Nano-ceramic particles are grown in situ within the aluminum alloy melt, combining aluminum's lightness and toughness with ceramic's strength and hardness.

This enables "cast-forging substitution", weight reduction, cost savings, and enhanced performance under casting processes.

Ideal for high-stiffness and dimensionally stable components in aerospace and electronic equipment, load-bearing and lightweight automotive chassis structures, and noise-reduction parts in rail transit.

Why use cast ceramic aluminum matrix composites

Cast ceramic aluminum matrix composites (Al-MMC / AlSiC) grow nano-ceramic particles in situ inside the aluminum melt, creating a particle-reinforced aluminum matrix that combines aluminum's low density and toughness with ceramic-like strength, stiffness and wear resistance.

- Cast-forging substitution with cost savings: Achieves forged-like strength, stiffness and ductility under casting processes, reducing forging and heavy machining, shortening lead time and lowering total cost.

- Lighter yet stronger and more stable: Compared with conventional cast aluminum alloys (such as A356), it offers significantly higher strength, stiffness and fatigue life, along with superior dimensional stability and damping during thermal cycling.

- Tailorable performance: By tuning ceramic particle content, size and the matrix alloy system, properties can be configured to meet specific targets for CTE, working temperature range and thermal conductivity in complex lightweight structures.

- Process-friendly one-step forming: Compatible with low-pressure casting (T6), squeeze casting (T6) and die casting (some grades heat-treatment free), enabling near-net-shape forming of complex geometries with excellent batch consistency.

- Proven in demanding applications: Already applied in aerospace structures, electronic equipment frames, automotive chassis parts and rail transit components where high stiffness, dimensional stability and weight reduction are critical.

In short, cast Al-MMC (AlSiC) enables high-strength, high-stiffness castings that meet or exceed mechanical targets while reducing weight and total cost, making it an attractive alternative to forged aluminum, titanium and cast iron solutions.

Chalco's popular cast ceramic aluminum matrix composite products

We provide custom and mass production of sand castings, metal mold low-pressure castings, gravity castings, and precision cast parts — offering one-stop delivery from prototyping to volume manufacturing.

Cast high-strength (JZ101) ceramic aluminum matrix composite

JZ101 is designed for critical load-bearing parts such as chassis knuckles and hinge arms, delivering higher strength and longer fatigue life at the same weight.

Contact us now

- Fracture strength: 410–420 MPa

- Yield strength: 340–350 MPa

- Elastic modulus: 85–95 GPa

Cast high-modulus (JZ109) ceramic aluminum matrix composite

JZ109 is developed for applications requiring high precision, low deformation, and vibration damping.

It delivers smaller elastic displacement and greater dimensional stability under the same load, making it ideal for electronic equipment components, tooling fixtures, and rail transit structures.

Contact us now

- Fracture strength: 360–370 MPa

- Yield strength: 320–330 MPa

- Elastic modulus: >90 GPa

Cast high-ductility (JZ110) ceramic aluminum matrix composite

JZ110 offers higher elongation and toughness to handle demanding impact and assembly tolerance conditions.

It provides excellent energy absorption and impact resistance, is tolerance-friendly during assembly, and reduces the risk of brittle failure.

Contact us now

- Fracture strength: 350 MPa

- Yield strength: 290 MPa

- Elongation: 14%

- Fatigue limit: 110 MPa

Other cast ceramic aluminum matrix composites (all series)

We also offer a wide range of cast ceramic aluminum matrix composite alloys to meet diverse application needs.

-

FC011 (Casting Series)

Tensile strength: 330–350 MPa

Yield strength: 280–300 MPa

Elastic modulus: 71–73 GPa

Elongation: 10–14%

Density: 2.72 g/cm³

Process: Low-pressure casting (T6)

-

FC031 (Casting Series)

Tensile strength: 380–400 MPa

Yield strength: 300–320 MPa

Elastic modulus: 80–85 GPa

Elongation: 2–3%

Density: 2.77 g/cm³

Process: Low-pressure casting (T6)

-

FC021 (Casting Series)

Tensile strength: 360–370 MPa

Yield strength: 320–330 MPa

Elastic modulus: 90–95 GPa

Elongation: 0.5–1%

Density: 2.82 g/cm³

Process: Low-pressure casting (T6)

-

FC041 (Casting Series)

Tensile strength: 530–550 MPa

Yield strength: 450–470 MPa

Elastic modulus: 78–80 GPa

Elongation: 3–4%

Density: 2.89 g/cm³

Process: Low-pressure casting (T6)

-

FC052S (Casting Series)

Tensile strength: 365–410 MPa

Yield strength: 290–350 MPa

Elastic modulus: 72–75 GPa

Elongation: 5–20%

Density: 2.72 g/cm³

Process: Squeeze casting (T6)

-

FC071S (Casting Series)

Tensile strength: 400–460 MPa

Yield strength: 340–380 MPa

Elongation: 2–5%

Density: 2.69 g/cm³

Process: Squeeze casting (T6)

-

FC081 (Casting Series)

Tensile strength: ≥630 MPa

Yield strength: ≥600 MPa

Elongation: ≥4%

Density: 2.85 g/cm³

Process: Casting (T6)

-

FC082 (Casting Series)

Tensile strength: 540–560 MPa

Yield strength: 460–490 MPa

Elongation: 7–15%

Process: Squeeze casting (T6)

-

FC061HTF (Casting Series)

Tensile strength: 185–210 MPa

Yield strength: 140–150 MPa

Elongation: 10–12%

Process: Die casting, heat treatment free

How to choose the right material for your project

- For higher strength and fatigue resistance, choose JZ101.

- For stiffness and dimensional stability, choose JZ109 or FC021.

- For high elongation and assembly-friendly performance, choose JZ110 or FC052S.

- For maximum impact strength, choose FC081 or FC041.

- For cost and efficiency priority, choose FC061HTF.

Send us your drawings, target specifications, and working conditions, and we'll deliver a customized material solution, process window, quotation, and lead time within 48 hours.

Comparison between ceramic aluminum matrix composites and cast aluminum alloy A356

A complete performance upgrade — achieving both lightweight design and high strength.

Compared with traditional cast aluminum alloy A356, Chalco ceramic aluminum matrix composites (JZ series) deliver remarkable improvements in strength, stiffness, and fatigue life, while maintaining low density and excellent machinability.

| Casting material | A356 (Conventional Cast Aluminum) | JZ101 (High Strength) | JZ109 (High Modulus) | JZ110 (High Ductility) |

| Fracture strength (MPa) | 280-310 | 410-420 | 325 | 350 |

| Yield strength (MPa) | 180-230 | 340-350 | 295 | 290 |

| Elastic modulus (GPa) | 68-72 | 85-95 | 72 | 73 |

| Elongation (%) | 2-3 | 2-3 | 0.5 | 14 |

| Density (g/cm³) | 2.70 | 2.77 | 2.71 | 2.72 |

| Fatigue limit (MPa) | 50 | 70 | - | 110 |

Chalco ceramic aluminum matrix composites — enabling your castings to be lighter, stronger, and beyond the limits of conventional aluminum alloys.

Advantages of cast ceramic aluminum matrix composites

- Low density: Naturally lightweight, with density comparable to aluminum alloys — ideal for achieving weight reduction goals.

- High strength: Tensile and yield strength are significantly higher than those of conventional cast aluminum alloys.

- High modulus: Elastic modulus up to 95 GPa, delivering smaller elastic deformation under the same load, better dimensional stability, and superior vibration damping.

- Fatigue resistance: Greatly improved fatigue life and limit under typical conditions such as rotating bending or double-hole tests.

- Wear resistance: Higher hardness and lower friction loss, suitable for long-term operation and high-frequency moving parts.

- Corrosion resistance: Retains the corrosion resistance of aluminum alloys, ensuring stable service in various environments.

- High-temperature and thermal fatigue resistance: Superior high-temperature strength and creep performance for better reliability under thermal cycling.

- Process and machining friendly: Compatible with low-pressure casting (T6), squeeze casting (T6), and die casting (some grades heat-treatment free); supports conventional machining and welding, and 3D printing powder options are also available.

Application cases of cast ceramic aluminum matrix composites

Aerospace applications

Tiangong-1:

- Solution: Replaced selected titanium alloy components with cast ceramic aluminum (Al-MMC / AlSiC).

- Result: Achieved about 30% weight reduction with higher stiffness and dimensional stability, enabling high-precision docking between Shenzhou spacecraft and the space station.

Tiangong-2:

- Delivery: 38 key structural components.

- Result: Achieved a total weight reduction of around 28 kg. Excellent dimensional stability and vibration damping ensured precise imaging, tracking, and pointing performance for onboard cameras.

Chang'e-3

- Solution: Substituted partial titanium alloy components with cast ceramic aluminum.

- Result: Achieved about 30% weight reduction, with significantly improved rotational accuracy and reliability of moving space parts, maintaining stable performance under thermal cycling and vibration conditions.

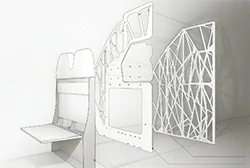

Aviation applications

-

The APU (Auxiliary Power Unit) intake door frame of the fuel and power system has already been successfully installed on the C919 large aircraft No. 003.

Other aerospace applications of ceramic aluminum matrix composites:

Cabin door components

Bionic cabin mechanisms

Aircraft hinge arms

The comprehensive performance of Chalco's ceramic aluminum matrix composites surpasses that of third-generation aluminum-lithium alloy 2196 and has been included in COMAC's material standards and qualified supplier list.

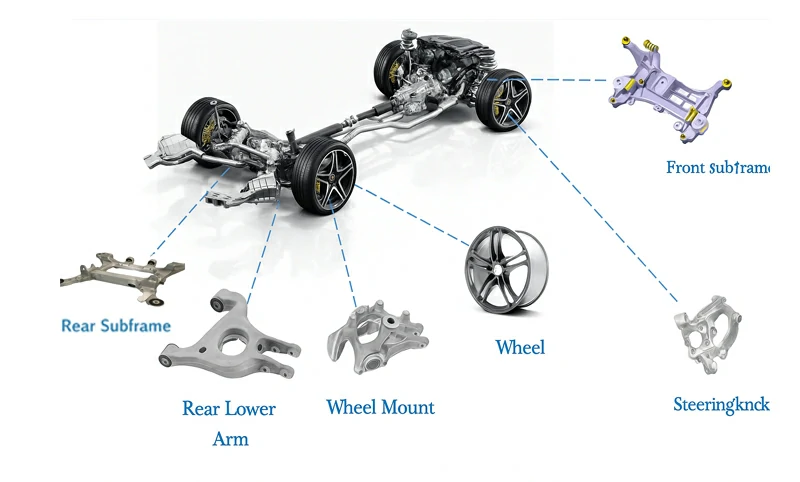

Automotive applications (chassis)

Cast ceramic aluminum matrix composites are used in subframes, steering knuckles, and control arms—key components of the automotive chassis.

They meet strength, stiffness, and fatigue requirements while replacing forged parts, achieving lighter weight, higher stability, and lower cost.

| Material & Process | QT450 Cast Steering Knuckle | 6082 Forged Steering Knuckle | Ceramic Aluminum (Cast) Steering Knuckle |

| Yield strength | 310MPa | 280MPa | 290MPa |

| Elongation after fracture | 9%-11% | 10%-11% | 10%-14% |

| Density | 7.1 g/cm³ | 2.71 g/cm³ | 2.71 g/cm³ |

Using ceramic aluminum for steering knuckles achieves strength and fatigue compliance, enabling cast-forging substitution, significant weight reduction, and more stable, efficient assembly.

Automotive steering knuckle

Using cast ceramic aluminum (Al-MMC) steering knuckles achieves about 56% weight reduction compared with cast iron and around 10% reduction compared with traditional aluminum alloys — all without increasing cost.

Contact us now

Automotive wheel hub

With cast ceramic aluminum (Al-MMC) wheel hubs, weight is reduced by about 70% compared with cast iron hubs and about 20% compared with conventional aluminum wheels.

Contact us nowIn addition to ceramic aluminum matrix composite solutions, Chalco also offers cast and forged aluminum wheel products, covering diverse needs for lightweight design, strength, and cost efficiency.

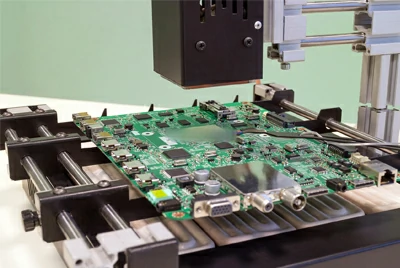

Chip welding and electronic packaging equipment

In next-generation chip welding and packaging equipment projects, the high-speed motion (16–20 g) operating conditions demand exceptional stiffness, dimensional stability, and superior vibration damping from structural components.

Contact us now

High-speed rail applications

Achieve lighter, more stable, and quieter performance while maintaining structural safety — ceramic aluminum matrix composites enable weight reduction, higher speed, energy efficiency, and noise reduction for high-speed trains.

By replacing imported cast iron with ceramic aluminum matrix composite castings, weight is reduced by about 60%, with better heat dissipation, lower vibration, and greater reliability under long-term high load and thermal cycling.

Contact us now

Our partners in cast ceramic aluminum matrix composites

We collaborate deeply with many industry-leading organizations and brands, focusing on the research, development, and application of high-performance ceramic aluminum matrix composites.

Our major partners include:

- CRRC (China Railway Rolling Stock Corporation): A global leader in rail transit equipment manufacturing.

- AVIC (Aviation Industry Corporation of China): Partnering in the development of advanced aircraft materials and components.

- CASIC (China Aerospace Science and Industry Corporation): Applying high-performance ceramic aluminum matrix composites in aerospace equipment.

- China North Industries Group (NORINCO): Using ceramic aluminum matrix composites in weapon systems and defense projects.

- China South Industries Group: Enhancing lightweighting and durability in defense equipment through ceramic aluminum composite technology.

- COMAC (Commercial Aircraft Corporation of China): The main developer of China's civil aircraft; ceramic aluminum matrix composites are used in C919 and other programs.

- AECC (Aero Engine Corporation of China): A pioneer in aero-engine R&D and manufacturing, widely applying ceramic aluminum matrix composites in engines and other critical components.

Our production equipment

We specialize in investment precision casting using the silica sol process, supported by strong collaboration with leading domestic universities and research institutes.

With robust technical capability, we have successfully mass-produced over 3,000 precision castings, covering complex structures and high-consistency requirements across multiple industries.

To shorten mold preparation time and quickly deliver prototypes for customers, we are equipped with:

A 3D intelligent sand core printer (2000 × 1000 × 750 mm).

Two 3D wax pattern printers (1200 × 1200 × 600 mm and 500 × 500 × 500 mm)

Wax injection equipment

Wax pattern equipment

Vacuum pressure furnace

These enable rapid production of sand molds, sand cores, and wax patterns, ensuring efficient and reliable casting of complex components.

Resin sand continuous molding line

This system includes a resin sand molding line and a box assembly line, providing the capacity to produce large castings.

Low-pressure casting line

This equipment enables continuous, large-scale production of castings in various specifications (maximum casting size 1200 × 1100 × 1000 mm).

Differential pressure casting machine — dual-station type

This system operates at a synchronized pressure of 6 bar and can cast parts up to 1500 × 1300 mm.

Gravity casting machine

A vertically parted gravity casting machine, suitable for producing smaller-sized castings.

Compliance and consistency: testing, R&D, and quality assurance

We have established an integrated verification system covering the entire process from incoming materials to production and final delivery.

All tests and records are conducted in accordance with ASTM / ISO / GB standards, ensuring batch consistency, full traceability, and the ability to provide Material Test Reports (MTR) and inspection certificates with each shipment.

We also support project-based test plans and third-party verification.

- Fluorescent penetrant inspection (FPI): Rapid detection of surface cracks and penetration defects to enhance the stability of material and casting surface quality.

- Real-time X-ray imaging (RT): Online inspection for shrinkage, inclusions, and cracks, helping optimize process parameters.

- Fatigue testing machine: Performs rotating bending, tension–compression, and open-hole fatigue tests, generating S–N curves and fatigue limits.

- Tensile testing machine: Measures Rm, Rp0.2, A, and E to verify strength, stiffness, and elongation compliance.

- Hydrogen / ONH analyzers: Monitor gas content and melt cleanliness to reduce porosity and brittle fracture risk.

- Metallographic microscope: Observes particle size/distribution, microstructure, and porosity to assess material stability.

- X-ray diffractometer (XRD): Analyzes phase composition, precipitates, and residual stress to guide heat treatment and performance optimization.

- Particle size analyzer (PSD): Measures D10 / D50 / D90 distribution to ensure reinforcement phase consistency and repeatability.

Send us your drawings, target specifications, and working conditions, and we'll deliver a customized material solution, process window, test plan, quotation, and lead time within 48 hours.

Packaging and transportation of cast ceramic aluminum matrix composites

To ensure the appearance and performance stability of ceramic aluminum matrix composites during global transportation, we use multi-layer protection and offer customized packaging options.

- Inner protection: Functional surfaces are covered with PE protective film, and dust-free interleaves are placed between sheets. Coated or mirror-finish parts are individually wrapped for scratch and pressure protection.

- Moisture and corrosion protection: VCI anti-rust film with vacuum-sealed aluminum-plastic barrier bags, containing desiccants and humidity indicator cards (HIC). Additional protection is available for sea freight.

- Structural reinforcement: EVA cushioning, custom positioning pallets, corner guards, stretch film, and strapping bands with clear shock and tilt warning labels ensure safe handling.

- Crates and certification: Plywood crates (ISPM 15 compliant) with four-way forklift access; recommended crate weight ≤1200 kg (commonly 300–800 kg).

- Accompanying documents: Packing list, invoice/bill of lading, EN 10204 3.1 material certificate, and inspection reports (dimensions, flatness, coating, etc.) available upon request.

Related questions FAQ

What is aluminum matrix composite (Al-MMC / AlSiC)?

It is a composite material made by introducing ceramic reinforcements (such as SiC, Al₂O₃, TiC, or TiB₂) into an aluminum alloy matrix, combining the lightweight and ductile nature of aluminum with the strength, hardness, and stability of ceramics.

It can be produced through in-situ reaction, powder metallurgy, or casting processes, with properties tailored by adjusting particle volume fraction, size, CTE/temperature range, and thermal conductivity.

AlSiC is a typical system using SiC particles as the reinforcement phase.

How strong are aluminum matrix composites?

They generally offer higher strength than conventional cast aluminum alloys, with significant improvements in stiffness and fatigue performance.

- JZ101 (High strength): 410–420 MPa

- FC041 (High strength): 530–550 MPa

- FC081 (Ultra-high strength): ≥630 MPa

Get samples and a quick quote

Customize your material based on target CTE, temperature range, or thermal conductivity — send us your drawings and working conditions, and we'll provide a material solution, process window, quotation, and lead time within 48 hours.