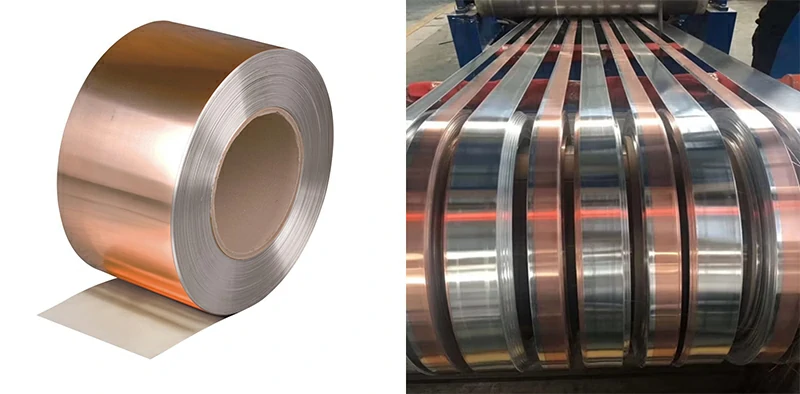

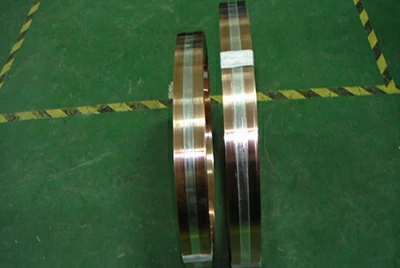

Copper clad aluminum strip combines the excellent conductivity and heat dissipation of copper with the lightweight,cost-effective benefits of aluminum.

Using advanced composite technology, it delivers strong bonding and stable performance. Widely used in cables,batteries, electric vehicles, and LED lighting, it offers a highly efficient and economical solution for conductiveapplications.

Copper clad aluminum strip specifications

Compliant with GB/T5231, GB/T1527, ASTM B694-01, ASTM B152M, and ASTM B248/B248M standards.

Certified by ISO 9001, ISO 14001, RoHS, and UL for quality, environmental, and safety assurance.

We offer free samples and mill test certificates to help you verify product quality before purchase withconfidence.

Instant QuoteCopper clad aluminum strip product details

- Typical materials: C11000 copper + 1060 aluminum (customizable upon request)

- Copper layer ratio: 10% to 30%

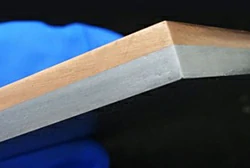

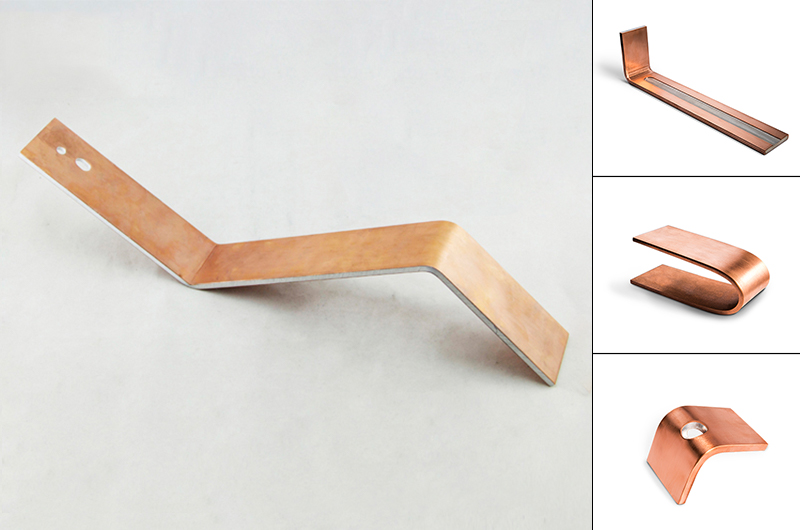

- Types: two-layer, three-layer, fully clad, inlay, and edge inlay

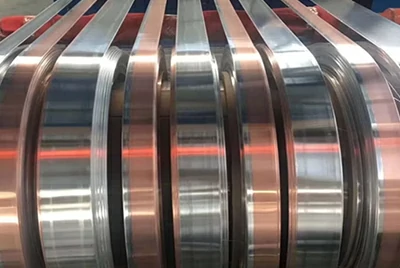

- Thickness range: 0.3mm to 20.0mm

- Width range: up to 1000mm (standard: 10–950mm)

- Max coil weight: up to 5 tons

- Bonding strength: > 40 MPa between copper and aluminum

- Surface finishes: black, galvanized, oiled, pickled

- Manufacturing methods: continuous casting and rolling, cold rolling, electrolytic process

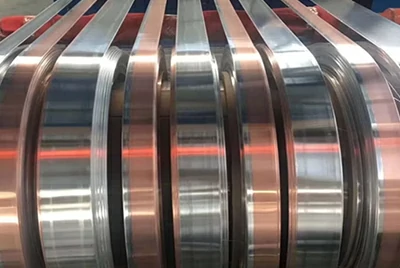

- Processing services: bending, welding, decoiling (slitting)

Popular related products to copper clad aluminum foil

We have strong manufacturing capabilities and offer a wide range of customizable copper clad aluminum products tomeet your specific needs.

Instant Quote

Copper clad aluminum foil

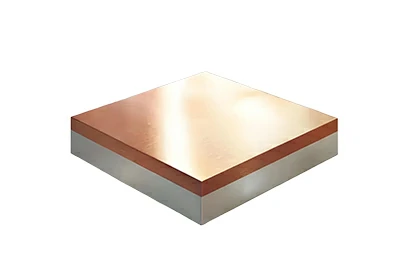

Copper clad aluminum plate

Copper aluminum bimetallic busbar

Copper-aluminum gasket

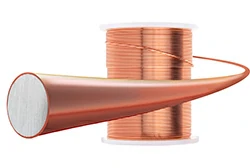

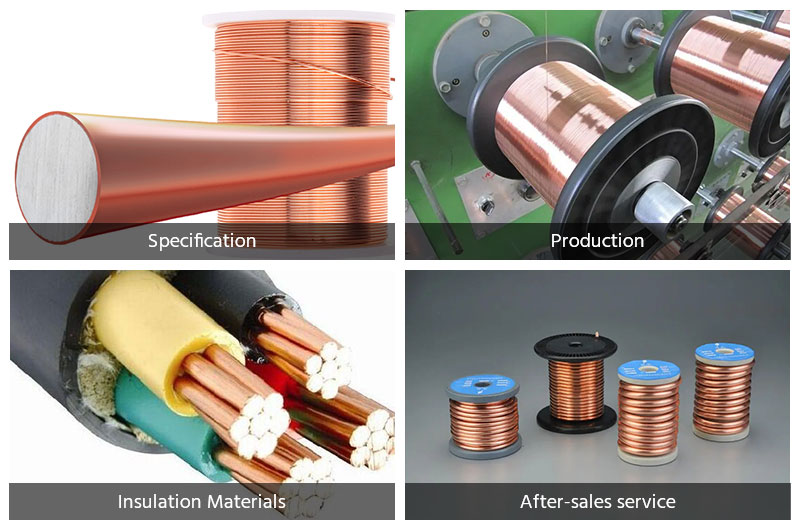

Copper-clad aluminium (CCA) wire

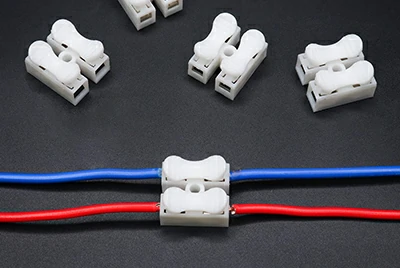

Copper-aluminum bimetallic cable connector

Advantages of copper clad aluminum strip

- High bonding strength: Copper and aluminum are tightly bonded using patented technology to ensure strongadhesion and prevent delamination.

- Excellent conductivity: The copper layer provides outstanding electrical conductivity for efficient powertransmission.

- Low contact resistance: Optimized composite structure reduces resistance between copper and aluminum, improvingcurrent flow.

- Strong impact resistance: Designed to withstand high-frequency impacts without damage.

- Cost-effective: Combines the benefits of copper and aluminum to significantly reduce material costs.

- Stable quality: Strict quality control ensures long-term performance and consistency.

- Lightweight: Aluminum's low density makes it ideal for applications requiring weight reduction.

- Corrosion resistance: Treated surfaces enhance durability in harsh environments.

- Improved energy efficiency: The copper-aluminum combination reduces weight while boosting energy transferefficiency.

Applications of copper clad aluminum strip

Copper clad aluminum strip is widely used in LED lighting, high-power power supplies, automotive systems, electricalequipment, electronics, medical devices, and industrial machinery.

We offer custom solutions based on your specific application needs—feel free to contact us anytime to discuss yourproject.

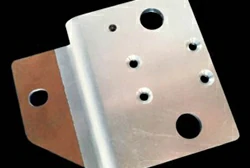

Instant QuoteLithium battery modules

Chalco's copper clad aluminum strip offers a reliable solution for connecting the positive and negativeterminals in lithium battery packs.

Contact us now

LED heat dissipation

With a thermoelectric separation design, it greatly improves heat dissipation for high-power LED chips,especially in 100W–1000W LED lighting products.

Contact us nowCable connectors

Copper clad aluminum strip is widely used in cable plugs, providing excellent conductivity and stableconnection performance.

Contact us now

Circuit boards (PCB, FPC, LED)

It is also extensively applied in PCBs, flexible circuits, and LED boards to enhance conductivity whilereducing material costs.

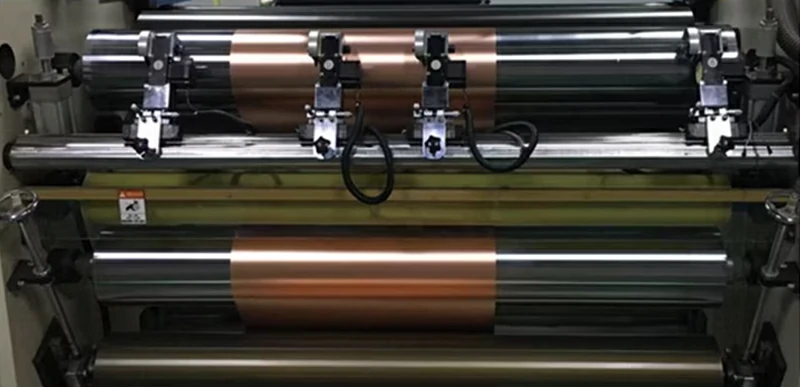

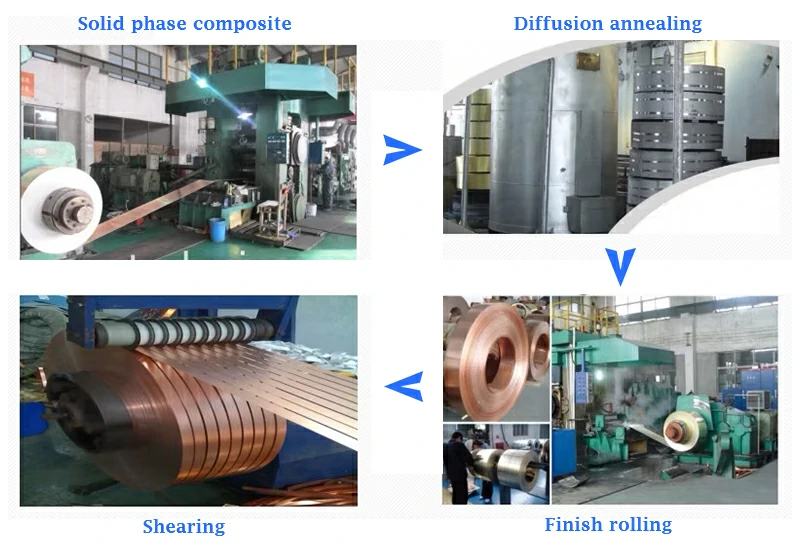

Contact us nowCopper clad aluminum strip process: continuous cast-rolling technology

The cast-rolling process is a cutting-edge innovation in copper clad aluminum strip production. It directly castsmolten aluminum onto copper, forming a strong metallurgical bond between the two metals.

Compared to traditional cold rolling, this method significantly enhances bonding strength, reduces brittleintermetallic compounds, and greatly improves conductivity, thermal performance, and mechanical stability.

This process supports various structures such as single-sided, double-sided, or partially clad copper surfaces. Itprovides a more reliable copper-aluminum connection for high-performance applications like lithium batteries,electric vehicles, and circuit connectors.

With 100% copper-aluminum contact, the material outperforms conventional cold-rolled composites in electrical,thermal, and structural performance—marking a major advancement in modern bimetallic technology.

Copper clad aluminum products people like to buy - Chalco stock

Copper-Clad Aluminum Bus Bar

Copper-aluminum Connecting Terminals

Copper Clad Aluminum Strip

Copper Clad Aluminum Wire

Copper Clad Aluminum Plate

Brazing Aluminum to Copper

Why choose us

Chalco is a manufacturing and international trading group with over 10 years of experience in copper, aluminum, andcomposite materials.

We specialize in delivering high-quality, cost-effective copper clad aluminum and copper-steel composite products.

Equipped with our own laboratory and professional testing team, we carry out strict inspections after everyproduction stage. Before delivery, we provide both paper and digital quality certificates.

Additional testing can be arranged based on your specific requirements.

We offer OEM services, full customization of materials and sizes, and fast delivery. Our team can also produceaccording to your drawings or samples.

With advanced equipment and a well-established quality control system, we ensure stable performance and long-termreliability—making us a trusted partner for your business.

Instant Quote

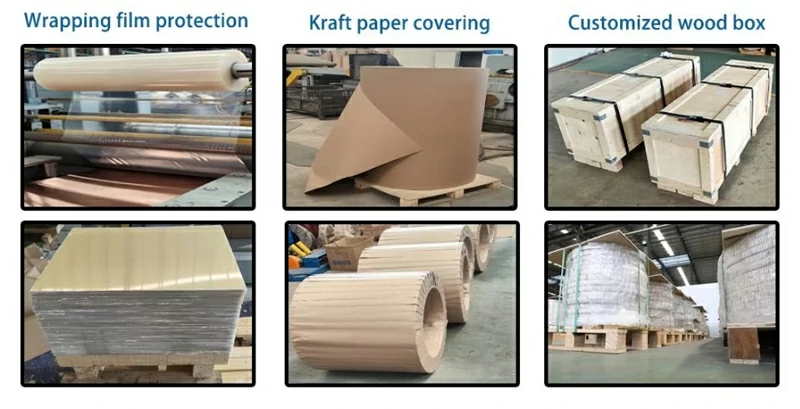

Packaging and shipping of copper clad aluminum strip

We use moisture-proof and rust-resistant packaging for every coil, wrapping each roll in waterproof film andsecuring it with fumigation-free wooden pallets to ensure safe and damage-free transport.

For high-end or export orders, we offer customized packaging options such as reinforced wooden crates, steelstrapping, and labeled tagging based on your requirements.

We support sea freight, air freight, and multimodal transport. Our experienced logistics team will tailor the mostefficient shipping plan according to your delivery timeline and destination—ensuring your products arrive safely, ontime, and hassle-free.

Copper vs aluminum vs copper clad aluminum – comparison

| Item | Pure Copper | Pure Aluminum | Copper Clad Aluminum |

| Conductivity | Excellent | Good | Close to pure copper |

| Cost | High | Low | Significantly lower than pure copper |

| Weight | Heavy | Light | Light |

| Workability | Easy to process | Moderate | Easy to process |

| Typical Uses | High-end electrical | Cost-sensitive projects | General applications like cables, batteries, and LEDs |

Copper clad aluminum strip material overview

Copper Grades

We offer a wide range of copper materials, including high-purity copper, oxygen-free copper, phosphorus-deoxidizedcopper, brass, tin bronze, and beryllium copper. Common grades include:

- High-conductivity copper: T1, T2, C10100, C10200, C11000, TU1, TU2

- Phosphorus-deoxidized / oxygen-free copper: TP1, TP2, C12000, C12200

- Precision alloy copper: C14500 (free-cutting copper), C17200 (beryllium copper), C44300–C44500 (naval brass),C71500 (copper-nickel alloy)

- Other specialty coppers: C26000, C27400, C63020, C68700

Aluminum Grades

The aluminum base layer typically uses high-purity or high-conductivity aluminum to ensure a balance of light weightand performance. Common grades include:

- High-purity aluminum: 1050, 1060, 1070, 1100

- Structural aluminum alloys: 3003, 5052, 6061 (customizable upon request)