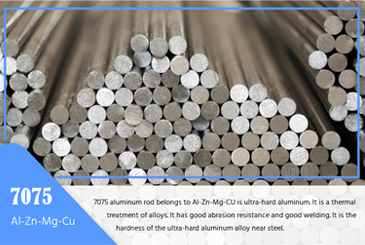

Chalco supplies high-performance 7075 aerospace grade aluminum bar rods to leading industry players including Boeing, Airbus, and Collins Aerospace. With ISO 9001 and AS9100 certifications, we ensure full compliance with international aviation standards. Our products are available in a wide range of tempers, dimensions, and surface finishes to meet the demanding requirements of structural, engine, and precision-machined components.

Chalco 7075 aluminum bar rod available tempers and aerospace standards

| Temper | Standard | Typical Applications |

| 7075-T6 | AMS 4122 | High-strength structural parts: fuselage frames, support brackets |

| 7075-T651 | AMS 4123 | Engine components: compressor blades, thrust support rings |

| 7075-T7351 | AMS 4124 | Fatigue-resistant parts: aircraft seats, satellite frames |

| 7075-TF | AMS 4186 | Aircraft ground support and life-saving equipment |

| 7075-O | AMS 4187 | Interior components: cabin panels, seats, non-load-bearing structural elements |

It should be noted that the above are only some common application cases, and specific applications should be selected and determined according to actual needs and relevant standards and specifications. At the same time, the design and manufacture of aircraft also need to comply with relevant aviation standards and certification requirements to ensure the safety and reliability of aircraft.

Instant QuoteChalco 7075 aerospace grade aluminum bar rod hot selling products

7075 Cold Finished Aerospace Aluminum Bar — Precision Ground | Tight Tolerance | Non-Critical Aircraft Parts

7075 Cold Finished Aerospace Aluminum Bar — Precision Ground | Tight Tolerance | Non-Critical Aircraft Parts7075 cold finished bars offer high dimensional accuracy, excellent roundness, and superior surface quality. Ideal for non-load-bearing aircraft components such as cabin structures, brackets, and fastening systems. Available in T6, T651, T7351, and TF conditions, fully compliant with AMS 4122 / AMS 4123 / AMS 4124 / AMS 4186.

Seating frames Interior rails Mounting structures 7075 Cold Drawn Precision Bar — ±0.05 mm Tolerance | Mirror Surface | High-Speed CNC Machining

7075 Cold Drawn Precision Bar — ±0.05 mm Tolerance | Mirror Surface | High-Speed CNC MachiningCold drawn 7075 bars deliver tight tolerances, high hardness, and excellent surface finishes required in aerospace tooling, actuation systems, and motion components. Available in round, flat, and square shapes, meeting AMS 4123 / AMS 4124 standards.

CNC shafts Guiding parts Housing components 7075 Chamfered Bar for Swiss-Type CNC Turning — Pre-Chamfered Ends | Jam-Free Machining | Automated Precision Components

7075 Chamfered Bar for Swiss-Type CNC Turning — Pre-Chamfered Ends | Jam-Free Machining | Automated Precision ComponentsSpecially designed for Swiss-type automatic lathes, Chalco's chamfered 7075 bars enable smooth bar feeding, reduce tool wear, and ensure consistent concentricity. Ideal for large-volume machining of aerospace connectors, sleeves, and precision fasteners.

Aerospace pins Bushes Threaded fittings 7075 Extruded Aerospace Aluminum Bar — High Strength | Uniform Profile | Structural Load-Bearing Components

7075 Extruded Aerospace Aluminum Bar — High Strength | Uniform Profile | Structural Load-Bearing ComponentsProduced through precision extrusion, these bars deliver uniform mechanical properties and consistent grain structure. Preferred for major structural parts like fuselage ribs, landing gear supports, and wing beams. Supports T651 and T7351 tempers per AMS 4169 / AMS 4167 / ASTM B221.

Frame members Struts External assemblies 7075 Forged Aerospace Aluminum Bar — Maximum Density | Excellent Fatigue Resistance | Critical Performance Zones

7075 Forged Aerospace Aluminum Bar — Maximum Density | Excellent Fatigue Resistance | Critical Performance Zones7075 forged bars are used where reliability under extreme conditions is essential. Their superior mechanical properties make them the best choice for load-critical aircraft parts such as main spars, engine mounts, and gear beams. Produced in T7351 / per project-specific AMS specs.

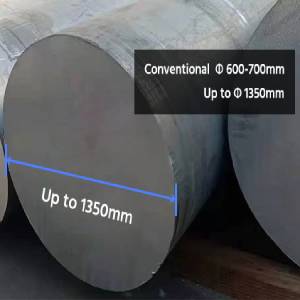

Wing spars Gear components Aircraft joints 7075 Large Diameter Aluminum Bar — Oversized Capability | Aerospace Tooling & Molds | Machinable Structural Blocks

7075 Large Diameter Aluminum Bar — Oversized Capability | Aerospace Tooling & Molds | Machinable Structural BlocksChalco provides extra-large 7075 bars (up to Ø1000 mm) through forging, extrusion, or hot rolling. Designed for structural-critical or tooling-intensive aerospace parts such as engine housings, support frames, and mold base blocks.

Mold blocks Tooling bases Heavy-duty supports

- 7075 aerospace aluminum round bar

- 7075 aerospace aluminum square bar

- 7075 aerospace aluminum flat bar

- 7075 aerospace aluminum hex bar

Chalco provides expert guidance on alloy tempers, machining compatibility, and aerospace standards. From Swiss-type CNC chamfered bars to oversized forged billets, we support your entire component lifecycle with precision-engineered solutions. Contact us now for a fast quote and technical recommendation tailored to your needs.

Instant Quote7075 chemical composition of aluminum rods bar for aviation

| Chemical composition limits | |||||||||||

| Weight% | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other Each | Others Total |

| Alloy 7075 min | Rem | - | - | 1.2 | - | 2.1 | 0.18 | 5.1 | - | - | - |

| Alloy 7075 max | Rem | 0.4 | 0.5 | 2 | 0.3 | 2.9 | 0.28 | 6.1 | 0.2 | 0.05 | 0.15 |

AMS 7075 aluminum alloy bar rod physical performance parameters

| Standard Product | Tensile strength | Yield strength | Elongation |

| AMS 4122 7075-T6 extruded aluminum rod | 524 MPa | 455 MPa | 0.11 |

| AMS 4123 7075-T651 cold-draw aluminum rod | 572 MPa | 503 MPa | 0.11 |

| AMS 4124 7075-T7351 cold-draw aluminum rod | 524 MPa | 455 MPa | 0.11 |

| AMS 4186 7075-TF cold-draw aluminum rod | 524 MPa | 455 MPa | 0.11 |

| AMS 4187 7075-0 cold-draw aluminum rod | 324 MPa | 124 MPa | 0.16 |

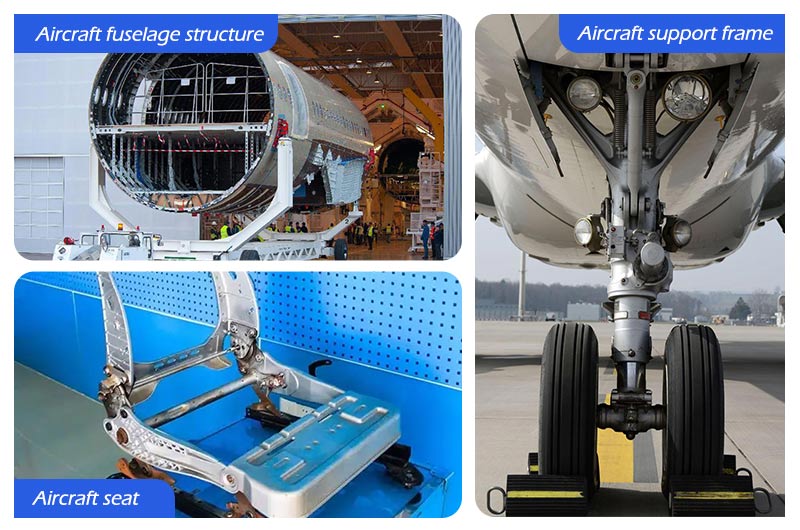

Trusted by leading aerospace manufacturers: real applications of Chalco 7075 aluminum bar

Chalco has supplied aerospace-grade 7075 aluminum bars to globally recognized aviation manufacturers and system integrators, including clients in cooperation with Boeing, Airbus, Collins Aerospace, and major military and satellite equipment contractors.

Our 7075 bars have been successfully applied in a wide range of certified aircraft programs and component systems, where material strength, fatigue performance, and machining consistency are critical.

Instant Quote- Structural Airframe Parts: Such as fuselage frames, wing spars, landing gear brackets — using 7075-T6 and T651 rods in compliance with AMS 4122 / 4123.

- Jet Engine Assemblies: Compressor blades, air intake housings, and engine thrust supports made from T651 and T7351 bars with strict dimensional tolerance.

- Aircraft Seating & Interiors: Lightweight seat frames, structural fittings, and cabin reinforcement parts manufactured using 7075-TF and 7075-O cold finished bars.

- Missile & Satellite Frames: 7075-T7351 and forged bars used in precision brackets, payload supports, and antenna arms in aerospace electronics and defense sectors.

- Ground Support Equipment: Deployment tools and structural frames supplied for maintenance hangars, emergency systems, and mobile platforms.

Chalco 7075 aerospace aluminum related products

7075 aluminum bar

7075 aerospace plate

7075 aerospace forging

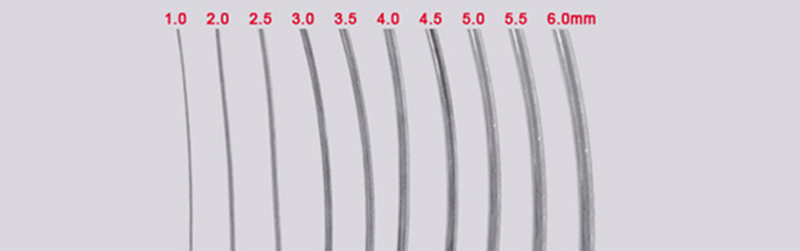

7075 aerospace wire

7075 aerospace extrusion

7075 military profile

FAQ for purchasing 7075 aerospace aluminum rods bar

Q1: Where can I purchase high-quality 7075 aerospace aluminum rods?

A: When buying 7075 aerospace aluminum rods, ensure the selected materials meet relevant standards for chemical composition, physical properties, and other indicators to guarantee stable and reliable quality. Selecting a reputable supplier like Chalco is key to obtaining reliable quality and comprehensive pre-sales and after-sales support.

Instant QuoteQ2: Can I find 7075 aerospace aluminum rods at a lower price?

A: The price of 7075 aerospace aluminum rods is influenced by factors like market supply and demand, raw material costs, processing expenses, specifications, and more. Various manufacturers and suppliers may have different pricing strategies and levels. Currency exchange rates and international economic conditions can also impact prices. Contact Chalco aluminum for a competitive quotation and service.

Instant QuoteQ3: How do I choose the size of 7075 aerospace bars?

A: The size of 7075 aerospace aluminum rods includes parameters like diameter, length, cross-sectional shape, and thickness, which should be chosen based on specific application requirements. Determine the required size range and tolerance needs when making a purchase, adhering to standard regulations.

Instant Quote