If you are looking to reduce weight by 20–30% vs. aluminum alloys or replace titanium in highly loaded structures while keeping fatigue life and stiffness, high-strength ceramic aluminum matrix composites (Al-MMCs) can be a practical solution.

Chalco provides certified grades already used in C919, EV battery enclosures and rail components.

- Replace titanium beams / struts to cut weight by ~30%

- 20% higher yield strength vs. conventional 2xxx/7xxx aluminum under GB/T 228.1 tests

- Proven on C919 and EV battery enclosures, with full test reports and traceable batches

Chalco offers customized high-strength ceramic aluminum matrix composite solutions

We integrate in-situ nano-ceramic particles into various aluminum alloy grades—using aluminum as the matrix and nano-ceramics as the reinforcement—and precisely control their content and distribution.

This enables the creation of tailored ceramic aluminum matrix composites with high strength, high ductility, high stiffness, or high damping properties, meeting the performance goals of aerospace, automotive, and rail applications.

- Matrix options: Supports 2xxx, 6xxx, and 7xxx alloy systems, balancing strength, ductility, corrosion resistance, and machinability.

- Particle control: Adjust the volume fraction, size, morphology, and distribution of nano-ceramics to achieve different focuses—from surface wear resistance to overall rigidity.

- Process flexibility: Extrusion, rolling, forging, ring rolling, machining, and welding routes ensure batch consistency and reproducibility.

Popular high-strength wrought ceramic aluminum matrix composites

For high-strength wrought series such as CT7055, CT2024 and LM0xx ceramic aluminum matrix composites, Chalco can supply multiple product forms to fit different design requirements, including:

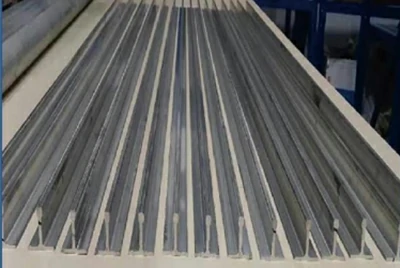

- Plates and sheets for skins, panels and structural members

- Extruded profiles for beams, frames and complex cross-sections

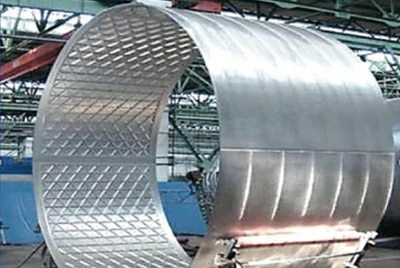

- Rings and ring-rolled sections for rotating parts and flanges

- Forgings for highly loaded, safety-critical components

- Powder feedstock for additive manufacturing and near-net-shape parts

Our company offers a wide range of high-strength Ceramic Aluminum Matrix Composites (Al-MMCs) covering different grades and application fields.

They are widely used in aerospace, automotive, and rail transportation industries where performance requirements are demanding.

High-strength CT7055 ceramic aluminum matrix composite

CT7055 Ceramic Aluminum Matrix Composite offers exceptional tensile strength and corrosion resistance, making it ideal for aerospace and other high-load structural components.

Contact us now

| Property | CT7055 (Ceramic Aluminum Matrix Composite) | 7055 (Aluminum Alloy) | Grade 5 (TC4 Titanium Alloy) |

| Ultimate Tensile Strength (MPa) | 805 | 669 | 895 |

| Yield Strength (MPa) | 750 | 655 | 825 |

| Elastic Modulus (GPa) | 86 | 71 | 109 |

| Elongation (%) | 8 | 11 | 12 |

| Density (g/cm³) | 2.96 | 2.86 | 4.44 |

| Specific Strength (MPa·cm³/g) | 0.272 | 0.234 | 0.202 |

Fatigue-resistant CT2024 ceramic aluminum matrix composite

CT2024 Ceramic Aluminum Matrix Composite offers outstanding fatigue resistance, making it an ideal choice for aerospace, automotive, and other high-cycle applications.

Contact us now

| Property | CT2024 (Ceramic Aluminum Matrix Composite) | 2024 (Aluminum Alloy) |

| Ultimate Tensile Strength (MPa) | 610 | 485 |

| Yield Strength (MPa) | 451 | 360 |

| Elastic Modulus (GPa) | 83.2 | 72.1 |

| Elongation (%) | 6.2 | 10.8 |

| Density (g/cm³) | 2.84 | 2.77 |

Other wrought ceramic aluminum matrix composites

We also offer various grades of Ceramic Aluminum Matrix Composites (Al-MMCs) to meet diverse application requirements.

-

ST051 (2xxx aluminum alloy)

Tensile strength: 500–550 MPa

Yield strength: 460–490 MPa

Elastic modulus: 75–80 GPa

Elongation: 8–10%

Density: 2.88

Process conditions: continuous casting and rolling (T8)

-

ST012 (2xxx aluminum alloy)

Tensile strength: 500–550 MPa

Yield strength: 380–480 MPa

Elastic modulus: 75–80 GPa

Elongation: 8–15%

Density: 2.86

Process conditions: continuous casting and rolling (T3)

-

LM041 (5xxx aluminum alloy)

Tensile strength: 370–400 MPa

Yield strength: 280–300 MPa

Elastic modulus: 72 GPa

Elongation: ≥7%

Density: 2.70

Process conditions: continuous casting and rolling (partial anneal)

-

LM032 (6xxx aluminum alloy)

Tensile strength: 300–320 MPa

Yield strength: 270–290 MPa

Elastic modulus: 70 GPa

Elongation: ≥6%

Density: 2.73

Process conditions: continuous casting and extrusion (T6)

-

LM052 (6xxx aluminum alloy)

Tensile strength: 340–360 MPa

Yield strength: 320–340 MPa

Elastic modulus: 71 GPa

Elongation: ≥8%

Density: 2.74

Process conditions: continuous casting and extrusion (T6)

-

LM062 (6xxx aluminum alloy)

Tensile strength: ≥400 MPa

Yield strength: ≥330 MPa

Elongation: ≥10%

Density: 2.82

Process conditions: continuous casting and extrusion/forging (T6)

-

LM044 (7xxx aluminum alloy)

Tensile strength: ≥610 MPa

Yield strength: ≥570 MPa

Elongation: ≥10%

Density: 2.82

Process conditions: continuous casting and extrusion (T6)

-

LM021 (7xxx aluminum alloy)

Tensile strength: 630–650 MPa

Yield strength: 570–590 MPa

Elastic modulus: 75–80 GPa

Elongation: 7–9%

Density: 2.86

Process conditions: continuous casting and extrusion (T6)

-

LM043 (7xxx aluminum alloy)

Tensile strength: 650–720 MPa

Yield strength: 590–650 MPa

Elastic modulus: 76–85 GPa

Elongation: 7–14%

Density: 2.88

Process conditions: powder metallurgy extrusion (T6)

-

LM042 (7xxx aluminum alloy)

Tensile strength: 680–720 MPa

Yield strength: 630–680 MPa

Elastic modulus: 75–80 GPa

Elongation: 7–9%

Density: 2.88

Process conditions: continuous casting and extrusion (T6)

-

LM032 (7xxx aluminum alloy)

Tensile strength: 700–750 MPa

Yield strength: 650–670 MPa

Elastic modulus: 75–80 GPa

Elongation: 4–7%

Density: 2.93

Process conditions: continuous casting and extrusion (T6)

These ceramic aluminum matrix composites feature exceptional strength, good ductility, and stable performance. They are widely used in aerospace, automotive lightweighting, and rail transportation industries.

In addition to ceramic aluminum matrix composites, we also supply high-strength wrought aluminum alloys such as 7075, 7050, 7055, 7068, 2024, and 2219.

These alloys meet the demanding lightweight and high-strength requirements of aerospace and automotive applications and are available in multiple specifications and temper conditions, including T6, T651, and T7451.

-

7075 aluminum alloy

A high-strength aluminum alloy for aircraft structures. Poor weldability and lower corrosion resistance.

-

2024 aluminum alloy

Good fatigue performance and high strength. Widely used in aircraft structures.

-

2219 aluminum alloy

A high-strength alloy for spacecraft structures. Offers good weldability.

-

7050 aluminum alloy

High resistance to stress corrosion. Used in aerospace structures.

-

7068 aluminum alloy

One of the strongest commercial aluminum alloys. Used in aerospace and automotive.

-

5083 aluminum alloy

Excellent corrosion resistance and weldability. Suited to marine and chemical equipment.

Advantages of high-strength wrought ceramic aluminum matrix composites

- Low density: Retains the lightweight advantage of aluminum alloys.

- High strength: Tensile strength can exceed 800 MPa, with specific strength surpassing that of titanium alloys.

- High stiffness: Elastic modulus up to about 95 GPa, giving higher specific stiffness than titanium alloys.

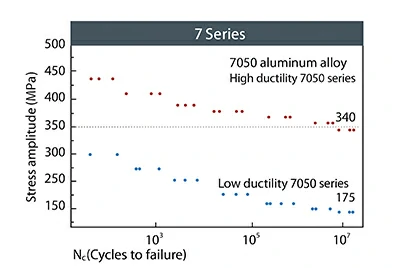

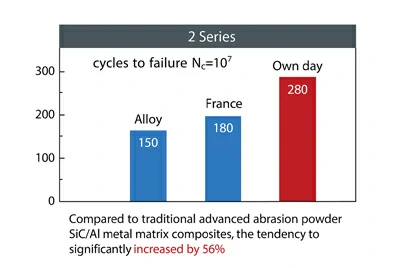

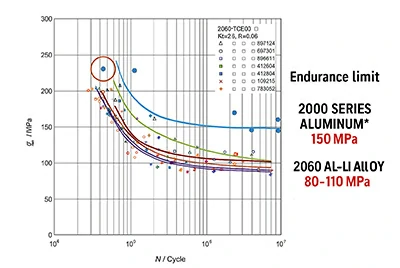

- Fatigue resistance: Under rotary bending, fatigue strength improves by about 94% over 7xxx alloys and 87% over 2xxx alloys; under axial double-hole loading, about 30% higher than AA2060 aluminum-lithium alloy.

- Wear resistance: Higher surface hardness and greatly reduced frictional wear.

- Corrosion resistance: Inherits the excellent corrosion resistance of aluminum alloys.

- High-temperature performance: Improved high-temperature strength and creep resistance with better thermal fatigue behavior.

- Excellent workability: Suitable for extrusion, rolling, forging, drawing, ring rolling, superplastic forming, machining, and welding.

Note: Specific strength and stiffness values depend on alloy grade, ceramic volume fraction, and heat treatment condition. Benchmark data can be provided based on project requirements.

Performance of high-strength wrought ceramic aluminum matrix composites

Our high-strength wrought Ceramic Aluminum Matrix Composites (Al-MMCs) demonstrate clear advantages across multiple key performance indicators.

Compared with titanium and conventional aluminum alloys, they deliver higher strength and stiffness while maintaining low weight and excellent reliability.

Mechanical properties of wrought ceramic aluminum matrix composites vs. titanium alloys

| Property | High-strength ceramic aluminum matrix composite (CT7055) | Titanium Alloy | ||

| Conventional Ingot | Rapid Solidification | Grade 12 (TC2) | Grade 5 (TC4) | |

| Ultimate Tensile Strength (MPa) | 770 | 805 | 685 | 895 |

| Yield Strength (MPa) | 751 | 750 | 620 | 825 |

| Elastic Modulus (GPa) | 84 | 86 | 108 | 109 |

| Elongation after Fracture (% | 5 | 8 | 12 | 12 |

| Density (g/cm³) | 2.96 | 2.96 | 4.55 | 4.44 |

| Specific Strength (10³ N·m²/kg) | 260 | 272 | 151 | 202 |

| Specific Stiffness (10⁶ N·m²/kg) | 28.4 | 29.1 | 23.7 | 24.5 |

Test standard: GB/T 228.1-2010. Testing institution: Analysis and Testing Center, Shanghai Jiao Tong University.

Fatigue performance of ceramic aluminum matrix composites

Compared with 7xxx series high-strength aluminum alloys, wrought Ceramic Aluminum Matrix Composites (Al-MMCs) show a 90% increase in fatigue limit.

Compared with French high-energy ball-milled powder metallurgy SiC/Al composites, their fatigue limit is 56% higher.

For 2xxx series Ceramic Aluminum Matrix Composites, the fatigue limit reaches 150 MPa, while the 2060 aluminum-lithium alloy achieves only 80–110 MPa.

Testing institution: Shanghai Aviation Materials and Structure Testing Co., Ltd.

Isotropy of ceramic aluminum matrix composites

Isotropy of 7xxx series ceramic aluminum matrix composite extrusions

| Direction | Tensile Strength (MPa) | Elongation (%) | ||

| Conventional Al-MMC | Isotropic Al-MMC | Ceramic aluminum matrix material | Isotropic | |

| LL (longitudinal) | 700 | 680-730 | 9% | 9%-12% |

| LT (long transverse) | 620 | 635-670 | 2.5% | 5%-7% |

| ST (short transverse) | 540 | 620-660 | 1.5% | 5%-6% |

Isotropy of 2xxx series ceramic aluminum matrix composite rolled plates

| Direction | Tensile Strength (MPa) | Elongation (%) |

| RD (rolling direction) | 504 | 22.1% |

| TD (transverse to rolling) | 503 | 23.8% |

| XD (45° direction) | 482 | 21.8% |

Application fields of high-strength wrought ceramic aluminum matrix composites

Aerospace

With superior strength, lightweight characteristics, and excellent fatigue resistance, high-strength wrought Ceramic Aluminum Matrix Composites (Al-MMCs) are widely used in the aerospace industry to enhance component performance, extend service life, and improve cost efficiency.

Rocket and satellite components

By replacing aluminum alloys, weight is reduced by 20%; by replacing titanium alloys, weight is reduced by one-third—significantly improving the performance and reliability of rocket and satellite parts.

Main load-bearing beams

As core structural members, the use of ceramic aluminum matrix composites greatly reduces overall weight while enhancing structural strength and stability.

Load-bearing struts

In load-bearing struts, these composites improve bending and fatigue resistance, ensuring long-term operational safety and reliability.

Storage tanks

When used in propellant and fluid storage tanks, ceramic aluminum matrix composites improve corrosion and high-temperature resistance while reducing weight for more efficient storage and transport.

Aircraft skin panels

The fatigue performance of these composites is about 30% higher than aerospace-grade fatigue-resistant aluminum alloys, showing potential to replace imported aluminum-lithium alloy skins.

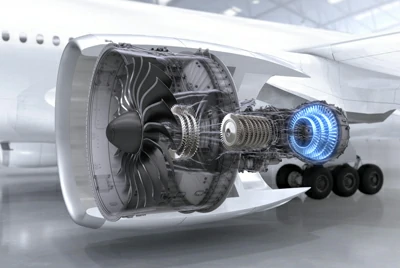

Aero-engine blades

Compared with titanium alloy blades, ceramic aluminum matrix composite blades reduce weight by one-third, enhance performance, and lower machining difficulty and cost.

Aerospace profiles

CT2024 fatigue-resistant material offers 90% higher fatigue strength, while CT7055 high-strength material reduces weight by 10–20%, boosting durability and cost efficiency of aerospace profiles.

Real-world application: China's C919 large passenger aircraft

Since 2015, high-strength wrought Ceramic Aluminum Matrix Composites (Al-MMCs) have undergone rigorous airworthiness certification and, by the end of 2021, officially received approval from the Civil Aviation Administration of China (CAAC).

This milestone marked the creation of China's first independently developed aerospace material grade — CA7075-3.5.

In the C919 large aircraft, ceramic aluminum matrix composites have been successfully applied in 155 key components, including the cargo floor, keel beam, and APU inlet door frame.

Their performance surpasses that of third-generation aluminum-lithium alloy (2196) and the material has been included in COMAC's official material standards and approved supplier list — demonstrating its superior strength, lightweight advantage, and durability.

In key performance indicators, CA7075-3.5 shows significant improvements over 2196-T8511:

| Test Item | CA7075-3.5 | 2196-T8511 | Improvement |

| Yield Strength (MPa) | 579 | 476 | +21.6% |

| Ultimate Tensile Strength (MPa) | 634 | 524 | +21.0% |

| Elongation (%) | 7.4 | 6 | +23.3% |

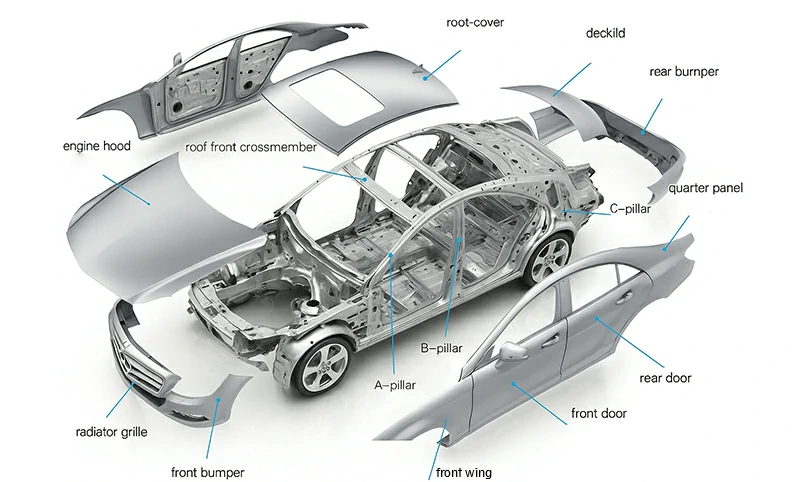

Automotive industry

The application of ceramic aluminum matrix composites in vehicle structural components increases strength by about 20% compared with conventional aluminum alloys, while maintaining the same level of ductility.

These composites can replace traditional materials such as steel and aluminum, significantly reducing overall vehicle weight. At the same time, they enhance structural reliability and safety, making them an ideal solution for modern lightweight and high-performance automotive design.

Real-world application of ceramic aluminum matrix composites in battery enclosures:

In battery housing applications, ceramic aluminum matrix composites effectively reduce weight compared with conventional aluminum alloys.

For example, with a driving range of 500 km, a traditional aluminum alloy battery box weighs 62 kg, while one made with ceramic aluminum matrix composites weighs only 42 kg, achieving a 32% weight reduction.

Weapons equipment

Ceramic aluminum matrix composites are in-situ nano-ceramic particle reinforced Aluminum Matrix Composite (Al-MMC) materials.

They significantly improve range, mobility, stealth, and service life. These composites have become indispensable materials in modern military equipment.

Contact us now

Our partners in ceramic aluminum matrix composites

We work closely with many leading organizations and brands, dedicated to the research and application of high-performance Ceramic Aluminum Matrix Composites (Al-MMCs). Our main partners include:

- CRRC (China Railway Rolling Stock Corporation): A global leader in rail transit equipment manufacturing.

- AVIC (Aviation Industry Corporation of China): A key force in China's aviation industry, collaborating with us in developing aircraft materials and components.

- CASIC (China Aerospace Science & Industry Corporation): Utilizes high-performance ceramic aluminum matrix composites in aerospace equipment.

- NORINCO (China North Industries Group): Applies ceramic aluminum matrix composites in weapons and defense systems.

- China South Industries Group: Uses our composites to enhance the lightweight design and durability of weapon systems.

- COMAC (Commercial Aircraft Corporation of China): The main developer of China's civil aircraft; our materials are applied in the C919 and related programs.

- AECC (Aero Engine Corporation of China): A pioneer in aero-engine R&D and manufacturing; ceramic aluminum matrix composites are widely used in its engine and other key components.

Our R&D and production equipment

Our company is equipped with advanced research and production facilities to ensure the high quality and efficiency of ceramic aluminum matrix composites and related products.

Ceramic aluminum matrix composite production lines

We operate multiple specialized lines, including in-situ synthesis, special casting, semi-continuous casting, and additive manufacturing powder production lines. These ensure precise production of various ceramic aluminum matrix composite grades.

Large-scale production equipment

We have over 100 sets of high-end equipment, such as reaction synthesis furnaces, anti-gravity casting systems, and large-format SLM metal 3D printers. These support large-scale, high-precision manufacturing.

Analytical and testing instruments

More than 20 high-precision analytical and testing devices—including photoelectric direct-reading spectrometers and image analyzers—are used for strict quality control, ensuring consistency and reliability across all production batches.

High production capacity

Our annual capacity reaches 18,000 tons of ceramic aluminum matrix composites and finished products, meeting large-scale customization demands.

Inspection and laboratory equipment

We are equipped with X-ray real-time imaging systems, fatigue testing machines, tensile testers, hydrogen analyzers, ONH analyzers, microscopes, X-ray diffraction instruments, particle size analyzers, and inductively coupled emission spectrometers. These ensure that all product properties meet the highest industry standards.

Based on advanced material systems, controlled process parameters, and digitalized equipment, we have established a closed-loop quality control and batch traceability system covering the entire process—from melting to delivery—ensuring stable mass production and long-term consistency.

Packaging and transportation of high-strength wrought ceramic aluminum matrix composites

Our company provides high-standard packaging solutions for ceramic aluminum matrix composite products to ensure safe and efficient global delivery.

Customized packaging: Packaging is tailored according to the product's shape and specifications to ensure safety during transportation.

High-strength protection: Strong wooden crates, bubble wrap, and foam padding are used to provide extra shock and impact protection, preventing any damage during transit.

Compliance standards: All packaging meets international shipping and safety standards, guaranteeing the products remain intact throughout long-distance transportation.

Eco-friendly materials: Environmentally friendly materials are used for packaging to minimize environmental impact.

Related questions (FAQ)

What is Aluminum Matrix Composite (Al-MMC / AMC)?

It is a composite material that uses aluminum or aluminum alloy as the matrix, reinforced with phases such as particles, whiskers, short fibers, or nano phases (e.g., SiC, Al₂O₃, TiC, TiB₂, B₄C, carbon fiber, etc.). It offers low density, customizable properties (strength, stiffness, CTE, thermal conductivity), excellent wear and fatigue resistance, and dimensional stability. Common fabrication methods include in-situ reaction, powder metallurgy, stir/low-pressure/extrusion casting, pressure infiltration, spray deposition, and additive manufacturing (3D printing).

How strong is Aluminum Matrix Composite?

Typical tensile strength ranges from 300–600+ MPa; with advanced reinforcement and optimized heat treatment, it can reach 600–700+ MPa. Its elastic modulus can be increased from the usual 70 GPa of aluminum alloys to 80–120 GPa. Fatigue and wear resistance are significantly improved, while ductility may decrease slightly as reinforcement content increases.

Get samples and a quick quote

Customize materials according to your target CTE, temperature range, or thermal conductivity — submit your drawings and working conditions, and receive a material solution, process window, quotation, and delivery schedule within 48 hours.