Chalco specializes in the design and production of custom aluminum forgings. With open-die forging, closed-die forging, ring rolling, and hot / cold forging capabilities, we can work from your 2D/3D drawings and applicable standards to produce everything from small precision parts weighing a few hundred grams to large rings, shafts and block forgings.

Combining aluminum alloy heat treatment, CNC machining and surface finishing as a one-stop service, we supply reliable aluminum forging solutions for the automotive, construction machinery, energy and rail transit industries.

Quick Selection

-

Choose by Alloy

6061 / 6082

5083

7075 / 7050 / 2014 / 2219 / 2618 / 4032

-

Choose by Process & Size

Open-die forging

Closed-die forging

Ring-rolled & Shaft forgings

-

Choose by Delivery State

As-forged blanks

Heat treatment + rough machining

Fully machined + surface treatment

Typical Forging Types, Sizes and Capabilities

| Forging methods | Types | Maximum weight | Maximum Specifications |

| Free forging | Forging blocks | ≤9T | Length ≤ 7000mm, Width ≤ 2000mm, Height ≤ 500mm Diameter ≤ φ2500mm |

| Forging discs | ≤5T | Quenched material outer diameter ≤ φ2500mm Unquenched material outer diameter ≤ φ4000mm, Height ≤ 500mm | |

| Forging rings | ≤5T | Outer diameter φ200~φ800mm, length ≤2000mm; Outer diameter φ810~φ2000mm, length ≤1500mm | |

| Forging cylinders | ≤5T | Length ≤7000mm, diameter ≤800mm | |

| Long shafts | ≤8T | Outer diameter ≤φ830mm, inner diameter ≤φ650mm, length ≤1800mm | |

| Reverse extrusion | Forging tubes | - | Projected area ≤3.0㎡ (diameter ≤φ1950mm) |

| Die forging | General die forgings | - | Projected area ≤1.5㎡ (diameter ≤φ1400mm) |

| Complex die forgings | - | Diameter ≤ φ2500mm |

The above table summarizes Chalco's typical size capability for aluminum forgings. For detailed equipment windows for open-die forging, closed-die forging, ring rolling and heat treatment, please click to view Forging Equipment & Production Capacity.

Which Forging Process Is Best for My Part?

Forging Processes: Open-Die Forging, Closed-Die Forging, Ring Rolling and Backward Extrusion

In aluminum forging design and production, open-die forging, closed-die forging, ring rolling and backward extrusion are selected based on part geometry, overall size and batch volume. The following sections summarize which forging types each process is best suited for, helping engineers make an initial process selection.

-

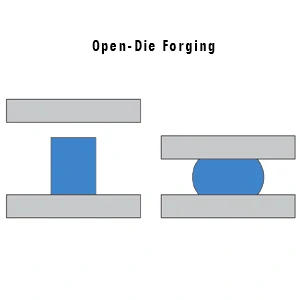

Open-Die Forging (Free Forging)

Open-Die Forging (Free Forging)

Suitable for medium and large aluminum forgings with relatively simple geometry. Multi-directional deformation produces continuous grain flow; the process is flexible and well-suited to multi-variety, small to medium batch production.

Typical part types: forging discs, blocks, aluminum rings, shaft forgings, hollow / cylindrical forgings.

Typical project profile: parts with larger overall dimensions or single-piece weight, simple contours and generous machining allowances.

-

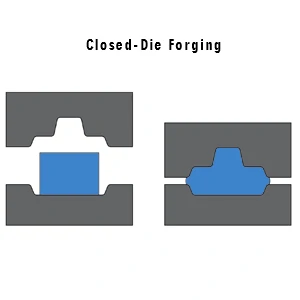

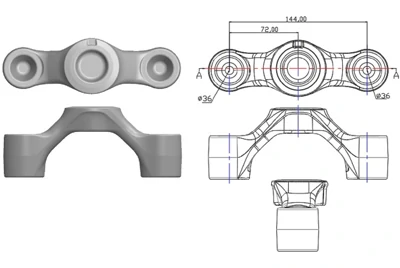

Closed-Die Forging

Closed-Die Forging

Closed-die forging uses dedicated dies to achieve near-net shape, ideal for more complex aluminum forgings that require stable mass production, helping reduce material waste and machining time.

Typical part types: aluminum forged control arms, steering knuckles, brackets, lugs and other chassis forgings, as well as aerospace structural parts, aluminum forged flanges and engine accessory brackets.

Typical project profile: three-dimensional shapes with complex contours and local ribs / stiffeners, classified as safety-critical or key load-bearing components, with at least medium annual volumes.

-

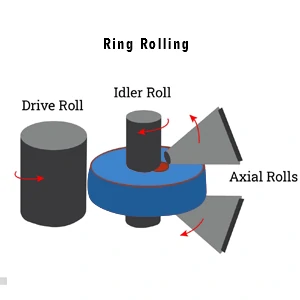

Ring Rolling

Ring Rolling

Ring rolling is used for medium and large ring-shaped aluminum forgings. It reduces weight and improves material utilization while aligning the grain flow in the circumferential direction, enhancing fatigue performance.

Typical part types: aluminum forged rings, wheel rims, gear rings, aluminum alloy flange rings, housing end rings, bearing races and similar ring components.

Typical project profile: ring or flange parts where the outer diameter is significantly larger than section thickness or width, section is basically uniform, and there are requirements on fatigue life, impact resistance and material utilization.

-

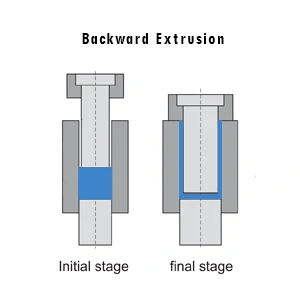

Backward Extrusion

Backward Extrusion

Backward extrusion forging is suitable for tubular, cup-shaped and cylindrical aluminum forgings, forming deep-cavity structures in one or a few blows with uniform wall thickness and good internal / external soundness. It is commonly used for parts with pressure and sealing requirements.

Typical part types: backward-extruded aluminum tubes, cup-shaped forgings, cylindrical housings, aluminum alloy cylinders, valve bodies and pressure vessel nozzles.

Typical project profile: deep-cavity or closed-bore parts that are sensitive to internal pressure strength, sealing performance and internal soundness, where the customer prefers not to build the cylinder from deep-hole drilling or thick-plate welding.

Forging Temperature Routes: Aluminum Hot, Warm and Cold Forging

In aluminum forging production, aluminum hot forging and warm forging are generally used for the main forming step. Depending on the required dimensional accuracy and surface quality, an additional aluminum cold forging / cold sizing step may be added. Different temperature routes focus on different priorities.

Aluminum Hot Forging

Mainly used for the primary forming of medium and large aluminum forgings. It offers good plasticity and low deformation resistance, and is suitable for most open-die forgings, closed-die forgings and ring-rolled forgings.

Suitable for: forgings with large overall size or large deformation, where the priority is stable grain flow and internal soundness.

Selection tip: when strength, ductility and forming reliability are the main targets and final dimensional accuracy can be achieved by subsequent machining, aluminum hot forging is usually the preferred route.

Warm Forging

The forming temperature lies between hot forging and cold forging. It balances plasticity with reduced oxidation and forming load, and is often used for small and medium-sized aluminum forgings with certain dimensional and surface requirements.

Suitable for: small and medium structural parts, some closed-die forgings, and shafts / flanges with slightly higher accuracy requirements.

Selection tip: when you want to improve dimensional accuracy and reduce oxidation and forming load while maintaining stable forming, warm forging or a "hot forging + warm sizing" route can be evaluated.

Aluminum Cold Forging

Mostly used as the final forging / sizing step for small parts or local high-precision areas, in order to improve the consistency of critical dimensions, tolerances and fit surfaces.

Suitable for: connectors, flange seats, small shaft ends, cold-forged fastener blanks and other parts sensitive to appearance, fit clearance or concentricity.

Selection tip: if the drawing specifies strict local tolerances, surface roughness or assembly accuracy, you can add an aluminum cold forging / cold sizing step after aluminum hot / warm pre-forming; otherwise hot / warm forging alone is usually sufficient to control cost.

For more details, please refer to the dedicated Aluminum Cold Forging page.

Which Aluminum Alloy Should I Choose for This Part?

Once the forging process is roughly defined, the choice of alloy grade is mainly determined by load level, service environment (temperature / corrosion / whether welding is required), and cost / availability.

For aluminum forgings, Chalco commonly uses the following four alloy families:

- General structural: 6061, 6082

- Welded structures / marine: 5083

- High-strength structures / aerospace: 7075, 7050

- High-temperature parts & forged pistons: 2014, 2219, 2618, 4032

General Structural Forgings: 6061 / 6082

Suitable for most general mechanical structures and medium-load bearing parts. They offer a balanced property profile and stable supply, and are among the most common base alloys for aluminum forging projects.

-

Good strength, machinability and weldability for general structural forgings.

-

Higher strength and stiffness than 6061, suitable for load-bearing structural parts.

Welded Structures / Marine Applications: 5083

Mainly used for aluminum forgings and welded structures that require welding and long-term exposure to seawater or humid media, and is well matched with 5083 plates and extrusions in the same system.

-

Offers excellent seawater corrosion resistance and weldability, and is commonly used for shipbuilding / offshore equipment connectors, welded flanges and low-temperature pressure-bearing aluminum forged structures.

High-Strength Structures / Aerospace Applications: 7075 / 7050

Used for critical load-bearing aluminum forgings with high specific strength and stiffness requirements, commonly found in aerospace, racing and high-end sports structures.

-

In suitable heat-treated tempers, it can deliver very high tensile and yield strength, making it ideal for high-strength lugs, forged aluminum shafts and lightweight structural parts.

-

Balances high strength with better thick-section toughness and stress-corrosion resistance, and is more often used for aerospace structural parts and high-reliability large aluminum forgings.

High-Temperature Parts & Forged Pistons: 2014 / 2219 / 2618 / 4032

This alloy family targets medium-to-high temperature service, engine accessories and forged pistons, with more focused performance in high-temperature strength, thermal stability or thermal fatigue resistance.

-

High strength with good machinability for medium-to-high temperature structural and pressure-bearing components.

-

Maintains strength and stability at elevated temperatures, ideal for cryogenic vessels and aerospace housings.

-

Excellent high-temperature strength and thermal fatigue resistance for engine pistons and connecting rods.

-

High silicon content provides low thermal expansion and excellent wear resistance for precision forged pistons.

If you have not yet finalized the exact alloy grade, simply send us your drawings and service conditions. The Chalco engineering team will help recommend suitable aluminum forging alloys and process routes.

Click Submit Drawings & RFQ Guidelines to see how to describe your drawings and operating conditions in a clear, engineering-friendly way.

Forging Equipment and Production Capacity

Chalco is equipped with multi-tonnage open-die forging, closed-die forging, ring rolling and aluminum-alloy dedicated heat treatment lines, supporting a wide range of aluminum forgings such as discs, blocks, rings, shafts and hollow / cylindrical parts. Key capability highlights are as follows.

Open-Die Forging Equipment

Equipped with approximately 25–60 MN (2 500–6 000 T) open-die hydraulic presses. Among them, the 60 MN open-die line offers a daylight of about 5 000 mm, stroke of about 3 000 mm, and a worktable of about 2 600 × 7 000 mm, with forging speed adjustable from 0–50 mm/s.

This line is suitable for pre-forging and final forging of medium and large aluminum billets, blocks, shafts and hollow / cylindrical forging stock.

Closed-Die Forging Lines

Closed-die presses cover approximately 40–500 MN (4 000–50 000 T). A typical vertical press provides a daylight of about 4 000 mm, stroke of about 2 000 mm, and worktable sizes of around 2 300 × 4 000 mm to 4 000 × 7 000 mm, with forging speed adjustable from 0.05–50 mm/s.

These lines are suitable for mass production of aluminum forged chassis parts, connectors, brackets, wheel components and other structural closed-die aluminum forgings.

Ring Rolling & Hollow Forging Capabilities

- Equipment platform: A large radial–axial ring rolling line can roll rings up to approximately φ9 000 mm in outer diameter, with a maximum radial rolling force of about 900 T and axial force of about 600 T. Upstream, 4 000–5 000 T class hydraulic presses are used for billet open-die forging / pre-forging.

- Typical aluminum alloy supply range: Considering process stability and economic batch size, aluminum alloy rolled rings are conventionally supplied up to about φ2 500 mm in outer diameter for quenched rings, and up to about φ4 000 mm and ≤5 T per piece in non-quenched condition. Cylindrical and backward-extruded hollow aluminum forgings are typically in the range of φ200–830 mm outer diameter and ≤1.8–2.0 m in length. Exact capability is confirmed based on drawing review.

Aluminum Alloy Heat Treatment Capacity

Dedicated aluminum alloy vertical quench furnaces and box-type ageing furnaces are available, with typical working zones such as φ3 × 7 m and 5 × 3 × 1.2 m, and single-furnace load capacity of about 5–15 T. Furnace temperature uniformity is controlled to around ±3 ℃, and transfer time meets aluminum quenching requirements.

According to project needs, relevant standards (such as AMS 2750) can be implemented to deliver common temper conditions like T6, T651 for 2xxx / 5xxx / 6xxx / 7xxx series aluminum forgings.

When part dimensions, single-piece weight or structural complexity approach the above capability limits, it is recommended to provide 2D/3D drawings, target dimensions and planned batch quantities at the RFQ stage. We will evaluate manufacturability based on equipment windows and process routes, and propose corresponding aluminum forging process solutions.

What Else Can We Provide Besides Forging?

Many aluminum forging projects not only need to "get the part forged", but also require CNC machining, surface treatment and inspection documents. Depending on how your supply chain is organized, Chalco can support different delivery depths.

First, choose your delivery scope

- Forged blanks only: we supply as-forged aluminum forgings, and your machining partner completes all subsequent machining.

- Forging + heat treatment + rough machining: we complete forging, heat treatment and main datum surfaces, and your side finishes the final machining.

- Forging + full machining + surface treatment: we deliver fully machined, surface-treated aluminum forgings ready for assembly, together with inspection documents.

Simply indicate how far you want us to go in your RFQ, and we will design the process route and quotation accordingly.

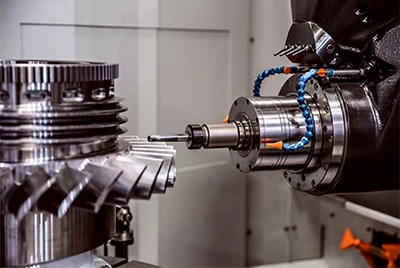

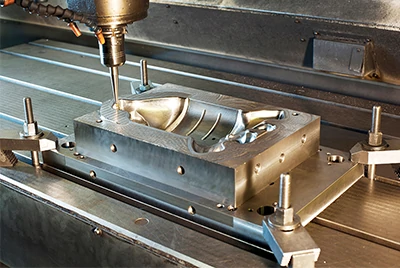

CNC Machining Capabilities for Aluminum Forgings

On top of forging, Chalco can provide CNC machining for aluminum forgings, from rough machining to full finish machining.

Machining operations: CNC turning, vertical / horizontal machining center milling, drilling, tapping, boring, keyway cutting, grooving, chamfering, etc.

Typical parts: aluminum forged flanges, aluminum forged shafts, valve bodies / housings, connector blocks, fixture bases, aluminum forged rings and stepped shaft forgings.

Accuracy & fits: we can control critical dimensional tolerances, concentricity and parallelism as per drawing, and reserve appropriate surface roughness levels for mating surfaces, sealing faces and fit bores.

Surface Treatment and Protection

For different service conditions and appearance requirements, Chalco can match aluminum forgings with common aluminum surface treatment processes to enhance corrosion resistance, wear resistance or decorative effect.

- Anodizing: general-purpose corrosion protection and decorative finish; color and film thickness can be specified per project.

- Hard anodizing: used in areas with heavier friction / wear or higher surface hardness requirements, such as bushings, guide surfaces and other highly loaded structural parts.

- Blasting / shot peening / brushing: to achieve a uniform matte appearance, remove minor surface imperfections, or provide a good base profile for subsequent coatings.

- Powder coating / painting: suitable for housings, flanges and structural parts with higher appearance and weathering requirements.

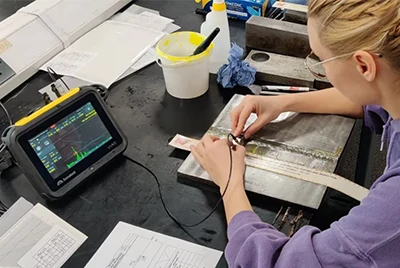

Inspection and Quality Documentation

According to project needs, Chalco can complete the required inspection before delivery of aluminum forgings and provide supporting quality documents to facilitate drawing acceptance, third-party inspection or system audits.

- Routine inspections: dimensional and geometric tolerance measurements, mechanical properties and hardness testing, surface quality checks, all in accordance with drawings and applicable standards.

- Non-destructive testing (NDT, as required): UT ultrasonic testing, RT radiographic testing, PT penetrant testing, etc., with testing coverage and levels set according to part criticality and contractual requirements.

- Special verifications (as required): for example leak testing, balance testing, surface roughness measurement, hardness distribution verification, etc., which can be defined in the technical agreement.

- Quality documents: material test certificates (MTC), heat treatment records, test / inspection reports, certificates of conformance (COC), etc., with content and format configurable to project or customer system requirements.

Please specify the required inspection items and report types together with your drawings at the RFQ stage, so we can configure an appropriate inspection plan and cost scope for your project.

Why Choose Chalco as Your Aluminum Forging Supplier?

Coverage of Mainstream Sizes and Process Windows

With open-die forging, closed-die forging, ring rolling and aluminum alloy–dedicated heat treatment lines, Chalco can cover typical aluminum forging needs from small and medium precision closed-die parts to large rings, shafts and cylindrical forgings within defined ranges. These capabilities match the common size windows and batch patterns found in aerospace, automotive and general industrial applications.

Design-for-Manufacturing Drawing and Process Review

For projects in the design or prototype stage, we can perform manufacturability reviews on your 2D/3D drawings based on forging processes and equipment capability. This includes suggestions on section and radius design, forging allowance and tolerances, datum and locating structures, as well as alloy and heat treatment selection, helping you balance performance, cost and mass-production stability early in the design phase.

One-Stop Machining and Inspection Support

Depending on your needs, we can supply as-forged blanks, forging + heat treatment + rough machining, or fully machined finished parts, while coordinating machining, surface treatment and inspection in-house. We can deliver matching material test reports (MTC), dimensional inspection reports, NDT reports, heat treatment records and certificates of conformance (COC), reducing schedule and quality risks associated with managing multiple suppliers.

Standards and Certification System Support

Our aluminum forgings can be produced and inspected in accordance with standards such as ASTM B247, EN 586 and aerospace forging standard AMS-A-22771. The plant operates under AS9100 quality management and relevant NADCAP special process approvals, and can also comply with automotive quality management requirements such as IATF 16949 where projects call for it.

Industry Applications & Solutions

Aerospace & Defense Solutions

In the aerospace and defense sector, aluminum forgings are mainly used for load-bearing structural parts, connectors and ring / cylindrical housings, typically using 2xxx / 7xxx series high-strength aluminum alloys with closed-die forging, open-die forging and ring rolling as the primary processes.

| Component System | Alloy | Forging Process | Forging Type | Inspection | Typical Parts |

| Landing Gear & Wheel Systems | 7xxx Series | Hot Forging / Warm Forging + Heat Treatment | Die Forging / Ring Rolled Forging | 100% UT + Dimensional Inspection | Landing Gear Supports, Fork Heads, Trunnions, Wheel Rings |

| Fuselage / Wing Structure Connectors | 2xxx / 7xxx Series | Hot Die Forging / Warm Forging | Die Forging | UT on Critical Sections / Zoned UT | Frame/Beam Connectors, Stiffeners, Hinge Seats, Radar/Antenna Brackets |

| Power, Hydraulic & Fuel Systems | Corrosion-Resistant Aluminum Alloy | Hot Forging + Heat Treatment | Free Forged Billet / Die Forging / Ring Rolling | UT + Leakage Test | Pump/Valve Bodies, Pipe Fittings, Annular Flanges, Cylindrical Housings |

Explore Aerospace Aluminum Forging Solutions

Passenger Cars, Commercial Vehicles & Rail Transit Solutions

In passenger car, commercial vehicle and rail transit applications, aluminum forgings are widely used in chassis and suspension systems, wheels and hubs, braking and steering components, as well as structural connectors. They commonly adopt 6xxx / 7xxx series high-strength aluminum alloys, with closed-die forging, warm / hot forging and local cold forging as the main routes.

| Component System | Alloy | Forging Process | Forging Type | Inspection | Typical Parts |

| Chassis & Suspension System | 6061, 6082, 7075 | Hot Die Forging / Warm Forging + Heat Treatment | Aluminum Die Forging | Fatigue Testing, Dimensional Inspection, NDT (Non-Destructive Testing) | Aluminum Control Arms, Steering Knuckles, Tie Rods, Shock Absorber Mounts, Subframe Connectors |

| Wheel & Hub Related Components | 6xxx Series | Hot Forging + Heat Treatment | Ring Rolled Forging, Die Forging | Dynamic Balance Testing, NVH Performance Control | Passenger Car Aluminum Wheel Blanks, Truck/Bus Rim Rings, Flange Rings |

| Braking, Steering & Structural Connectors | 6xxx, 7xxx Series | Hot Die Forging / Warm Forging | Die Forging | Full Dimensional Inspection, UT (Ultrasonic Testing) | Brake Caliper Brackets, Steering System Connection Eyes, Body/Frame Aluminum Connectors, Towing/Trailer Aluminum Forged Joints |

Explore Automotive Aluminum Forging Solutions

Construction Machinery, Energy & Fluid Control Solutions

In construction machinery, energy and fluid control fields, aluminum forgings are frequently used for pump and valve housings, pressure pipeline fittings, flanges and structural connectors, balancing lightweight design, corrosion resistance and sealing reliability.

| Component System | Alloy | Forging Process | Forging Type | Inspection | Typical Parts |

| Fluid Control & Pressure Piping | Corrosion-Resistant Aluminum Alloy | Die/Ring Rolling Hot Forging + Heat Treatment | Die Forging / Ring Rolled Forging | UT, Leakage Testing, Dimensional Inspection | Pump Bodies, Valve Housings, Pipe Fittings, Butt-Weld Flanges, Quick Connectors, etc. |

| Structural & Rotating Components | 5xxx / 6xxx / 7xxx Series | Large Diameter Ring Rolling / Free Forging | Ring Rolled Forging / Free Forging | Concentricity, Flatness, NDT (Non-Destructive Testing) | Wind Turbine Nacelle Connectors, Slewing Bearing Aluminum Rings, Equipment Structural Flanges and Brackets, etc. |

General Machinery & Equipment Manufacturing Solutions

In general machinery and equipment manufacturing, custom aluminum forgings are mainly used for flange rings, couplings, brackets, connecting rods, fixtures and non-standard structural parts, with greater focus on structural reliability, machining accuracy and overall cost efficiency.

| Component System | Alloy | Forging Process | Forging Type | Inspection | Typical Parts |

| Flange & Coupling Components | Medium Strength or Corrosion-Resistant Aluminum Alloy | Ring Rolling / Free Forging + Die Forging Combination + Heat Treatment | Ring Rolled Forging, Die Forging | Dimensional Inspection, Local NDT (Non-Destructive Testing) | Various Aluminum Flange Rings, Coupling Blanks, Disk Connectors |

| Structural Components & Fixture Bases | - | Free Forging / Die Forging | Free Forging, Die Forging | Ensure Rigidity and Stability | Equipment Brackets, Connecting Blocks, Non-Standard Structures, Jigs/Fixture Bases |

Submit Drawings & RFQ Guidelines

To evaluate your custom aluminum forging project efficiently and provide suitable process and quotation proposals, we recommend including the following information in your RFQ:

- 2D/3D drawings: indicate units and include all critical dimensions, tolerances, surface roughness, datums and locating faces, and key sections.

- Alloy grade and heat treatment condition: such as 6061-T6, 6082-T6, 7075-T73, etc. If you are still evaluating options, you can also indicate acceptable alternatives.

- Applicable standards: for example ASTM B247, EN 586, AMS-A-22771 or your internal specifications, so we can evaluate according to a consistent standard.

- Annual usage and supply mode: annual consumption, batch quantities, and whether the current phase is samples, small batches or mass production.

- Target delivery state: as-forged blanks, forging + heat treatment + rough machining, or fully machined finished parts, and whether surface treatment is included.

- Required tests and quality documents: such as dimensional reports, UT / other NDT, hardness / mechanical testing, leak testing, dynamic balance, MTC, COC, etc.

- Key operating conditions and special requirements: for example working temperature, medium and pressure level, fatigue life target, safety factors, etc.

After receiving your drawings and requirements, we will typically:

- Perform a manufacturability and process route assessment (open-die / closed-die / ring rolling / cold forging and temperature routes), checking size windows and alloy / temper compatibility.

- Propose recommended forging and heat treatment schemes, delivery state and machining scope, and confirm applicable standards and test items.

- Once the technical is agreed, provide a preliminary quotation including unit price, tooling or fixture cost (if applicable), and lead time ranges for trial and mass production.

You are welcome to send your drawings and a brief description of your needs to the Chalco engineering and commercial team. We will provide a tailored aluminum forging solution for your project and help you move quickly towards the next stage of development and procurement.