Due to its excellent mechanical properties and excellent corrosion resistance, 6056 aluminum alloy is widely used in aerospace, rocket engines and other fields.

Why choose Chalco ALuminum's 6056 T4 T6 aerospace aluminum wire?

Quality could full meet world wide aviation standard

AMS 4190H

AMS 4191E

Production and management comply with international aviation quality system certification

AS9100

OHSAS 18001

ISO14001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

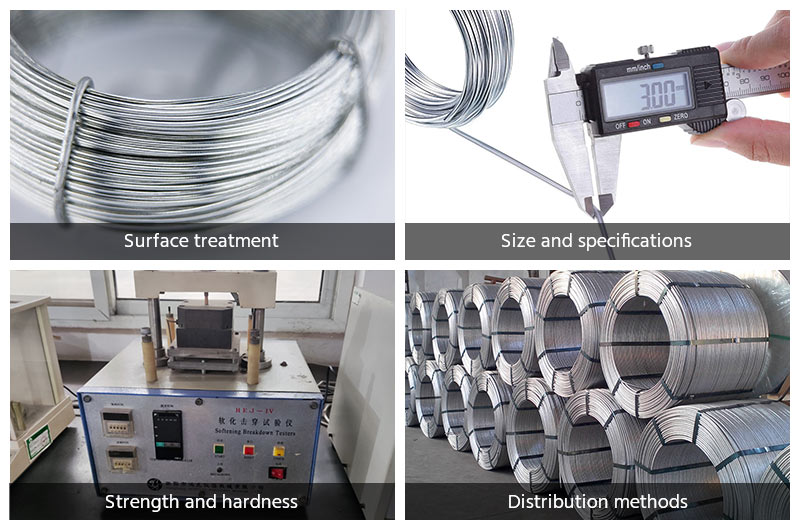

Specs of 6056 T4 T6 aerospace aluminum wire

| Alloy | 6056 |

| Temper | O, T4, T6 |

| Diameter | 1mm-50mm |

| Packing | Spools |

| Standard |

AMS 4190H AMS 4191E |

Chemical composition of 6056 aluminum alloy

| 6056 Alloy % | |

| Si | 0.7-1.3 |

| Fe | 0.50 |

| Cu | 0.5-1.1 |

| Mn | 0.40-1.00 |

| Mg | 0.6-1.2 |

| Cr | 0.25 |

| Zn | 0.1-0.7 |

| Ti+Zr | 0.20 |

| Al | Remainder |

Physical property of 6056 aluminum wire

| Physical property | 6056 T6 aluminum wire | 6056 T4 aluminum wire |

| Diameter | 1-12mm | 1-12mm |

| Tension strength | ≥550 MPa | ≥380 MPa |

| Yield strength | ≥470 MPa | ≥250 MPa |

| Elongation | ≥5% | ≥15% |

| Physical property | 6056 T6 aluminum wire |

| Diameter | 12.1-50mm |

| Tension strength | ≥515 MPa |

| Yield strength | ≥455 MPa |

| Elongation | ≥6% |

Features of 6056 aerospace aluminum wire

6056 aluminum wire is a high-strength, corrosion-resistant aluminum alloy material with the following properties:

High strength: 6056 aluminum wire has high strength and rigidity, can withstand large loads and stresses, and is suitable for manufacturing aerospace structural parts that require high strength.

Good corrosion resistance: 6056 aluminum wire can still maintain good corrosion resistance under high temperature, high humidity and harsh environments, and is not easily affected by oxidation, corrosion and wear.

Lightweight: the density of 6056 aluminum wire is low, about 2.78g/cm3, which is about one-third of that of steel, which can effectively reduce the weight of structural parts.

Good machinability: 6056 aluminum wire can be processed by forging, extrusion, rolling and other processing techniques, which is convenient for manufacturing aluminum products of various shapes and specifications.

Good conductivity: 6056 aluminum wire has excellent conductivity and can be used in fields that require conductivity.

To sum up, 6056 aluminum wire has the characteristics of high strength, good corrosion resistance, light weight, good machinability and good electrical conductivity, and is one of the widely used aluminum alloy materials in the aerospace field.

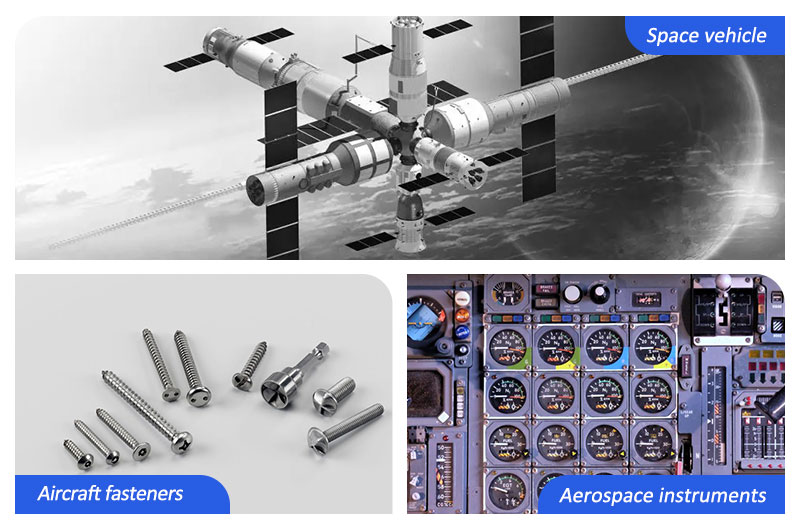

Uses of 6056 aerospace aluminum wire

Aircraft fasteners: the high strength and low density of the aluminum alloy material can effectively reduce the weight of the aircraft, improve fuel efficiency and flight performance.

Spacecraft: spacecraft needs to be lightweight, high-strength and corrosion-resistant. 6056 aluminum wire can be used to manufacture various structural parts and components of spacecraft such as satellites and rockets.

Aerospace instruments: 6056 aluminum wire can be used to manufacture aerospace instruments, such as measuring equipment, navigation instruments, etc. The material has the characteristics of high strength, corrosion resistance and electrical conductivity, which can ensure the performance and stability of the instrument.

What precautions should be taken when purchasing 6056 aerospace aluminum wire?

Material specifications and status: appropriate material specifications and status should be selected according to specific usage scenarios and requirements.

Material quality: regular suppliers should be selected to ensure that the material quality meets the requirements of relevant standards.

Material packaging: attention should be paid to whether the packaging of the material is intact to avoid material damage during transportation and storage.

Material price: price comparison should be carried out according to the market situation and the actual situation of the supplier, and a reasonable price should be selected.

Delivery date: the delivery date should be confirmed with the supplier to ensure that the material can arrive on time.

Logistics and transportation methods: appropriate logistics and transportation methods should be selected to ensure that materials can be transported to designated locations in a safe and timely manner.

Other precautions: during the purchase process, attention should also be paid to the comprehensive evaluation of the supplier's qualification, reputation and service level to ensure that the 6056 aluminum wire that meets the requirements is purchased.