Designed for aerospace, semiconductor and high-precision equipment parts that need higher stiffness, lower CTE and better dimensional stability than AlSi10Mg.

- Strength: 400–560 MPa, modulus 70–82 GPa

- Lower CTE & better dimensional stability vs. AlSi10Mg

- Ready-made parameter packages for EOS, BLT, 3D Systems etc.

Why choose Chalco's ceramic aluminum-based composite powder

Many engineers still struggle with warpage, dimensional drift, long parameter-tuning cycles, and unstable batch quality when using conventional aluminum or AlSi10Mg powders on SLM/LPBF machines.

Looking for parts that form right the first time—with stable performance, less rework, and higher reliability? That's exactly why we designed our powder.

Chalco optimizes the entire chain—equipment, process, and material—to make your printing easier, more controllable, and more cost-efficient.

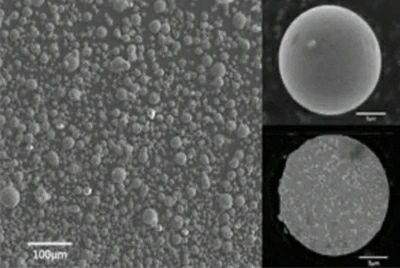

- Smoother powder spreading: High sphericity and low satellite content ensure excellent flowability and uniform layer thickness, reducing spatter and porosity.

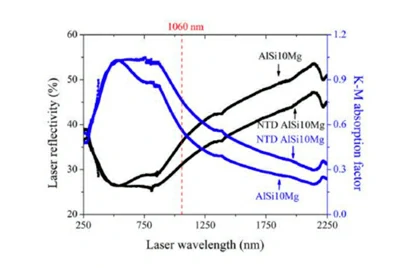

- More stable melt pool: Nano-ceramic reinforcements enhance laser absorption, broaden the process window, and minimize sensitivity to parameters.

- Finer microstructure: Promotes ultra-fine equiaxed grains and dispersion strengthening, achieving superior strength, stiffness, wear, and fatigue resistance.

- Higher batch consistency: Fully controlled from melting to classification, guaranteeing uniform performance and reliable mass production.

- Lower overall cost: Higher first-pass yield and faster parameter validation shorten tuning and delivery cycles.

Compatible with mainstream LPBF and other additive processes (standard particle size 15–106 μm, customizable formula and size range available).

Backed by joint R&D and standardized testing procedures, Chalco ensures full quality traceability.

We offer in-house R&D, production, and integrated printing services for dedicated ceramic aluminum alloy powders.

Customized solutions for ceramic aluminum-based composite powder (powder specifications)

The ceramic aluminum-based composite powder features high sphericity, low satellite content, narrow particle size distribution, excellent laser absorption, superior flowability, and higher apparent and tap density.

Chalco has established standardized production and testing procedures for ceramic aluminum alloy powders, with specification numbers available upon request in quotation or COA.

Standard and customized particle sizes

- 15–45 μm: Common range for LPBF and selective laser melting (SLM).

- 15–53 μm: General-purpose range suitable for different machine types.

- 45–106 μm: Designed for L-DED and powder-fed cladding processes.

Other particle size ranges can be customized based on equipment type and part wall thickness.

Typical particle size distribution

| Powder Specification | D10/μm | D50/μm | D90/μm |

| 15-45μm | 20±3 | 33±5 | 50±3 |

| 15-53μm | 23±3 | 35±5 | 58±3 |

| 45-106μm | 45±5 | 70±10 | 100±10 |

O/N/H content (ppm)

| O | ≤600 ppm |

| N | ≤100 ppm |

| H | ≤100 ppm |

Low gas content helps reduce porosity, improve density, and enhance mechanical performance.

This powder is specifically designed for laser powder bed fusion (SLM/LPBF) and is compatible with mainstream metal 3D printing platforms such as EOS (Germany), 3D Systems (USA), and advanced domestic systems developed by Chinese institutes and companies like Farsoon and BLT.

Simply provide your equipment model and part requirements, and we will match the appropriate particle size range and initial parameter package.

We also offer recommendations for powder spreading and recycling to help you achieve fast and stable printing results.

Chemical composition of ceramic aluminum-based composite powder

Chalco's formulation incorporates TiB₂ ceramic reinforcement into a lightweight aluminum matrix, optimized with Si and Mg for enhanced laser absorption, melt pool stability, and improved part strength, wear resistance, and dimensional stability.

The X series balances strength and general printability, while the Y series, with a high-silicon design, offers better flowability and lower thermal expansion—ideal for thin-walled and complex structures.

TiB₂ content is available in 1%, 2%, 6%, and 10% options to meet specific application needs.

| Grade | TiB2 | Si | Mg | Cu | Mn | Zn | Ni | Fe | Al |

| FCA101X-1 | 0.50-1.50 | 6.50-7.50 | 0.90-1.50 | ≤0.10 | ≤0.20 | ≤0.20 | ≤0.08 | ≤0.40 | Balance |

| FCA101X-2 | 1.50-2.50 | 6.50-7.50 | 0.90-1.50 | ≤0.10 | ≤0.20 | ≤0.20 | ≤0.08 | ≤0.40 | Balance |

| FCA101X-6 | 5.50-6.50 | 6.50-7.50 | 0.90-1.50 | ≤0.10 | ≤0.20 | ≤0.20 | ≤0.08 | ≤0.40 | Balance |

| FCA101X-10 | 9.50-10.50 | 6.50-7.50 | 0.90-1.50 | ≤0.10 | ≤0.20 | ≤0.20 | ≤0.08 | ≤0.40 | Balance |

| FCA101Y-1 | 0.50-1.50 | 9.00-11.00 | 0.30-0.55 | ≤0.10 | ≤0.45 | ≤0.10 | ≤0.05 | ≤0.55 | Balance |

| FCA101Y-2 | 1.50-2.50 | 9.00-11.00 | 0.30-0.55 | ≤0.10 | ≤0.45 | ≤0.10 | ≤0.05 | ≤0.55 | Balance |

| FCA101Y-6 | 5.50-6.50 | 9.00-11.00 | 0.30-0.55 | ≤0.10 | ≤0.45 | ≤0.10 | ≤0.05 | ≤0.55 | Balance |

| FCA101Y-10 | 9.50-10.50 | 9.00-11.00 | 0.30-0.55 | ≤0.10 | ≤0.45 | ≤0.10 | ≤0.05 | ≤0.55 | Balance |

The above table lists standard composition ranges.

If you have specific targets for strength, stiffness, wear resistance, thermal expansion (CTE), or thermal conductivity, Chalco can fine-tune the formulation accordingly.

Performance of ceramic aluminum-based composite powder

Before heat treatment

All grades show tensile strength around 400–550 MPa, increasing with higher TiB₂ content.

The Y series (high-silicon) delivers higher strength and stiffness at the same TiB₂ level.

Elastic modulus ranges from 70–82 GPa (the higher the TiB₂, the stiffer the material), while elongation gradually decreases from ≥12% to ≥4%, meeting various needs from general-purpose parts to high-load and wear-resistant components.

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Elastic Modulus (GPa) |

| FCA101X-1 | 400-450 | 260-310 | ≥ 12 | 70 |

| FCA101X-2 | 450-500 | 310-360 | ≥ 9 | 72 |

| FCA101X-6 | 460-510 | 320-370 | ≥ 7 | 75 |

| FCA101X-10 | 470-520 | 330-380 | ≥ 5 | 80 |

| FCA101Y-1 | 420-460 | 290-330 | ≥ 10 | 72 |

| FCA101Y-2 | 460-500 | 300-340 | ≥ 8 | 74 |

| FCA101Y-6 | 480-520 | 310-350 | ≥ 6 | 78 |

| FCA101Y-10 | 500-550 | 320-360 | ≥ 4 | 82 |

After heat treatment

With the same elastic modulus retained, the yield strength increases significantly (about +30–60 MPa), while the tensile strength rises slightly overall.

Elongation typically drops by about 2 percentage points, favoring applications that require higher strength and dimensional stability in printed components.

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Elastic Modulus (GPa) |

| FCA101X-1 | 430-480 | 320-370 | ≥ 10 | 70 |

| FCA101X-2 | 480-530 | 370-410 | ≥ 7 | 72 |

| FCA101X-6 | 490-540 | 380-430 | ≥ 5 | 75 |

| FCA101X-10 | 500-550 | 390-440 | ≥ 3 | 80 |

| FCA101Y-1 | 430-480 | 320-360 | ≥ 8 | 72 |

| FCA101Y-2 | 480-520 | 330-370 | ≥ 6 | 74 |

| FCA101Y-6 | 500-540 | 340-380 | ≥ 4 | 78 |

| FCA101Y-10 | 520-560 | 350-390 | ≥ 3 | 82 |

Note: Mechanical properties are based on parts produced by selective laser melting (SLM).

Selection guide

- For strength/stiffness/wear resistance: choose X-6 / X-10 or Y-6 / Y-10.

- For thin-walled, complex parts, or low thermal expansion: choose the Y series.

- For general, easy-to-adopt applications: start with X-1 / X-2.

For more on Chalco’s aluminum matrix composites and AlSiC materials, see our Al-MMC & AlSiC materials overview.

Application cases of ceramic aluminum-based composite powder

The nano-ceramic reinforced aluminum alloy 3D printing material features high laser absorption and fine grain size.

After 3D printing, it enables customized, lightweight, and integrated complex structures, with mechanical properties that meet or exceed forged part standards.

C919 aircraft door hinge arm

Product size:450 × 350 × 600 mm

Powder grade:FCA101Y-6

Equipment:BLT-S500 (BLT, China)

Performance:Tensile strength >500 MPa, Yield strength >300 MPa, Elongation >6%

Key electronic chip welding components – ASM company

Product size:116 × 28 × 12 mm

Powder grade:FCA101Y-10

Equipment:ProX200 (3D Systems, USA)

Performance:Elastic modulus >85 GPa

Aero engine fan blade

Product size:452 × 284 × 900 mm

Powder grade:FCA101X-2

Equipment:BLT-S500 (BLT, China)

Performance:Tensile strength >500 MPa, Yield strength >400 MPa, Elongation >8%

Lightweight lattice structures

Application:Ceramic-reinforced aluminum lattice and topology-optimized structures

Design focus:Significant weight reduction with maintained stiffness and thermal performance

Key benefit:Supports complex, integrated lightweight designs for high-performance components

From large load-bearing structures to precision components—even artistic designs—Chalco delivers consistent and high-quality 3D printed results.

Chalco's equipment capability

Chalco is equipped with both industrial-scale and research-grade SLM/LPBF platforms.

We can produce large components up to 1.5 meters in a single build and fabricate micro and complex precision parts with high accuracy.

Comprehensive parameter packages, process validation, and mass production replication services are provided to ensure reliable performance.

Two industrial-grade laser additive manufacturing systems

Model: BLT-S500, BLT-S500+

Brand: BLT (China)

Laser power: 4 × 500 W

Maximum build size: 500 × 500 × 1500 mm

Forming accuracy: <200 μm

One research-grade laser additive manufacturing system

Model: ProX200

Brand: 3D Systems (USA)

Laser power: 300 W

Build size: 140 × 140 × 100 mm

Forming accuracy: <100 μm

Our partners in ceramic aluminum-based composite materials

We collaborate closely with many industry-leading organizations and brands, dedicated to the research, development, and application of high-performance ceramic aluminum-based composite materials.

Our key partners include:

- CRRC (China Railway Rolling Stock Corporation): A global leader in rail transit equipment manufacturing.

- AVIC (Aviation Industry Corporation of China): Partner in developing aerospace materials and components.

- CASIC (China Aerospace Science and Industry Corporation): Applies our high-performance ceramic aluminum composites in aerospace systems.

- NORINCO (China North Industries Group): Utilizes ceramic aluminum composites in weapon systems and defense projects.

- China South Industries Group: Employs our composites to enhance lightweighting and durability in defense equipment.

- COMAC (Commercial Aircraft Corporation of China): Uses Chalco's ceramic aluminum composites in civil aircraft programs such as the C919.

- AECC (Aero Engine Corporation of China): A pioneer in aero-engine R&D and manufacturing, applying ceramic aluminum-based composites in engines and other key components.

Packaging and transportation of ceramic aluminum-based composite powder

We treat our powder like a precision component — ensuring full protection against moisture, oxidation, and static electricity, with complete traceability.

All shipments comply with international standards for hazardous or general goods.

- Inner layer (double protection): Aluminum-plastic composite vacuum-sealed bag filled with inert gas (Ar/N₂) and secondary sealing, containing desiccant and humidity indicator card.

- Outer layer: Antistatic UN-certified fiber or steel drum with shockproof lining, lock ring, and tamper-evident seal.

- Labeling: Includes grade/particle size, batch number, net weight, production date, handling instructions, and QR codes for COA/SDS. Hazard or antistatic warning labels are added when required by SDS.

- Transport options: Air, sea, or land — shipped according to the latest SDS classification under IATA DGR, IMDG, or ADR as applicable.

- Compliance: Uses UN-certified outer packaging and pallets, with correct bill of lading terms, package count, net/gross weight, shipping marks, and necessary dangerous goods documentation.

- Trade terms supported: EXW, FOB, CIF, DAP, and DDP (for selected countries), with the option to work with the customer's designated forwarder.

Related questions – FAQ

What is an aluminum matrix composite (Al-MMC / AMC)?

It is a composite material made by combining an aluminum alloy matrix with ceramic reinforcements such as TiB₂, SiC, or Al₂O₃.

It merges aluminum's lightweight, thermal conductivity, and machinability with ceramics' high strength, stiffness, wear resistance, and low thermal expansion, making it ideal for lightweight yet high-performance components.

How strong is the aluminum matrix composite?

Under SLM/LPBF conditions, our grades typically show tensile strength of 400–560 MPa, yield strength of 300–440 MPa, and elastic modulus of 70–82 GPa.

Higher TiB₂ content increases stiffness and wear resistance (with some reduction in elongation).

After heat treatment, yield strength usually rises by an additional 30–60 MPa.

What advantages does it have over common AlSi10Mg aluminum powder?

It offers higher laser absorption, more stable melt pools, greater modulus and wear resistance, lower thermal expansion, and better dimensional stability.

Ideal for thin-walled parts, complex flow channels, and large structural components.

We provide corresponding parameter packages for smooth process integration.

Which 3D printers is the powder compatible with?

It supports most mainstream SLM/LPBF platforms, including EOS, 3D Systems, SLM Solutions, Renishaw, and Chinese systems like Farsoon, BLT, and Eplus3D.

Provide your equipment model when ordering, and we'll match the proper particle size and process window.

How does it compare with titanium alloys?

It has lower density, better thermal conductivity, and lower cost.

While its modulus and high-temperature strength are lower than titanium's, it excels in heat dissipation, dimensional stability, and lightweight structural applications.

How to get samples and a quick quotation?

Customize your material based on target CTE, temperature range, and thermal conductivity — submit your drawings and working conditions, and Chalco will deliver a material solution, process window, quotation, and lead time within 48 hours.