Forgings play a critical role in military platforms—from armored vehicles and missile launchers to naval and aerospace systems—offering superior strength, fatigue resistance, and durability under extreme conditions.

Chalco provides customized medium and large military forgings with full in-house capabilities: free forging, die forging, ring rolling, heat treatment, CNC machining, and NDT. Our solutions meet demanding requirements for strength, safety, weight reduction, and traceability, serving major defense programs across land, sea, air, and space.

- Aviation and missile systems: fighter landing gear, fuselage and wings, flight control and transmission systems

- Ground combat platforms: Tank systems, armored vehicles, self-propelled artillery and special vehicles

- Naval vessels and underwater combat systems: surface ships, propeller shafting and power modules, submarines and underwater platforms

- Weapon systems: artillery and ammunition, precision guidance and electronic systems, multi-purpose support and interfaces

- Missile systems: tactical missile structures, strategic missiles and long-range aircraft, missile launch platforms

- Command, Control and Protection Systems: radar mounts, control housings, and protective armor components

The most critical guarantee for military product supply: strict confidentiality and professional services

We support signing confidentiality agreements to ensure full confidentiality throughout the design and model development process, with strict access control to safeguard clients’ core information.

We cooperate with clients on drawing optimization, structural improvements, and material upgrades, assisting with first-article verification and project finalization to ensure precise product matching.

Multiple production lines are coordinated to quickly respond to single-piece trials and small-batch deliveries, ensuring project timelines and flexibility.

From smelting, forging, processing to testing, every step is fully recorded to support project compliance and filing.

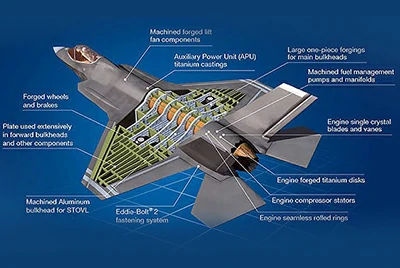

Application of aviation forgings | high-strength core component solutions for load-bearing, connection and lightweight

Modern aircraft require components that are strong, lightweight, and fatigue-resistant—making forgings ideal for landing gear, cockpit frames, and structural joints. Chalco supplies aerospace-grade aluminum, titanium, and steel forgings for various aircraft types through advanced forging processes. Below are recommended alloys and typical application parts.

Military fighter and transport aircraft landing gear system forgings

The landing gear is the main load-bearing structure during aircraft takeoff and landing. It bears the huge load of the aircraft during ground taxiing and landing impact, and has extremely high requirements on the strength, impact toughness and processing accuracy of the forgings.

Contact us now

Chalco military fighter and transport aircraft landing gear system adaptation product display

- Main support shaft

- Connecting forged shaft

- Landing gear flange

- Buffer guide

- Install forging block

- Cover structure

Fuselage and wing structural forgings

Structural parts such as the mid-fuselage frame, wing roots and pylons have extremely high requirements for the accuracy, streamline direction and consistency of forgings, especially in supersonic models, which require matching high-performance aluminum materials.

Contact us now

Chalco fuselage and wing structure forgings adaptation product display

- Wing-body connection

- Spar reinforcement ring

- Cabin frame support

- Mounting ring

Flight control and transmission system forgings

The flight control system 's servo connectors, transmission shafts and guide structures are small and medium-sized high-precision forgings, which require both structural stability and processing accuracy.

Contact us now

Chalco flight control and transmission system forgings adaptation product display

- Power transmission shaft

- Servo connection flange

- Flight control guide ring

Land combat platform forging application | core structural solutions that emphasize both pressure bearing and impact resistance

In the Army platform, whether it is the main battle tank for assault operations, or the multi-purpose armored vehicles, self-propelled artillery and missile launch platform, they all rely on key forgings with strong structures and reliable service to ensure their survivability and mobility. Forgings not only bear high impact loads, but also need to maintain dimensional stability and connection strength in extreme terrain. Chalco can provide forging solutions of various materials including aluminum alloys, titanium alloys and high-strength steel to meet the Army platform's multiple performance requirements for strength, lightweight, corrosion resistance and other requirements.

Tank system forgings

Main battle tanks have extremely high requirements for forging strength, fatigue resistance and dimensional stability, which are mainly concentrated on key structures in load-bearing and rotating parts.

Contact us now

Chalco tank system forgings adaptation product display

- Main gun base support

- Track drive shaft shaft

- Transverse body flange

- Turret rotating platform ring

- Transmission connector plate

Structural forgings for armored vehicles and wheeled assault vehicles

Armored vehicle chassis, drive systems and other parts require lightweight, high-strength forgings that combine corrosion resistance with impact bearing capacity under complex terrain.

Contact us now

Chalco armored vehicles and wheeled assault vehicles structural forgings adaptation product display

- Wheel bushing axle

- Drive axle flange

- Chassis reinforcement ring

- Armor support block

Application of structural forgings for self-propelled artillery and special vehicles

Artillery and battlefield support vehicles (such as obstacle-laying vehicles, mine-clearing vehicles, and repair vehicles) need to withstand high loads, high heat, and severe impacts, and are suitable for large-size, high-toughness alloy material solutions.

Contact us now

Chalco self-propelled artillery and special vehicle structural parts forgings adaptation product display

- Gun carriage plate

- Ammunition connector

- Rear anchor shaft

- Explosion-proof ring

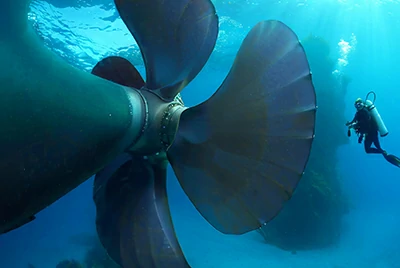

Naval and underwater combat forging applications | corrosion resistance and structural core support

Modern naval platforms demand high corrosion resistance, strength, and long-term stability for key components. Forgings are essential for propulsion shafts, pressure hulls, and structural joints due to their dense structure and controlled grain flow. Chalco provides aluminum, titanium, and special steel forgings for hulls, drive systems, and control modules, supporting custom shafts, rings, and complex parts.

Surface ship structural system

Forgings used to connect the ship's frame and supports must have both large-size forming capabilities and seawater corrosion resistance, and are the core foundation of the ship's structural strength and stability.

Contact us now

Chalco surface ship structure system forgings adaptation product display

- Propeller shaft forging

- Intermediate shaft joint

- Steering base forging

- Rudder support forging

- Stern shaft ring

- Sealing flange

- Hull frame ring

Propeller shaft system and power module

The ship propulsion shaft system requires high axial strength, fatigue resistance and dimensional consistency. It is one of the systems with the most stringent requirements for precision turning and multi-pass quality control.

Contact us now

Chalco propeller shaft system and power module forgings adaptation product display

- Propeller shaft forging

- Intermediate shaft forging

- Sealing flange ring

- Thrust base forging

Submarine and underwater platform structures

Underwater unmanned platforms, submersibles and other equipment require both lightweight and structural pressure resistance, and are suitable for thin-walled, complex configuration and large-size forging solutions.

Contact us now

Chalco submarine and underwater platform structure forgings adaptation product display

- Pressure tank head forging

- Main thruster sleeve

- Cabin flange & seal ring

- Sonar bracket forging

Application of weapon system forgings | performance support for high-precision load-bearing structures and high-speed moving parts

Modern weapon systems demand materials with high fatigue resistance, thermal stability, and precise dimensional control under extreme conditions. Forgings meet these needs with superior strength and customizability. Chalco offers integrated forging solutions for artillery, missiles, and launch systems, delivering high-strength, high-reliability, and complex-shaped components.

Forgings for artillery and ammunition launching systems

Key forgings used in artillery mainframes, magazine structures, etc. must have excellent dynamic load-bearing capabilities and thermal fatigue resistance, and are the main load-bearing components in weapon systems.

Contact us now

Chalco forgings for artillery and ammunition launching system

- Gun carriage forging ring

- Ammunition chamber bracket

- Fire control base forging

- Launch rail flange

Precision guidance and electronic systems

Forgings for parts such as the seeker and control mechanism must have excellent dimensional stability and electromagnetic compatibility, taking into account both structural strength and the ability to form complex shapes.

Contact us now

Chalco precision guidance and electronic system adaptation product display

- Gyro platform housing

- Guide cabin support block

- Micromotor mounting ring

- Photoelectric bracket part

Multi-purpose support and interface connectors

Modular weapon systems require forgings to have multi-position coordination and complex geometric compatibility, which is the basic support for system integration capabilities.

Contact us now

Chalco support and interface connection forgings adapter product display

- Reinforcement flange

- Tail thread connection block

- System conversion ring

- Multi-axis rotating sleeve

Missile system forging applications | structural support materials under high-speed flight and extreme loads

Missile system forgings must withstand high speeds, vibration, and temperature extremes, demanding exceptional strength and stability. Chalco supplies key structural components like barrel rings, nozzle flanges, and control system parts for tactical missiles, strategic aircraft, and launch platforms.

Tactical missile structural forgings

Suitable for the main structure of tactical missiles, it needs to take into account strength, light weight and rapid processing capabilities to meet the needs of rapid deployment and high-intensity combat environments.

Contact us now

Chalco tactical missile structural parts forgings adaptation product display

- Tail nozzle ring

- Projectile head

- Thrust cylinder ring

- Attitude control flange

Strategic missiles and long-range aircraft forgings

Such systems need to withstand longer ranges, greater temperature differences and stronger combustion shocks, and place extremely high demands on the forming consistency and structural strength of forgings.

Contact us now

Chalco strategic missile and long-range aircraft forgings adaptation product display

- Missile cylinder ring

- Nozzle ring & base block

- Combustion casing forging

- Main bearing flange

Land-based missile launch platform structural parts

Of the launch device must have good assembly stability and reusability, while supporting the processing and inspection of large-sized and complex forgings.

Contact us now

Chalco land-based missile launch platform structural parts adaptation product display

- Launch tube flange

- Hydraulic lift bracket shaft

- Base support ring

Forgings for command control and protection systems | equipment solutions with high protection and structural stability

As key platforms for battlefield information processing and survivability, command and control systems and ground protection systems pose multi-dimensional challenges to the protection level, load strength and environmental adaptability of structural components. Whether it is the missile launch platform base, radar array support, electronic jammer mounting ring, or vehicle-mounted armor module connection, forgings have become irreplaceable basic structural parts in these systems with their outstanding strength, stability and customizability.

Chalco can provide a variety of forging products made of aluminum alloy, titanium alloy and high-strength steel, and support the customization of complex structures such as special-shaped forgings, flange rings, heavy-load connecting rings, etc. With ±0.05mm level processing accuracy and full-process quality control system, it can meet the stringent military standards.

| Application area | Recommended alloy | Features |

| Missile launch platform structural frame | 7050 / 2024 / Ti-6Al-4V | High strength and corrosion resistance, suitable for alternating load environment |

| Electronic warfare system device fixing ring | 6061 / 7075 / Gr.5 | Balance of strength and processability, suitable for high-precision connection and assembly |

| Radar system mounting base/connection flange | 2219 / Gr.9 / 42CrMo | Excellent thermal stability and weldability, suitable for large and complex radar structure support |

| Electromagnetic interference and communication equipment support structure | 6082 / Gr.2 / 17-4PH | Anti-corrosion, resistant to environmental changes, suitable for structural base of high-altitude/coastal deployment devices |

| Vehicle protection module load-bearing connection ring | 7075 / Gr.5 / 35CrMo | High specific strength + fatigue resistance, suitable for dynamic impact load parts |

| Remote command platform base | 6061 / 2024 / Ti-6Al-6V-2Sn | It has both weldability and strength, suitable for medium and strong loads and equipment interface structures |

| Armor module flange connector | 7050 / Gr.5 / 20CrMnTi | Impact resistant, with high-strength steel/ceramic composite armor structure |

| Tactical communication relay station structural support and docking ring | 2219 / Ti-6242 / 42CrMo | High temperature stability and strong structural integrity, suitable for continuous operation environment |

Overview of alloy standards and configurations for common military forgings

In order to meet the multiple requirements of strength, fatigue, corrosion resistance and thermal stability of different aircraft structures, power systems and hot-end components, Chalco has a long-term inventory of a variety of aviation-grade forging alloys, and can provide cut-to-length processing and heat treatment state customization according to customer needs. All products support third-party inspection and standard traceability.

Instant QuoteAluminum alloy forgings

| Type | Temper | Specifications |

| 2014 Aluminum | T6 / T651 | AMS4133, 4134, 4314, AMS-A-22771 |

| 2024 Aluminum | T4 / T42 / T6 | AMS-QQ-A-367 |

| 2219 Aluminum | T6 / T62 | AMS4143, 4144, AMS-QQ-A-367, AMS-A-22771 |

| 2618 Aluminum | T61 / T651 | AMS4132, AMS-QQ-A-367, AMS-A-22771 |

| 5083 Aluminum | O / H111 | ASTM B247 / GB/T 6892 / ISO 6361 |

| 6061 Aluminum | T6 / T651 | AMS4127, 4146, AMS-QQ-A-367, AMS-A-22771 |

| 6082 Aluminum | T6 / O | EN 586 / ISO 6361 / GB/T 6892 |

| 7049 Aluminum | T73 / T7351 | AMS4111, AMS-QQ-A-367, AMS-A-22771 |

| 7050 Aluminum | T74 / T76 | AMS4107, 4108, AMS-A-22771 |

| 7075 Aluminum | T6 / T73 / T76 | AMS4126, 4131, 4141, 4147, AMS-QQ-A-367 |

| 7175 Aluminum | T73651 / T7351 | AMS4148, 4149, 4179, AMS-A-22771 |

| 7475 Aluminum | T61 / T7351 | AMS 4085 / HB |

Titanium alloy forgings

| Type | Specifications |

| CP-GRADES 1, 2, 3, 4 | AMS4921, ASTM-B348 |

| 6Al-4V | AMS4928, 4931, 4965, AMS-T-9047, C50TF12 |

| 6Al-4V ELI | AMS4930, 4931, 6932, BMS-7-269 |

| 6Al-2Sn-4Zr-2Mo | AMS495, 4976, B50TF22 |

| 6Al-6V-2Sn | AMS4978 |

| 8Al-1Mo-1V | AMS4972, 4973, C50T81 |

| 10V-2Fe-3Al | AMS4983 |

Military general forgings product types

Forged Ring

Used for sealing connections, fuselage reinforcement, fuel tank interfaces.

Forged Block

High-strength support, bracket anchor point, control system carrier.

Forged Shaft

Landing gear struts, control shafts, transmission systems.

Forged Disc

Engine flange, tail nozzle connection, wheel rim structure.

Forged Plate

Bulkheads, support panels, structural reinforcements.

Forged Tube

Fuel pipe interfaces, cooling system accessories, support insulation sleeves.

Chalco military and defense equipment forging manufacturing capabilities

Large-tonnage open forging and precision die forging system

Equipped with an 80,000kg open forging hammer and a 12,000-ton hydraulic press, capable of forming structural parts up to Ø2500mm in diameter and 23m in length;

Multi-station closed die forging technology suitable for complex curved precision forgings;

Parallel production of multiple materials including titanium alloy, aluminum alloy, and steel.

CNC ring rolling and integrated forming process

Maximum ring size of Ø3500mm × 1000mm;Radial and axial synchronous rolling ensures streamlined integrity and roundness error ≤0.05%, meeting high-precision requirements.

Aerospace/military heat treatment system

Vacuum heat treatment and precision cooling system suitable for various alloys;

Supports multiple heat treatment states and complies with GJB, HB, AMS, MIL standards.

Precision machining capabilities

Vertical/horizontal lathes with diameters up to Ø5000mm and lengths up to 15m;

Five-axis machining centers with positioning accuracy of ±0.015mm;

Supports a variety of complex machining processes.

FAQs for purchasing military forgings

What materials do you support for military forgings?

Chalco can provide a variety of forging materials such as aluminum alloy, titanium alloy, steel, copper alloy, etc. to meet the different performance requirements of military equipment for lightweight, high strength, corrosion resistance, impact resistance, etc. Aluminum alloys include 7075, 7050, 2219, 2618, 2024, etc. Titanium alloys include TA2, TC4, Ti-6242, etc. Steel supports alloy steel, stainless steel, high-strength alloy steel, etc.

Can military forgings comply with national military standards or industry standards?

Yes. We support the implementation of multiple standards such as GJB, HB, AMS, ASTM, ISO, etc. We can also customize processing according to the drawings or technical agreements provided by users to ensure that all kinds of materials and structural parts meet the requirements of the military quality system in terms of performance, traceability, delivery documents, etc.

Does it support closed die forging and special-shaped parts forging?

Yes. Chalco has a multi-station closed die forging system that is suitable for complex nodes, connection flanges, tail nozzle rings, special-shaped reinforcements and other structures commonly found in military equipment. We can also provide a mixed process of free forging and die forging to meet the dual requirements of precision and strength of various structural parts.

Can military forgings be equipped with heat treatment and processing services?

Yes. We support heat treatment state control such as T6, T651, annealing, quenching and tempering, normalizing, solution + aging, and have finishing capabilities such as vertical/horizontal CNC turning, deep hole drilling, and five-axis milling. Customers can choose near-net-size delivery or finished product delivery to reduce the cost of later assembly.

Can you provide third-party testing and quality reports for military projects?

Yes. All forging products support ultrasonic testing, metallographic analysis, tensile testing, hardness testing and other inspection methods, and can issue authoritative third-party inspection reports such as SGS, TÜV, BV, etc. We can also provide a full set of delivery materials such as material certification, heat treatment records, process traceability documents, etc.

Does the military forging project support custom development or confidentiality agreements?

Support. We have long-term experience in serving military scientific research institutions, equipment factories, etc., and can provide collaborative development services from drawing review, material recommendation, trial production to batch delivery. The project can sign a confidentiality agreement and a project-oriented agreement to ensure data isolation and results protection.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote