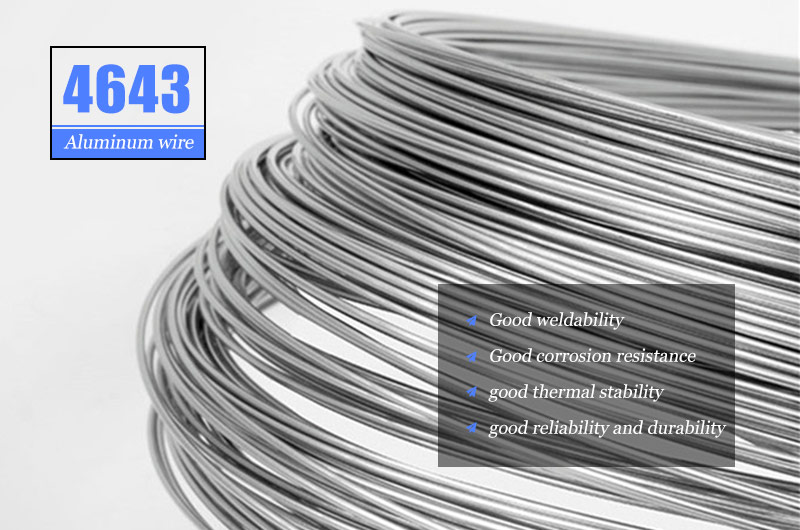

The 4643 aviation aluminum wire produced according to AMS 4189, UNS A94643, USWC 4189(C) standards is a high-strength aluminum alloy wire, which is usually used in the manufacture and processing of the aviation field; in addition, it has good welding performance and low thermal deformation, can also be used as aviation welding materials.

Why choose Chalco 4643 aviation aluminum wire?

Chalco Aluminum provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

Quality could full meet aviation standard.

Standard

AMS 4189,

UNS A94643,

USWC 4189(C),

ER 4643 (AWS A5.10) etc.

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO9001

NADCAP HT

NADCAP NDT

IATP16949

We have a complete set of domestic advanced aerospace materials research and development, testing and analysis instruments, which guarantee the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements. In addition, our R&D & innovation and verification capabilities can help enhance customers' competitiveness by saving time and cost in new product development and marketing.

The Chalco brand stands for quality, delivery and a solid reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.

The specification introduction of 4643 aerospace aluminium alloy wire

| Alloy | 4643 |

| Temper |

Soft temper: O Hard temper: H14, H16, H18, H19, H22, H24, H26 etc. |

| Diameter(mm) | 0.8-10 |

| Standard Sizes Available with TIG(mm) Straight wire | 1.6, 2.0, 2.40, 3.0, 3.2, 4.0, 5.0 etc. Length: 1000 |

| Standard Sizes Available with MIG (mm) Reel-mounted wire | 0.8, 1.0, 1.2, 1.6 etc. |

| Packing with TIG Straight wire | Carton box, wooden pallet |

| Packing with MIG Reel-mounted wire (Spools with diameter) | Spools with Carton box, wooden pallet 100mm, 200mm, 270mm, 300mm, etc. |

The chemical composition of 4643 aircraft aluminum wire

| 4643 Alloy % | |

| Si | 3.6-4.6 |

| Fe | 0.8 |

| Cu | 0.10 |

| Mn | 0.05 |

| Mg | 0.10-0.30 |

| Zn | 0.10 |

| Be | 0.0008 |

| Ti | 0.15 |

| Al | Remainder |

The physical properties of 4643 aerospace aluminum wire

| Physical properties | 4643 aviation aluminum wire |

| Density | 2.69 g/cm3 |

| Melting range | 1065°- 1175°F |

What are the characteristics of 4643 aerospace-grade aluminum wire?

High strength

4643 aviation aluminum wire has high strength and hardness, can withstand large force and strain, and has good fatigue resistance and crack growth resistance, and can run stably in complex aviation application environments.

Good plasticity and weldability

4643 aviation aluminum wire has good plasticity and weldability, and can perform a variety of complex forming and welding processes. At the same time, it has good forming performance and surface quality, which can ensure the dimensional accuracy and surface quality of parts.

Good corrosion resistance

4643 aviation aluminum wire has good corrosion resistance and can be used in harsh environments for a long time. It also has high thermal stability and corrosion resistance, and can resist various corrosion and oxidation.

Lightweight

Compared with traditional metal materials such as steel and copper, 4643 aviation aluminum wire has a lighter weight, which can play a role in improving the load capacity of the aircraft and reducing the weight of the aircraft itself, thereby achieving a lightweight design.

Good thermal stability

4643 aviation aluminum wire has good thermal stability, can maintain its mechanical properties and stability in high temperature environment, and has good oxidation resistance and thermal expansion resistance.

Good reliability and durability

The 4643 aviation aluminum wire has undergone strict quality control and testing, which can guarantee the stability and reliability of its quality and performance, and can maintain its strength and stability in long-term use.

Easy to process and form

4643 aviation aluminum wire has good processability and formability, and can perform a variety of complex forming processes and precision machining to meet the manufacturing needs of parts of different shapes and sizes.

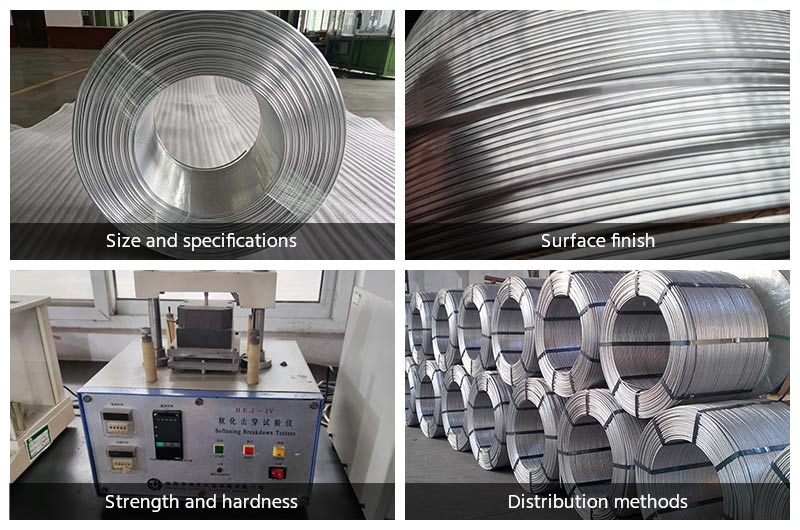

What items should be paid attention to when purchasing 4643 aircraft & aerospace aluminum wire?

Specification and size: the specification and size of 4643 aviation aluminum wire are very important selection factors. Chalco Aluminum can supply you with suitable specifications and dimensions according to your specific application requirements.

Material quality: selecting high-quality 4643 aviation aluminum wire can ensure its performance and reliability. Chalco Aluminum is produced in strict accordance with AMS 4189, UNS A94643 and other standards to ensure that it complies with relevant material standards and specifications.

Surface quality: the surface quality of aluminum wire is especially important for some applications, such as high-precision machining, electronic components, etc. Chalco Aluminum can provide aluminum wire with smooth surface, no scale and burrs to ensure its processing and use quality.

Price: considering the price of 4643 aviation aluminum wire, the price of Chalco Aluminum is moderate, and it is widely favored by aviation parts manufacturers.

Certificate and certification: if you use 4643 aviation aluminum wire in the aviation field, Chalco Aluminum has AS9100, OHSAS 18001 and other certifications to ensure that the 4643 aviation aluminum wire you purchase meets the relevant aviation material standards and certification requirements.

Packaging and transportation: since 4643 aviation aluminum wire is a high-precision material, Chalco Aluminum adopts appropriate packaging and transportation methods to ensure that it can be fully protected during packaging and transportation.

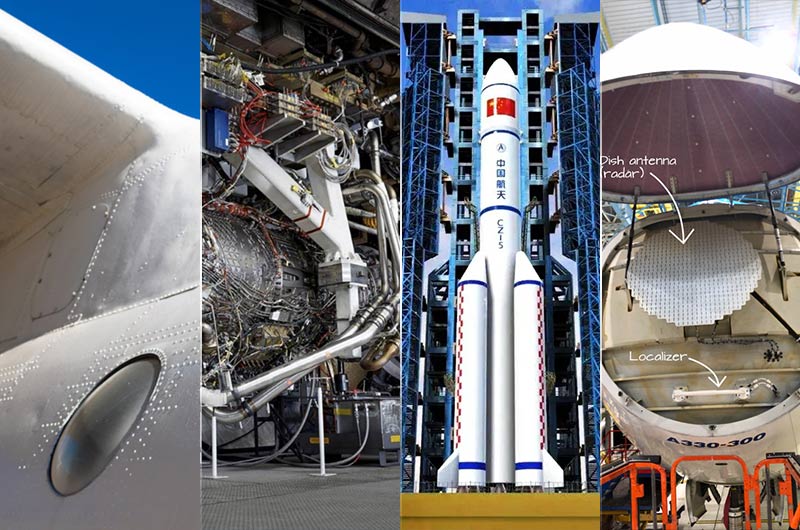

The usage of 4643 aviation aluminum wire

Applications of 4643 aluminum wire in the aerospace field

4643 aluminium alloy wire is a high-strength aluminum alloy wire, which is also widely used in the aviation field.

In the field of aerospace, 4643 aluminum wire is mainly used in the manufacture of fasteners, screws, rivets and other connections in aircraft structures. Compared with other aluminum alloy wires, 4643 aluminum wire has higher strength and better corrosion resistance, and can withstand greater loads and harsher environments in aircraft structures.

In addition to connectors, 4643 aluminum wire can also be used to manufacture electrical wiring harnesses and electrical connectors inside aircraft. Due to its high strength and good workability, 4643 aluminum wire can withstand the vibration and shock of the aircraft, and can easily install and connect various electrical equipment in the aircraft.

Welding applications of 4643 aluminum wire in the aerospace field

4643 aluminum welding wire is widely used as welding material in the aviation field, mainly for TIG (argon arc welding) and MIG (gas shielded welding) welding of aluminum alloys. The following are some welding applications of 4643 aluminum wire in the aviation field:

Welding of aircraft structural parts: 4643 aluminum wire can be used for welding of aircraft structural parts, such as wings, fuselage, empennage, etc. Due to its high strength and good weldability, it can withstand important loads and vibrations in aerospace devices.

Welding of aerospace equipment: in addition to welding of aircraft structural parts, 4643 aluminum wire can also be used for welding of aerospace equipment, such as satellites, rockets, missiles, etc. These devices usually require high strength and lightweight materials, and 4643 aluminum wire just meets these requirements.

Welding of aviation electrical equipment: 4643 aluminum wire can also be used for welding of aviation electrical equipment, such as radar, communication equipment, aviation instruments, etc. These devices often require lightweight and high-strength materials to ensure the performance and safety of aerospace components.

Welding of aviation aluminum alloy sheets: 4643 aluminum wire can be used for TIG welding of aviation aluminum alloy sheets, such as aircraft skins, ribs, etc. Due to the good machinability of 4643 aluminum wire, high-precision welding can be achieved, so it can be used to manufacture high-quality aeronautical components.

Welding in high temperature environment: 4643 aluminum wire can be used for welding in high temperature environment, such as jet engine, rocket engine, etc. Because 4643 aluminum wire has good high temperature resistance and oxidation stability, reliable welding can be achieved under high temperature and extreme conditions.