Why choose Chalco aluminum plastic composite strip for cables and optical cables?

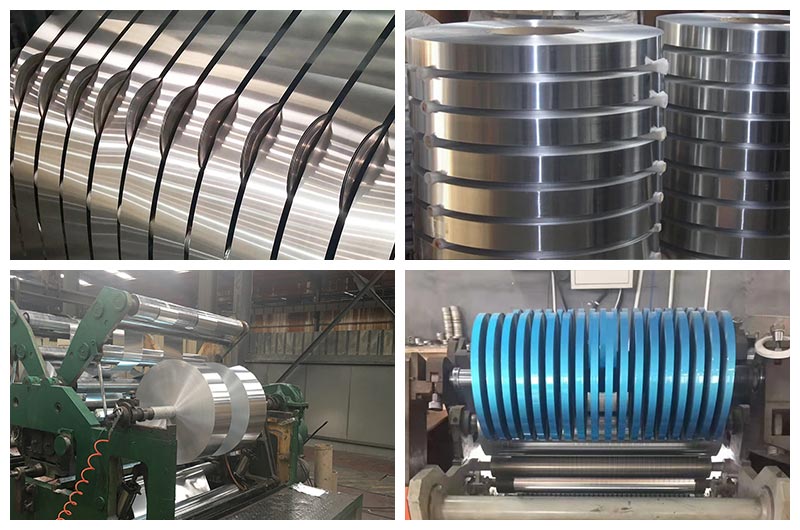

Advanced equipment: Chalco has cutting-edge production equipment, including high-speed coating machines, laminating machines, and automatic cutting machines. These machines are highly automated and equipped with precise control systems, ensuring efficient production and accurate processing.

Quality monitoring: We have established multiple quality monitoring points throughout the production line to ensure the stability and consistency of product quality. Through real-time detection and monitoring, we closely monitor key indicators such as coating thickness, composite strength, and surface roughness, ensuring that our aluminum plastic composite strip meets the highest quality standards.

Product classification of Chalco aluminum-plastic composite strips for optical cables

| Product | Type code |

| Polyethylene type single sided aluminum plastic composite strip | YL |

| Polyethylene type double-sided aluminum plastic composite strip | YLY |

| Copolymer type single sided aluminum plastic composite strip | EL |

| Copolymer type double-sided aluminum plastic composite strip | ELE |

Specifications of Chalco aluminum-plastic composite strip for optical cable

| Type code | Aluminum strip nominal thickness /mm | Nominal width of aluminum-plastic composite strip /mm | Nominal length of aluminum-plastic composite strip /m | |

| Uncut | Sliced | |||

| YL | 0.10, 0.15, 0.20 | 290 400 600 | According to user requirements | 1020 1200 1300 2030 2230 2400 2600 |

| YLY | ||||

| EL | ||||

| ELE | ||||

Dimensional tolerance of aluminum-plastic composite strip for Chalco cable

| Aluminum strip nominal thickness (mm) | Thickness and tolerance of aluminum-plastic composite strip (mm) | Nominal thickness and tolerance of plastic layer (mm) | Nominal width and tolerance of aluminum-plastic composite strip (mm) | Nominal length and tolerance of aluminum-plastic composite strip (m) | ||

| Single sided | double sided | Uncut | Sliced | |||

| 0.10 | 0.16±0.021 | 0.22±0.034 | 0.58±0.013 |

290±5 400±5 600±5 |

user request width ±0.5 | 1020+20 1200+20 1300+30 2030+30 2230+30 2400+40 2600+40 |

| 0.15 | 0.21±0.025 | 0.27±0.038 | ||||

| 0.20 | 0.26±0.029 | 0.32±0.042 | ||||

Performance of Chalco aluminum plastic composite strip for cable and cable

| Performance Items | Performance Requirement | |

| Tensile strength | ≥54MPa | |

| Elongation | ≥15% | |

| Peel strength between aluminum strip and plastic film | ≥6.13N/cm | |

| Shear strength of heat-sealing zone of aluminum-plastic composite strip | The aluminum-plastic composite strip is broken or the bond between the plastic layer and the aluminum strip is damaged first, and the heat-sealing area between the plastic layers should not produce shear damage | |

| Heat sealing strength of aluminum-plastic composite strip | ≥17.5N/cm | |

| Water resistance (68±1℃, 168h) Peel strength | ≥6.13N/cm | |

| Resistance to filling compounds (68±1℃, 168h) | No delamination between aluminum strip and plastic film | |

| corrosion resistance (0.1mol/L, NaOH, 480h) | ≥7 | |

| Dielectric strength | Single-sided composite aluminum strip, 1Kv d.c., 1min | No breakdown |

| Double-sided composite aluminum strip, 2Kv d.c., 1min | No breakdown | |

Winding requirements of Chalco aluminum-plastic composite strip for cables and optical cables

Aluminum plastic composite strip should be tightly wound on a core tube made of steel or aluminum or equivalent with an inner diameter of 204 ± 3 mm and an outer diameter of 225 ± 5 mm. The length of the core tube should be equal to or greater than the bandwidth, but the maximum should not exceed 2 mm;

When used vertically, the belt should not collapse;

Two or more aluminum plastic composite strips are not allowed to be wound on the same core tube;

The same plate (roll) of aluminum plastic composite strip is not allowed to have overlapping joints, but butt welding joints are allowed.

The color of the aluminum-plastic composite strip

According to the standard, the color of the aluminum-plastic composite belt should be blue and natural.

Advantages of Chalco aluminum plastic composite strip for cable and cable

High quality: Chalco has advanced production equipment and complete process flow, which can produce high-quality aluminum plastic composite strips for cables and optical cables.

Excellent shielding performance: Chalco aluminum plastic composite strip is made of high-quality aluminum strip with excellent shielding effect, which can effectively block external interference signals and ensure high-quality transmission of optical cables.

Durability and corrosion resistance: Chalco aluminum plastic composite strip has undergone special treatment, which has excellent durability and corrosion resistance, can resist physical damage and corrosion, and protect optical cables and cables from long-term stable operation.

High waterproofing: High waterproof performance ensures effective protection of cables and optical cables from humid environments and prolongs their service life under humid conditions.

FAQ

Q1: Are you factory or trading company?

A1: Industry and trading company.

Q2: Wonder if you accept small orders?

A2: Do not worry. Feel free to contact us .in order to get more orders and give our clients more convener, we accept small order.

Q3: Can you send products to my country?

A3: Sure, we can. If you do not have your own ship forwarder, we can help you.

Q4: When can I get the quotation?

A4: We usually quote you within 24 hours after we get your inquiry. If you are very

urgent to get the quotation. Please call us or tell us in your mail, so that we could

regard your inquiry priority.

Q5: Do you have after sale service?

A5: Yes. Any quality problem occurs within one year, pls take photos, we will be responsible.

Q6: How do you guarantee the quality of the product?

A6: Aluminum imports Achenbach Buschhutten wide rolling mill, OPTIFOILR slitting machine and coiler. With those advanced equipment and technology, we can ensure best product for you.