Why choose Chalco?

Certifications

AS9100

OHSAS 18001

ISO14001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

Standard

ASTM B221

ISO 209-1

Production request

The production requirements for 2A02 aircraft aluminum rod are typically governed by industry standards and regulations that specify the material composition, manufacturing process, and quality control procedures that must be followed to ensure the material meets the required performance and safety standards.

Some of the key production requirements for 2A02 aircraft aluminum rod include:

Chemical composition: the chemical composition of the 2A02 aluminum alloy must meet the specifications outlined in industry standards, such as ASTM B221 or ISO 209-1.

Manufacturing process: the manufacturing process for 2A02 aluminum rod typically involves extrusion, which involves shaping the material by forcing it through a die. The process must be carefully controlled to ensure the material meets the required dimensional tolerances and surface finish.

Heat treatment: the 2A02 aluminum rod must undergo a specified heat treatment process to achieve the desired mechanical properties, such as strength and ductility. The specific heat treatment process will depend on the required temper, which may be T6, T651, T3, T4, T8 or other.

Quality control: to ensure the material meets the required performance and safety standards, rigorous quality control procedures must be followed throughout the manufacturing process. This may include inspection of the raw materials, dimensional and surface finish checks during extrusion, and mechanical testing of the finished product.

In addition to these production requirements, 2A02 aircraft aluminum rod may also be subject to additional specifications and requirements based on the specific application and customer requirements. It is important to work with a reputable supplier who can provide material that meets the required production requirements and quality standards.

2A02 aircraft aluminum rod size

Diameter: 6.35mm-254mm

Length: 1m-12m or as required

People concern about 2A02 aerospace aluminum rod

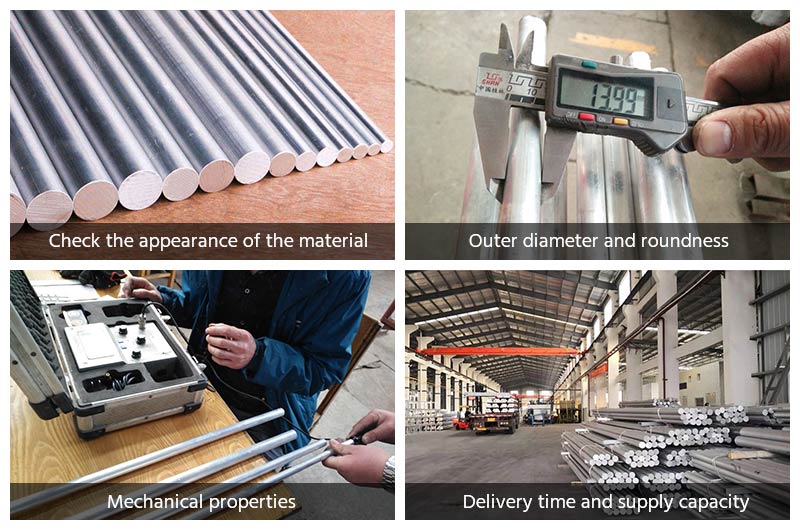

Material Quality: customers need to ensure that the 2A02 aircraft aluminum rods they purchase meet the required chemical composition and mechanical property requirements, as well as the relevant industry standards and regulations, such as ASTM or ISO standards.

Dimensional accuracy: customers may be concerned about the accuracy of the diameter, length and other dimensional parameters of the 2A02 aircraft aluminum rods to ensure compliance with their design requirements.

Surface finishes: customers may require specific surface finishes to meet their application requirements and aesthetic standards.

Delivery time and supply capacity: customers may need to deliver on time and ensure supply capacity in order to meet their production needs.

Price and cost effectiveness: customers need to consider the price and cost effectiveness of 2A02 aircraft aluminum rods to ensure that they receive a high-quality product while staying within their budget.

2A02 aerospace aluminum rod chemical composition

| Element | Composition |

| Si | 0.3 |

| Fe | 0.3 |

| Cu | 2.6-3.2 |

| Zn | 0.1 |

| Mn | 0.45-0.7 |

| Mg | 2.0-2.4 |

| Ti | 0.15 |

| Remainder (each) | 0.05 |

| Remainder (total) | 0.1 |

| Al | Remainder |

2A02 aerospace aluminum rod mechanical property

Tensile strength: approx. 350 MPa

Yield strength: approx. 200 MPa

Elongation: approx. 16%

Hardness: HB95

2A02 aerospace aluminum rod application

2A02 aviation aluminum bar is a common aviation aluminum alloy material, widely used in the manufacture of aircraft structural components, such as aircraft fuselage, wings, brackets, rudder surfaces and flaps.

Among them, the wing is one of the key components of the aircraft, bearing great weight and wind impact. 2A02 aviation aluminum bar can meet the requirements of high strength, high stability and impact resistance of the wing components. In addition, 2A02 aviation aluminum bar also has good corrosion resistance and wear resistance, which makes it advantageous in the service life of aircraft.

In addition to the wing, 2A02 aviation aluminum bar is also commonly used in the manufacture of aircraft shells and fuel tanks and other components. In the engine, 2A02 aviation aluminum bar is also commonly used in the manufacture of engine parts.

In short, 2A02 aviation aluminum bar is widely used in the aviation industry, with excellent mechanical properties, good processing performance and light weight, becoming an irreplaceable material in the aviation industry.