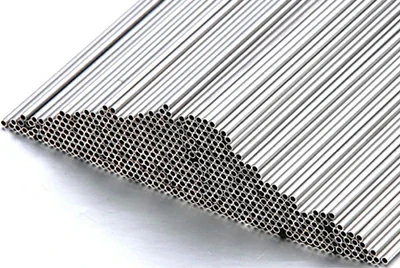

Aluminum capillary tube is a fine-walled tubing with outer diameters typically from 0.5 to 10 mm and inner diameters as small as 0.2 mm. It is widely used in fluid control, refrigeration, and micro-transmission in medical, automotive, and lab systems. For slightly larger sizes (φ4.8–20 mm), small aluminum tubes offer a practical alternative when ultra-fine precision is not required.

Chalco is committed to one-stop production of high-precision aluminum tubes, offering a complete manufacturing solution from aluminum billet casting to cold drawing, precision extrusion, surface treatment, and delivery customization. Both coil tubing and fixed-length straight tubes are available to meet the strict requirements of various industries.

Instant QuoteKey Features of Chalco Aluminum Capillary Tubes

As a critical tubing solution for microfluidic control and precision transmission, Chalco aluminum capillary tubes offer the following outstanding advantages:

Precision Flow Control

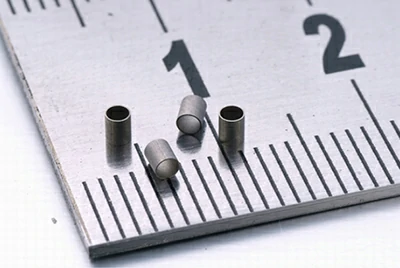

Precision Flow ControlChalco capillary tubes provide ±0.01mm inner diameter tolerance, ensuring stable flow rates and pressure regulation in systems such as refrigerant throttling, liquid sampling, and gas delivery.

Lightweight Design

Lightweight DesignWith a density only one-third of copper, aluminum significantly reduces overall system weight, making it ideal for new energy vehicles, portable equipment, and aerospace micro-systems.

Excellent Thermal Conductivity

Excellent Thermal ConductivityWith a thermal conductivity of up to 230 W/m·K, aluminum enhances heat exchange efficiency in air conditioning systems, sensor cooling, and thermal control in experimental equipment, enabling smaller heat exchanger designs.

Superior Machinability and Flexibility

Superior Machinability and FlexibilityChalco aluminum capillary tubes exhibit excellent formability and bendability, suitable for flaring, punching, U-bending, and end sealing, compatible with diverse connection methods and automated assembly processes.

Outstanding Corrosion Resistance

Outstanding Corrosion ResistanceThe natural oxide film, enhanced with anodizing or tin coating, ensures long-term operation even under salt spray, high humidity, or elevated temperature conditions, ideal for outdoor condensing units and pharmaceutical cold chains.

Excellent Formability and Compatibility

Excellent Formability and CompatibilityChalco tubes support mainstream processes like flaring, expansion, welding, and brazing, and integrate seamlessly with automated assembly lines, thanks to their ductility and bend strength.

High Environmental Recyclability

High Environmental RecyclabilityMade from 100% recyclable aluminum, Chalco's tubes comply with RoHS and REACH regulations, making them a preferred choice for sustainable manufacturing.

If you seek enhanced heat transfer efficiency, lightweight system design, or precision micro-delivery solutions, Chalco aluminum capillary tubes offer a high-performance, cost-effective alternative.

Instant QuoteSpecifications of Aluminum Capillary Tubes

| Alloy | 1050 / 1060 / 1070 / 3003 / 6063 |

| Temper | O, F, H112, T3, T5, T8, etc. |

| Outer Diameter | 0.5 – 10 mm |

| Inner Diameter | 0.3 – 9.8 mm |

| Wall Thickness | 0.2 – 2.5 mm |

| Length | 5 – 6000 mm |

| Surface Finish | anodized, polished, tinned, sandblasted, electroplated, etc. |

| Tolerance Grade | outer diameter ±0.02 mm; wall thickness ±0.01 mm |

| Standard | ASTM B483 / B210 / B241, EN 754-7 / EN 1396 |

For special requirements such as micro-perforated structure, ultra-thin wall ratio, roundness control, or custom end processing, please contact us for tailored solutions.

Instant Quote

Product Categories of Aluminum Capillary Tubes

Seamless aluminum capillary tubes are produced by extrusion and multi-stage cold drawing. Their weld-free design ensures excellent sealing and dimensional stability, ideal for precision uses like refrigeration control and medical tubing. Post-drawing, they provide high pressure resistance and stable flow, meeting top technical standards.

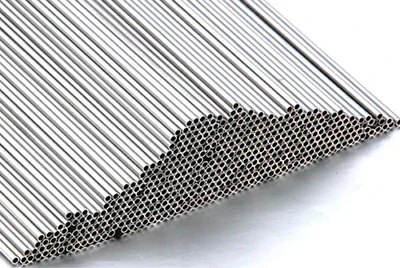

Straight Length tube

Straight aluminum capillary tubes are supplied in custom-cut lengths, commonly used in structural assembly, precision instruments, and small connector manufacturing. With high straightness and clean cuts, they are ideal for further punching, flaring, welding, and other customized end-processing needs.

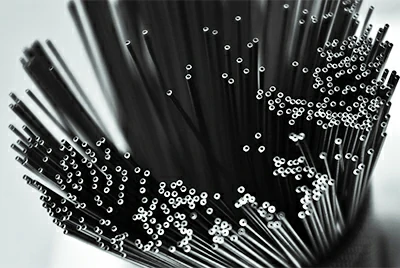

Coiled aluminum capillary tubes are supplied in continuous wound form, suitable for long-distance routing and space-constrained installations, commonly used in refrigerators, air conditioners, and heat pump refrigerant delivery systems. These tubes offer excellent flexibility and support automatic feeding and automated assembly requirements.

Thick Wall Capillary Tube

Thick wall aluminum capillary tubes provide superior pressure resistance and burst strength, suitable for high-pressure refrigerant systems, industrial microfluidic hydraulics, and other applications with high-strength demands. Even at smaller diameters, they maintain excellent mechanical stability and bend control.

Thin wall aluminum capillary tubes offer faster thermal response and greater flow control accuracy due to their ultra-thin walls. They are ideal for energy-efficient refrigeration systems and laboratory flow control setups, offering lightweight construction, rapid heat exchange, and the ability to reduce refrigerant charge.

Comparison Table of Common Aluminum Capillary Tube Alloys

| Alloy | Main features | Application areas |

| 1050 / 1060 | High thermal conductivity, easy processing, high cost performance | Refrigerator capillary tubes, air conditioning refrigerant tubes, electronic thermal control systems |

| 1070 | High purity, excellent corrosion resistance, good cleanliness | Medical catheters, chromatograph tubes, laboratory microfluidic tubes |

| 3003 | Strength is better than pure aluminum, corrosion resistance, suitable for brazing | Air conditioning capillary microfluidic tubes, refrigeration pipelines, home appliance heat exchangers |

| 6063 | Good extrudability and formability, moderate strength | Small structural support tubes, guide rails, decorative tubes |

Different aluminum alloys offer varied performance characteristics. Whether you prioritize heat transfer efficiency, dimensional precision, corrosion resistance, or cost optimization, Chalco can provide tailored material recommendations to support your efficient project development.

Contact us now to request samples and get a quote!

Instant Quote

Typical Applications of Aluminum Capillary Tubes

Refrigeration & Air Conditioning

Aluminum capillary tubes serve as expansion devices in refrigerators and A/C systems, precisely controlling refrigerant flow and pressure drop. Lighter and more cost-effective than copper, they are ideal for compact, energy-efficient heat exchangers.

Medical & Laboratory Equipment

Used in needles, ventilators, gas analyzers, and samplers, aluminum capillaries ensure accurate microfluid control. Their high precision, formability, and light weight, plus options like anodizing and tin plating, enhance performance and biocompatibility.

Automotive & Electronics

Common in A/C, fuel, and cooling systems, aluminum capillaries offer excellent heat conductivity, bendability, and light weight. They support efficient thermal control in EVs and precision electronics with space-saving, high-performance design.

Instrumentation & Precision Devices

Ideal for sensors, regulators, and meters, aluminum capillaries provide accurate IDs, clean surfaces, and good machinability. They offer a lighter, more economical alternative to stainless steel in portable instruments and micro-fluid systems.

New Energy & Environmental Equipment

Widely used in inverters, storage, and fuel cells, aluminum capillaries combine thermal conductivity, corrosion resistance, and light weight—ideal for dense layouts and efficient thermal management in green energy systems.

Manufacturing Process of Capillary Aluminum Tubes and Chalco's Capabilities

Chalco offers a fully integrated production system, from aluminum ingot casting to finished product delivery, to meet the demanding requirements of high-precision capillary aluminum tubes across various industries. We specialize in stable control of microstructures and high cleanliness standards, making us a trusted partner in refrigeration, medical, and precision equipment sectors.

Capillary Aluminum Tube Production Process

- Casting & Extrusion: Selected soft alloys such as 1050, 1060, 1070, and 3003 are melted and extruded to produce high-uniformity billets, serving as premium raw material for subsequent cold drawing processes.

- Cold Drawing + Intermediate Annealing: Multiple cold drawing steps combined with annealing ensure precise control of wall thickness and inner diameter within ±0.01mm, suitable for microstructures with inner diameters as small as 0.3mm.

- Ultrasonic Cleaning & Optical Inspection: Automated ultrasonic cleaning systems work in tandem with optical dimension inspection units to minimize impurities and dimensional deviations, ensuring high cleanliness standards.

- Surface Finishing & Packaging: Customized surface treatments such as anodizing, sandblasting, and electroplating are available to meet different functional needs, including anti-oxidation and corrosion resistance.

Chalco's Manufacturing Capabilities

- Specialized capillary tube drawing dies and coiling systems to support both coiled and straight-length supply;

- Small-batch custom production and rapid prototyping, ideal for R&D and specialized applications;

- Full-process digital traceability and quality records to ensure batch consistency and product traceability.

Want to learn more about our precision aluminum tubing production lines, processing capabilities, and delivery timelines? Contact us today for prototyping and custom solutions!

Instant QuoteAluminum Capillary Tube vs. Copper Capillary Tube

| Comparison dimensions | Aluminum capillary tube | Copper capillary tube |

| Raw material cost | Aluminum is cheaper, processing energy consumption is low, and the overall cost is reduced by 40%~60% | Raw materials are expensive, prices fluctuate greatly, processing energy consumption is high, and the overall cost is significantly high |

| Weight density | Density is about 2.7 g/cm³, which is about 1/3 of copper, suitable for lightweight systems | Density is about 8.9 g/cm³, heavy weight, not suitable for mobile or lightweight design scenarios |

| Thermal conductivity | The thermal conductivity is about 237 W/m·K, and most refrigeration needs can be met through microstructure optimization | Thermal conductivity is about 398 W/m·K, which is more advantageous in extreme heat exchange demand scenarios |

| Molding processability | Excellent ductility, suitable for bending, shrinking and expanding, flanging, cold drawing, precision coiling, etc. | Difficult to process, easy to harden, strong rebound, and high processing equipment requirements |

| Corrosion resistance | After anodizing or galvanizing, it can operate stably in salt spray, high humidity, and chemical environments | With its own antioxidant film, it has strong natural corrosion resistance and is suitable for highly corrosive environments |

| Surface treatment | Can be anodized, polished, tinned, electrophoresed, etc., with various surface effects | Usually no additional treatment is required, suitable for bare tubes or simple protection |

| Environmental protection and recycling | 100% recyclable, low recycling energy consumption, low carbon emissions, in line with sustainable policies | Also recyclable but with higher recycling energy consumption, relatively high environmental pressure |

| Typical applications | Household appliance refrigeration, HVAC, new energy vehicle cooling, medical equipment, small experimental equipment | High-precision instruments, high-pressure refrigeration, military or special environment refrigeration systems |

If you prioritize lightweight design, cost, and production efficiency, aluminum capillary tubes are a more economical choice. For extreme temperatures or highly corrosive environments, copper tubes may perform better. Contact us for expert material recommendations!

Instant QuoteFAQs

What is the role of aluminum capillary tubes in refrigeration systems? How do they differ from expansion valves?

Aluminum capillary tubes act as throttling components in refrigeration systems. They lower pressure and control the flow of high-pressure liquid refrigerant into the evaporator, facilitating phase change. With a simple structure and no external control, they are ideal for compact systems like home appliances, freezers, and automotive AC units. In contrast, expansion valves are adjustable and used in larger systems that require higher precision and faster response.

Why use aluminum for capillary tubes? Can it replace copper?

Aluminum offers advantages such as lightweight, easy processing, and lower cost—its density is only 1/3 that of copper, reducing costs by 40%–60%. Thanks to precision processes like cold drawing and annealing, aluminum capillary tubes now match copper in performance and processability. In most standard conditions, aluminum is a viable and cost-efficient alternative to copper, especially for mass production and lightweight system designs.

How precise can the inner diameter and wall thickness of aluminum capillary tubes be? Are they suitable for high-precision use?

With multi-stage drawing processes and laser dimensional inspection, Chalco's aluminum capillary tubes can achieve ±0.01mm inner diameter accuracy and ±0.005mm wall thickness tolerance. Typical inner diameters range from 0.3–9.8mm, meeting the stringent requirements of medical devices, laboratory chromatography, and electrical sensors.

Can aluminum capillary tubes withstand long-term use in corrosive environments?

Aluminum has natural passivation properties. Chalco offers additional corrosion protection via anodizing, zinc coating, electrophoresis, and more. After surface treatment, our tubes can withstand salt spray tests for 1000–2000 hours, making them suitable for kitchens, coastal areas, and industrial cooling systems.

Does Chalco support small-batch customizations such as specific lengths, shaped ends, or pre-bending?

Yes. Our flexible production lines support minimum order quantities from 100–200 meters, and we provide various custom services such as non-standard mold creation, length cutting, flaring, necking, flanging, perforation, and cleaning. These are ideal for R&D samples and small-scale custom needs.

Instant QuoteCan aluminum capillary tubes be used in medical or electronics industries? Are there concerns about contamination or insufficient precision?

We offer medical-grade cleaning and precision cutting, including automated ultrasonic degreasing and dust-free packaging, ensuring no particle or metal contamination. Our products meet dimensional and surface quality standards for medical and electronic applications, such as respirator connectors, laser optics, and gas flow channels.

Must capillary tubes be seamless? Are welded options supported?

Seamless capillary tubes are preferable for applications requiring high sealing and precision, such as compressor systems and medical diagnostics. However, we also provide welded and seamless options. The choice depends on pressure, cost, and processing needs, and our engineers can assist with material selection.

What is Chalco's lead time and supply capacity? Do you support overseas orders?

We stock standard sizes for 5–7 day delivery. Custom sizes are typically delivered within 15–30 days. Chalco has export licenses and regularly supplies customers in Europe, America, Japan, and Korea, offering CIF, FOB, DDP, and other trade terms, along with full technical and after-sales support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote