Aluminum roofing sheet, also known as aluminum roof panels, is a lightweight, corrosion-resistant roofing material with a long service life. It is widely used in residential buildings, industrial workshops, commercial facilities, and agricultural structures. Compared to traditional roofing materials, aluminum sheets offer superior weather resistance and rust protection, making them suitable for various harsh environments.

Instant QuoteAluminum roof panels also offer excellent heat reflectivity and ease of installation, helping to reduce indoor temperatures and save on construction time and labor costs. Whether for new construction or renovation of aging roofs, aluminum roofing panels are an ideal choice that combines performance with aesthetics.

Chalco: Your trusted roofing material partner

- Chalco specializes in the production of high-quality aluminum roofing panels, widely used in industrial plants, commercial buildings, and residential projects.

- We offer various panel profiles (corrugated, trapezoidal, standing seam, etc.), customizable alloys (3003, 5052, 1060, etc.), and surface treatments (color coating, anodizing, lamination). Panel thickness ranges from 0.25 to 1.5 mm, with widths up to 2650 mm, meeting diverse project requirements.

- Equipped with advanced machinery, we ensure precise dimensions and uniform coatings. Our products comply with international standards such as ASTM and EN, support third-party testing, and are certified to ISO 9001, RoHS, and REACH.

- Fast response, tailored solutions, global delivery—choose Chalco to build a more durable and efficient roofing system.

Aluminum roofing sheet introduction

Shapes: Corrugated, trapezoidal, flat, embossed, wave tile, and custom profiles

Thickness: 0.25 mm – 1.5 mm (customizable upon request)

Width Range: 600 mm – 2650 mm or customized

Length: Standard 1000 mm – 6000 mm, customizable or cut-to-length

Alloy: 3003, 3004, 5052, 8011, 1060, 1100

Surface Finishes: Mill finish, painted (PE/PVDF), anodized, embossed, laminated

Connection Types: Overlapping, snap-lock, standing seam systems

Applications: Industrial facilities, residential buildings, carports, warehouses, airports, greenhouses, gas stations

Key Features: Corrosion-resistant, highly weatherproof, lightweight, easy to install, recyclable

Standards: ASTM B209, EN 485, GB/T 3880, JIS H4000

Certifications: ISO 9001:2015, CE, SGS, RoHS, REACH

Types of aluminum roofing sheets offered by Chalco

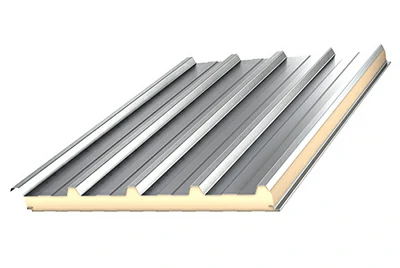

Aluminum insulated roof panels

Equipped with an insulating core, it offers multiple functions such as thermal insulation, fire resistance, and anti-condensation—making it ideal for energy-efficient buildings.

Contact us now

Panel Material: 3003, 3105, 5052

Core Types: Polyurethane (PU) / Polyisocyanurate (PIR) / Expanded Polystyrene (EPS)

Total Thickness: 50 mm – 150 mm (including core)

Panel Thickness: 0.5 mm – 1.0 mm

Width Range: 1000 mm – 2500 mm

Applications: Cold storage, food processing facilities, logistics and warehousing centers

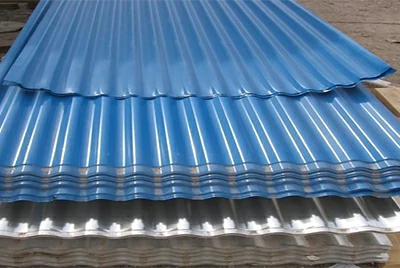

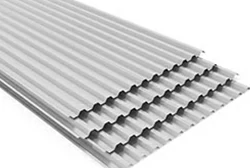

Corrugated aluminium roofing sheets

Lightweight and corrosion-resistant, with a corrugated structure for excellent drainage performance, ideal for roofing in industrial plants, warehouses, and similar buildings.

Contact us now

Common Alloys: 1050, 1060, 1100, 3003, 3105, 5052, 8011

Thickness: 0.2 mm – 1.5 mm

Effective Cover Width: 750 mm – 1050 mm

Total Uncoiled Width: Typically 914 mm / 1000 mm / 1200 mm depending on profile

Rib Height: 16 mm – 30 mm

Pitch: 76 mm – 130 mm

Surface Finishes: Mill finish, anodized, color coated (PE, PVDF), embossed

Available Colors: Silver, grey, blue, red, green (customizable via RAL codes)

Maximum Length: Generally up to 6 meters; up to 12 meters for special projects

Applications: Factories, warehouses, logistics centers, agricultural buildings, temporary structures

Aluminum pan roof panels

Flat structure with clean lines, combining both decorative appeal and practical function; widely used in roofing systems for light structures such as carports, balconies, and terraces.

Contact us now

Common Alloys: 1060, 1100, 3003, 3105

Thickness Range: 0.6 mm – 1.2 mm

Panel Width: Standard 300 mm – 600 mm; uncoiled width customizable up to 1000 mm

Flat Panel Height (Edge Height): 20 mm – 50 mm (varies by structure)

Surface Finishes: Anodized, color coated, laminated, anti-fingerprint treated

Maximum Length: Up to 6 meters; customizable to 8–12 meters for special projects

Connection Methods: Overlapping, snap-lock, concealed fastening (some paired with purlins or clamps)

Applications: Balcony roofs, carports, garden pavilions, commercial shading structures, light steel buildings

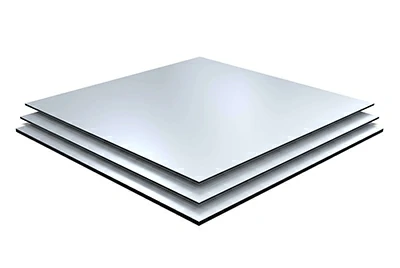

Aluminum composite panel roof

Aluminum composite panel roofing features two aluminum layers and a polymer core, offering lightweight, high strength, insulation, and decorative appeal.

Contact us now

Face Alloy: 1100, 3003, 3105

Thickness: 3 mm – 6 mm (common: 3mm, 4mm, 5mm, 6mm)

Core Types: LDPE, FR (fire-retardant), mineral-filled core

Standard Sizes: 1220×2440 mm, 1250×3200 mm, 1500×3000 mm (customizable)

Width Range: Commonly 1000 mm – 2650 mm

Fire Rating: B1 / A2 (depending on core type)

Surface Finishes: Roller coating, wood grain, brushed, mirror, stone pattern, perforated

Available Colors: RAL standard, metallic, custom patterns

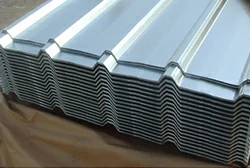

Long span aluminium roofing sheet

Long-span aluminum roofing panels are ideal for large-span roof systems with minimal purlin support. They offer a lightweight yet high-strength structure, fewer joints, and enhanced installation efficiency.

Contact us now

Common Alloys: 3003, 3004, 5052

Thickness Range: 0.6 mm – 1.5 mm

Effective Cover Width: 750 mm – 2650 mm (varies by panel profile)

Maximum Length: Over 12 meters (seamless single-piece forming)

Rib Height: 25 mm – 40 mm

Pitch: 100 mm – 200 mm

Surface Finishes: Color coated (PE / PVDF), anodized, laminated

Installation Methods: Overlapping, concealed seam, specialized clamps

Key Features: Large-span coverage, structural stability, fast installation, low maintenance cost

Applications: Large warehouses, logistics parks, aircraft hangars, exhibition halls, industrial plants

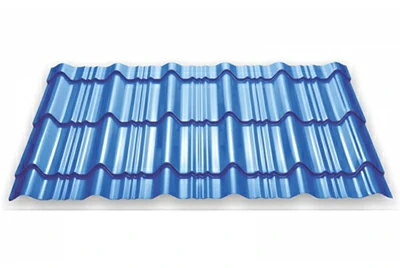

Aluminum step tiles roofing sheet

Aluminum step tile roofing panels resemble traditional tiles in appearance and offer a lightweight, attractive, and corrosion-resistant solution, widely used in villas, clubs, and resorts for mid-to-high-end roofing systems.

Contact us now

Common Alloys: 3003, 3105, 5052

Thickness Range: 0.4 mm – 0.7 mm

Panel Width: Typically 365 mm – 420 mm (tile width)

Panel Length: 1.2 m – 3 m (customizable)

Tile Waves per Sheet: Usually 5 to 7 waves

Coating Types: PE / PVDF / Polyester film (selected based on weather resistance requirements)

Surface Finishes: Color coating, embossed, sandblasted, stone grain, wood grain, etc.

Color Options: Red, brown, gray, green, blue, and custom RAL colors

Service Life: Over 25 years (depending on environment and coating type)

Installation Method: Overlapping with fasteners, compatible with wood battens or metal purlins

Applications: High-end residences, villas, clubs, religious buildings, resorts, renovation projects

Aluminium coated roofing sheets

Color-coated aluminum roofing panels feature a colored coating on the aluminum substrate, offering excellent corrosion resistance, weather durability, and decorative appeal—ideal for industrial, commercial, and residential roofing systems.

Contact us now

Base Alloy: 1060, 3003, 3105, 5052

Thickness Range: 0.3 mm – 1.2 mm

Effective Cover Width: 750 mm – 1050 mm

Coating Types: PE (Polyester), PVDF (Fluorocarbon), SMP (Silicone Modified Polyester)

Color Options: Silver white, gray, red, blue, green, and other RAL colors

Coating Adhesion: Complies with ASTM D3359, no peeling

UV Resistance: Excellent (PVDF provides over 20 years of weather resistance)

Surface Finishes: Glossy, embossed, matte, wood grain, stone grain

Service Life: 15–30 years (depending on coating type and environment)

Applications: Factories, shopping malls, warehouses, residential roofs, sunshades

Here are the common types of color-coated aluminum roofing panels:

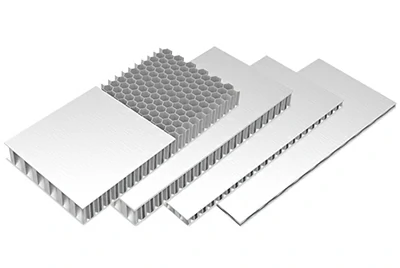

Aluminium honeycomb roof panel

Aluminum honeycomb roofing panels use a sandwich structure with a honeycomb core, offering high rigidity, excellent insulation, and lightweight performance—ideal for premium roofs, façades, and ceiling systems.

Contact us now

Panel Material: 3003, 5052, 5056 aluminum alloy

Core Type: Hexagonal aluminum honeycomb core

Core Thickness: 6 mm – 100 mm (commonly 15 mm – 25 mm)

Total Thickness: 10 mm – 50 mm (standard: 15 mm, 20 mm, 25 mm)

Face Sheet Thickness: 0.6 mm – 1.5 mm

Common Sizes: 1220 × 2440 mm / 1500 × 3000 mm (customizable)

Weight: Approx. 4 – 8 kg/m² (depending on thickness)

Coating Types: PVDF, PE, anodized

Weather Resistance: Service life up to 20–30 years (outdoor use)

Surface Finishes: Glossy, brushed, mirror, perforated, stone grain, wood grain

Installation Methods: Snap-in, keel system, adhesive systems, etc.

Applications: Exhibition centers, airports, railway stations, ceiling roofs, outdoor shading systems

Aluminum zinc roofing sheets

Alu-zinc roofing panels are coated with an alloy of 55% aluminum, 43.5% zinc, and 1.5% silicon, offering excellent corrosion resistance, reflectivity, and weather durability.

Contact us now

Coating Composition: 55% Aluminum + 43.5% Zinc + 1.5% Silicon

Coating Weight: AZ100 – AZ150 (100–150 g/m², double-sided)

Base Material: Cold-rolled steel (commonly G300 / G550 high-strength steel)

Thickness Range: 0.25 mm – 1.2 mm

Effective Cover Width: 750 mm – 1100 mm (depends on profile)

Surface Finishes: Mill finish, embossed, painted (PE, PVDF optional)

Reflectivity: ≥ 75% (infrared reflectance, reduces roof heat absorption)

Corrosion Resistance: Salt spray test > 1000 hours without red rust

Service Life: 15 – 30 years (depending on environment and coating)

Forming Options: Corrugated, trapezoidal, standing seam, concealed fixing systems

Applications: Factories, warehouses, cold storage, residential buildings, greenhouses, commercial roofs

Chalco Aluminum roofing panel application showcase

Advantages of Chalco aluminum roofing sheets

- Strong rust resistance: Remains rust-free for years, with no red rust stains—ideal for exposed roof structures.

- Clean appearance: Resists dust and rust streaks, keeping the roof looking neat and attractive.

- Flexible forming: Can be shaped into curves, cones, and waves to meet architectural design needs.

- Good sound insulation: Produces less rain noise than color steel, suitable for homes and villas.

- Photovoltaic compatible: Works with solar mounting systems without galvanic corrosion, extending system lifespan.

- Long-lasting color: PVDF coating resists UV rays, maintaining color and finish for over 20 years outdoors.

- Excellent heat resistance: High reflectivity prevents heat absorption; won't deform or soften under extreme heat—ideal for hot climates like the Middle East, Southeast Asia, and Africa.

- Low maintenance: No need for regular rust removal or repainting; virtually maintenance-free during use.

- Strong decorative appeal: Available in custom wood grain, stone grain, and embossed textures to enhance visual depth.

Hot-selling sizes of Chalco aluminum roofing sheets

The table below lists the aluminum roofing sheet sizes most favored by Chalco's customers. If you don't find a suitable option, feel free to contact us for customization.

Instant Quote| Thickness (mm) | Sheet Width (mm) | Effective Coverage (mm) | Length Range (mm) |

| 0.25mm aluminum roofing sheet | 914 | 750–1050 | 1000–6000 |

| 0.3mm aluminum roofing sheet | 1000 | 750–1050 | 1000–6000 |

| 0.4mm aluminum roofing sheet | 1200 | 750–1050 | 1000–6000 |

| 0.5mm aluminum roofing sheet | 1220 | 750–1050 | 1000–6000 |

| 0.55mm aluminum roofing sheet | 1250 | 750–1050 | 1000–6000 |

| 0.6mm aluminum roofing sheet | 1500 | 750–1050 | 1000–6000 |

| 0.7mm aluminum roofing sheet | 1500–2650 | 750–1050 | 1000–12000 |

| 0.8mm aluminum roofing sheet | 1500–2650 | 750–1050 | 1000–12000 |

| 1mm aluminum roofing sheet | 1500–2650 | 750–1050 | 1000–12000 |

| 1.2mm aluminum roofing sheet | 1500–2650 | 750–1050 | 1000–12000 |

| 1.5mm aluminum roofing sheet | 1500–2650 | 750–1050 | 1000–12000 |

Products you may be interested in

Chalco also offers roofing-related products you may be interested in. Click the items below to learn more.

Aluminum Corrugated Sheet

3003 Aluminum Corrugated Sheet

1050 Aluminum Corrugated Sheet

Aluminum Roofing Material

8011 Aluminum foil for Roof

1100 Aluminum Foil for Roof

Optional configurations and customization services for Chalco aluminum roofing sheets

Profile selection and color customization

A variety of panel profiles are available, including corrugated, trapezoidal, standing seam, and step tile designs to meet different structural and aesthetic needs.

Surface colors can be customized based on RAL standards, with popular options such as gray, white, red, and green, as well as special finishes like metallic, wood grain, stone pattern, and camouflage.

Surface treatment options

Based on environmental conditions and aesthetic preferences, various surface treatments are available:

- Color coating (PE/PVDF): Ideal for outdoor use with UV resistance and corrosion protection

- Anodizing: Enhances surface hardness and metallic texture, suitable for modern architectural styles

- Lamination: Improves scratch and stain resistance, perfect for high-end residential and decorative projects

- Embossing: Offers both anti-slip and decorative effects with textures like orange peel or diamond patterns

Custom length and cutting service

Panel lengths can be customized from 1 to 12 meters, with widths precisely cut according to the uncoiled panel profile. Maximum uncoiled width reaches up to 2650 mm, allowing for adaptation to various roof spans and assembly methods—reducing on-site cutting and improving installation efficiency.

Matching fixing systems and accessories

A full range of roofing system accessories is available to ensure easy installation and reliable sealing:

- Aluminum alloy / galvanized steel purlins

- Self-tapping screws, waterproof washers, edge trims

- Waterproof sealant, flashing cover plates

- PV mounting brackets and connectors (suitable for distributed solar rooftops)

All components can be customized in size, hole positioning, and surface anti-corrosion treatment based on project requirements.

How to install aluminum roof panels?

- Prepare tools: Electric drill, screws, sealant, measuring tape, safety gear, etc.

- Inspect the structure: Ensure the roof base is level and secure, with appropriate purlin spacing.

- Install from bottom to top: Start at the eaves and install upward in the direction of drainage.

- Side overlap: Overlap each sheet by one rib or as per the panel design.

- Fix at the crest: Secure with specialized screws at the rib crest, using waterproof washers.

- Apply sealant: Apply waterproof sealant at overlaps and edges to prevent leakage.

- Install edge trims: Add ridge caps and side flashing to enhance sealing.

- Clean and inspect: Remove metal debris and check all fixings and waterproofing.

Chalco aluminum roofing sheet FAQs

What is the price per square meter of aluminum roofing sheets?

The price depends on thickness, alloy type, surface coating (e.g., PE or PVDF), and order quantity. Custom colors or special sizes may incur additional costs.

How to get an accurate aluminium roofing sheet price quote?

Simply provide the required thickness, width, length, color, quantity, and delivery address. We’ll send a formal quote within 24 hours. Contact us.

Is aluminum roofing better than steel?

Aluminum doesn’t rust, is lighter, and easier to install—ideal for projects requiring high load performance or long-term corrosion resistance. Though the initial cost is higher, overall lifetime cost is lower.

Can the color or profile be customized?

Yes. We offer RAL color customization, wood/stone grain finishes, embossed surfaces, and custom lengths, rib heights, and cover widths to suit various designs and functions.

Is it suitable for solar roofing systems?

Absolutely. Aluminum is compatible with PV systems, with no risk of galvanic corrosion, and offers excellent weather resistance—perfect for distributed solar rooftops.

How long do aluminum roofing sheets last?

With color coating (PE, PVDF) or anodizing, service life exceeds 20 years under normal use with minimal maintenance, even in coastal, humid, or hot climates.

Why choose Chalco?

- Free samples: We offer free samples for testing, allowing customers to confirm quality before placing orders with confidence.

- Competitive pricing: Exclusive discounts are available for returning clients and bulk orders, helping reduce procurement costs.

- Fast delivery: Ample stock of standard sizes and quick turnaround on custom orders help shorten project timelines.

- Timely price updates: Prices are quoted based on current aluminum ingot rates, ensuring accuracy and competitiveness.

- Comprehensive quality inspection: Each batch comes with mill test certificates (MTC), dimensional checks, and chemical analysis; third-party testing (e.g., SGS) is also available upon request.

- Solution-oriented support: We provide profile selection advice, custom cutting plans, and accessory recommendations tailored to your project—offering complete, one-stop service.