.

Can you provide the flame retardancy rating? Do you have a test report?

Yes. Flame-retardant structures can be configured upon request, and corresponding test reports and technical verification documents can be provided.

Does the panel support processing? For example, edge banding, hole drilling, or grooving?

Supported. Chalco can perform cutting, edge banding, grooving, hole drilling, and reinforcement installation, facilitating system integration.

Can this product be used outdoors or in humid environments? Will it absorb water?

Yes. The FRP surface layer is corrosion-resistant and non-absorbent, and the aluminum honeycomb structure is stable and will not deform due to humidity or temperature differences.

What is the delivery time? Is the export packaging safe?

Standard configurations typically take 10–15 days to deliver; for exports, measures such as film covering, anti-collision corner protection, and wooden pallet reinforcement are used to ensure safe long-distance transportation.

Can you provide a sample?

Yes, we can provide small-sized samples for evaluation based on the structure and thickness.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote