Engineered 5xxx aluminum-magnesium solution for hazardous-goods tank trucks — combining high elongation, reliable weldability, and corrosion resistance to meet ADR requirements.

- Compliant with EN 14286 / ASTM B209, supplied with EN 10204 3.1 MTC for ADR hazardous-goods tankers

- High elongation, excellent weldability, and corrosion resistance for shells, heads, and baffles

- Stock available: 3–12 mm thickness, 1000–2600 mm width, cut-to-length up to 12 m with drawing-based supply

View 5182 aluminum plate stock and available sizes

Specifications of 5182 aluminum sheet plate for oil tanker

| Alloy | 5182 |

| Temper | 5182-H111 (shell/body); 5182-O (heads & baffles) |

| Supply size | Thickness 3–12 mm; width 1000–2600 mm; length up to 12 m (cut-to-size & drawing-based delivery) |

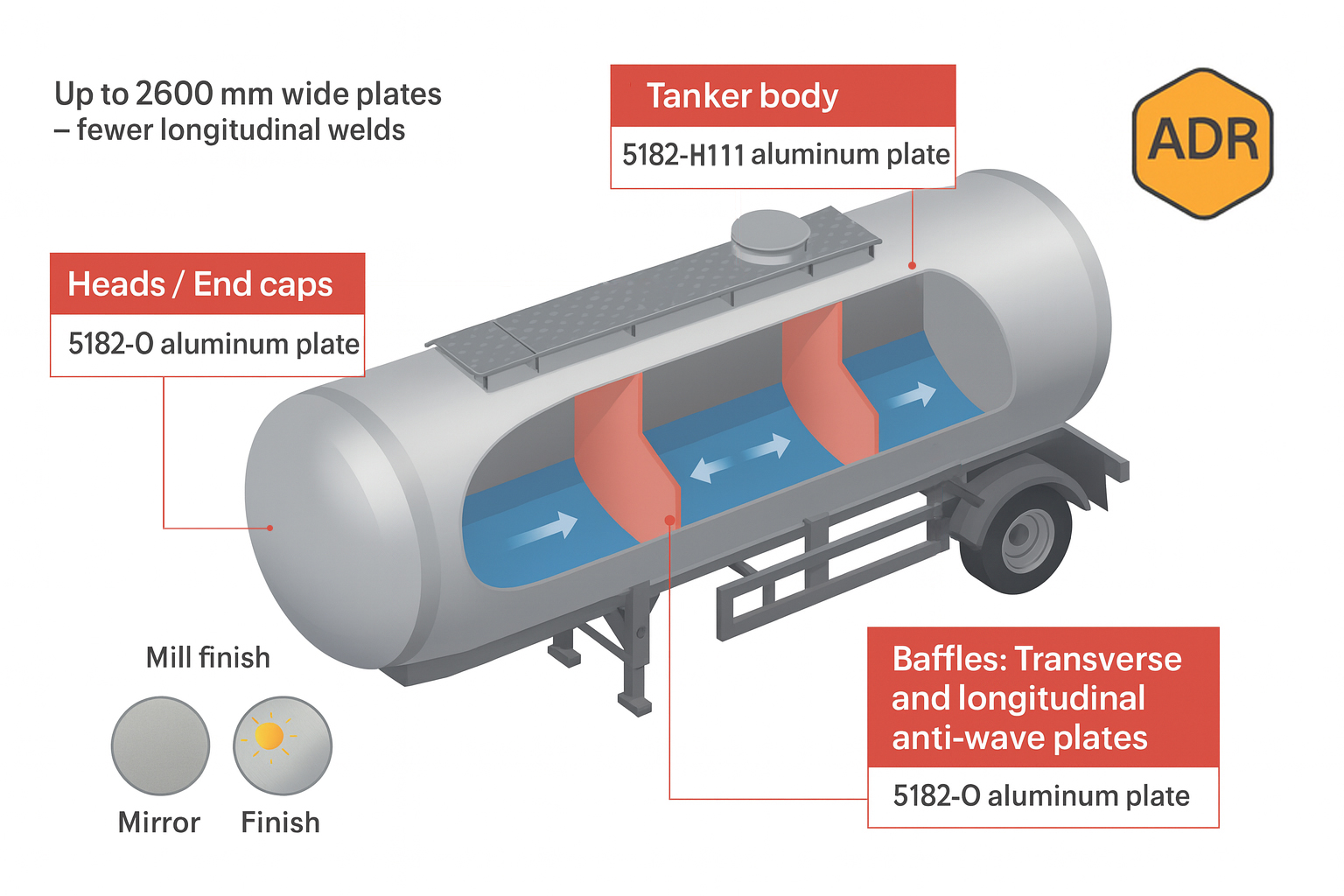

| Surface | Mill finish: for standard paint/polish; Mirror finish: high reflectivity to reduce heat absorption, ideal for hot climates (e.g., Middle East) (#surface) |

| Standards & certificates | EN 14286 / ASTM B209; material certificate EN 10204 3.1 |

| Processing & packaging | Cut-to-size, formed parts on request; PE protective film (single/double side, optional); reinforced moisture-proof packing |

| Permissible deviation | Thickness tolerances graded by plate width — see the "Permissible deviation” section for full table |

Processing Capability & Component Supply

Chalco beyond supplying plates, we deliver drawing-based parts that are weld- or install-ready — helping you cut on-site cutting/nesting time, reduce scrap and rework, keep consistent quality, and shorten the overall lead time.

- 5182-H111 Shell Plates: cut-to-size with edge prep/bevels and marked or pre-cut openings (manholes, gauges). Kit-packed by compartment to speed assembly.

- 5182-O Heads: spun/pressed heads with weld-ready edges (bevels & fit-up options) — ready to join upon arrival.

- 5182-O Baffles / Bulkheads: pre-cut, punched and bent to drawing; rounded edges to minimize coating damage and scratching.

- Mirror Finish 5182 Plates: for exterior panels; high reflectivity helps reduce heat absorption — ideal for hot climates (e.g., Middle East). Mill finish also available for standard paint/polish workflows.

- Custom Tanker Parts: longitudinal anti-wave plates, partitions, manhole reinforcement rings, ladder/rail brackets — with kit-packing so parts go straight to assembly.

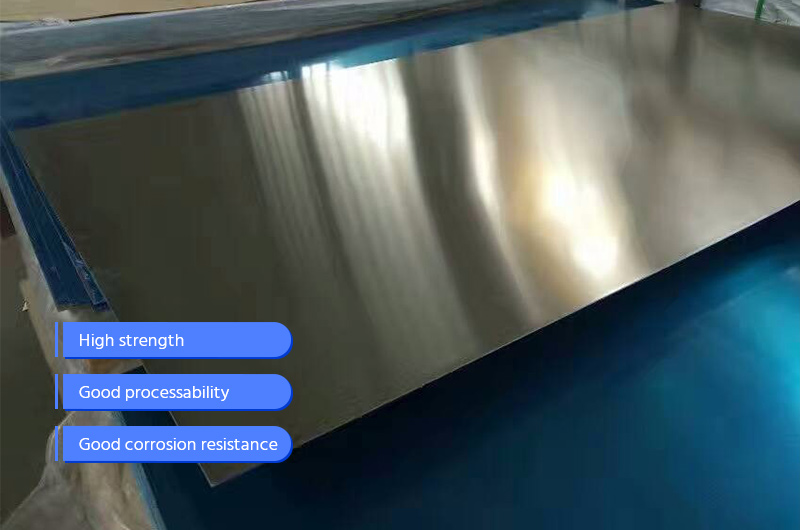

Features of 5182 Aluminum Plate for Tank Trucks

High elongation and welding reliability: 5182 is a high-magnesium alloy with elongation ≥24% and excellent joint strength, ideal for shells, heads, and baffles with long weld seams to enhance overall safety.

Excellent corrosion resistance: Resists common petroleum products and road salt exposure, extending tanker service life and reducing maintenance frequency.

Wide plate reduces seams: Available in widths up to 2600 mm to minimize longitudinal welds, speed up production, and improve flatness and sealing reliability.

Good forming performance: O temper is suitable for deep drawing and spinning, while H111 is good for rolling, meeting complex tank designs and reducing forming cracks.

Lightweight with high load capacity: Low density and high specific strength help reduce overall vehicle weight, increasing payload and transport efficiency.

Sustainable value: Fully recyclable, supporting green manufacturing and optimized lifecycle cost.

Where 5182 Fits in a Tank Trailer

Shell / Body

5182-H111 is ideal for tanker shells, combining high elongation and excellent weldability. With plate width up to 2600 mm, fewer longitudinal welds are required, which helps increase overall strength and corrosion resistance of the tank.

Heads / End Caps

5182-O temper offers excellent formability for spinning or pressing head components. It ensures good weld integrity and reliable sealing performance after forming.

Baffles / Bulkheads

5182-O temper is also used for baffles and partitions. These components control liquid surge inside the tank, improving vehicle stability and braking safety.

Why Choose Chalco Aluminum?

Focused on ADR hazardous-goods tanker applications, Chalco delivers a turnkey 5182 solution — not only plates, but also drawing-based parts and complete process documentation to help you cut on-site work and speed assembly.

- Compliance & documentation: Supplied per EN 14286 / ASTM B209; EN 10204 3.1 available. NAMLT (ASTM G67) reports and WPS/NDT guidance (PT/RT/UT) on request.

- Integrated parts supply: 5182-O heads, 5182-O baffles/bulkheads, and 5182-H111 shell plates — kit-packed to drawings for direct assembly, reducing on-site cutting, nesting time, and scrap.See components

- Welding & process support: Filler matching for ER5356/ER5183 with sample WPS; beveling/marking delivered with the parts to speed fit-up and improve joint consistency. See welding

- Consistency & traceability: In-process control with dimensional reports and batch traceability; surface consistency (mill finish / mirror finish) and export-grade packing.

- Industry experience & delivery: Trusted by tanker OEMs (e.g., CIMC Lingyu, Al-Mutlak); proven global shipping and support for hot-climate applications.

Welding & Filler Matching

When you source 5182 plates and drawing-based parts (e.g., 5182-O heads / baffles) from us, welding can proceed directly with the following process and filler guidance. 5182 provides excellent weldability for tanker fabrication with reliable joint elongation in long-term service.

- Process essentials: Dual cleaning (mechanical & chemical) before welding; control heat input and interpass temperature to reduce porosity and distortion.

- Filler selection: ER5356 for general use (balanced strength & corrosion resistance); ER5183 when higher as-welded strength or harsher environments are required (e.g., coastal salt spray, selected chemical media).

- Quality & NDT: Recommend PT / RT / UT for critical seams; smooth toe transitions and generous radii to improve fatigue life.

- Documentation with parts: WPS reference ranges and sample records available; beveling/marking and drawing-based delivery supplied with the parts to speed assembly.

Procurement Guide — 5182 Tanker Aluminum Plate

Pricing & delivery: Quoted per sheet/kg with EXW/FOB/CIF/DDP terms, multi-currency available. Formal quotation is provided within 24h after receiving your specifications and drawings.

Typical lead time: Samples in 5–7 days, bulk production in 2–3 weeks. Expedited production and partial shipments are available to match your assembly schedule.

- Submit specs/drawings via message board or email

- Price factors: alloy/temper, thickness/tolerance, cutting/bevel, quantity, destination port

- MOQ & samples: mixed specifications supported; samples with EN 10204 3.1 MTC available

- Packing & compliance: PE film + ISPM15 wooden box; COO, REACH/RoHS, NAMLT report optional

- Transport & customs: sea/air/rail multimodal; DDP available with insurance and full shipping docs

Send us your specs by message or email to get an accurate quote and lead time for 5182 tanker plates.

Instant Quote

Tanker Plate Selection Guide (5182 | 5083 | 5454 | 5754)

| Dimension \ Alloy | 5182 | 5083 | 5454 | 5754 |

| Positioning / Scenario keywords | ADR hazardous goods; ambient–medium temperature; emphasis on elongation and welding stability | Cryogenic/LNG; marine/salt-spray; general corrosion resistance | Long-term medium–high temperature / insulated cargo (e.g., asphalt / emulsified asphalt) | General welded structures; food/personal care; everyday corrosion resistance |

| Typical parts & tempers | Shell: 5182-H111; Heads/Baffles: 5182-O | Shell: 5083-H111/H321; Heads/Bulkheads: 5083-O | Shell: 5454-H111/H32; Heads/Bulkheads: 5454-O | Shell/Internals: 5754-H111/O (per forming need) |

| Operating boundaries & risk control | For 5xxx under sustained higher temperature + stress, perform NAMLT assessment; for long-term higher temperature also evaluate 5454 | Excellent at low temperature and marine service; not recommended for long-term high temperature | Better stability at medium–high temperature than 5182/5083; still manage NAMLT risk | Moderate strength; verify media and regulatory fit per project |

| What customers value most | High elongation and weldability; wide plates reduce seams; drawing-based parts available | Proven corrosion/cryogenic performance; strong track record in LNG/coastal projects | Stable service life at medium–high temperature; suited to insulated cargo and hot routes | Good formability and cost profile; fits general tanker structures |

If your application is ADR hazardous goods at ambient–medium temperature, choose 5182 aluminum sheet.

If it involves cryogenic/LNG or coastal salt-spray environments, choose 5083 aluminum sheet.

If it requires long-term medium–high temperature or insulated cargo, choose 5454 aluminum sheet.

If it is a general welded structure or food/personal care with common corrosion demands, choose 5754 aluminum sheet.

5182 Aluminum Sheet Stock List for Tank Trucks

5182 H111 Aluminum Sheet Stock List

| Alloy | Temper | Thickness | Width | Length | Weight (KG) | Piece |

| 5182 | H111 | 10 | 1600 | 6000 | 4380 | 17 |

| 5182 | H111 | 10 | 1600 | 6000 | 4380 | 17 |

| 5182 | H111 | 10 | 1600 | 6000 | 4380 | 17 |

| 5182 | H111 | 10 | 1600 | 6000 | 1030 | 4 |

5182 O Aluminum Sheet Stock List

| Alloy | Temper | Thickness | Width | Length | Weight (KG) | Piece |

| 5182 | O | 5.5 | 1900 | 6600 | 4395 | 24 |

| 5182 | O | 5.5 | 1900 | 6600 | 4395 | 24 |

| 5182 | O | 5.5 | 1900 | 6600 | 4395 | 24 |

| 5182 | O | 10 | 1500 | 6000 | 2385 | 10 |

| 5182 | O | 5.5 | 2620 | 2650 | 4375 | 42 |

| 5182 | O | 5.5 | 2620 | 2650 | 4585 | 44 |

| 5182 | O | 5.5 | 2620 | 2650 | 4585 | 44 |

| 5182 | O | 5.5 | 2620 | 2650 | 1980 | 19 |

| 5182 | O | 5.5 | 2620 | 2650 | 4585 | 44 |

| 5182 | O | 5.5 | 2620 | 2650 | 3225 | 31 |

| 5182 | O | 5.5 | 2620 | 2650 | 4585 | 44 |

| 5182 | O | 8 | 2580 | 5160 | 4180 | 15 |

| 5182 | O | 8 | 2580 | 5160 | 4180 | 15 |

| 5182 | O | 8 | 2580 | 5160 | 1975 | 7 |

| 5182 | O | 5.5 | 2580 | 2880 | 4500 | 41 |

| 5182 | O | 5.5 | 2580 | 2880 | 4500 | 41 |

| 5182 | O | 5.5 | 2580 | 2880 | 2630 | 24 |

5182 Aluminum Strip Stock List

| Alloy | Temper | Thickness | Width | Length | Weight (KG) | Piece |

| 5182 | H111 | 5.5 | 2520 | C | 16190 | 1 |

| 5182 | H111 | 5.5 | 2520 | C | 15530 | 1 |

| 5182 | O | 6 | 2390 | C | 16940 | 1 |

| 5182 | O | 6 | 2390 | C | 16530 | 1 |

| 5182 | H111 | 6 | 2200 | C | 16200 | 1 |

Chemical composition of 5182 aluminum sheet plate for oil tanker

| Element | Composition % |

| Si | 0.20 |

| Fe | 0.35 |

| Cu | 0.50 |

| Mn | 0.0-0.5 |

| Mg | 4.0-5.0 |

| Cr | 0.10 |

| Ni | - |

| Zn | 0.25 |

| Ti | 0.10 |

| Al | Remainder |

Mechanical properties of 5182 aluminum sheet plate for oil tanker

| Temper | Thickness/mm | Tensile Strength /MPa | Specified non-proportional Tensile Strength/MPa | Elongation After Break/% | A50 mm | Bending Radius |

| H111 | 3.00-6.00 | ≥280 | ≥125 | ≥24 | ≥6600 | 1.0t |

| >6.00-12.00 | ≥280 | ≥125 | ≥24 | ≥6600 | 2.0t | |

| O | 3.00-6.00 | ≥280 | ≥125 | ≥26 | ≥7280 | 1.0t |

| >6.00-12.00 | ≥280 | ≥125 | ≥26 | ≥7280 | 2.0t |

Surface grade of 5182 aluminum sheet plate for oil tanker

| Type | Standard Plate | High Class Plate | Bright Plate | Mirror Plate |

| Surface | ★★★☆☆ | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Roughness Ra/μm | 0.5-0.8 | 0.3-0.5 | 0.1-0.3 | ≤0.04 |

| Product Description | Smooth surface Defect deepness <Minus Tolerances Of Thickness | Fine and smooth surface No or only very little colour aberration and chatters | Bright, fine and Smooth surface No colour aberration and chatters | Mirror reflective Surface Reflectance ≥86% |

| Applicable Standards | GB/T 3880 | EN14286 ASTM B209 EN485 Customer special requirements | EN14286 ASTM B209 Customer special requirements | EN14286 ASTM B209 Customer special requirements |

| Application | Use directly or After brashing Tanker Body, Tanker Head Wall Partition, Resistance Plate | Use directly Tanker Body, Tanker Head Wall Partition, Resistance Plate | Use directly Tanker Body, Tanker Head | Use directly Tanker Body, Tanker Head |

Permissible deviation of 5182 aluminum sheet plate for oil tanker

| Thickness tolerances within the following width ranges | ||||

| Thickness | ≤1250 | >1250-1600 | >1600-2000 | >2000-2600 |

| 3.00-3.50 | +0.28 | +0.28 | +0.30 | +0.40 |

| >3.50-6.00 | +0.32 | +0.32 | +0.40 | +0.45 |

| >6.00-8.00 | +0.38 | +0.45 | +0.50 | +0.60 |

| >8.00-12.00 | +0.45 | +0.55 | +0.65 | +0.80 |

FAQ — 5182 Aluminum for Tank Trucks

How should I choose between 5182-H111 and 5182-O?

Use 5182-H111 for shells/body where rolling and welding stability are key. Choose 5182-O for heads and baffles that require spinning, pressing, or bending; complex shapes favor O temper.

Do I need NAMLT testing for my project? What thresholds are typical?

NAMLT (ASTM G67) helps assess sensitization/SCC risk under sustained temperature and stress. A practical project target is < 15–25 mg/cm² (lower is safer); align with your service conditions.

Is mirror finish better than mill finish in hot climates?

Mirror finish offers higher solar reflectivity to reduce heat absorption and improve appearance consistency in hot regions. Mill finish suits standard paint/polish workflows and structural parts.

Can I purchase ready-made components to reduce on-site work?

Drawing-based parts such as 5182-O heads, 5182-O baffles/bulkheads, and 5182-H111 shell plates can be pre-cut, punched, beveled, and kit-packed to minimize cutting time and scrap.

How should 5182 be welded, and which filler should I choose?

MIG/TIG with dual cleaning and controlled heat input/interpass temperature works well. Choose ER5356 for general applications; select ER5183 when higher as-welded strength or harsher corrosion resistance is required.

Which standards and documents can you provide?

Supplied per EN 14286 / ASTM B209 with EN 10204 3.1 MTRs and dimensional inspection records; NAMLT reports and WPS/NDT guidance available on request.

How is pricing calculated, and what about MOQ and samples?

Specification-based pricing considers alloy/temper, surface, dimensions/tolerances, processing route, quantity, and destination. MOQ and samples depend on the specification and processing scope.

What are the lead time, delivery terms, and packing options?

Lead time starts after drawing and commercial confirmation; expedited and partial shipments are available. Kit-packing per compartment and export-grade packing with PE film and reinforced protection can be provided.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote