Specifications of Chalco Aluminium alloy 1145 aerospace sheet plate

Alloy: 1145

Material temper: O, etc.

Standards: AMS 4011

Thickness: usually between 0.5mm and 100mm,

Width: 1000mm, 1220mm, 1500mm

Length: can be customized according to needs, it may vary from a few centimeters to tens of meters.

Chemical composition of Chalco 1145A aerospace aluminum alloy

| 1145 alloy chemical | |

| Chemical Element | % Present |

| Mn | 0.05 |

| Mg | 0.05 |

| Cu | 0.05 |

| Ti | 0.03 |

| V | 0.05 |

| Zn | 0.05 |

| Other (Each) | 0.05 |

| Aluminium (Al) | 99 |

Mechanical properties of Chalco 1145 aerospace high quality sheet plate

| Material Sheet, Strip, Plate | Temper | Thickness (mm) | Tensile strength (N/mm²) | Elongation in 50mm % | ||||

| 0.5mm | 0.8mm | 1.3mm | 2.6mm | 30mm | ||||

| Alloy 1145 | O | 0.2 - 10 | 60-100 | 15 | 20 | 25 | 30 | 28 |

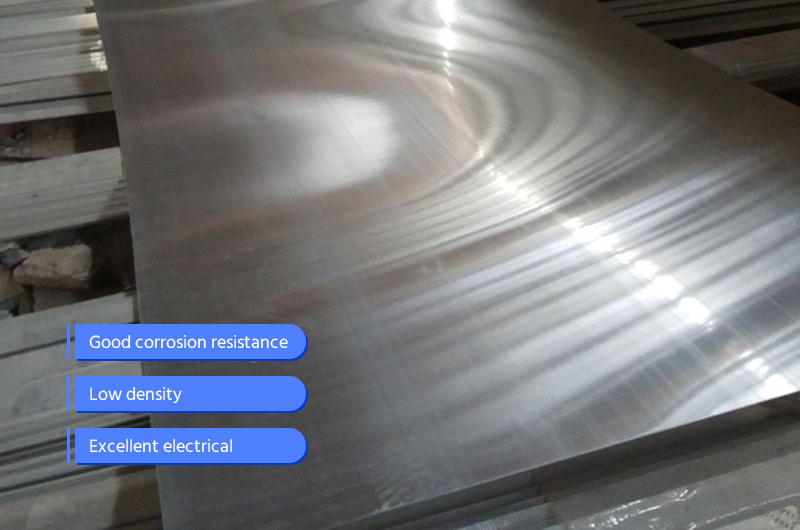

Product features of Chalco 1145 aviation aluminum alloy sheet plate

Good corrosion resistance: 1145 aluminum alloy plate has good corrosion resistance and can resist the erosion of most chemical substances.

Good formability: 1145 aluminum alloy sheet can be formed by rolling, stretching, etc., and is easy to process into various shapes and sizes.

Low density: 1145 aluminum alloy plate has a low density and is lighter than steel. It is suitable for manufacturing high-performance products such as light aircraft.

Excellent electrical conductivity: 1145 aluminum alloy plate has excellent electrical conductivity and can be used in the manufacture of electronic devices and circuit boards.

Lower price: compared with other high-strength aluminum alloy sheets, 1145 aluminum alloy sheets are cheaper and suitable for some cost-sensitive aviation product applications.

The specific application of Chalco 1145 aviation aluminum plate O, H14 H24 temper in aviation parts

1145 aviation aluminum sheet O temper is often used in the manufacture of large structural parts such as aircraft shells, fuselages, and wing surfaces, as well as small parts such as wings and fuselages. In addition, it is also used in the manufacture of bulkheads, dashboards, seats, shelves and other accessories inside aircraft.

The high strength and light weight of the O-temper of 1145 aviation aluminum sheet make it an ideal material for manufacturing aviation components. It is also very resistant to corrosion, able to maintain its performance and appearance in harsh environments. These characteristics make 1145 aviation aluminum sheet O temper widely used in the manufacture of civil and military aircraft.

Production process of Chalco Aluminum alloy 1145 (UNS A91145) sheet plate

Preparation of aluminum ingots: aluminum ingots are raw materials for the production of aluminum plates, and are generally prepared by electrolysis or alumina pyrolysis.

Smelting: heating the aluminum ingot to the melting point, and adding a small amount of alloying elements such as copper and magnesium to improve the strength and hardness of the aluminum plate.

Continuous casting: the molten aluminum is continuously cast into a slab with a thickness of about 200mm through a continuous casting machine.

Rough rolling: the slab is sent to the rough rolling mill, and after several times of rolling, the thickness is gradually reduced to reach the target thickness.

Hot rolling: send the rough-rolled slab into a hot rolling mill for multiple rolling and annealing treatments to achieve ideal mechanical properties and surface quality.

Milling and cutting: milling and cutting the hot-rolled aluminum sheet to make aluminum sheets of different sizes and shapes.

Inspection and packaging: strict inspection and testing are carried out on the aluminum plate to ensure that it meets the standards of the aviation industry, and then it is packaged and shipped.

Why choose Chalco Aluminium as alloy 1145 aerospace sheet plate aircraft materials manufacturer?

Chalco provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting future challenges.

We have a complete set of domestic advanced aerospace materials research and development, testing and analysis instruments, which guarantee the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements.

In addition, our R&D & innovation and verification capabilities can help enhance customers' competitiveness by saving time and cost in new product development and marketing.

We have passed the AS9100 certification required by the aviation industry and the Colin Aviation certification, and produce according to the AMS 4011standard required by customers, providing a strong guarantee for the quality of aerospace materials produced by our company.

The Chalco brand stands for quality, delivery and a solid reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.